Patents

Literature

109results about How to "Realize one-piece molding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

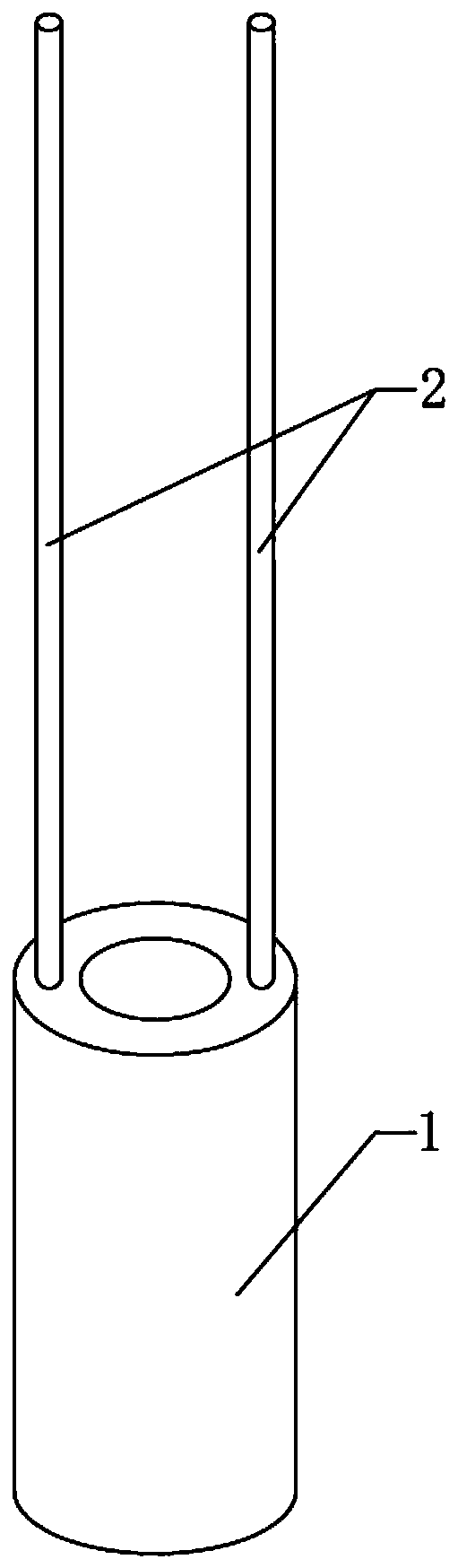

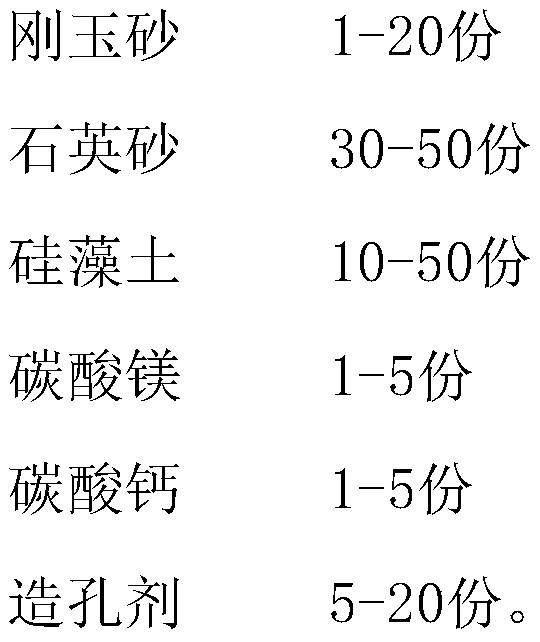

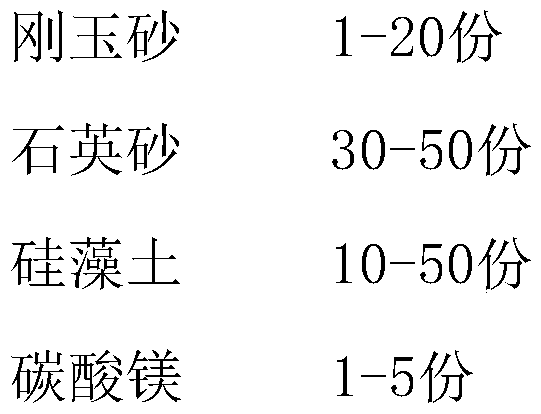

Porous ceramic heating body and preparation method thereof

InactiveCN110981454AHigh strengthImprove performanceTobaccoCeramicwareElectronic cigaretteSilicon dioxide

The invention relates to the technical field of electronic cigarettes, in particular to a porous ceramic heating body and a preparation method thereof. The porous ceramic heating body comprises a porous ceramic matrix and a metal heating element. The porous ceramic matrix comprises the following raw materials in parts by weight: 1-20 parts of emery, 30-50 parts of quartz sand, 10-50 parts of diatomite, 1-5 parts of magnesium carbonate, 1-5 parts of calcium carbonate and 5-20 parts of a pore forming agent. The porous ceramic heating body is novel in structure, high in product porosity and highin strength; the metal heating element is not oxidized; the diatomite forms gaps under the action of the pore forming agent, so the porosity of the produced porous ceramic heating body is guaranteed;magnesium carbonate and calcium carbonate can decompose a part of carbon dioxide gas under a high-temperature condition, so porosity is improved; and magnesium oxide and calcium oxide generated afterhigh-temperature decomposition form aluminosilicate together with silicon dioxide and aluminum oxide, so the inter-binding property of material particles is improved, and the structural stability andstrength of the porous ceramic matrix are improved.

Owner:KEY MATERIAL

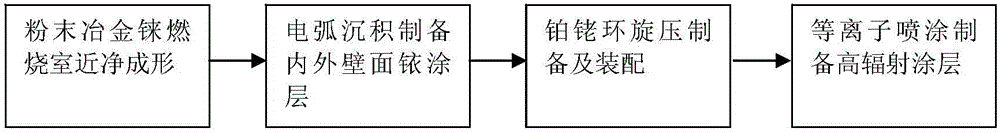

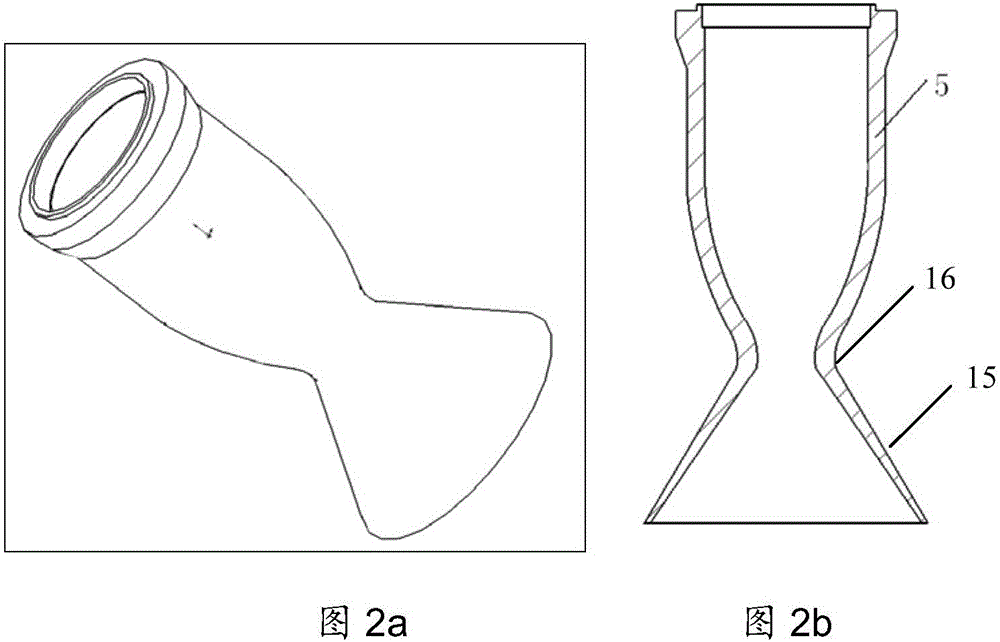

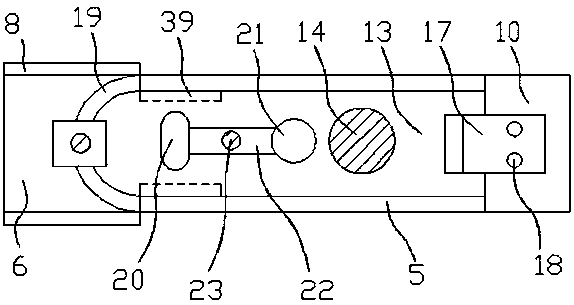

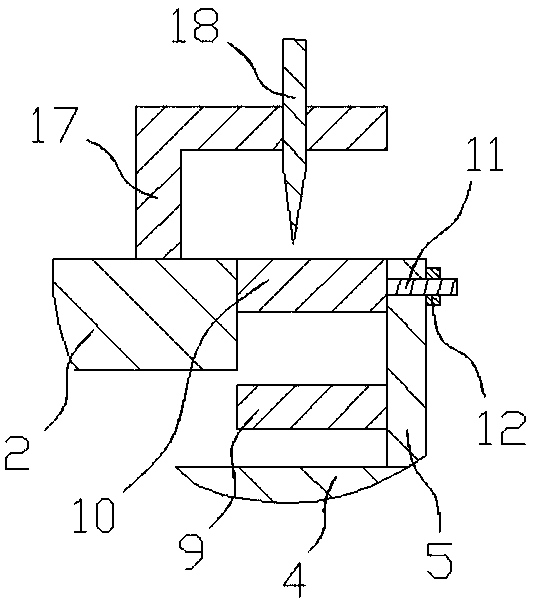

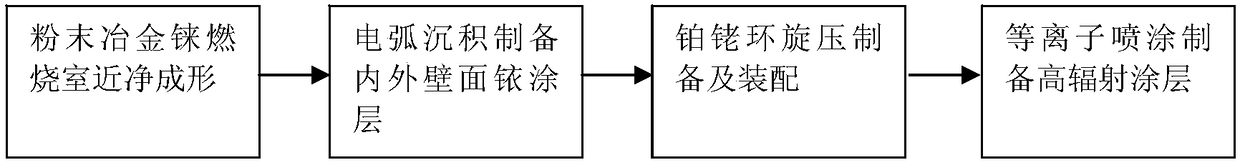

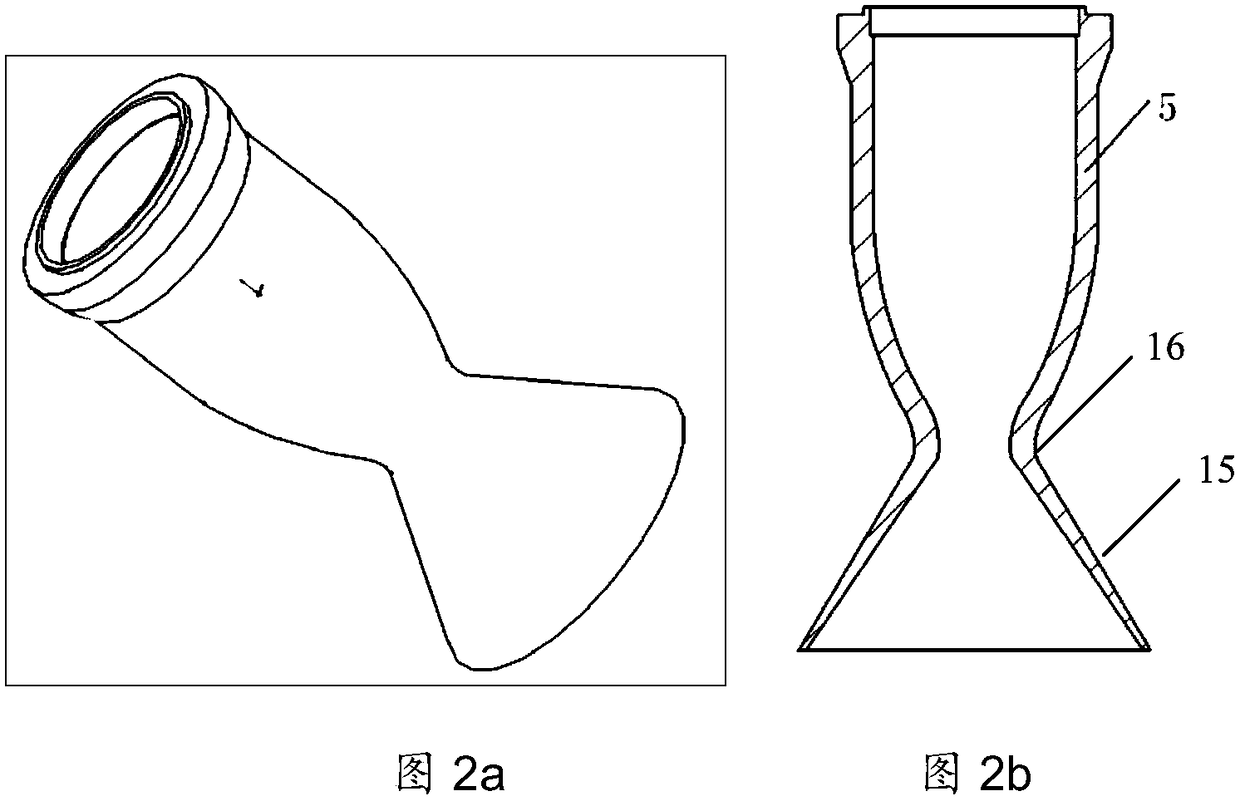

Preparation method for rhenium-iridium combustion chamber

ActiveCN106001554AIncrease the allowable operating temperatureImprove specific impulseShaping toolsMolten spray coatingRheniumIridium

The invention relates to a preparation method for a rhenium-iridium combustion chamber. The preparation method comprises the following steps: preparing a rhenium combustion chamber by adopting a powder metallurgy near-net shape forming technology; preparing iridium coatings at inner and outer surfaces of the rhenium combustion chamber by adopting an electric-arc deposition technology; preparing a platinum-rhodium ring by adopting a spinning technology and assembling the platinum-rhodium ring on the inner wall surface of the combustion chamber; and preparing a metal oxide high-radiation coating on the outer surface of the combustion chamber by adopting a plasma spraying technology. According to the preparation method, by virtue of an optimized design of process methods and process conditions at different stages of a preparation process, the prepared rhenium-iridium combustion chamber is applied to an engine, so that a use and working environment of the engine can be remarkably increased, specific impulse can be improved for the engine, and technical support is provided for prolonging flight life of an aircraft, increasing effective load of the aircraft or increasing range of the aircraft.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +1

