A kind of organosilicon modified polyurethane conductive adhesive

A technology of silicone and conductive adhesive, applied in the field of conductive adhesive, can solve the problems of low weather resistance, high hardness, large stress, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

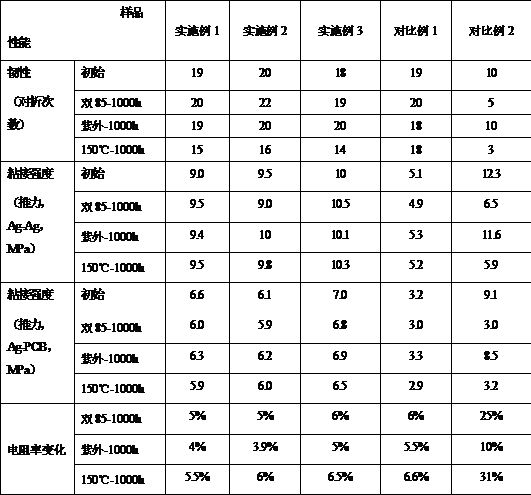

Examples

Embodiment 1

[0052]Silicone modified prepolymer: use professional synthesis equipment (with stirrer, condensate return pipe, temperature sensor, gas protection device-nitrogen, etc.), weigh 30g of silicone oil of structural formula (3) (where n=1) and 15g Put polyol D (where m=4) of structural formula (1) into a container, heat to 120°C for 1.5h under reduced pressure, then cool down to 55°C, then add 30g of isocyanate A and 10g of isocyanate B, 0.05g of catalyst, after 30min Raise the temperature to 80°C, react at 80°C for 4 hours, then cool down to 55°C, add 20g of castor oil, then raise the temperature to 80°C after 30min, and react at this temperature for 2h to obtain a silicone-modified prepolymer, and cool to room temperature.

[0053] Component A: Weigh 39g of the silicone-modified prepolymer prepared above, then weigh 1.8g of water-absorbing agent into a vacuum defoaming mixing equipment, mix well, then add 60g of flake silver powder (particle size 5 microns), mix Uniformly, A comp...

Embodiment 2

[0056] Silicone modified prepolymer: use professional synthesis equipment, weigh 25g of silicone oil of structural formula (3) (where n=10) and 10g of polyol D of structural formula (1) (where m=5) into a container, heat to Dehydration under reduced pressure at 120°C for 1.5h, then lower the temperature to 55°C, add 35g of isocyanate A and 13g of isocyanate B, 0.07g of catalyst, heat up to 80°C after 30min, react at 80°C for 4h, then cool down to 55°C, then add 25g of castor Sesame oil, then heated up to 80°C after 30 minutes, and reacted at this temperature for 2 hours to obtain a silicone-modified prepolymer, and cooled to room temperature.

[0057] Component A: Weigh 38.5g of the silicone-modified prepolymer prepared above, then weigh 1.5g of water-absorbing agent into the vacuum defoaming mixing equipment, mix evenly, and then add 61.5g of silver-coated copper powder (particle size 10 microns ), and mix evenly to obtain component A.

[0058] Component B: First, polyol D a...

Embodiment 3

[0060] Silicone modified prepolymer: use professional synthesis equipment, weigh 20g of silicone oil of structural formula (3) (where n=20) and 5g of polyol D of structural formula (1) (where m=3) into a container, heat to Dehydration under reduced pressure at 120°C for 1.5h, then lower the temperature to 55°C, then add 40g of isocyanate A and 15g of isocyanate B, 0.10g of catalyst, heat up to 80°C after 30min, react at 80°C for 4h, then cool down to 55°C, then add 30g of castor Sesame oil, then heated up to 80°C after 30 minutes, and reacted at this temperature for 2 hours to obtain a silicone-modified prepolymer, and cooled to room temperature.

[0061] Component A: Weigh 38g of the silicone-modified prepolymer prepared above, then weigh 2g of water-absorbing agent into the vacuum defoaming mixing equipment, mix evenly, then add 59.5g of gold powder (particle size 20 microns), mix evenly, A component is prepared.

[0062] Component B: First, polyol D and polyol E are dehydr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com