Nanoporous antioxidant resin-based composite material and preparation method thereof

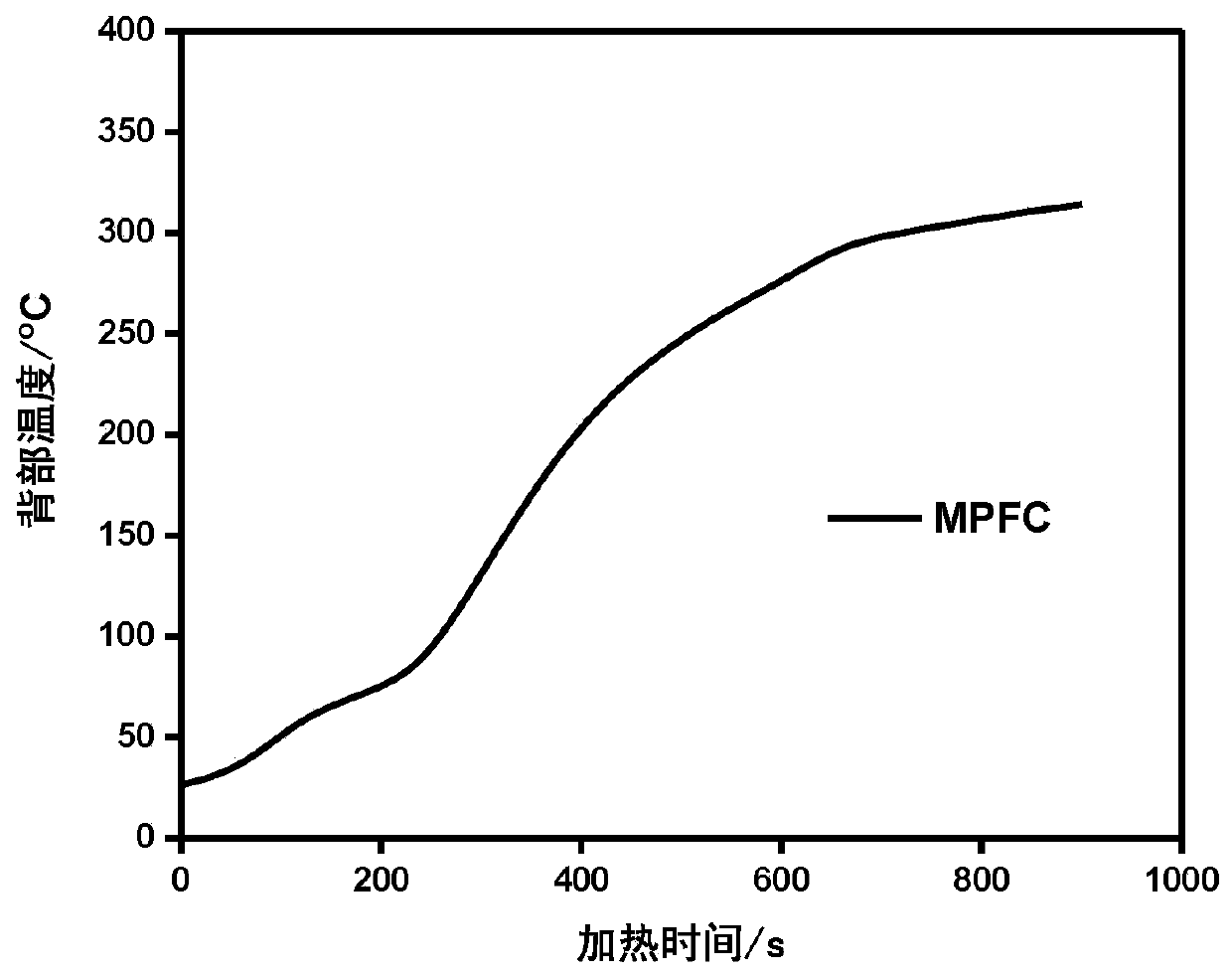

A composite material and anti-oxidation technology, applied in the field of composite materials, can solve the problems of inability to meet the requirements of long-term hypersonic flight, poor anti-oxidation performance, and high thermal conductivity, and achieve excellent micro-ablation/thermal insulation performance. The effect of good ablation and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