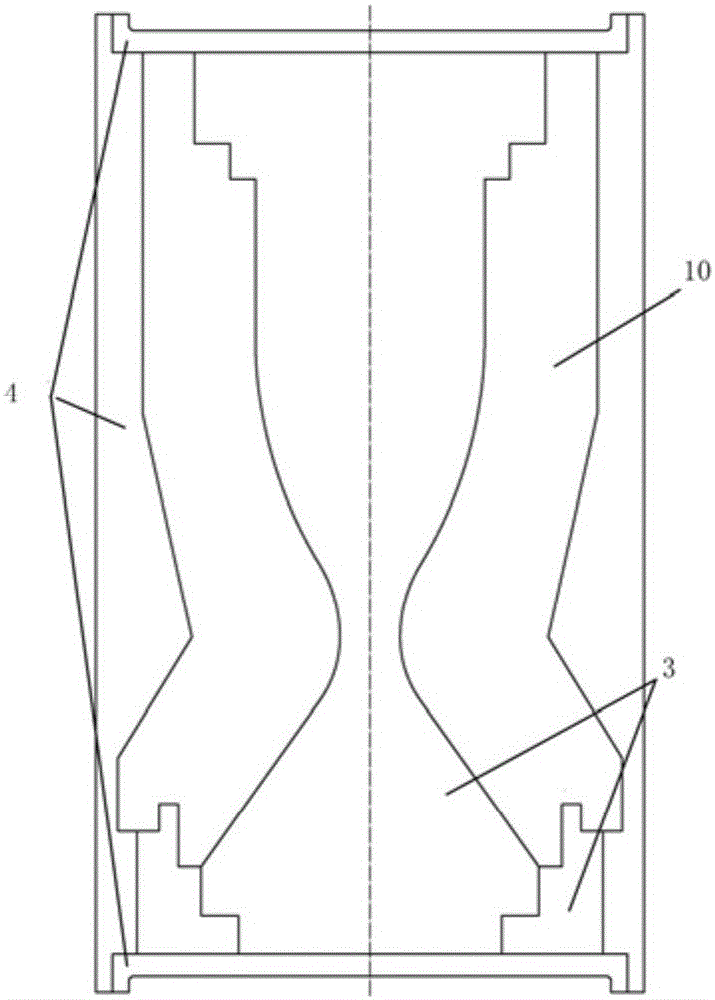

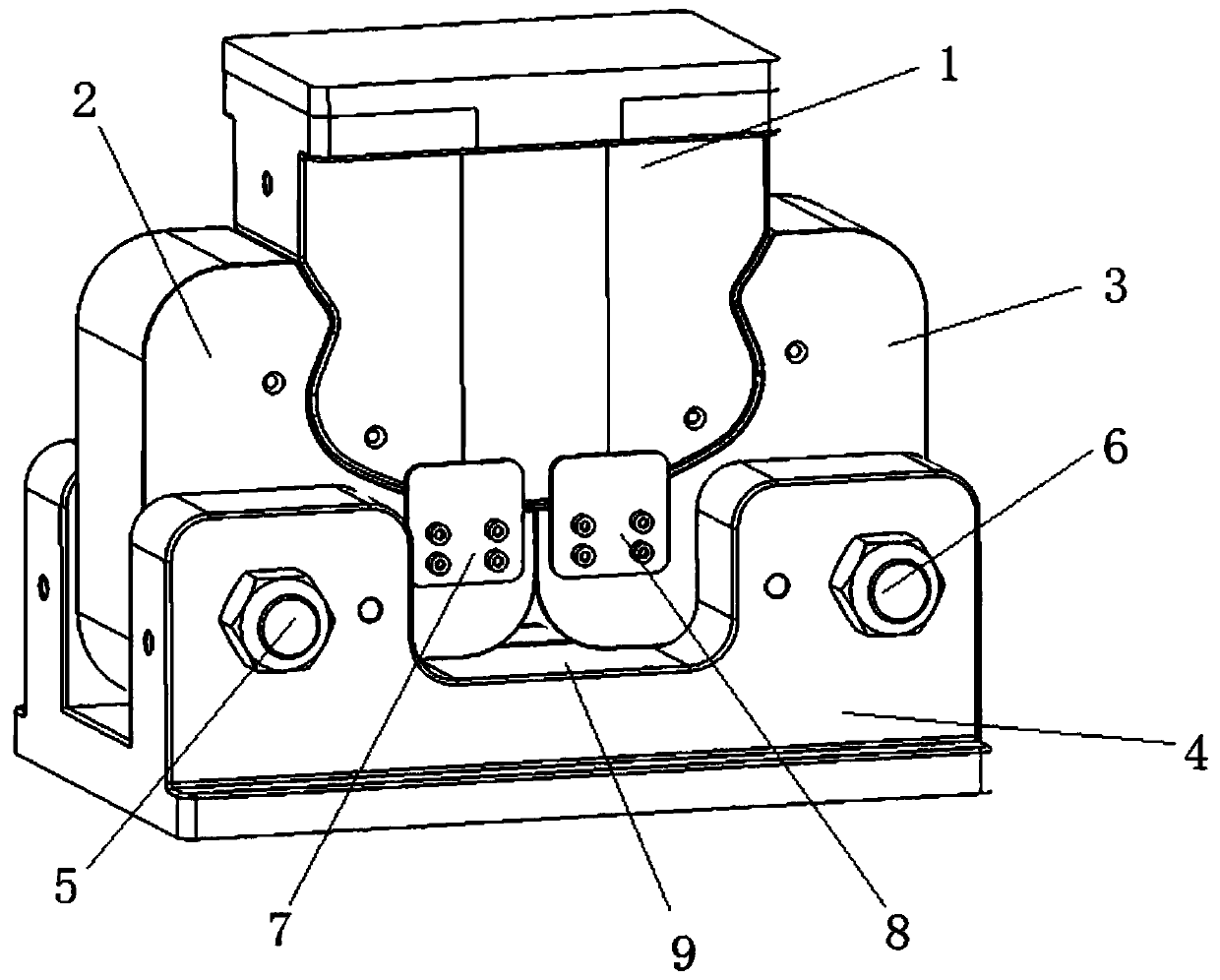

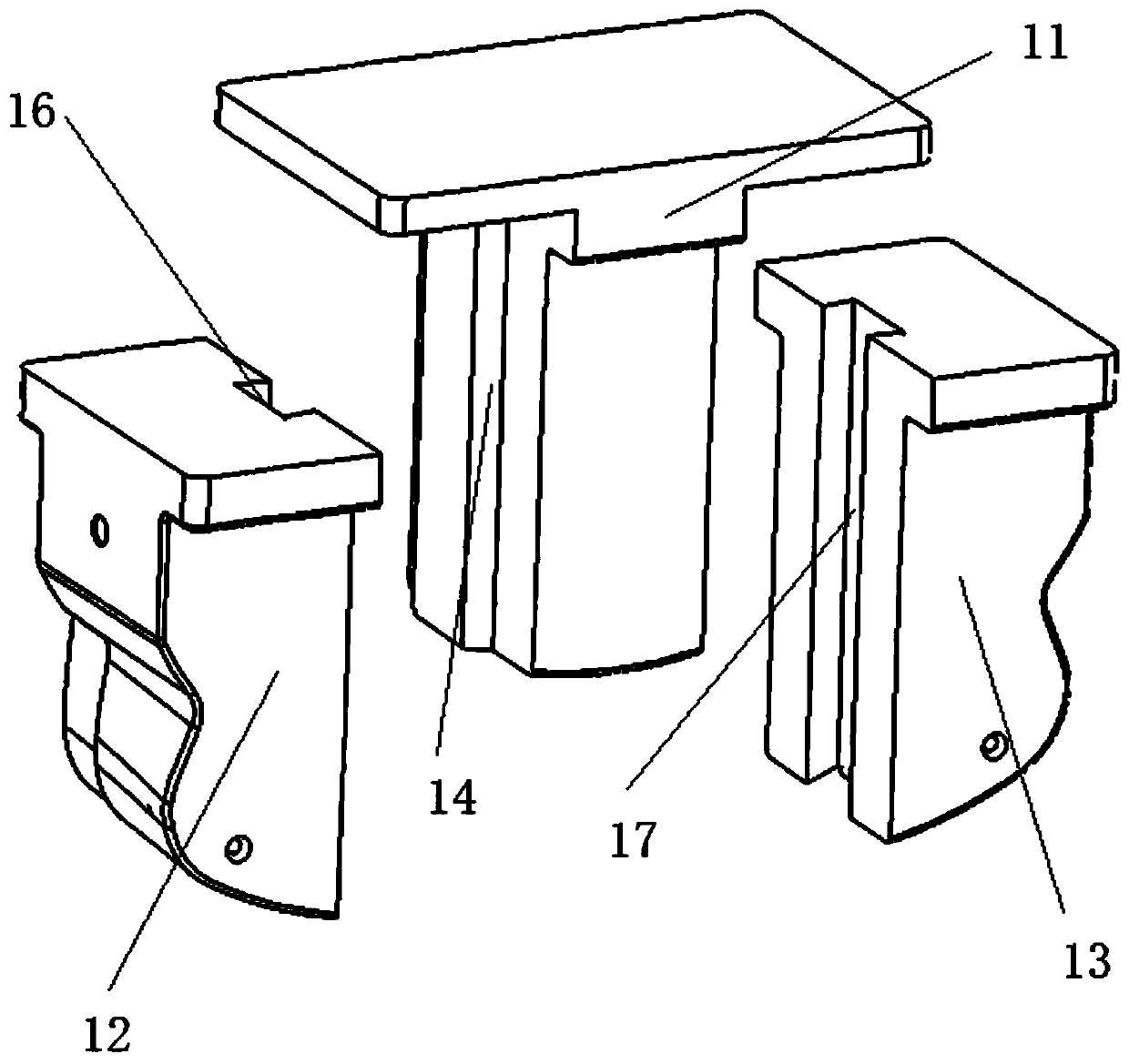

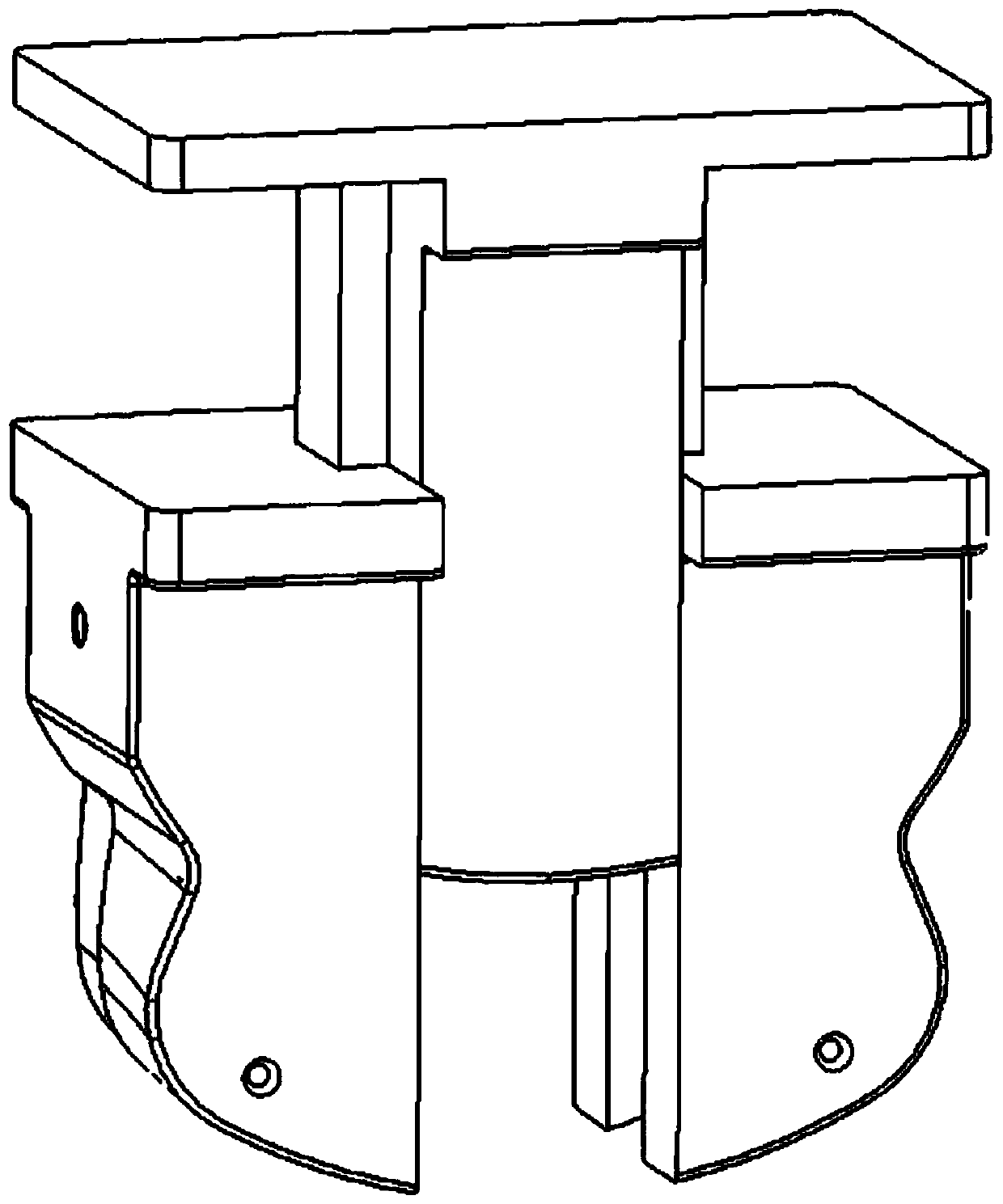

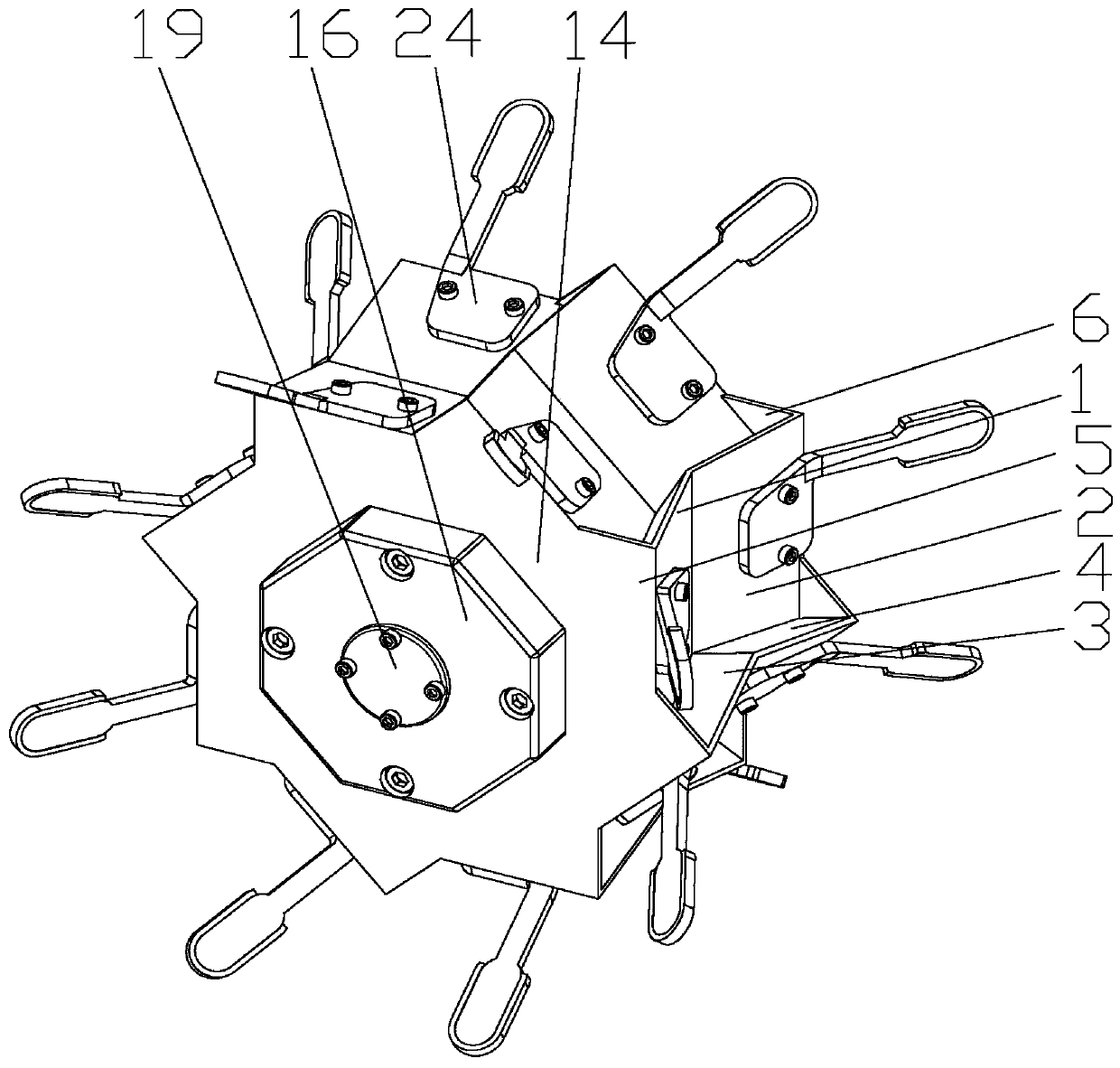

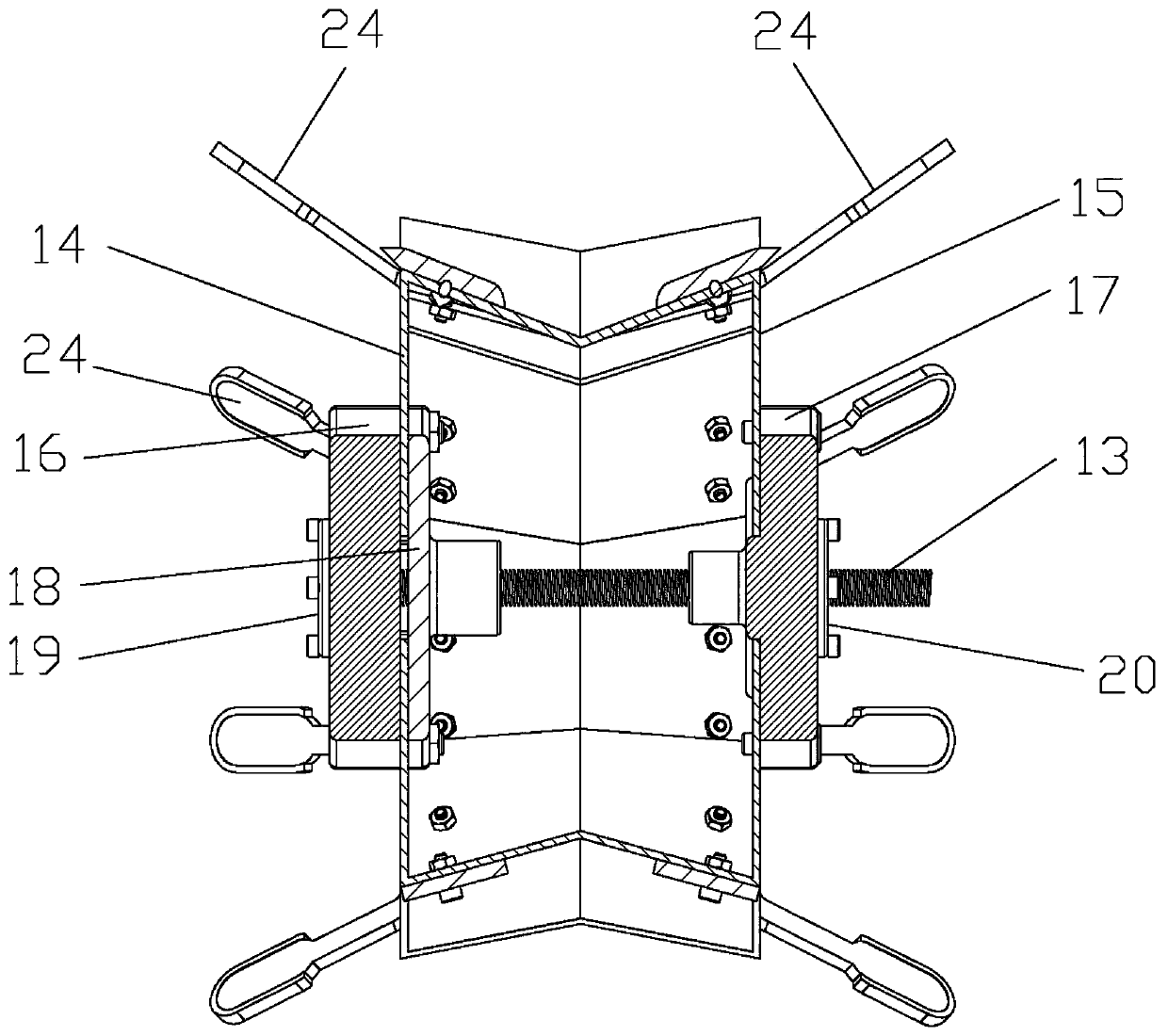

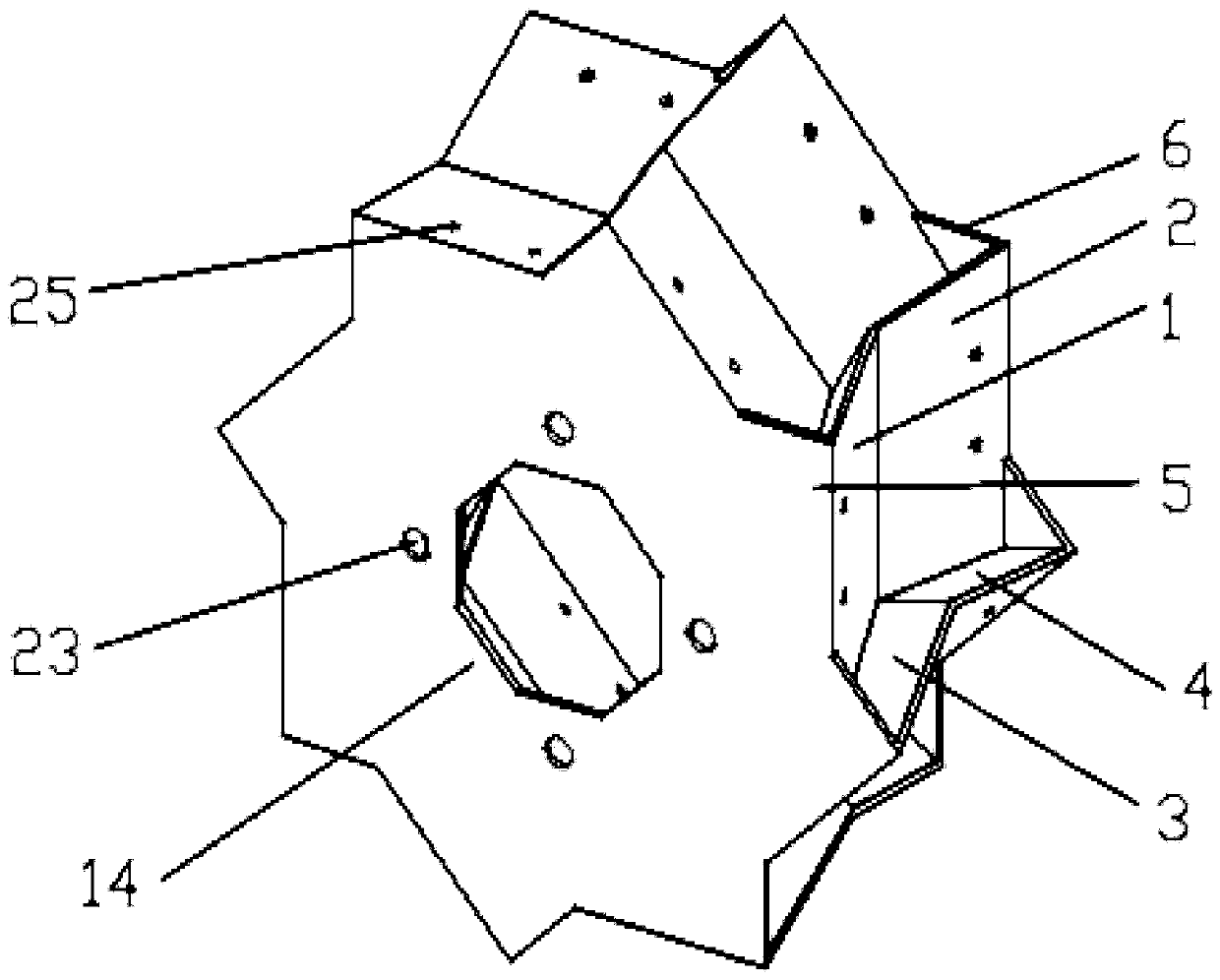

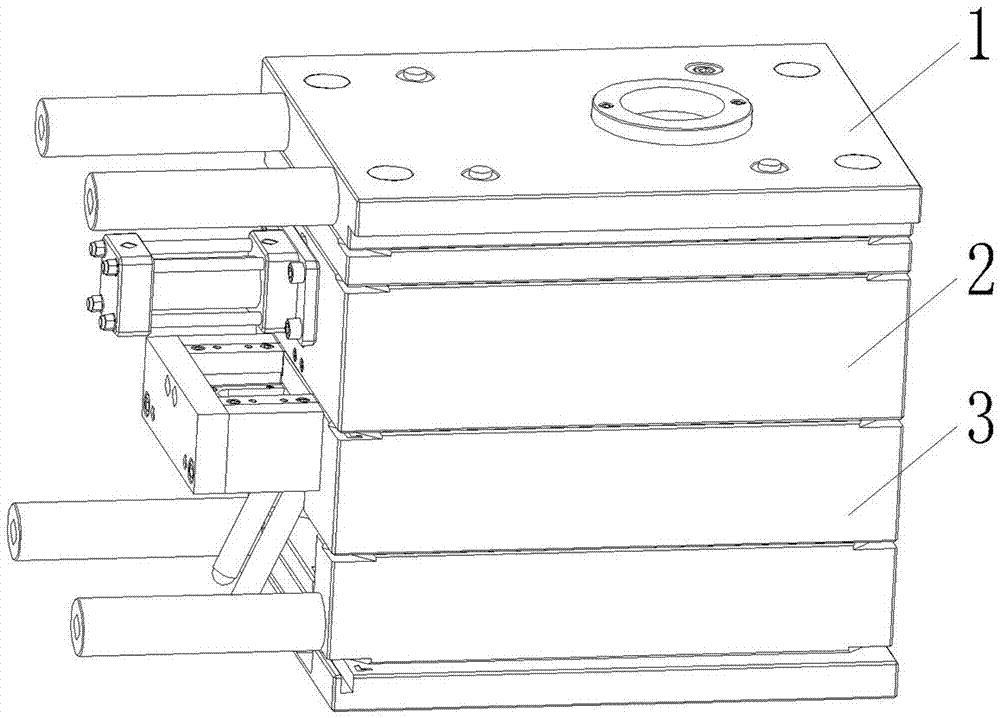

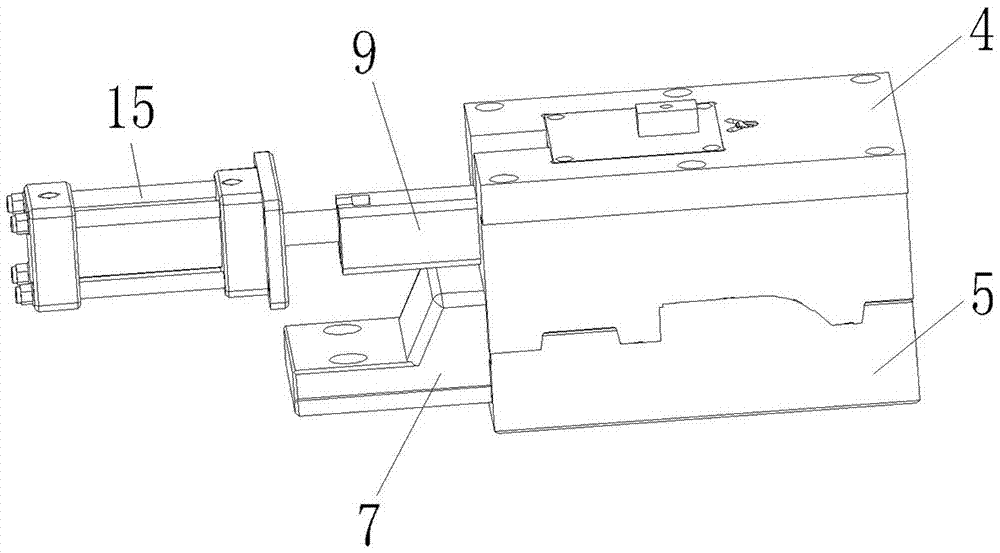

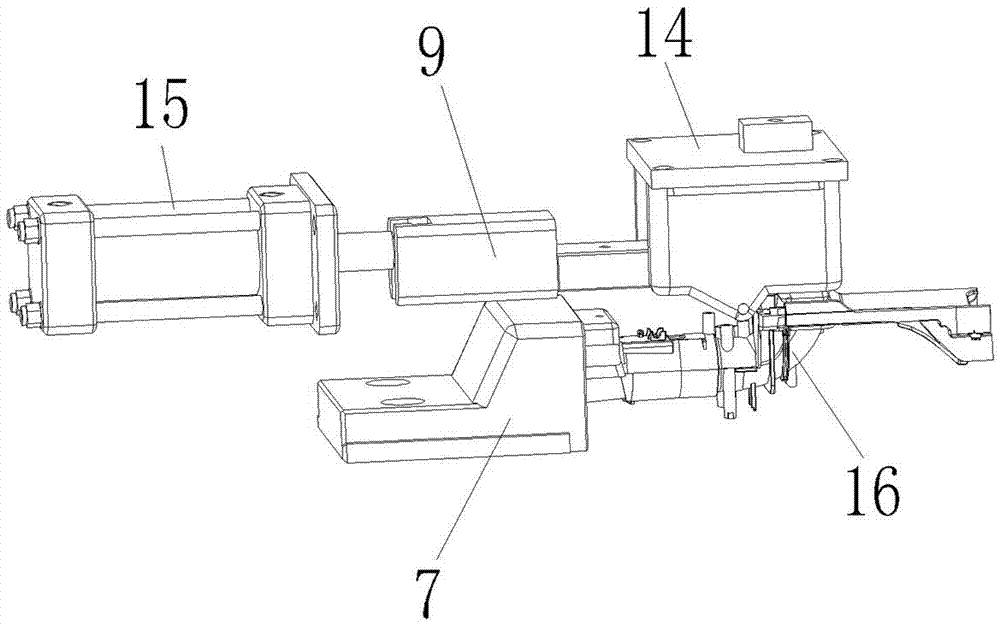

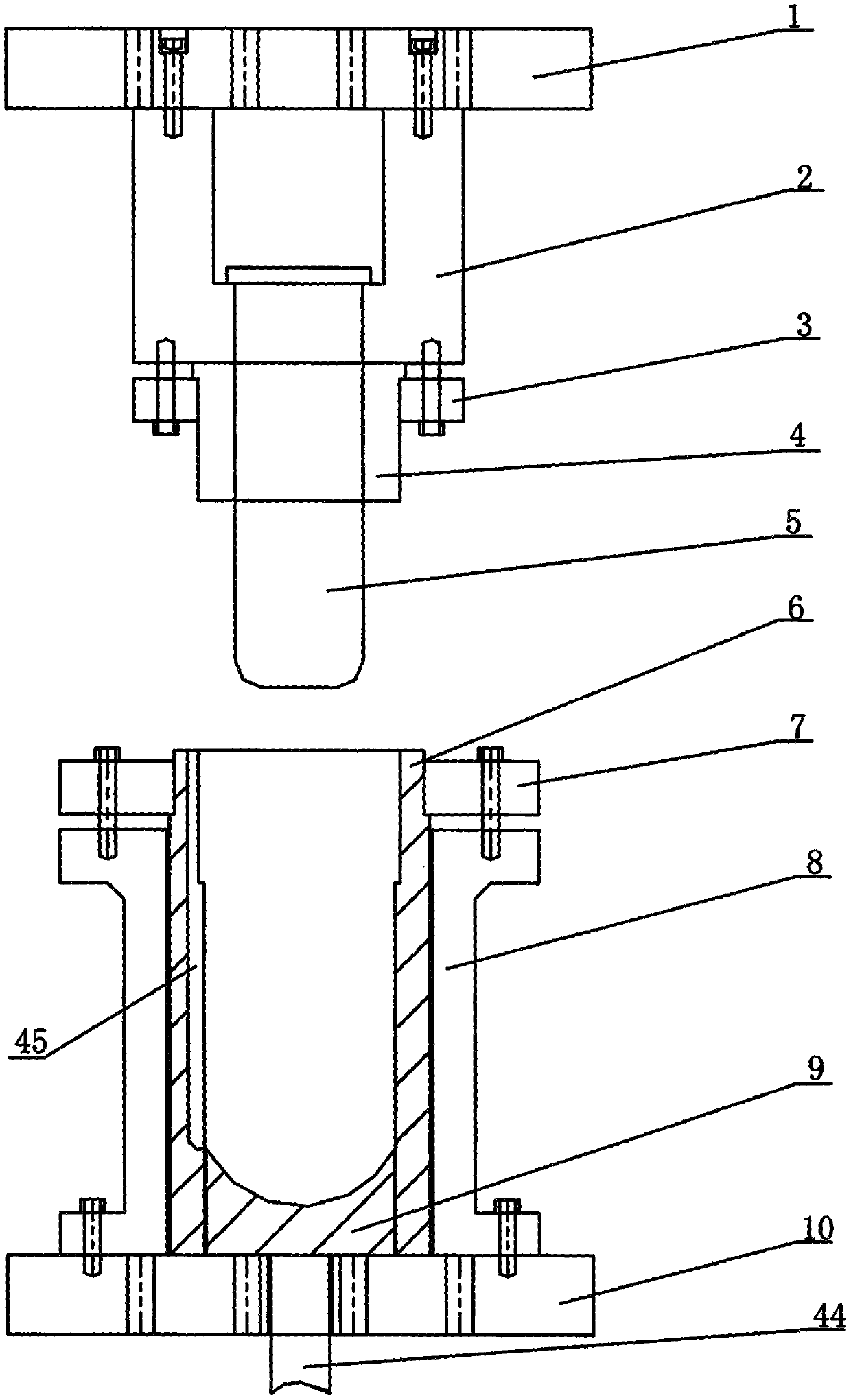

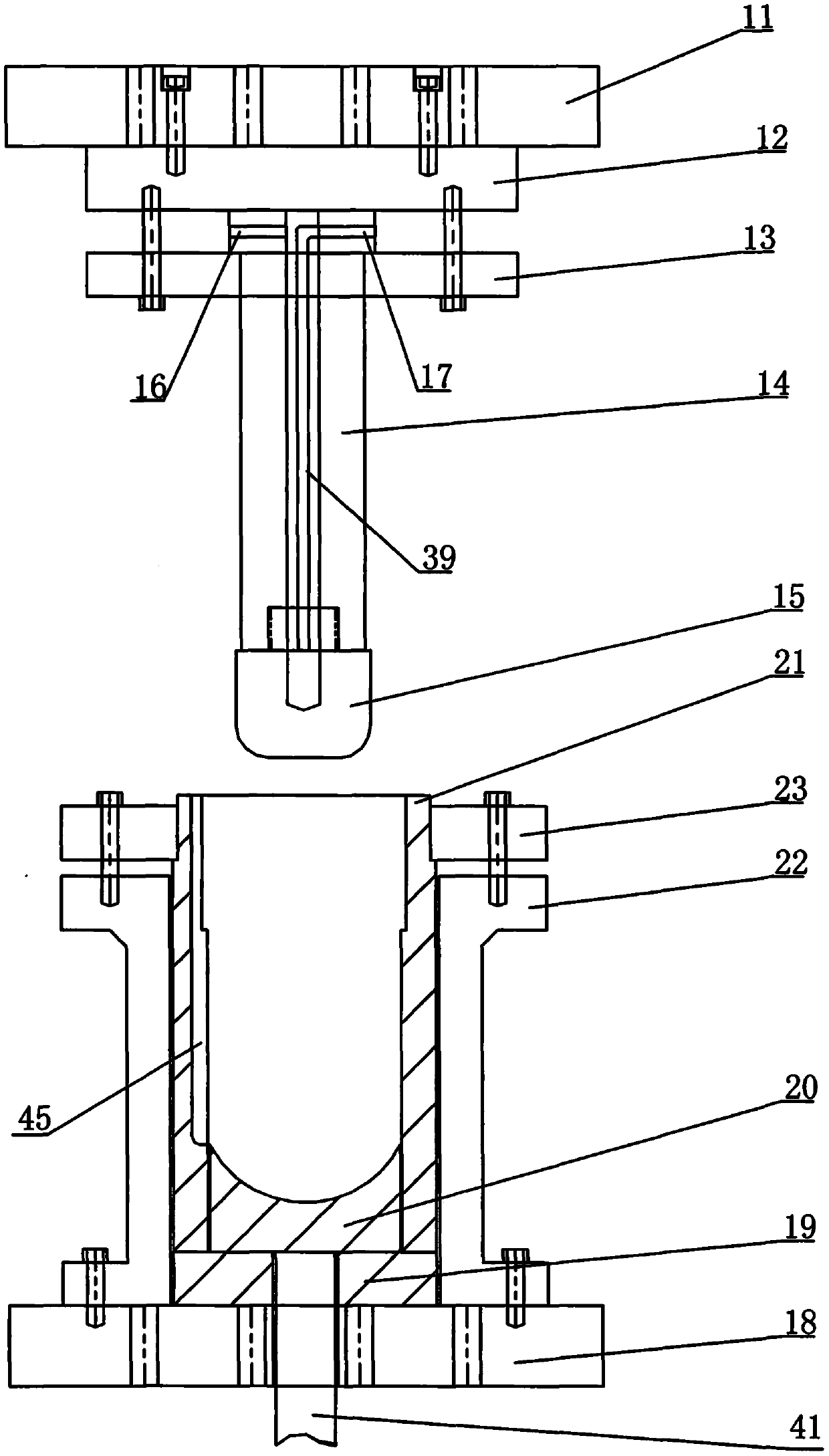

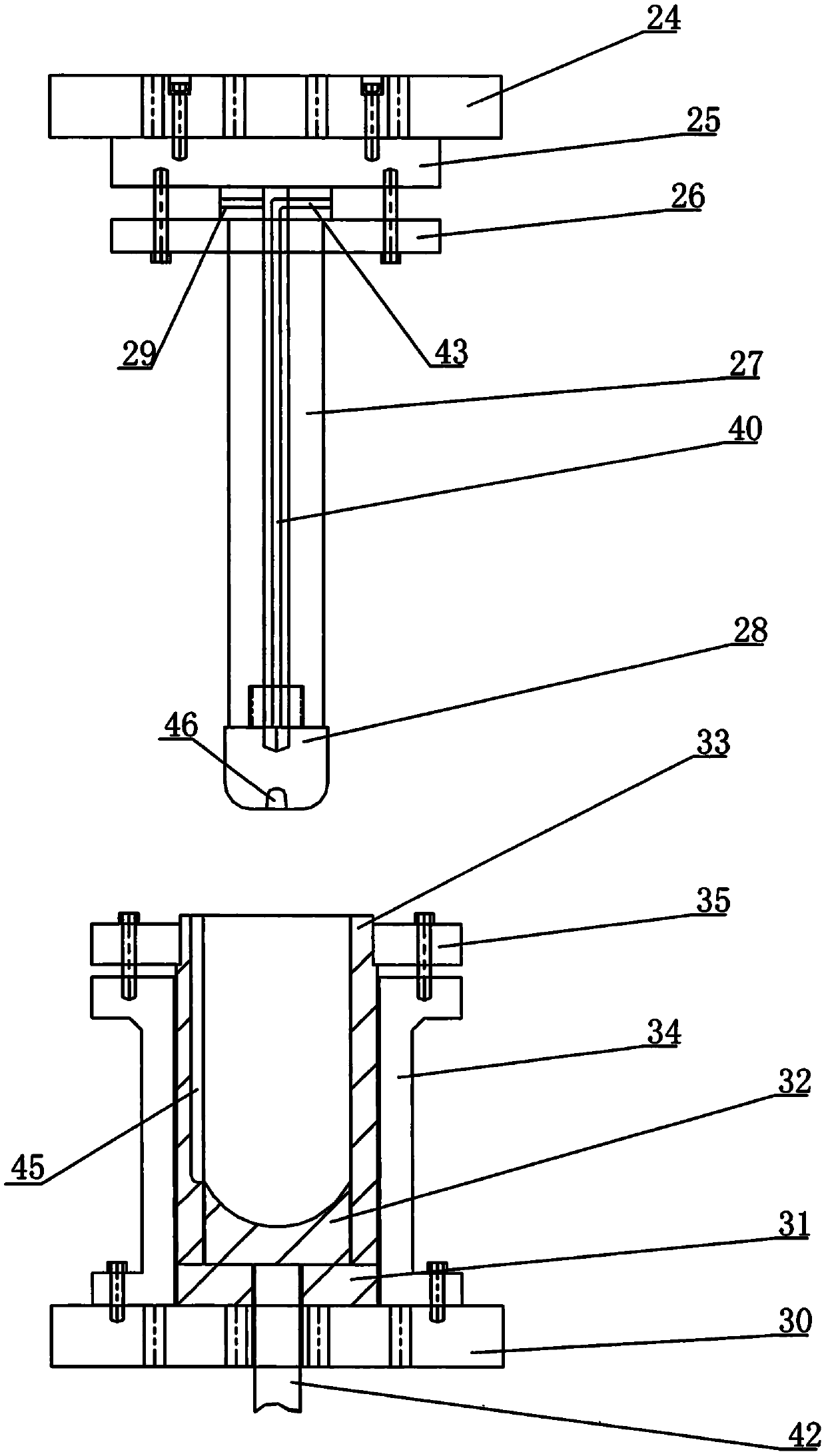

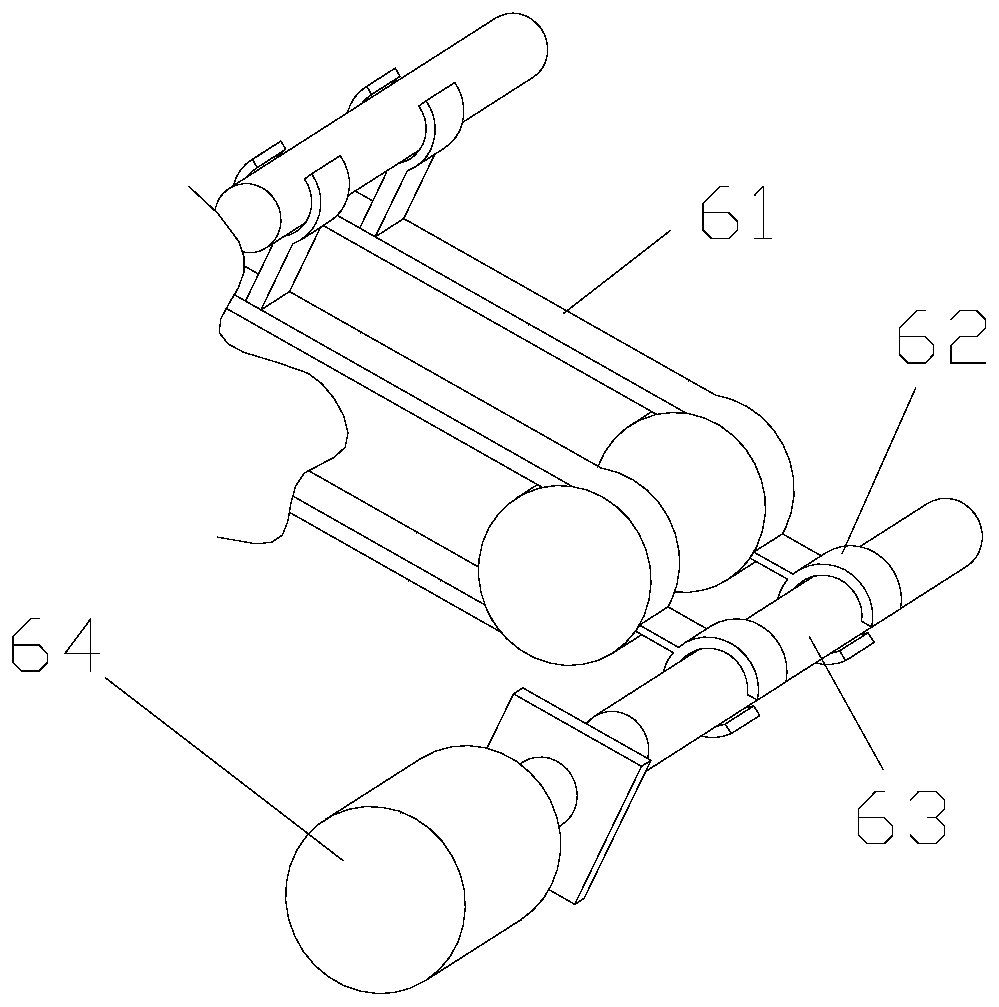

Multi-directional integral hot-pressing partitioning die for negative-angle parts and forming method

The invention relates to a multi-directional integral hot-pressing partitioning die for negative-angle parts and a forming method, belongs to the field of precise sheet metal processing, and solves the problems that the negative-angle parts are difficult to integrally form at one time, tailor-welded deformation is caused, a welding seam reduces the mechanical property, and the parts rebound. The partitioning die comprises a male die, a female die, a base, rotary shafts, an ejector block and material baffle boards; the male die and the female die are all formed by splicing divided blocks; the male die consists of an insert