Multi-element gradient modified iridium coating layer and preparation method thereof

A coating and gradient technology, applied in the field of multi-gradient modified iridium coating and its preparation, can solve the problems of high equipment requirements, low efficiency, complex multi-layer coating technology and process, and achieve good integration, simple process flow, guarantee Effects of high temperature oxidation resistance and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

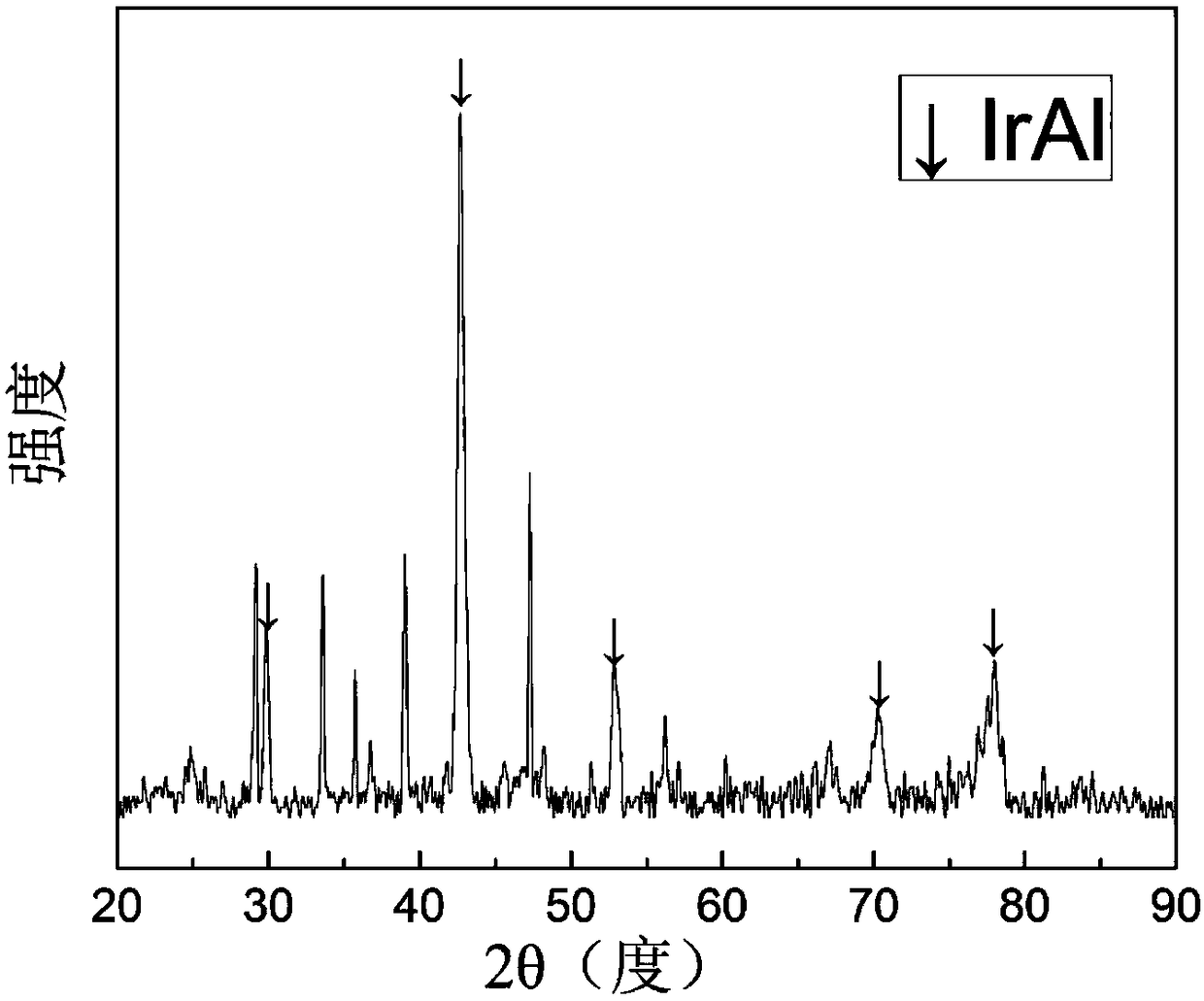

[0048] A kind of multiple gradient modified iridium coating of the present invention, this multiple gradient modified iridium coating comprises the Re layer, the Ir layer, the Ir-Al layer and the permeation Hf layer that are arranged on the graphite substrate successively from bottom to top, wherein Ir- The thickness of the Al layer is about 15 μm, and the thickness of the Hf-infiltrated layer is about 4 μm.

[0049] A preparation method of the multiple gradient modified iridium coating of the present embodiment, comprising the following steps:

[0050] (1) Deposit a layer of 40 μm thick transition layer rhenium coating on the graphite substrate by chemical vapor deposition method (CVD method), and then deposit a layer of 40 μm thick iridium coating by molten salt electroplating method. Graphite samples with 40 μm Ir (the graphite substrate / rhenium / iridium system as the original material) were ultrasonically cleaned with ethanol for 10 min, then ultrasonically cleaned with dei...

