Application method of photocuring-based graphene heat-dissipating coating

A technology of heat-dissipating coatings and graphene, which is applied to devices and coatings that coat liquids on the surface, and can solve the problems of demanding high-temperature resistance of substrate materials, poor electrical and thermal conductivity of coatings, and slow curing speed of thermosetting resins, etc. No problem, no requirement for high temperature resistance, good thermal conductivity, and reduced curing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

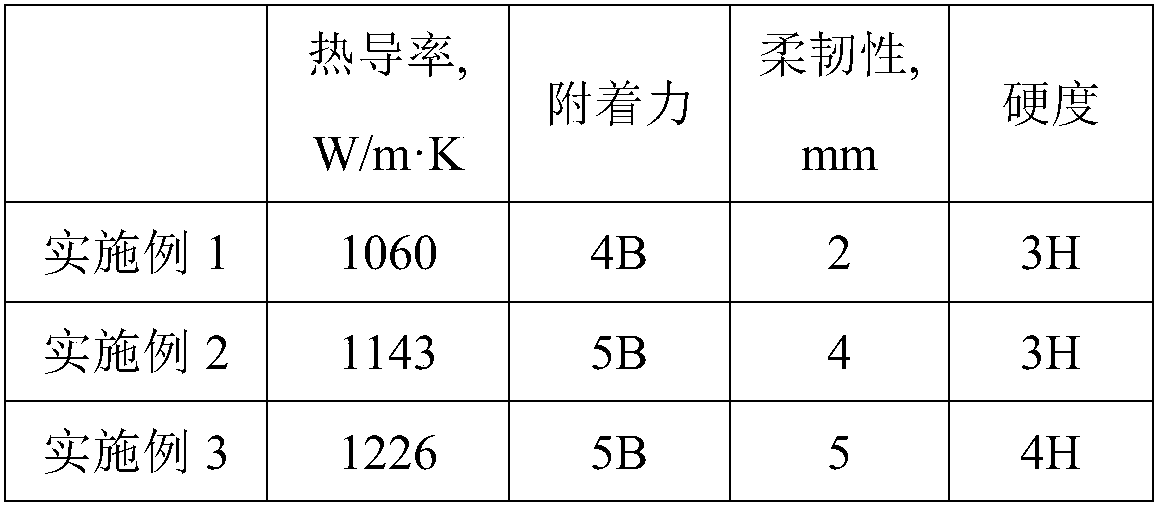

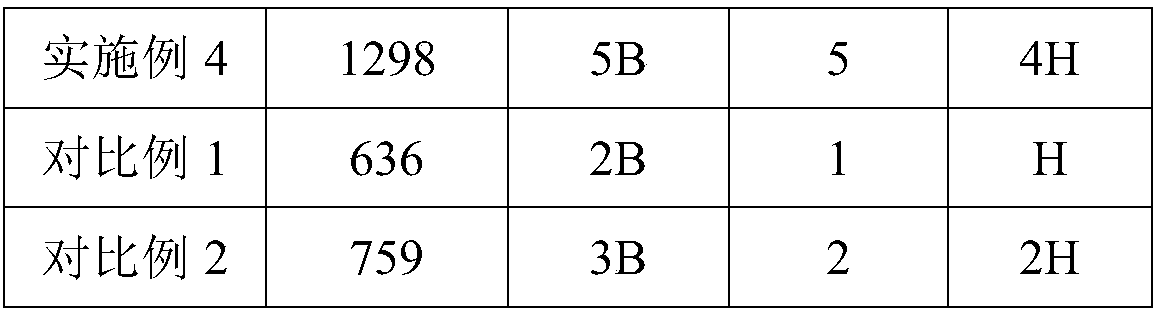

Examples

Embodiment 1

[0034] The present embodiment provides a printing method based on light-cured graphene conductive ink, comprising the following steps:

[0035] S1. Prepare graphene heat dissipation coating:

[0036] S11. Mixing, grinding and shearing the graphene quantum dots, graphene, monomer and solvent under the action of ultrasound, the ultrasonic power is 1000W, and the time is 60min, to obtain a composite slurry material;

[0037] S12. After adding urea-formaldehyde resin, additives and carbon nanotubes to the composite slurry material prepared in step S11, stir at a speed of 1000 to 1200 rpm and a stirring time of 2 to 4 hours to obtain a graphene heat dissipation slurry;

[0038] S13. Add heat-conducting metal powder to the graphene heat-dissipating slurry obtained in step S12, fully stir, the rotating speed is 1200~1500rpm, and the stirring time is 2~3h. After mixing evenly, the graphene heat-dissipating coating is obtained;

[0039] Wherein, in step S1, the graphene heat dissipati...

Embodiment 2

[0048] The present embodiment provides a printing method based on light-cured graphene conductive ink, comprising the following steps:

[0049] S1. Prepare graphene heat dissipation coating:

[0050]S11. Mixing, grinding and shearing the graphene quantum dots, graphene, monomer and solvent under the action of ultrasound, the ultrasonic power is 1200W, and the time is 40min, to obtain a composite slurry material;

[0051] S12. After adding urea-formaldehyde resin, additives and carbon nanotubes to the composite slurry material prepared in step S11, stir at a speed of 1000 to 1200 rpm and a stirring time of 2 to 4 hours to obtain a graphene heat dissipation slurry;

[0052] S13. Add heat-conducting metal powder to the graphene heat-dissipating slurry obtained in step S12, fully stir, the rotating speed is 1200~1500rpm, and the stirring time is 2~3h. After mixing evenly, the graphene heat-dissipating coating is obtained;

[0053] Wherein, in step S1, the graphene heat dissipatio...

Embodiment 3

[0062] The present embodiment provides a printing method based on light-cured graphene conductive ink, comprising the following steps:

[0063] S1. Prepare graphene heat dissipation coating:

[0064] S11. Mixing, grinding and shearing the graphene quantum dots, graphene, monomer and solvent under the action of ultrasound, the ultrasonic power is 1100W, and the time is 50min, to obtain a composite slurry material;

[0065] S12. After adding urea-formaldehyde resin, additives and carbon nanotubes to the composite slurry material prepared in step S11, stir at a speed of 1000 to 1200 rpm and a stirring time of 2 to 4 hours to obtain a graphene heat dissipation slurry;

[0066] S13. Add heat-conducting metal powder to the graphene heat-dissipating slurry obtained in step S12, fully stir, the rotating speed is 1200~1500rpm, and the stirring time is 2~3h. After mixing evenly, the graphene heat-dissipating coating is obtained;

[0067] Wherein, in step S1, the graphene heat dissipati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com