block, a left block and a right block, the left block and the right block are inserted at two sides of the insert block, and rapid demoulding can be realized; the femaledie comprises a left half die and a right half die; the left half die and the right half die are rotationally mounted on the base; the two half dies of the female die are rotationally separated towards two sides through the ejector block which moves up and down in the middle of the base, demoulding of the female die is realized, the ejector block moves downwards, and the negative-angle parts can be integrally formed by the coupling between the male die and the female die and are fixedly shaped through multidirectional hot pressing. According to the multi-directional integral hot-pressing partitioning die for the negative-angle parts and the forming method, the problems of the part deformation, the mechanical property reduction, the parts rebounding and the like caused by tailor-welded operation are avoided, and the size precision of the parts is improved.

Owner:BEIJING HANGXING MACHINERY MFG CO LTD

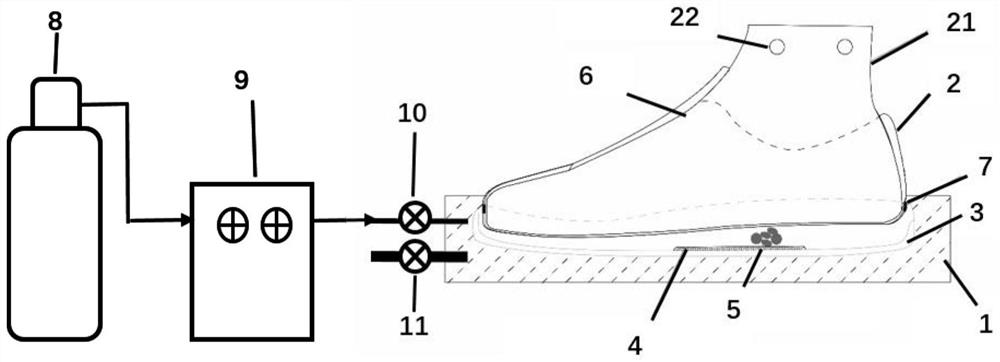

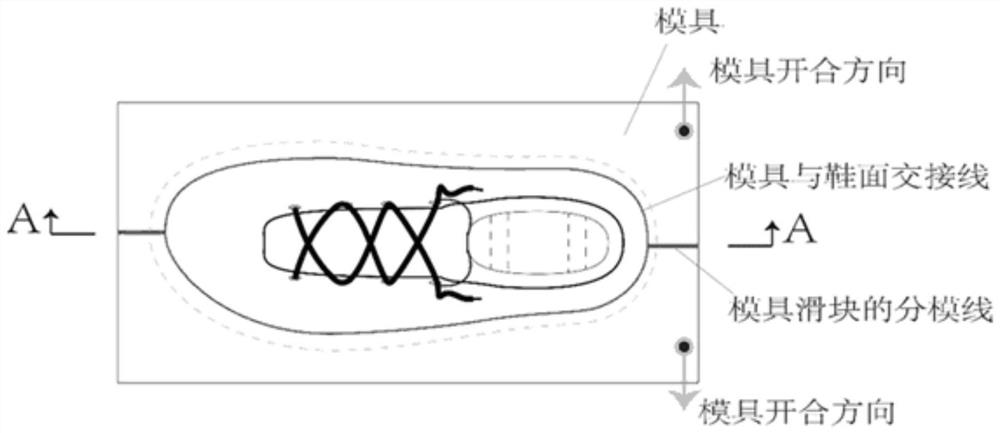

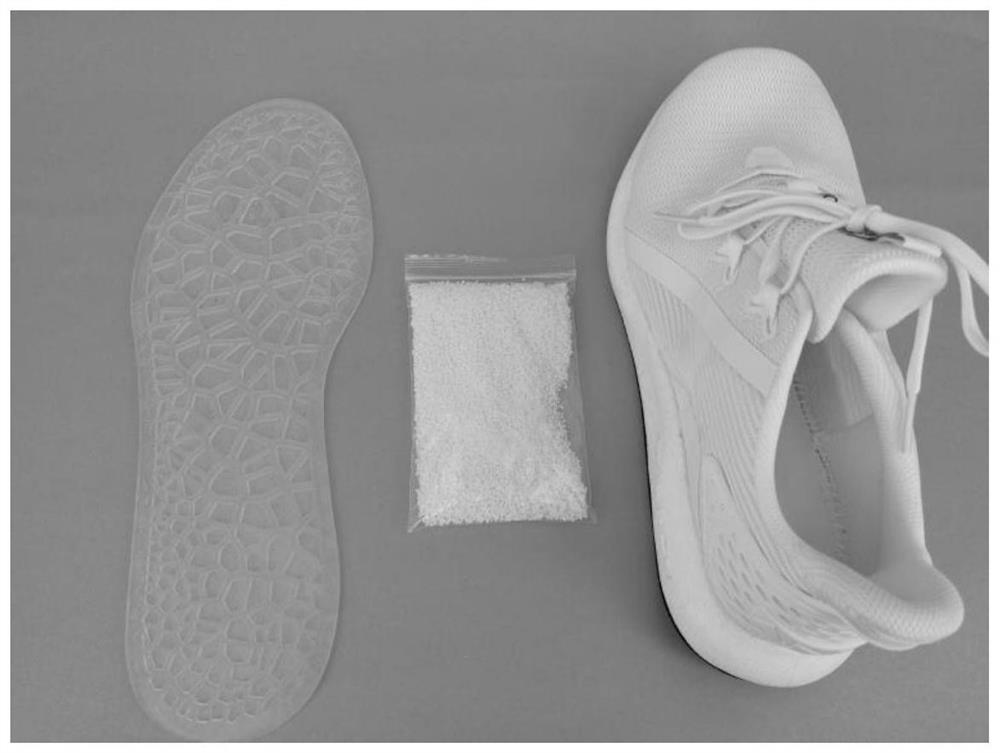

Production method for integrally forming shoes

ActiveCN112120351ARealize one-piece moldingShort preparation processShoe gluingElastomerPolymer science

The invention provides a production method for integrally forming shoes, which comprises the following steps of putting an outsole part at the bottom of a shoe mold, adding thermoplastic elastomer particles into the midsole of the mold, putting a shoe tree sleeved with a vamp into the mold, and closing the mold to realize sealing, wherein at the position close to the thermoplastic elastomer particles, the surface of the outsole part and the surface of the vamp are both covered with a permeation blocking material; hot melt adhesive films are placed at the interface of the outsole part and the midsole position and the interface of the midsole position and the vamp; and the Vicat softening point temperature of the thermoplastic elastomer particles is 50-140 DEG C. introducing gas into the sealed shoe mold, raising the temperature to enable the gas reaching the supercritical state to impregnate and saturate the thermoplastic elastomer particles, then releasing the pressure to form a foamedmidsole part, and meanwhile, realizing bonding of all shoe parts, and removing a shoe tree to obtain the whole shoe. The method is short in preparation process and high in efficiency; and the prepared shoes are high in resilience rate, low in density and beneficial to application.