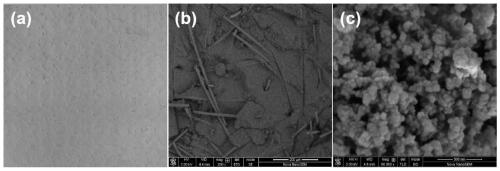

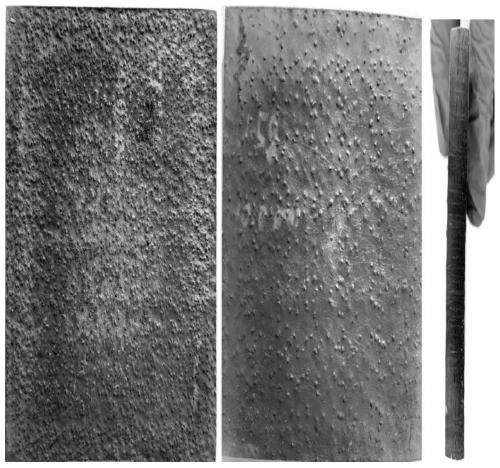

[0049] A nanoporous anti-oxidation resin-based composite material and a preparation method thereof, comprising the following steps:

[0050] Add ethanol, melamine, formaldehyde and sodium hydroxide to react in the reactor, the mol ratio of melamine and formaldehyde is 0.16:1, the mol ratio of sodium hydroxide and formaldehyde is 1:100, obtains the methylol melamine resin oligomer; Then add phenol and boric acid, the molar ratio of phenol and formaldehyde is 0.42:1, the mass ratio of boric acid and formaldehyde is 0.5:6, adjust the pH=7, continue the reaction for 1h, the obtained solution is heated at 50°C, -0.09MPa Distilled under reduced pressure to obtain antioxidant resin.

[0051] Then weigh a certain amount of the anti-oxidation resin and isopropanol respectively, add them into the stirring tank, stir mechanically until they are completely dissolved, finally add hexamethylenetetramine, and continue stirring for 1 hour to obtain the anti-oxidation resin solution, wherein t...

Embodiment 2

[0055] A nanoporous anti-oxidation resin-based composite material and a preparation method thereof, comprising the following steps:

[0056] Add ethanol, melamine, formaldehyde and sodium hydroxide to react in the reactor, the mol ratio of melamine and formaldehyde is 0.2:1, the mol ratio of sodium hydroxide and formaldehyde is 1:50, obtains the methylol melamine resin oligomer; Then add phenol and boric acid, the molar ratio of phenol and formaldehyde is 0.4:1, the mass ratio of boric acid and formaldehyde is 0.5:6, adjust the pH=7, continue the reaction for 1h, the obtained solution is heated at 55°C, -0.08MPa Distilled under reduced pressure to obtain antioxidant resin.

[0057] Then weigh a certain amount of the anti-oxidation resin and isopropanol respectively, add them into the stirring tank, stir mechanically until they are completely dissolved, finally add hexamethylenetetramine, and continue stirring for 1 hour to obtain the anti-oxidation resin solution, wherein the ...

Embodiment 3

[0061] A nanoporous anti-oxidation resin-based composite material and a preparation method thereof, comprising the following steps:

[0062] Add methanol, urea, formaldehyde and potassium hydroxide to the reactor for reaction, the molar ratio of urea to formaldehyde is 0.16:1, and the molar ratio of potassium hydroxide to formaldehyde is 1:40 to obtain a reaction solution; then add resorcinol And white carbon black, the molar ratio of phenol and formaldehyde is 0.52:1, the mass ratio of white carbon black and formaldehyde is 0.5:6, adjust the pH=7, continue the reaction for 1h, put the obtained solution at 50°C, -0.09MPa Distill under reduced pressure to obtain antioxidant resin.

[0063] Then weigh a certain amount of the anti-oxidation resin and isopropanol respectively, add them into the stirring tank, stir mechanically until they are completely dissolved, finally add hexamethylenetetramine, and continue stirring for 1 hour to obtain the anti-oxidation resin solution, where...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com