Embodiment 2

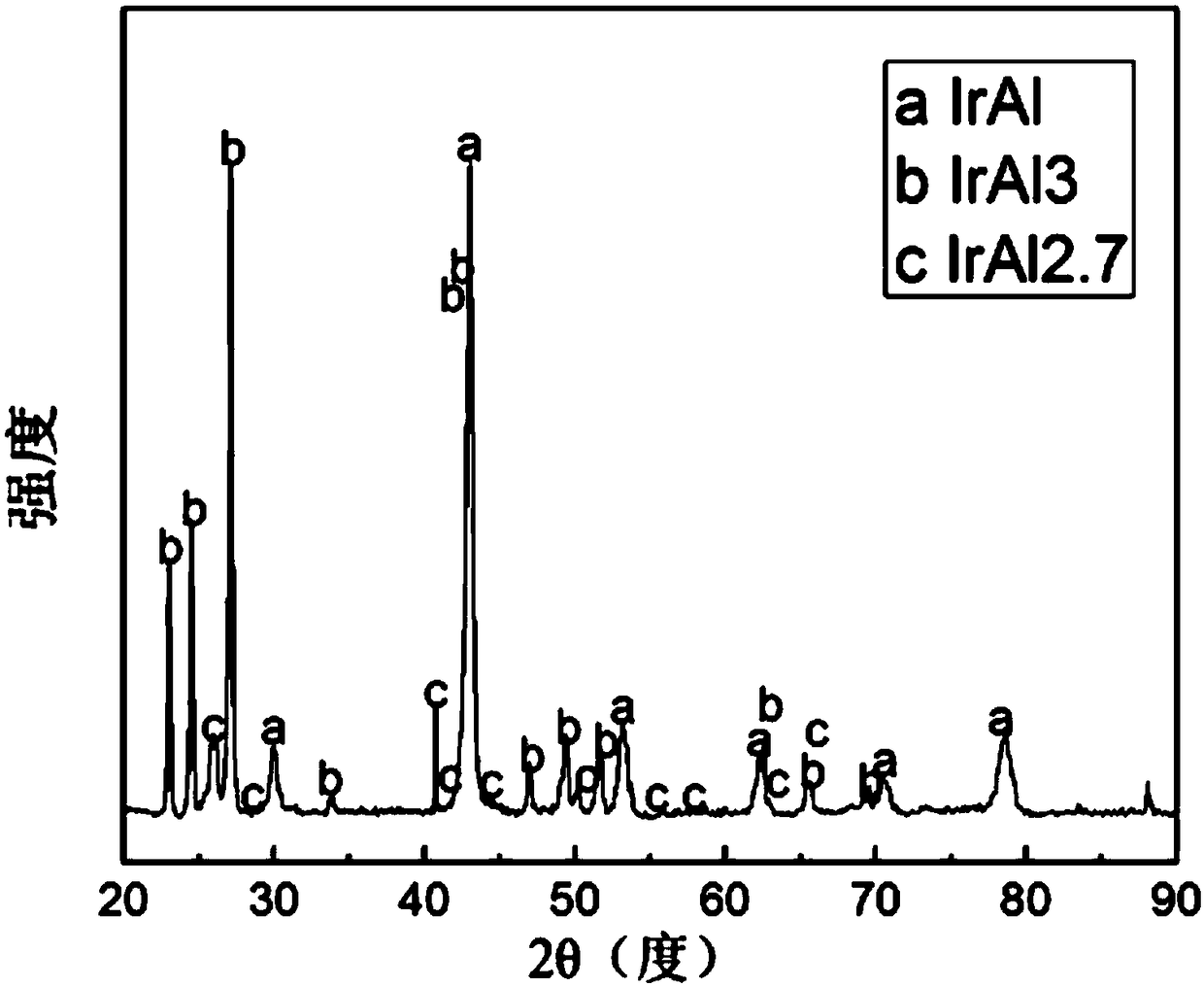

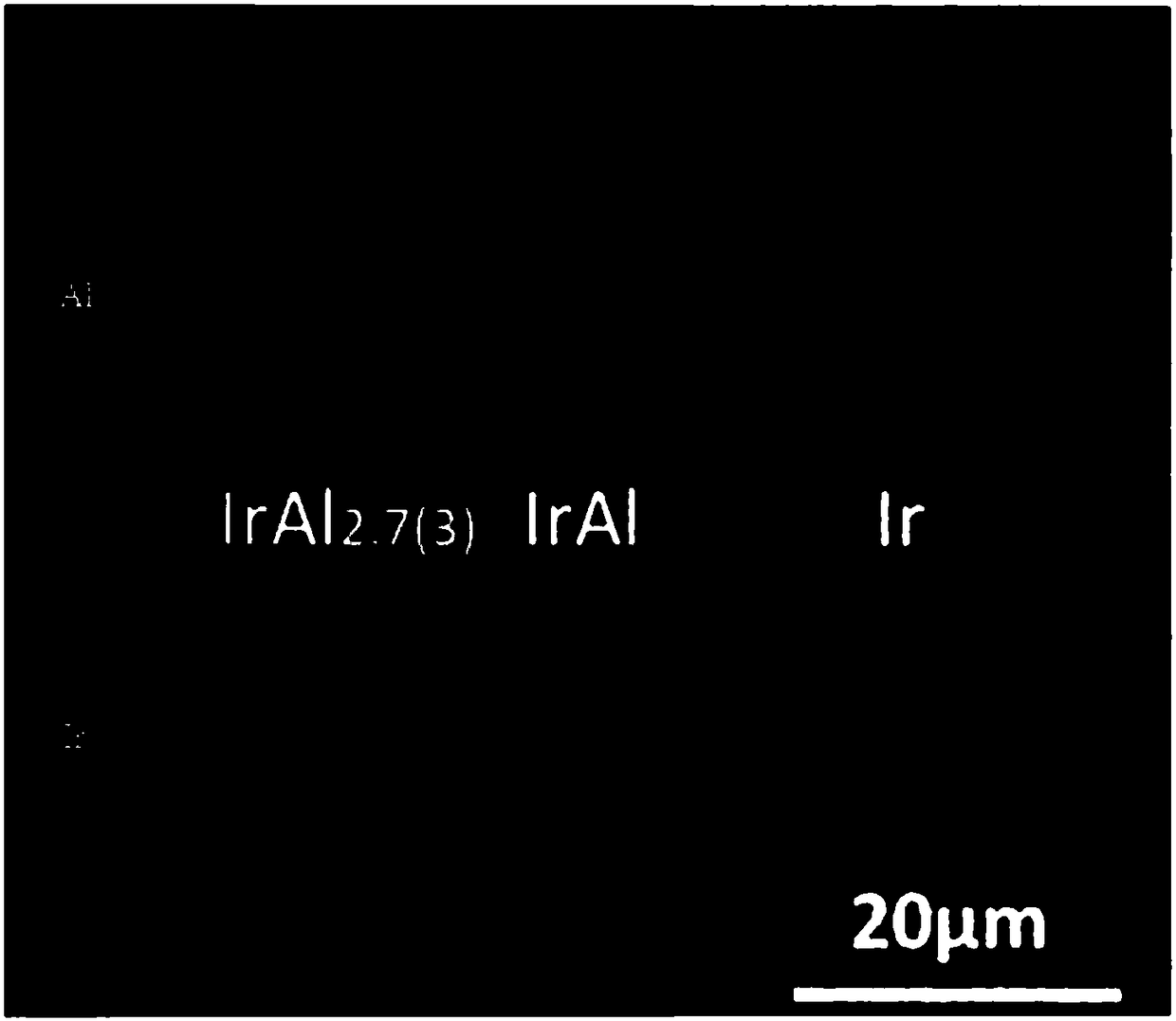

[0056] A kind of multiple gradient modified iridium coating of the present invention, this multiple gradient modified iridium coating comprises Re layer, Ir layer, IrAl layer, IrAl layer that are arranged on graphite substrate successively from bottom to top 2.7(3) layer and permeated Hf layer, in which the thickness of IrAl coating is about 15μm, IrAl 2.7(3) The thickness of the layer is about 5 μm, and the thickness of the Hf-infiltrated layer is about 5 μm.

[0057] A preparation method of the multiple gradient modified iridium coating of the present embodiment, comprising the following steps:

[0058] (1) First deposit a layer of 40 μm thick transition layer rhenium coating on the graphite substrate by chemical vapor deposition method, and then deposit a layer of 40 μm thick iridium coating by molten salt electroplating method, for the deposition of 40 μm Re and 40 μm Ir The graphite samples were ultrasonically cleaned with ethanol for 10 min, then deionized water for 5 m...

Embodiment 3

[0064] A kind of multiple gradient modified iridium coating of the present invention, this multiple gradient modified iridium coating comprises Re layer, Ir layer, IrAl layer and impregnated Zr layer that are arranged on graphite substrate successively from bottom to top, wherein the IrAl coating The thickness is 15 μm, and the thickness of the Zr-impregnated layer is 2 μm.

[0065] A preparation method of the multi-element gradient modified iridium coating of the present invention, comprises the following steps:

[0066] (1) The graphite sample deposited with 40 μm Re and 40 μm Ir was ultrasonically cleaned with ethanol for 10 minutes, then ultrasonically cleaned with deionized water for 5 minutes, and then dried at 100 ° C for 10 minutes;

[0067] (2) Penetration agent preparation: Al powder, Al 2 o 3 The powder and the halogen donor are mixed until uniform, and the metal Al powder is 2%, and the metal oxide Al 2 o 3 Powder is 97%, halogen donor NH 4 Cl is 1%, and the i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com