Owner:ANTA CHINA

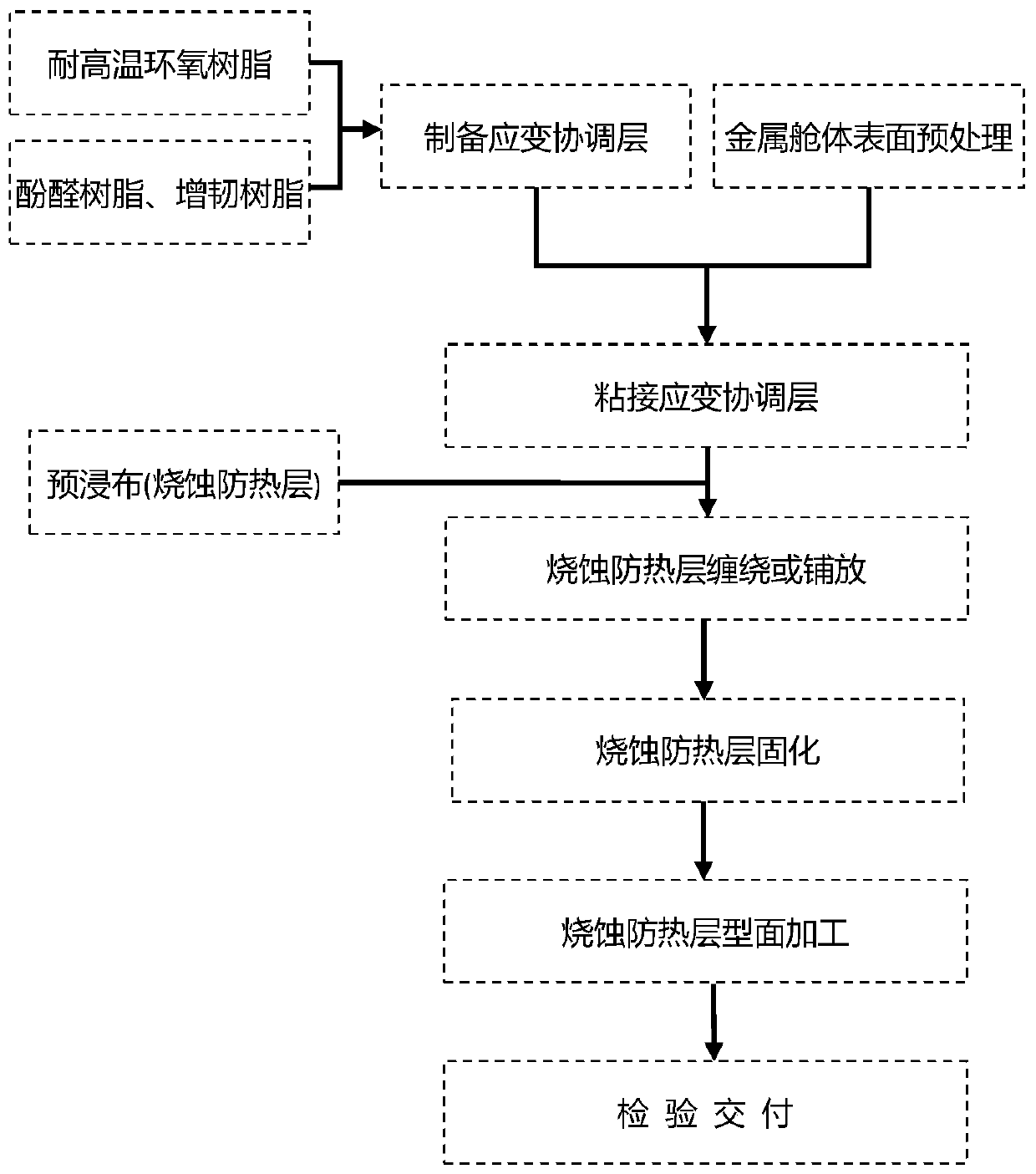

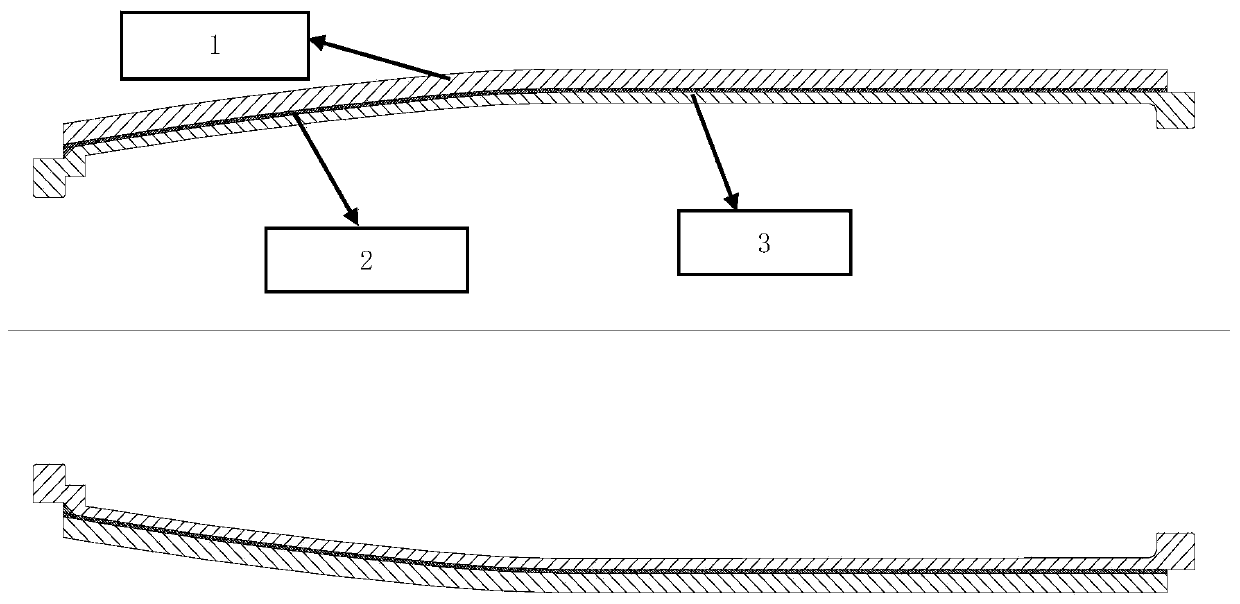

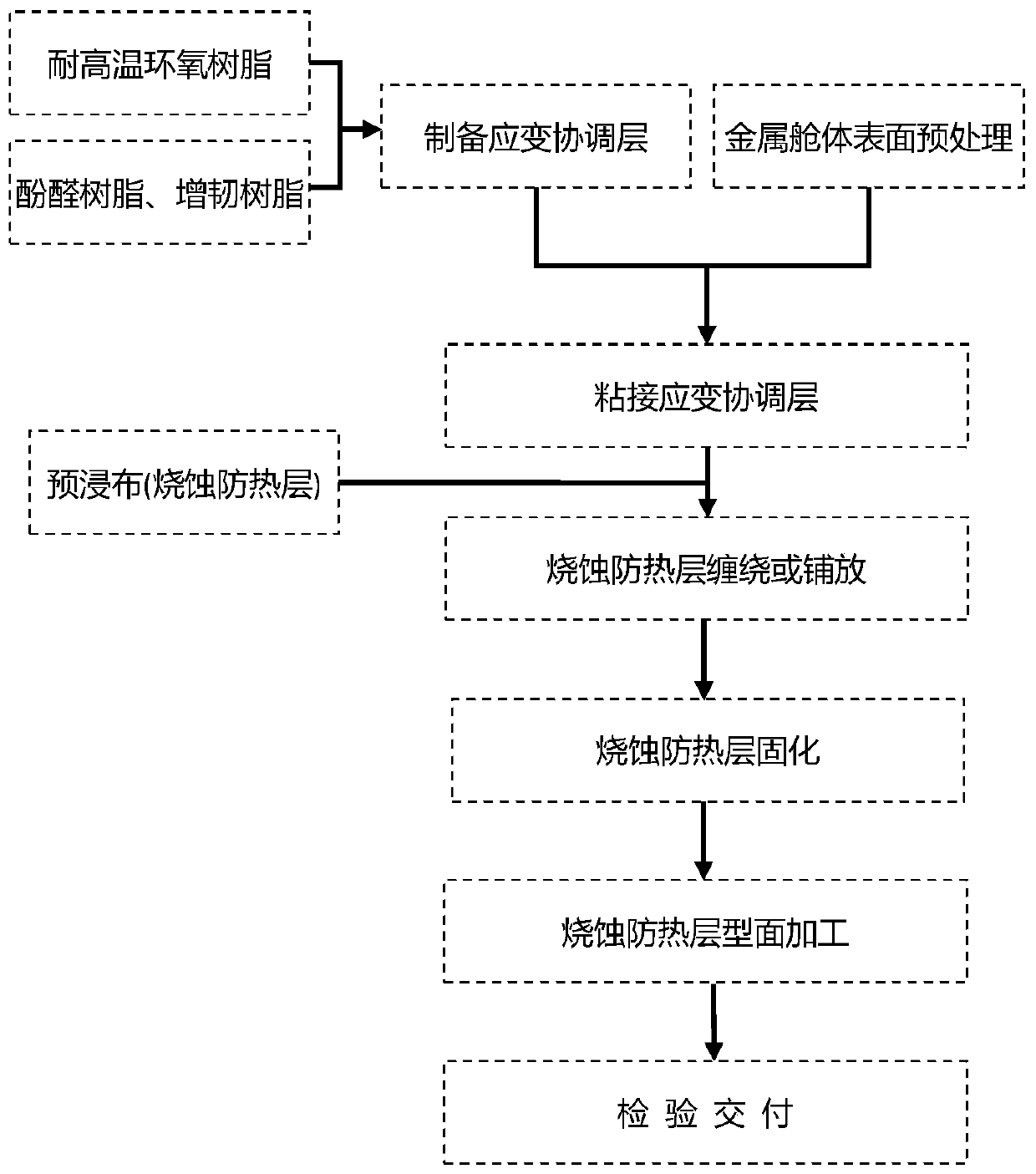

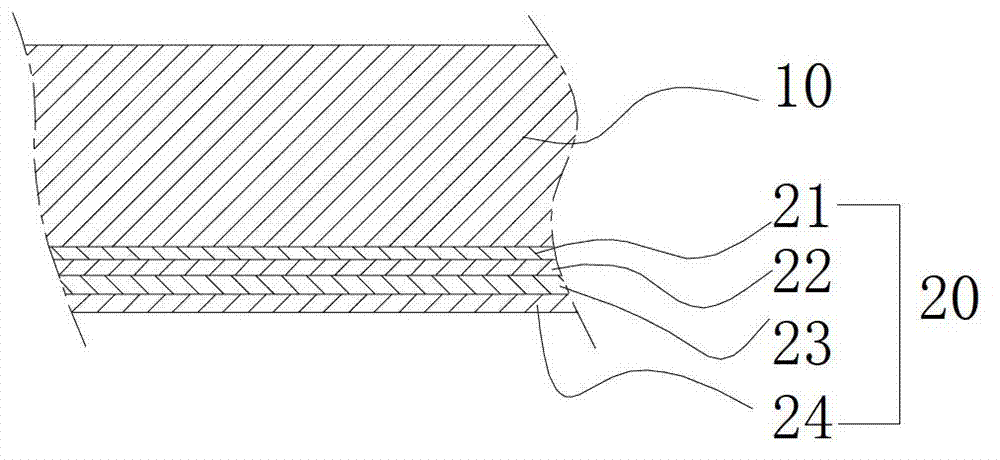

Strain coordination layer for integral forming of ablative thermal protection structure as well as preparation method thereof and application

ActiveCN111136935ASimple processShort production cycleSynthetic resin layered productsVehicle componentsFlight vehicleChemistry

The invention relates to a strain coordination layer which is compounded from a film and a carrier, wherein the film is prepared by a high-temperature-resistant phenolic aldehyde modified epoxy resinsystem; and the carrier is glass fiber fabric, quartz fiber fabric, polyester fiber fabric and the like. The invention further relates to a method for preparing the strain coordination layer, a methodof preparing a cabin from the strain coordination layer and the cabin prepared by the method. The strain coordination layer can realize integral forming and curing of a metal cabin body and an outerheat-resistant layer, is simple in technological process, is short in production period, and is especially suitable for mass production. The strain coordination layer disclosed by the invention can realize thermal deformation and stress matching with the heat-resistant layer / the metal cabin body very well, realizes requirements of high shear strength and high peel strength, prevents the cabin fromrelatively great deformation, avoids heat-resistant layer cracking de-bonding risk, has high impact resistance and damping anti-seismic characteristics, and can be suitable for large-area ablative heat-resistant application of a metal structure surface-layer material of a high-speed aircraft under various complex working conditions.

Owner:AEROSPACE INST OF ADVANCED MATERIALS & PROCESSING TECH

Photocuring aluminum oxide ceramic paste and atomization cavity integrated forming method thereof

PendingCN112919887AHigh solid contentImprove uniformityAdditive manufacturing apparatusOxide ceramicStearic acid

The invention discloses a photocuring aluminum oxide ceramic paste and an atomization cavity integrated forming method thereof. The paste comprises ceramic powder, stearic acid powder, premixed liquid and a dispersing agent. The forming method comprises the following steps: printing the photo-cured aluminum oxide ceramic paste into an atomization cavity structure, and then performing degreasing and sintering; and adjusting atomization cavity structure parameters, printing process parameters and degreasing sintering process parameters. The atomization cavity structure parameters comprise the overall wall thickness and the connecting fillet radius of an atomization cavity; the printing process parameters comprise a printing support gap, printing laser power, layer thickness and curing depth; and the degreasing sintering process parameters comprise heating rate, powder burying amount, pre-sintering temperature, degreasing temperature point and heat preservation time. By optimizing the components of the photocuring aluminum oxide ceramic paste, the structure of the atomization cavity and the post-treatment process, the performance (strength, corrosion resistance and the like) of the aluminum oxide atomization cavity is improved, the cracking deformation of the atomization cavity in the preparation process is reduced, and the preparation yield of the atomization cavity is further improved.

