Device and method for coproducing synthesis gas through coupling of carbon dioxide capturing process and methane reforming process

A carbon dioxide and synthesis gas technology, applied in chemical instruments and methods, hydrogen/synthesis gas production, petrochemical industry, etc., can solve the problems of reducing the selectivity of synthesis gas, affecting catalyst activity, and high operating costs, so as to reduce the risk of explosion, Improve operational safety and facilitate installation and operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the purpose, technical solution and features of the present invention clearer, the following will be described in detail in conjunction with the accompanying drawings.

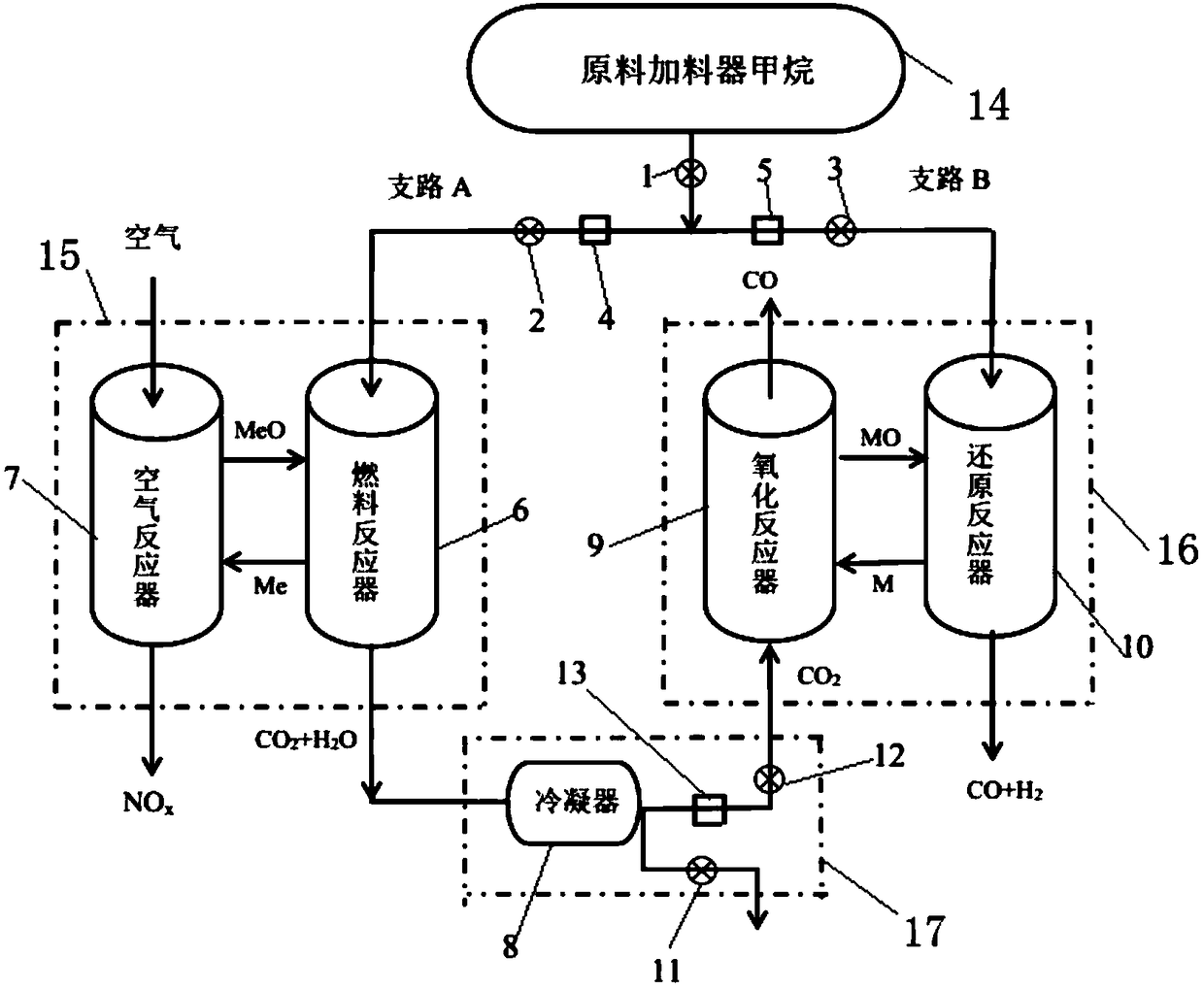

[0025] Such as figure 1 As shown, a CO 2 Coupling device for producing high-quality syngas by coupling capture and methane reforming process, including raw material feeder 14, condenser system 17, chemical looping combustion system 15 and chemical looping reforming system 16; raw material feeder 14 mainly provides fuel CH 4 , the condenser system 17 includes a condenser 8, the chemical looping combustion system 15 includes a connected fuel reactor 6 and an air reactor 7, and the chemical looping reforming system 16 includes an connected oxidation reactor 9 and a reduction reactor 10; raw material feeder 14 is provided with a first flow regulating valve 1 at the outlet, and the outlet of the raw material feeder 14 is divided into two routes, one of which is connected to the fuel reacto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com