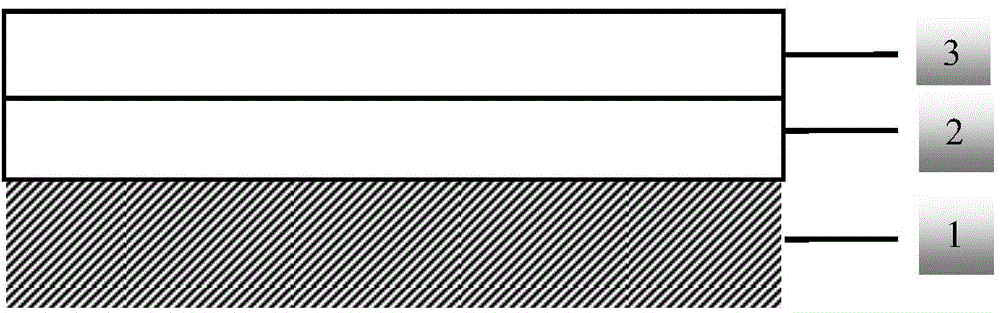

Double-layer photothermal conversion composite material and preparation method thereof

A composite material, photothermal conversion technology, applied in the field of solar energy utilization, can solve the problems of poor thermal matching performance, pitting, cracking or peeling, etc., and achieve the effect of high working temperature, high thermal radiation rate and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Preparation of ZrO on Ni-based Materials by Physical Vapor Deposition 2 -Y 2 o 3 / SiC double-layer light-to-heat conversion composite material:

[0027] A Ni alloy substrate with a size of 300×300 is used as the base material;

[0028] Polish the Ni alloy substrate sequentially with 400 mesh, 800 mesh and 1200 mesh sandpaper to remove scale and ensure the surface roughness is above 10nm;

[0029] The polished Ni alloy substrate was ultrasonically treated in water for 10 minutes;

[0030] Use 40% ethanol solution and acetone solution to clean the Ni alloy substrate surface after ultrasonic treatment in sequence;

[0031] Place the surface-treated Ni alloy substrate in the physical vapor deposition equipment, and select the target material ZrO 2 and Y 2 o 3 Simultaneous deposition, vacuum degree 7×10 -3 Pa, target distance 500mm, electron beam intensity 60mA, substrate deposition temperature 523K. After repeated deposition, ZrO with a thickness of 3mm was obtaine...

Embodiment 2

[0039] Preparation of TiO on Fe-based Materials by Magnetron Sputtering and Chemical Vapor Deposition 2 / TiC double-layer light-to-heat conversion composite material:

[0040] A hemispherical Fe alloy substrate with a diameter of 50mm is used as the base material;

[0041] Use 400-mesh, 800-mesh and 1200-mesh sandpaper to polish the Fe alloy substrate in sequence to remove scale and ensure that the surface roughness is above 5nm;

[0042] Ultrasonic treatment of the polished Fe alloy substrate in water for 10 min;

[0043] Using 40% ethanol solution and acetone solution to clean the surface of the Fe alloy substrate after ultrasonic treatment in sequence;

[0044] Place the surface-treated Fe alloy substrate in the magnetron sputtering equipment, using a metal Ti target, the reaction gas O 2 , sputtering gas Ar, reaction pressure 2Pa, substrate temperature 573K, pre-sputtering with Ar for 1min, TiO with a thickness of 50nm was obtained on the Fe alloy substrate 2 bottom tr...

Embodiment 3

[0052] Preparation of SiO on Co-based Materials by Physical Vapor Deposition and Chemical Vapor Deposition 2 / C double-layer light-to-heat conversion composite material:

[0053] A Ni alloy substrate with a size of 20×50 is used as the base material;

[0054] Polish the Co alloy substrate sequentially with 400-mesh, 800-mesh and 1200-mesh sandpaper to remove scale and ensure that the surface roughness is above 10nm;

[0055] The polished Co alloy substrate was ultrasonically treated in water for 10 minutes;

[0056] Use 40% ethanol solution and acetone solution to clean the surface of the Co alloy substrate after ultrasonic treatment in sequence;

[0057] Place the surface-treated Co alloy substrate in the physical vapor deposition equipment, and select the target material SiO 2 , vacuum degree 7×10 -3 Pa, target distance 500mm, electron beam intensity 60mA, substrate deposition temperature 473K. After repeated deposition, SiO with a thickness of 2 μm was obtained on the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com