Owner:XI AN JIAOTONG UNIV

Glass door, manufacturing technique and refrigeration equipment

InactiveCN106193905ASolve the smellSolve curing timeDomestic cooling apparatusLighting and heating apparatusEngineeringRefrigeration

The invention provides a glass door which comprises an outer glass sheet, an inner glass sheet and a spacing bar. The outer glass sheet is separated from the inner glass sheet through the spacing bar, and a hollow space is formed. The spacing bar is located on the periphery of the hollow space. The outer side of the spacing bar is located between the outer glass sheet and the inner glass sheet, and the outer glass sheet and the inner glass sheet are bonded through a sealant. A PU frame is arranged on the outer side of the sealant. The PU frame wraps the periphery of the inner glass sheet or wraps the periphery of the inner glass sheet and the periphery of the outer glass sheet at the same time. The invention further provides a manufacturing technique of the glass door and refrigeration equipment adopting the glass door. Integrated formation of a door body is achieved by combining the PU and the RIM technique, the hollow glass sheets are sealed into an integral module through the PU material, and the undesirable odor problem of a sealant of a hollow glass door is solved; meanwhile, condensation of a frame can be prevented; and by the adoption of the integral forming technique, a few hours of curing time of the hollow glass sheets and the frame is shortened, the product takt time is shortened, and the production quality is improved.

Owner:QINGDAO HAIER SPECIAL ICEBOX

Massage air bag and pneumatic massage cushion

InactiveCN103126873AImprove reliabilityRealize one-piece moldingBack restsChiropractic devicesHuman bodyPhysical medicine and rehabilitation

The invention provides a massage air bag. The massage air bag is composed of two diaphragms, the two diaphragms overlap with each other and are connected through a connecting portion, and the head of the connecting portion and the tail of the connecting portion extend to edges of diaphragms respectively, so that an inflatable portion is formed between the connecting portion and edges; and the tail end of the inflatable portion which is arranged between the close head and the tail and extends to edges forms a gas channel through which the inflatable portion is communicated with the air. The massage air bag is provided with the gas channel which is integrated with the inflatable portion, so that the integrated forming of a plurality of massage air bags and gas channels and the mutual communication of the plurality of massage air bags can be achieved, no additional air duct is required for connection, the quantity of air ducts and fault points are reduced, the operation reliability of massage air bags can be improved, and the provided massage air bag and an air bag group containing the massage air bag are small in massage area contacting with human bodies, high in pressure and good in massage effect.

Owner:李征 +2

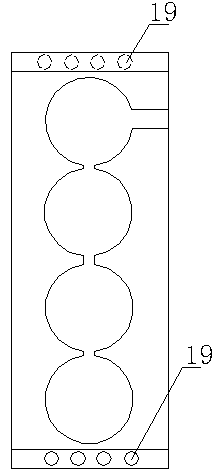

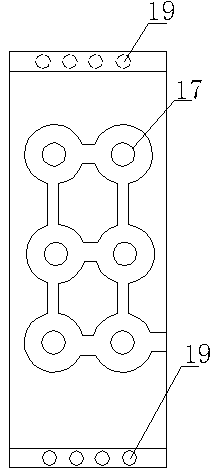

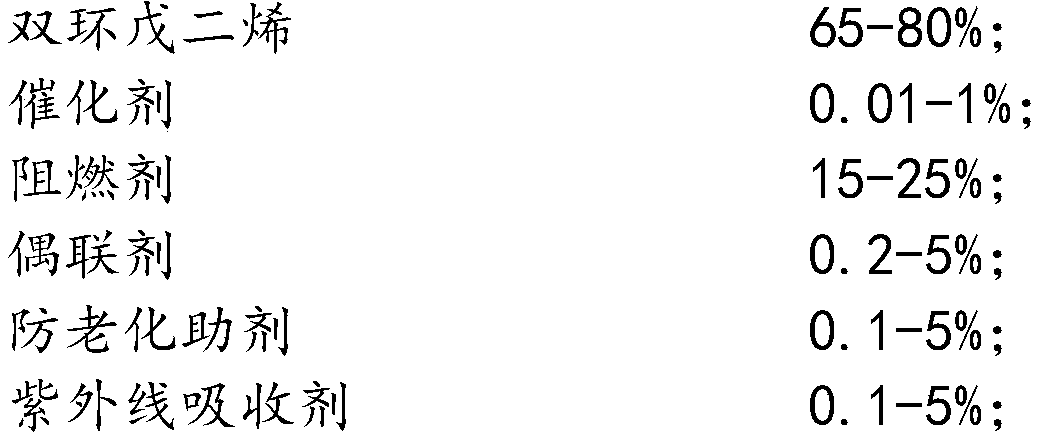

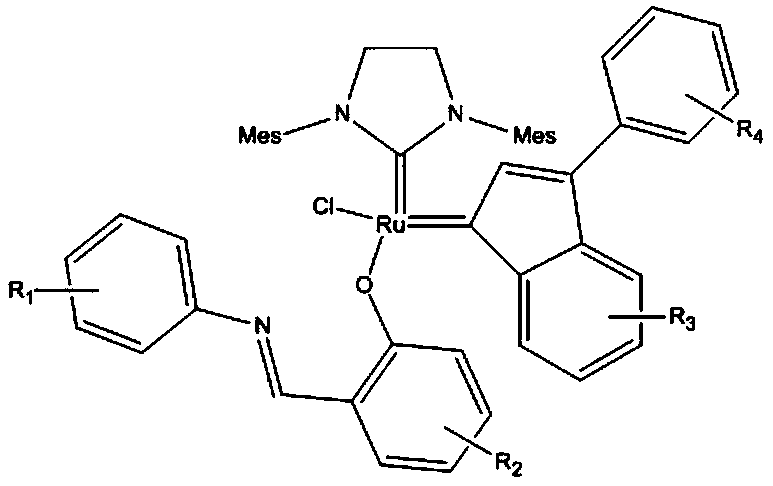

Manufacturing system and method of polydicyclopentadiene composite material with pre-embedded glass fibers

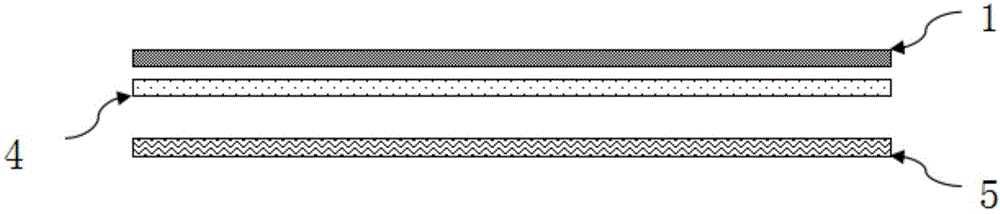

The invention provides a manufacturing system of a polydicyclopentadiene composite material with pre-embedded glass fibers. The manufacturing system of the polydicyclopentadiene composite material with the pre-embedded glass fibers is characterized in that a mold and a fiber cloth assembly are included, wherein the fiber cloth assembly is pre-embedded in the mold, the fiber cloth assembly is composed of two layers of fiber cloths and a diversion layer, and the diversion layer is clamped between the two layers of fiber cloths. The materials manufactured by the manufacturing system is low in labor cost, capable of achieving automation, safe, and environmentally friendly, and has the performance superior to that of traditional glass fiber reinforced plastic materials.

Owner:克琴新材料科技(上海)有限公司

Self-supporting cicada-preventing butterfly cable and production equipment for processing same

PendingCN111399151AOptimize the space areaIncrease fiber densityFibre mechanical structuresCore (optical fiber)Electrical and Electronics engineering

The invention discloses a self-supporting cicada-preventing butterfly cable which comprises an optical cable body. The optical cable body comprises an outer sheath, a communication unit and a reinforcer, and the outer sheath wraps the communication unit and the reinforcer; the communication unit comprises a winding optical fiber ribbon and two symmetrically arranged protection sheets, and the winding optical fiber ribbon is arranged between the two protection sheets; the two sides of the outer sheath are respectively provided with two tearing grooves, and the distance between the two tearing grooves at one side is greater than the width of the protection sheet, thereby solving the problem that the optical fiber attenuation exceeds the standard or the structure of the optical cable is damaged because cicadas are attached to the optical cable. The invention also discloses production equipment for processing the self-supporting cicada-preventing butterfly cable, the protection sheet pay-off rack is additionally arranged, and the extrusion molding die core and the extrusion molding die sleeve of the plastic extruding machine are improved so that the production process of integrated extrusion molding can be completed, the integrated molding of the novel optical cable is realized, and the production efficiency is relatively high.

Owner:FURUKAWA ELECTRIC XIAN OPTICAL COMM

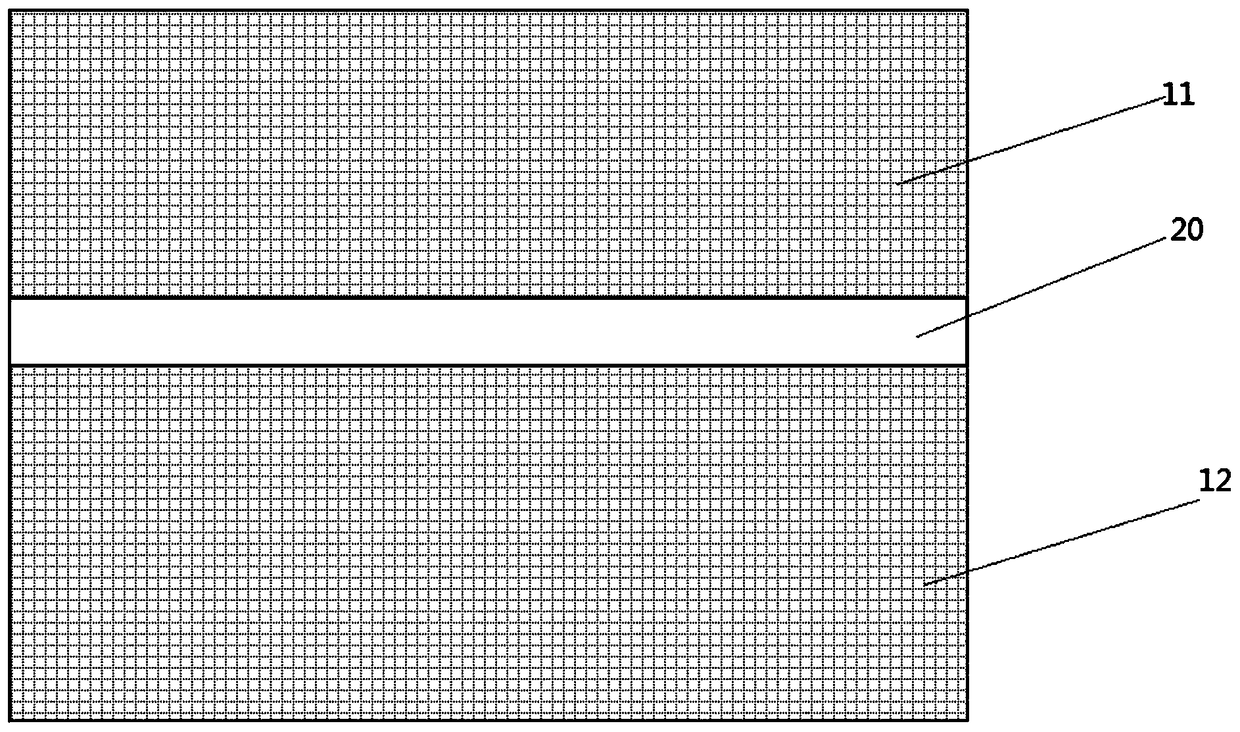

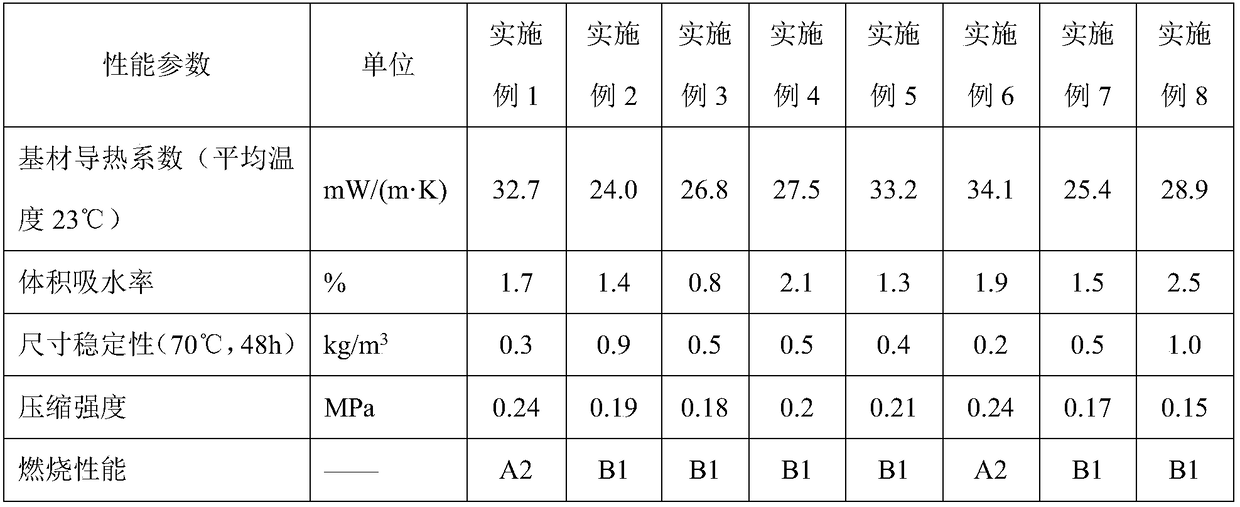

Electrothermal floor heating insulation board and preparation method thereof

InactiveCN108948324ARealize one-piece moldingResponse Speed SynchronizationFlooringCombustionInorganic particle

The invention discloses an electrothermal floor heating insulation board, which comprises a surface material and a substrate. The surface material is arranged on upper and lower surfaces of the substrate, and the surface material on the upper surface of the substrate is an electrothermal film. The substrate is formed by a reaction among inorganic particles, a solid flame retardant and a rigid polyurethane foam foaming material, and comprises the following raw materials (by weight): 34-83 parts of inorganic particles, 2-17 parts of a solid flame retardant, and 15-49 parts of the rigid polyurethane foam foaming material. Thermal conductivity coefficient of the substrate is 24.0-35.0 mW / (m.K), and the combustion performance grade is not lower than the B1 grade in GB8624-2012 ''Classificationof Combustion Performance of Building Materials and Products''. According to the electrothermal floor heating insulation board, water absorption per volume is less than or equal to 3.0%, dimensional stability (30 DEG C, 48 h) is less than or equal to 1.0%, compression strength is greater than or equal to 0.15 MPa, and the product has characteristics of low temperature radiation, water resistance and heat preservation and good high temperature dimensional stability, is capable of bearing, is integrated as a whole and is easy to install and maintain.

Owner:南京红宝丽新材料有限公司

Valve cover wax pattern integral forming die

The invention provides a valve cover wax pattern integral forming die which is used for realizing integral wax pattern forming. An internal wax pattern comprises a dead head wax pattern part and at least one valve cover casting wax pattern part integrally formed on the dead head wax pattern part; the valve cover wax pattern integral forming die comprises the followings: an upper die cavity is formed in the inner surface of an upper die and comprises upper dead head die cavity parts communicating with each other and at least one upper valve cover die cavity part connected onto the upper dead head die cavity parts; and a lower die cavity matched with the upper die cavity is formed in the internal surface of a lower die and comprises low dead head die cavity parts communicating with each other and at least one lower valve cover die cavity part connected onto the lower dead head die cavity parts. When the upper die and the lower die are assembled, the upper die cavity and the lower die cavity are buckled to form a closed integral wax pattern die cavity matched with a to-be-formed integral wax pattern in shape. The valve cover wax pattern integral forming die can realize integral forming of the valve cover casting wax pattern and the dead head wax pattern.

Owner:纽威工业材料(大丰)有限公司

Method for preparing composite shell

InactiveCN108274199ARealize one-piece structureLow cost manufacturing processCoatingsDie castingSeam welding

The invention relates to a method for preparing a composite shell. The method comprises the steps: (1) forging and pressing stainless steel or aluminum alloy to form an outer frame; (2) die-casting the aluminum alloy to form an inner frame; (3) conducting CNC finish machining for the outer frame and the inner frame for laser welding; (4) conducting laser deep-seam welding for the outer frame and the inner frame, and thus forming a structural metal part; and (5) conducting CNC finish machining for the structural metal part, etc. The method has the advantages of small loss, easy machining, low comprehensive production cost and easy mass production.

