Air-entrained concrete defoaming pouring device

An air-entrained concrete and pouring head technology, which is applied to clay preparation devices, supply devices, cement mixing devices, etc., can solve the problems of reducing flow, difficulty in demoulding, and reducing the amount of end face removal, so as to reduce flow, reduce splashing, The effect of reducing the content of air bubbles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

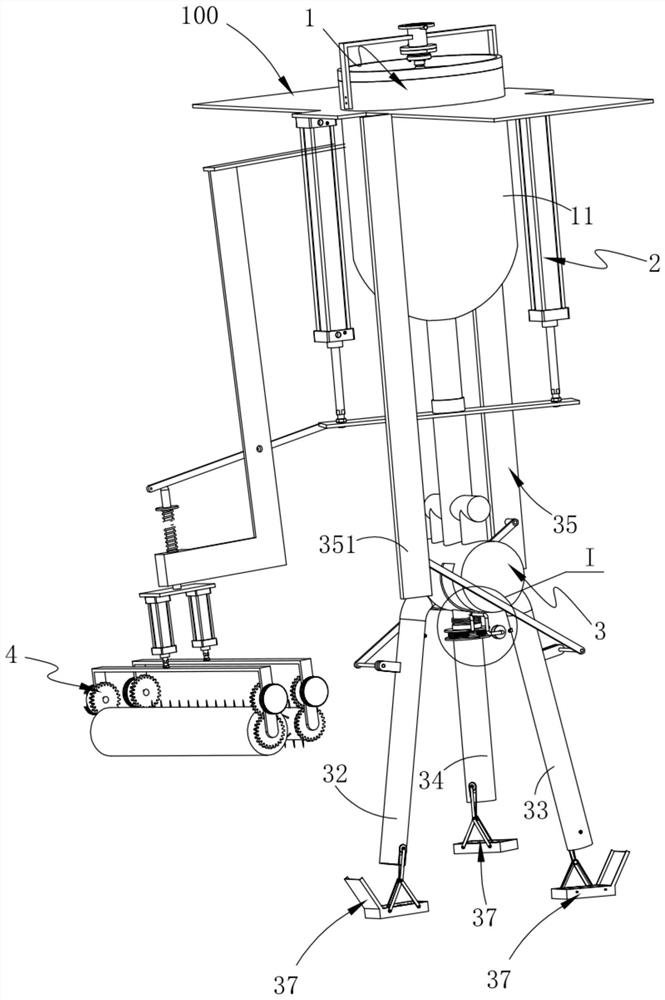

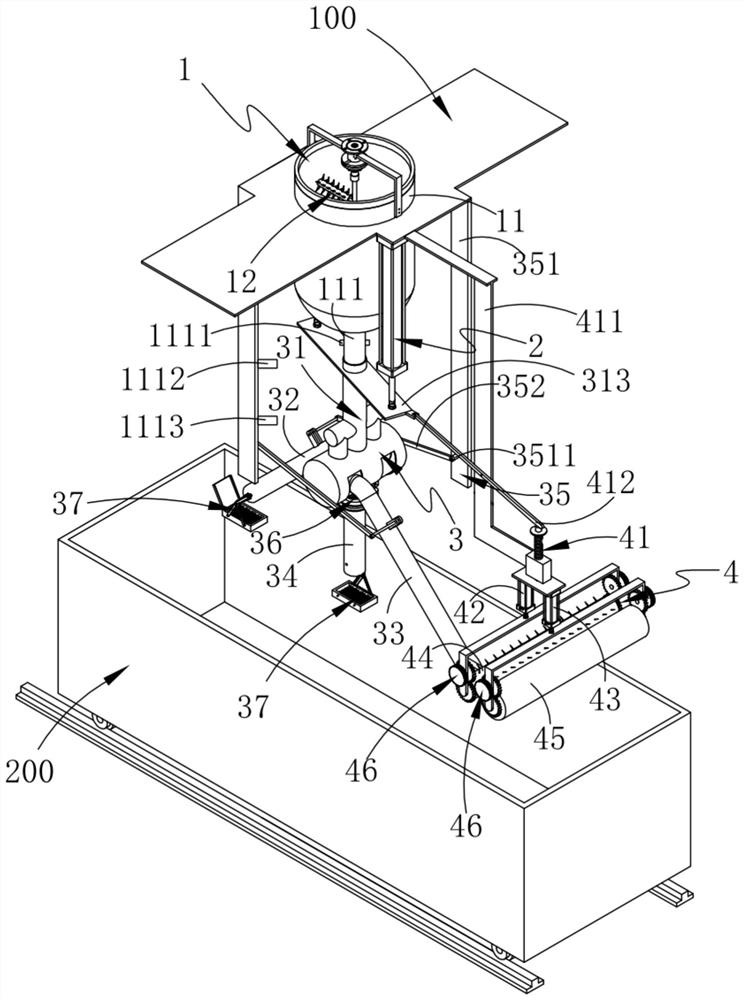

[0069] like Figure 1-2 As shown, an air-entrained concrete defoaming pouring device includes:

