LOW-E coated laminated glass, hollow glass and preparation method of LOW-E coated laminated glass

A technology for laminated glass and glass, which is applied in parallel glass structures, chemical instruments and methods, glass/slag layered products, etc., can solve the problems of low product yield and low production efficiency, and achieve improved output, product quality and production efficiency. Increase, avoid oxidation or damage effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

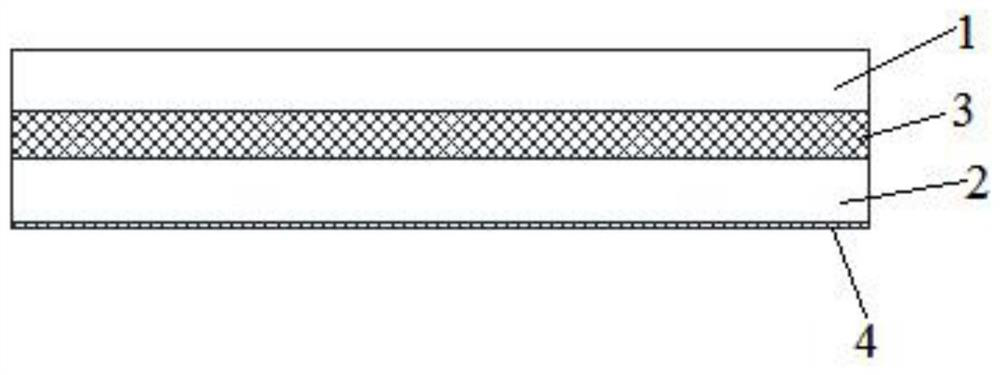

[0056] Preparation of LOW-E coated laminated glass, final products such as figure 1 As shown, from top to bottom are the first glass substrate 1 , the interlayer interlayer film 3 , the second glass substrate 2 and the PVC protective film 4 .

[0057] Specific steps include:

[0058] Step 1. Prepare 2 float glass substrates with a thickness of 12 mm. The 2 glass substrates are the first glass substrate 1 and the second glass substrate 2 from top to bottom; The sheet 2 is cleaned and dried, and the bottom of the second glass substrate 2 is processed by vacuum magnetron sputtering LOW-E coating;

[0059] Step 2. The first glass substrate 1 is cleaned and dried, and the first glass substrate 1 is laminated on the top of the second glass substrate 2 obtained in the step 1, and the interlayer film is interlayered. The material of 3 is common transparent PVB (polyvinyl butyral resin), obtains the first crude product of glass;

[0060] Step 3. In the first glass crude product obta...

Embodiment 2

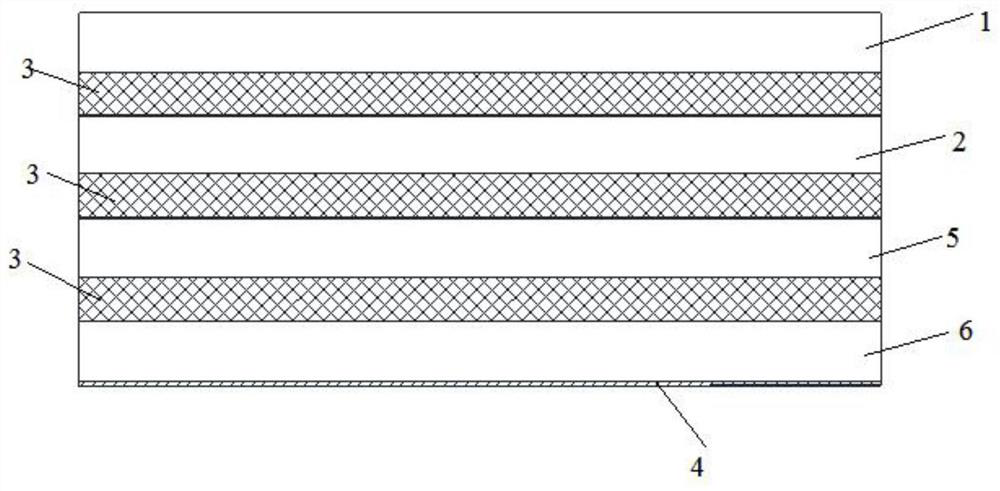

[0067] Preparation of LOW-E coated laminated glass, final products such as image 3 As shown, from top to bottom are the first glass substrate 1, the interlayer interlayer film 3, the second glass substrate 2, the interlayer interlayer film 3, the third glass substrate 5, the interlayer interlayer film 3, and the fourth glass substrate 6 and PVC protective film4.

[0068] The specific steps include the following:

[0069] Step 1. Prepare 4 heat-strengthened flat glass substrates with a thickness of 15 mm. The 4 glass substrates are the first glass substrate 1, the second glass substrate 2, and the third glass substrate 5 from top to bottom. and the fourth glass substrate 6; the fourth glass substrate 6 is cleaned and dried, and the bottom of the fourth glass substrate 6 is processed by vacuum magnetron sputtering LOW-E coating;

[0070] Step 2. Clean and dry the first glass substrate 1, the second glass substrate 2 and the third glass substrate 5, and sequentially clean the ...

Embodiment 3

[0078] Preparation of LOW-E coated laminated glass

[0079] Step 1. Prepare three glazed glass substrates with a thickness of 6 mm. The three glass substrates are the first glass substrate 1, the second glass substrate 2 and the third glass substrate 5 from top to bottom; The third glass substrate 5 is cleaned and dried, and the bottom of the third glass substrate 5 is processed by vacuum magnetron sputtering LOW-E coating;

[0080] Step 2. Clean and dry the first glass substrate 1 and the second glass substrate 2, and clean the second glass substrate 2 and the second glass substrate 5 on top of the third glass substrate 5 obtained in the step 1. A glass substrate 1 is subjected to interlayer lamination processing, the material of the interlayer interlayer film 3 is SGP, and the first crude glass product is obtained;

[0081] Step 3. In the first glass crude product obtained in the step 2, the bottom of the third glass substrate 5 is pasted with a 0.03mm thick PVC protective ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com