Owner:GUANGDONG JANUS SMART GRP CO LTD +1

Paper folding type wheel with variable width

PendingCN111391573APreserve collapsibilityExtended production timeWheelsStructural engineeringMechanical engineering

The invention relates to a paper folding type wheel with the variable width. The paper folding type wheel comprises a reducing wheel carrier and a wheel shaft installed on the reducing wheel carrier.The reducing wheel carrier comprises a plurality of folding units sequentially connected end to end to form a ring. Each folding unit is provided with a first plane, a second plane, a third plane, a fourth plane, a fifth plane and a sixth plane; a first valley fold line is arranged between the first plane and the second plane and is symmetrically arranged by taking the first valley fold line as acenter; a first mountain fold line is arranged between the third plane and the fourth plane and is symmetrically arranged by taking the first mountain fold line as the center; a second valley fold line is arranged between the first plane and the third plane, a third valley fold line is arranged between the second plane and the fourth plane, the fifth plane and the sixth plane are symmetrically arranged with the first valley fold line as the center, and the fifth plane and the sixth plane are connected with the first plane and the second plane respectively. The paper folding type wheel with thevariable width can adjust the width of the variable-diameter wheel carrier, and belongs to the technical field of variable-width wheels and variable-diameter wheels.

Owner:GUANGZHOU UNIVERSITY

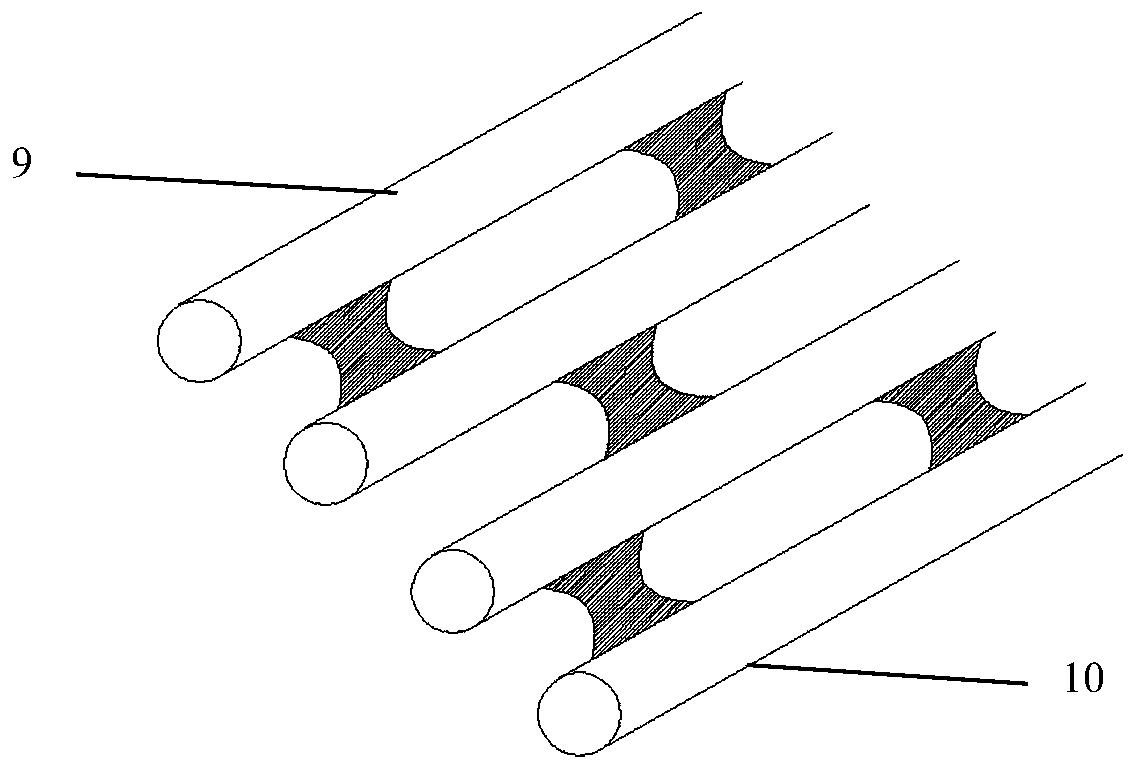

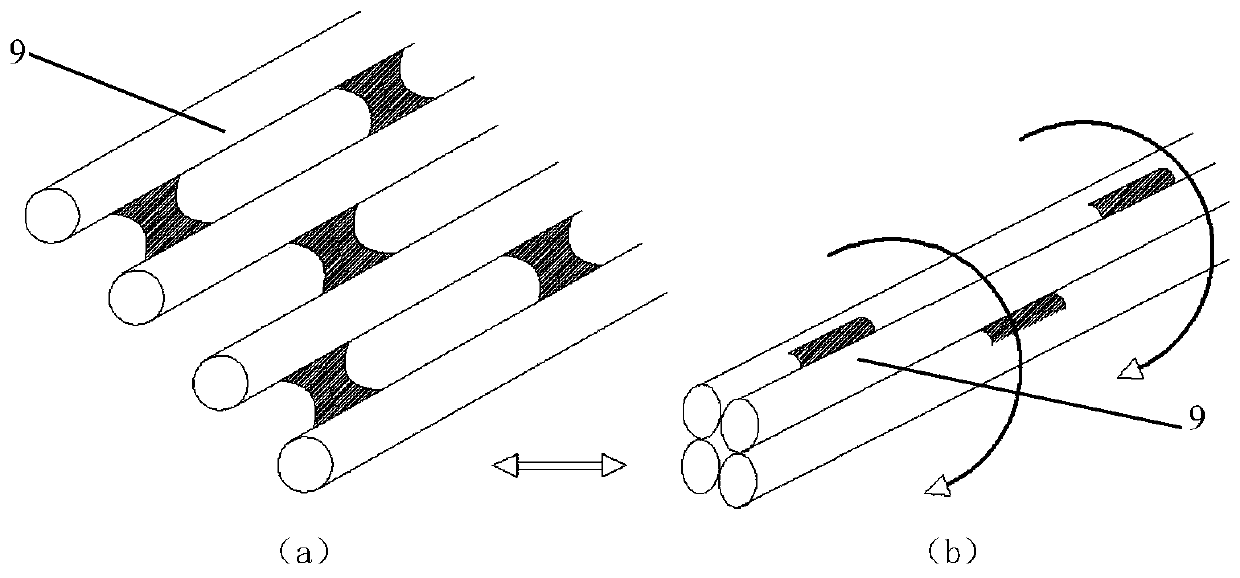

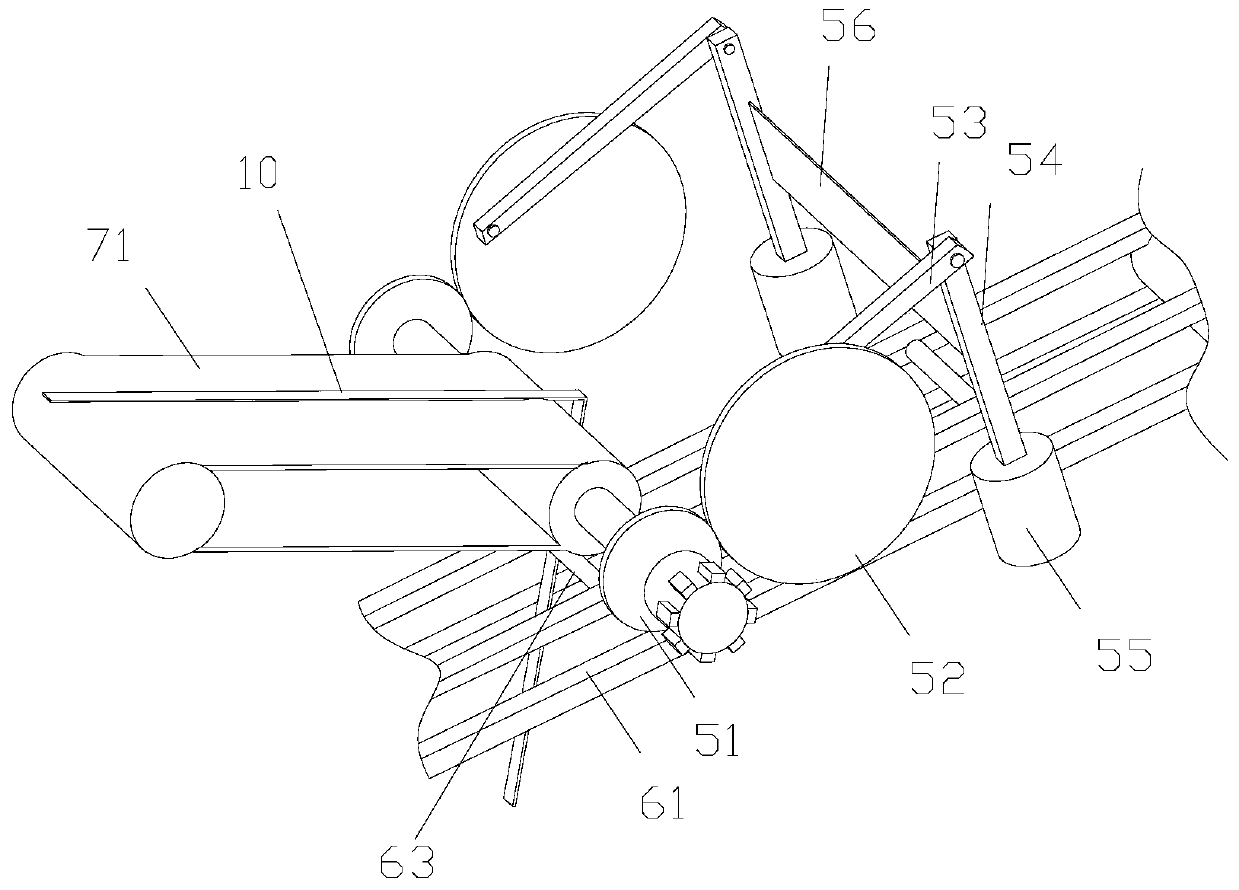

Rebound deformation inhibition method for laser-assisted in-situ forming of thermoplastic composite structural component

The invention relates to a rebound deformation inhibition method for the laser-assisted in-situ forming of a thermoplastic composite structural component. The rebound deformation inhibition method forthe laser-assisted in-situ forming of the thermoplastic composite structural component comprises the steps of (1) heating and pressing laid prepregs for the first time by adopting a laser light and apressing roller; (2) stopping laying a new prepreg, and heating and pressing the laid parts in the step (1) for multiple times; and (3) repeating the step (1) and the step (2) until a sample is prepared. Through heating and pressing for the first time, high-temperature melting resins in the adjacent layers of prepregs flow under the pressure action of the pressing roller, so that favorable interlayer bonding is formed. Through heating and pressing for multiple times, the sample releases an internal stress caused by the viscoelasticity of materials and rapid cooling through high temperature functions for multiple times, so that a rebound angle is reduced. According to the rebound deformation inhibition method for the laser-assisted in-situ forming of the thermoplastic composite structuralcomponent provided by the invention, online adjustment of rebound deformation can be realized, so that automatic integrated forming is realized favorably; the rebound deformation inhibition method canbe applied to laying and forming of the thermoplastic composite structural components in different shapes, and is simple to operate and capable of remarkably improving the geometric accuracy of the structural components; and a laser heat source is accurate and controllable, so that the localized adjustment of rebound deformation can be realized.

Owner:DALIAN UNIV OF TECH

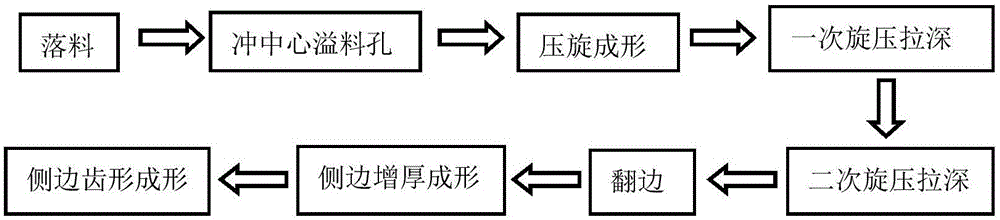

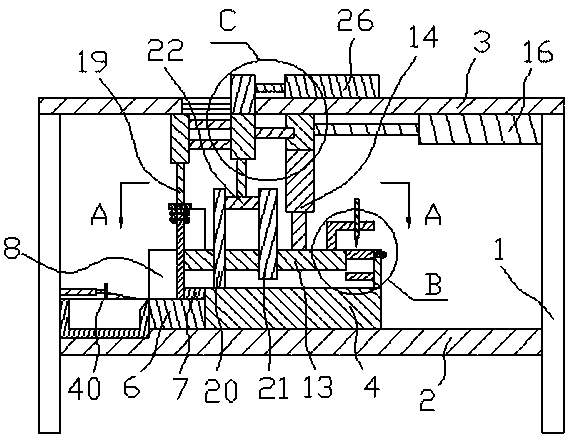

Pressing spiral formation process for belt pulley

ActiveCN106424433AOvercome disassembly difficultiesOvercome flexibilityShaping toolsGear wheelsReduction driveReducer

The invention discloses a pressing spiral formation process for a belt pulley, and belongs to the technical field of robot transmission part processing methods. The pressing spiral formation process for the belt pulley comprises the following steps: dropping a material, forming a central overflowing hole, performing pressing spiral formation, performing primary spiral pressing drawing, performing secondary spiral pressing drawing, performing side turning, performing lateral side thickening formation and performing lateral side tooth-shaped formation. Compared with the prior art, the pressing spiral formation process has the advantages that a novel process of 'pressing spiral'formation is invented, and a novel process for a robot joint speed reducer transmission part matching area formation is provided; the transmission freedom degree is increased, conventional transmission is achieved in a shaft pin transmission manner, a shaft cannot be separated from the belt pulley, and by adopting the pressing spiral formation process, the belt pulley can be separated and combined with a matching transmission part in transmission, and thus the robot can act relatively flexibly; and in a whole belt pulley plasticity formation process, the belt pulley of a robot joint speed reducer is formed in a spiral pressing manner completely, so that the production efficiency is effectively improved, and integral formation of the belt pulley transmission part can be achieved.

Owner:HEFEI UNIV OF TECH

Die-casting machine for plug-and-socket fasteners

The invention relates to a die-casting machine for plug-and-socket fasteners. The die-casting machine comprises a machine frame; a lower working plate and an upper working plate are arranged on the machine frame; the lower working plate is provided with a lower module, and side plates are arranged on the front side, the rear side and the right side of the lower module; a clamping opening forming block and a clamping opening forming cover plate are arranged on the inner side of the right side plate of the lower module; a pressing block lifting cylinder is arranged below the upper working plate;the lower portion of the pressing block lifting cylinder is connected with an upper mold pressing block matched with the lower module; the left end of the upper mold pressing block is arc, and buckleplate forming openings are formed in the lower portions of the front side and the rear side of the left end; a socket opening forming column is arranged on the upper mold pressing plate and located between the two buckle plate forming openings in a penetrating and inserting fit mode; the upper end of the socket opening forming column is connected with a socket opening forming lifting block; the upper portion of the socket opening forming lifting block is connected with a socket opening forming lifting cylinder which is matched with a mold unloading movable device on the upper working plate; and the upper working plate is further provided with a side mold device in arc fit with the left end of the upper mold pressing block. By means of the die-casting machine, lateral mold-loading can be achieved, and the fastener machining efficiency is improved significantly.