[0070] Stirring system 1, the stirring system 1 is installed on the equipment platform 100; in order to facilitate pouring, the equipment platform 100 is generally an upper work surface designed on the upper and lower sides;

[0071] Power system 2, the power system 2 is located on both sides of the stirring system 1, the top of which is connected to the equipment platform 100, and the power system 2 is preferably hydraulically driven to ensure the stability of its up and down movement. You can choose pneumatic transmission or other linear transmission methods;

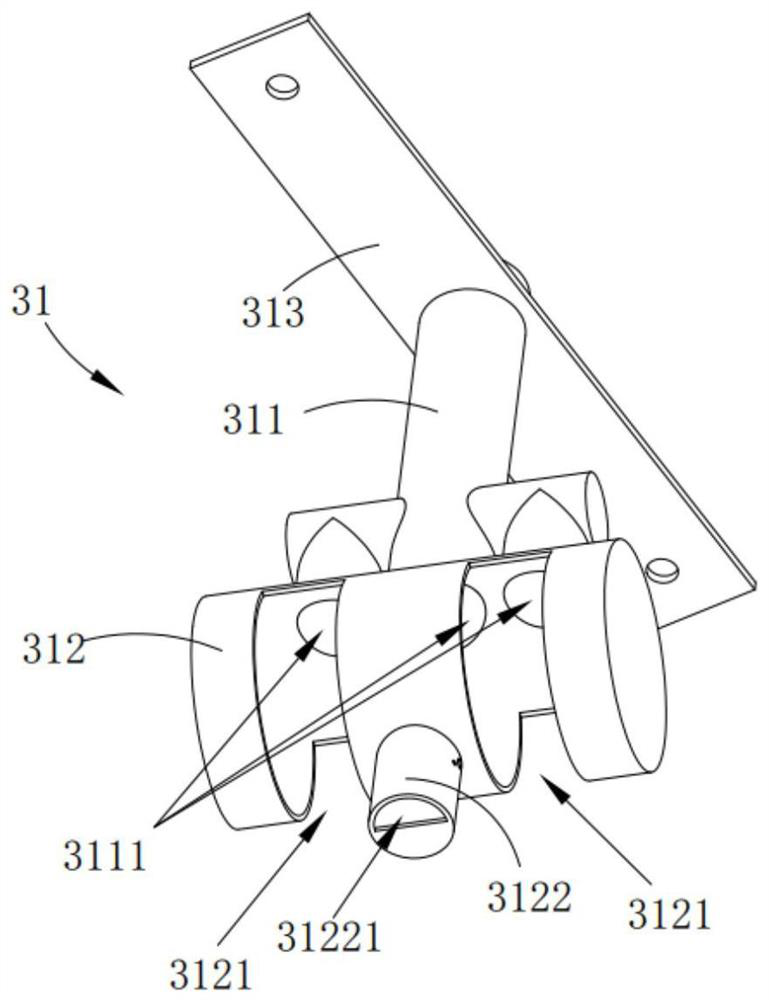

[0072] The pouring system 3, the pouring system 3 is arranged under the stirring system 1 and communicated, and the output end of the power system 2 is connected with the pouring system 3; the pouring system 3 includes a material receiving unit 31, a rotating The first pouring head 32 and the second pouring head 33 dispo...

Embodiment 2

[0104] like Figure 10-12 As shown, the same or corresponding components as those in the first embodiment are given the corresponding reference numerals as in the first embodiment. For the sake of brevity, only the points of difference from the first embodiment are described below. The difference between the second embodiment and the first embodiment is:

[0105] As an improvement, the pouring system 3 further includes an end surface foam breaking unit 37 respectively disposed at the bottom ends of the first pouring head 32 , the second pouring head 33 and the third pouring head 34 , and the end surface foam breaking unit 37 is used for removing Air bubbles in the slurry at the pouring surface.

[0106] as an improvement, such as Figure 10-11 As shown, the end face foam breaking unit 37 includes a power paddle 371 rotatably arranged inside the discharge end of the pouring head, a first drive assembly 372 connected with the power paddle 371, a fixing rod 373 disposed outside...

Embodiment 3

[0114] like Figure 13 As shown, the same or corresponding components as those in the first embodiment are given the corresponding reference numerals as in the first embodiment. For the sake of brevity, only the points of difference from the first embodiment are described below. The difference between the third embodiment and the first embodiment is:

[0115] as an improvement, such as figure 2 , 13 As shown, the stirring system 1 includes a stirring tank 11 connected to the equipment platform 100 and a stirring unit 12 arranged in the stirring tank 11; the stirring unit 12 includes a stirring motor 121 arranged above the stirring tank 11 and The output ends of the stirring motor 121 are axially staggered with a plurality of stirring paddles 122; the stirring paddles 122 are provided with a number of needles 123; the bottom end of the stirring tank 11 is provided with a discharge pipe 111;

[0116] It should be noted that during the stirring process, bubbles will be genera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com