Owner:DONGGUAN UNIV OF TECH

A kind of preparation method of rhenium iridium combustor

ActiveCN106001554BIncrease the allowable operating temperatureImprove specific impulseShaping toolsMolten spray coatingRheniumIridium

The invention relates to a preparation method for a rhenium-iridium combustion chamber. The preparation method comprises the following steps: preparing a rhenium combustion chamber by adopting a powder metallurgy near-net shape forming technology; preparing iridium coatings at inner and outer surfaces of the rhenium combustion chamber by adopting an electric-arc deposition technology; preparing a platinum-rhodium ring by adopting a spinning technology and assembling the platinum-rhodium ring on the inner wall surface of the combustion chamber; and preparing a metal oxide high-radiation coating on the outer surface of the combustion chamber by adopting a plasma spraying technology. According to the preparation method, by virtue of an optimized design of process methods and process conditions at different stages of a preparation process, the prepared rhenium-iridium combustion chamber is applied to an engine, so that a use and working environment of the engine can be remarkably increased, specific impulse can be improved for the engine, and technical support is provided for prolonging flight life of an aircraft, increasing effective load of the aircraft or increasing range of the aircraft.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +1

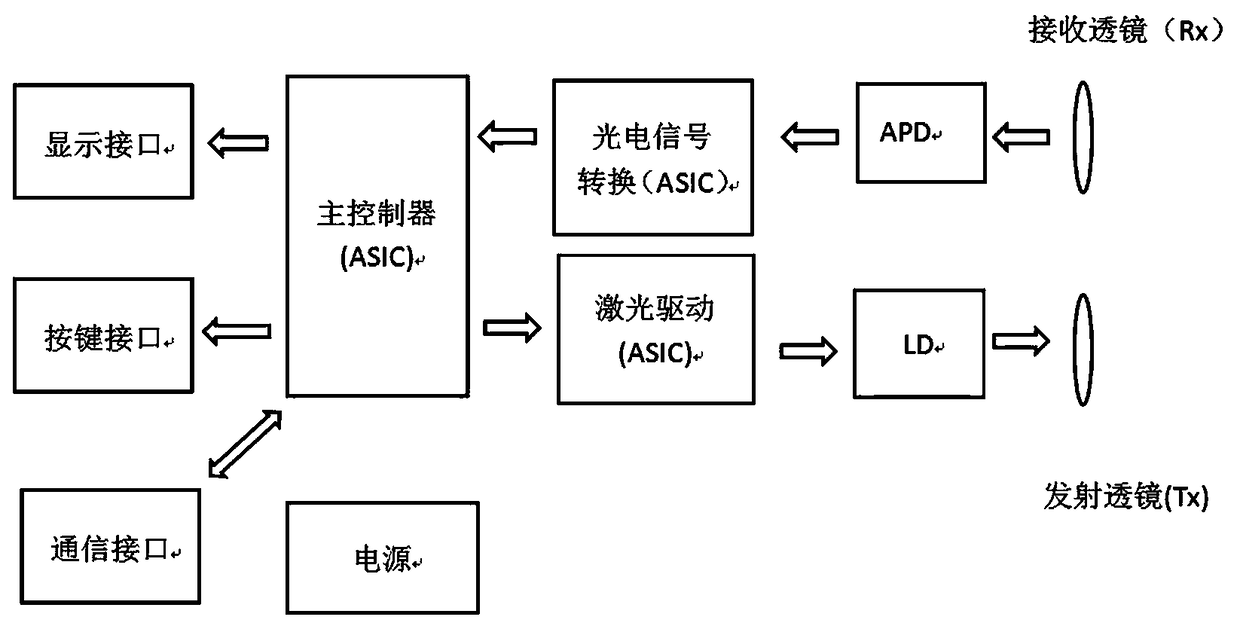

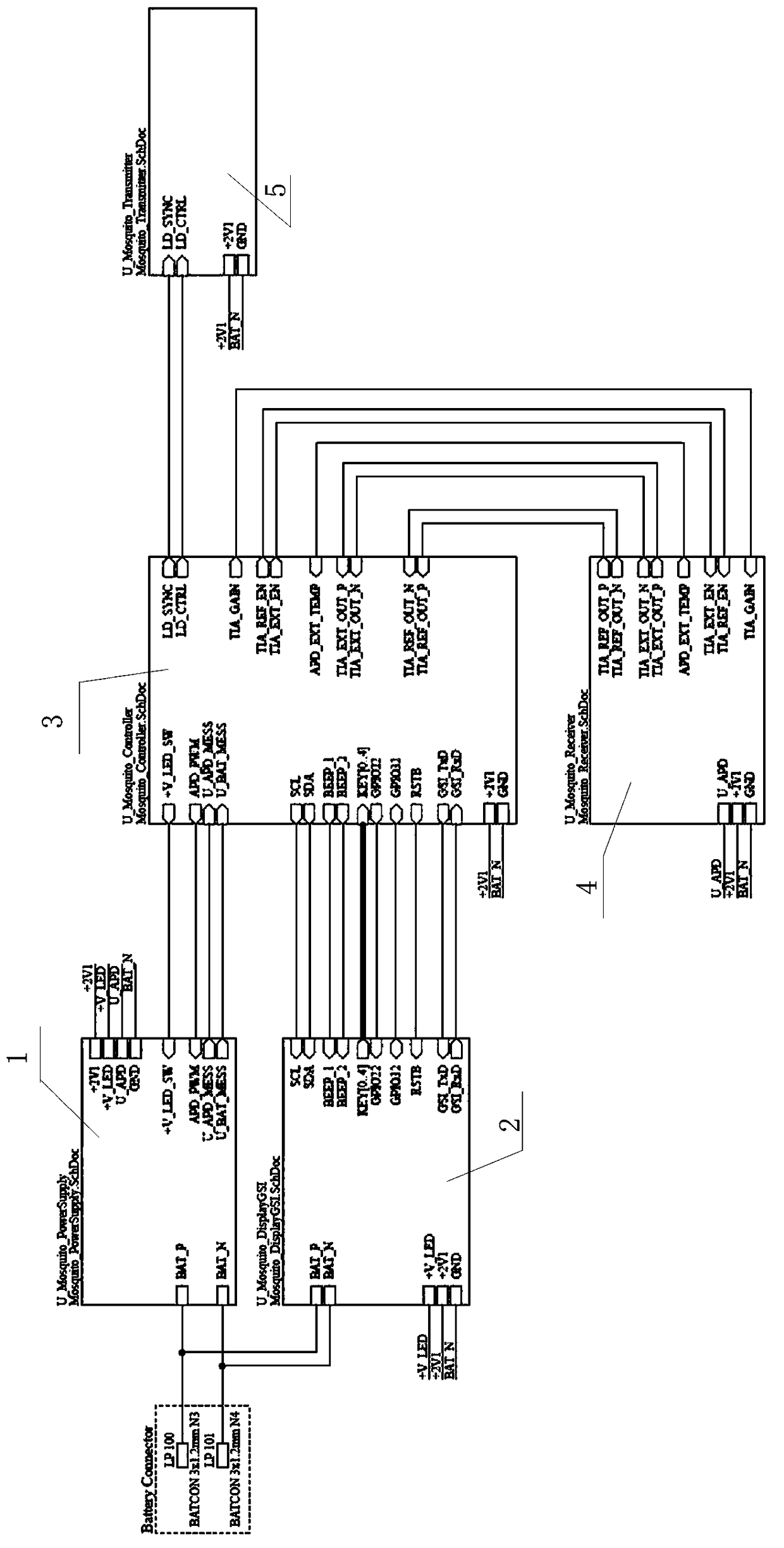

Special module for laser range finder

InactiveCN109254301AImprove accuracyReduce volumeElectromagnetic wave reradiationLaser rangingOptoelectronics

The invention discloses a special module for a laser range finder, and relates to a ranging tool. Existing laser ranging products are high in cost and large in size. The special module comprises a module interface used for external equipment; a laser receiving and photoelectric signal processing part which is composed of a photoelectric signal conversion ASIC chip and a peripheral circuit; a lasertransmitting part which is composed of a laser driver ASIC chip and a peripheral circuit; and a main control part including a main control chip and a peripheral circuit. According to the technical scheme of the invention, the laser receiving and photoelectric signal processing part, the laser transmitting part and the main control part replace a traditional general circuit through a special ASICchip, so that the size of the special module for the laser range finder is greatly reduced, integral forming of the module structure can be realized, the quality stability and reliability are improved, and laser ranging products can be conveniently miniaturized and are convenient to carry; and besides, the module cost is greatly reduced, and the use and popularization of the laser ranging productsare facilitated.

Owner:HANGZHOU GREAT STAR IND CO LTD

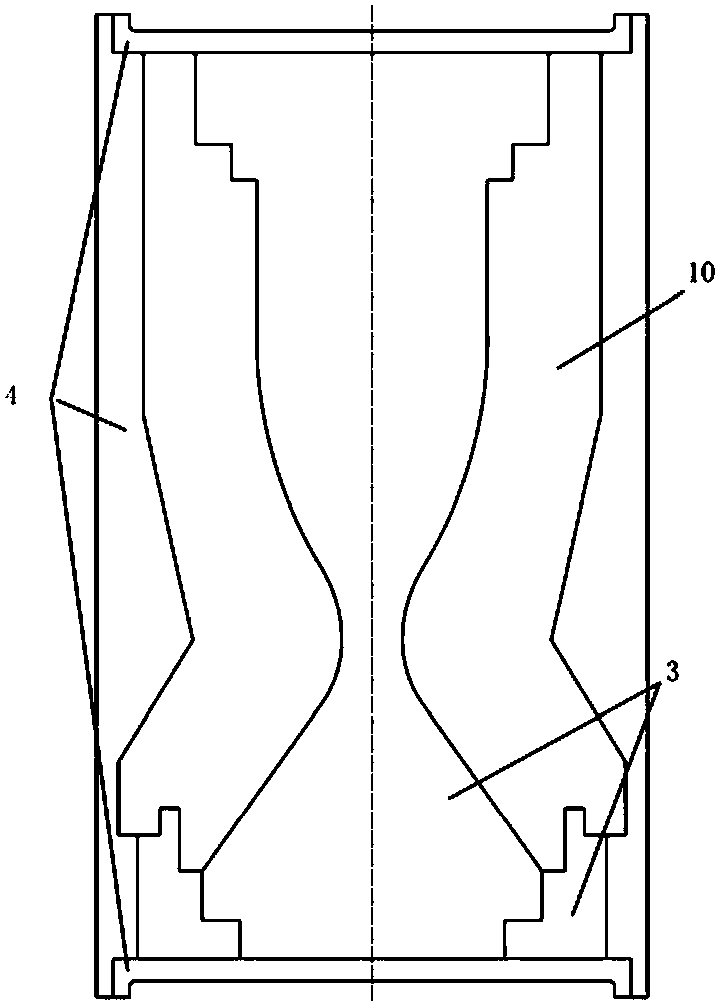

Circular arc core pulling mechanism for injection mould

A circular arc core pulling mechanism for an injection mould comprises a mould main body. An upper mould base and a lower mould base are arranged in the mould main body. A male mould body is arranged in the upper mould base, a female mould body is arranged in the lower mould base, and a mould cavity is formed between the male mould body and the female mould body. A first straight insert is arranged in the female mould body, and a first laterally-protruding sliding block is arranged on the lower mould base and connected with the first insert. A second bent insert is arranged in the male mould body, a second laterally-protruding sliding block is arranged on the upper mould base, a first connecting rod is arranged at the front end of the second sliding block, a second connecting rod is hinged to the upper end of the second insert, and the first connecting rod is hinged to the second connecting rod. The front end of the first insert is connected with the lower end of the second insert. According to the circular arc core pulling mechanism, core pulling is conducted on the first insert and the second insert, and a secondary connecting rod core pulling structure is composed through the first connecting rod and the second connecting rod, so that interference of the second bent insert with an injection finished product and an upper mould core is eliminated when core pulling is conducted on the second bent insert, smooth demoulding of the second insert is guaranteed, and accordingly a large-angle bent pipe is formed integrally.

Owner:NINGBO HENGHE PRECISION INDUSTRY CO LTD

Training fragile bullet and manufacturing method thereof

InactiveCN107576227ARealize one-piece moldingReduce manufacturing costTraining ammunitionPlastic materialsMetal powder

The invention discloses a training fragile bullet. The training fragile bullet includes a metallic powder material, a binding material, and a composite plastic material. The training fragile bullet includes, by weight, 10-20 parts of the metallic powder material, 37-45 parts of the binding material, and 35-53 parts of the composite plastic material. The invention also discloses a method for manufacturing the training fragile bullet. The method includes the following steps: A, manufacturing a bullet die; B, injecting the metallic powder material, the binding material, and the composite plasticmaterial to the bullet die at the temperature of 140-240 DEG C, allowing the materials to become a molten material, wherein the parts by weight of the materials are 10-20 parts of the metallic powdermaterial, 37-45 parts of the binding material, and 35-53 parts of the composite plastic material; C, continuously applying pressure to the bullet die at the pressure of 200 pa-300 pa, and compacting the molten material; D, cooling the bullet die; and E, performing demoulding on the bullet die.

Owner:黄建军 +1

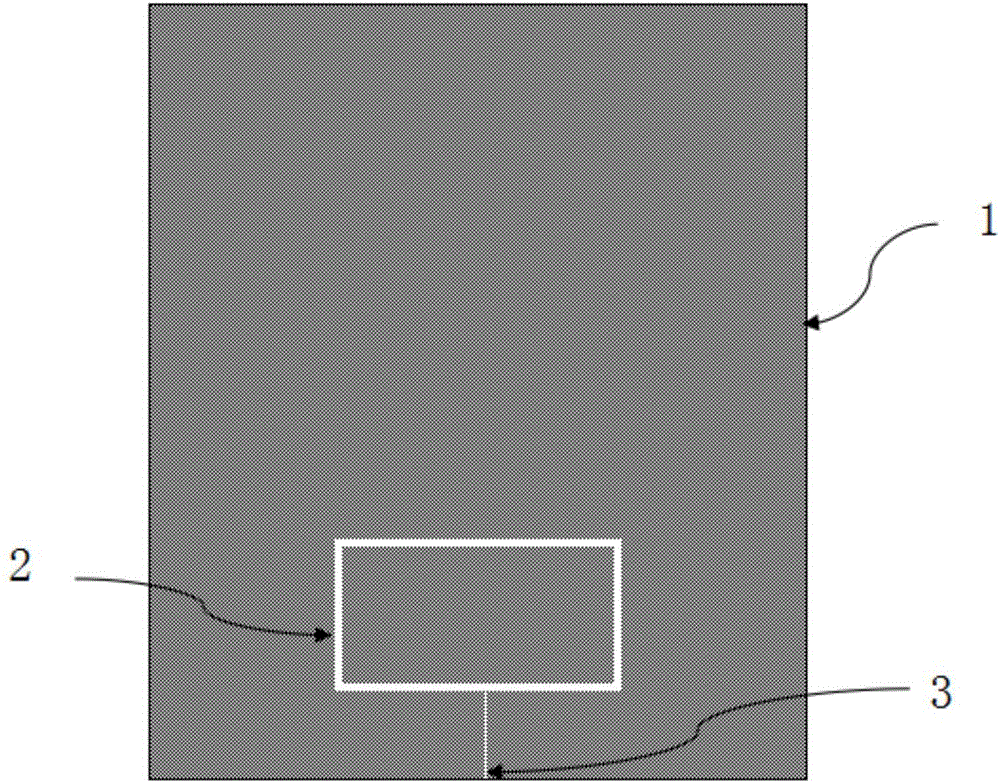

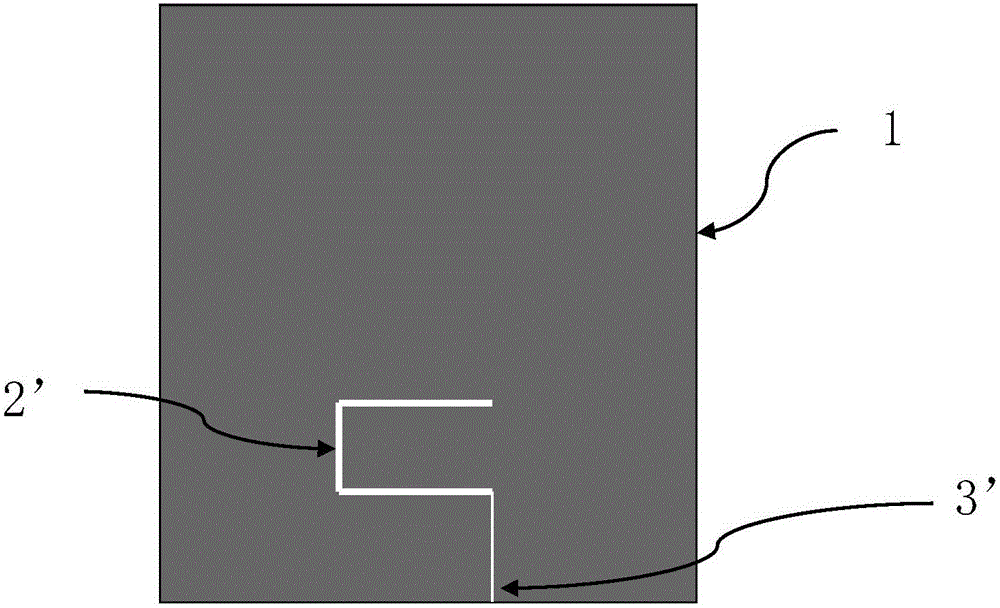

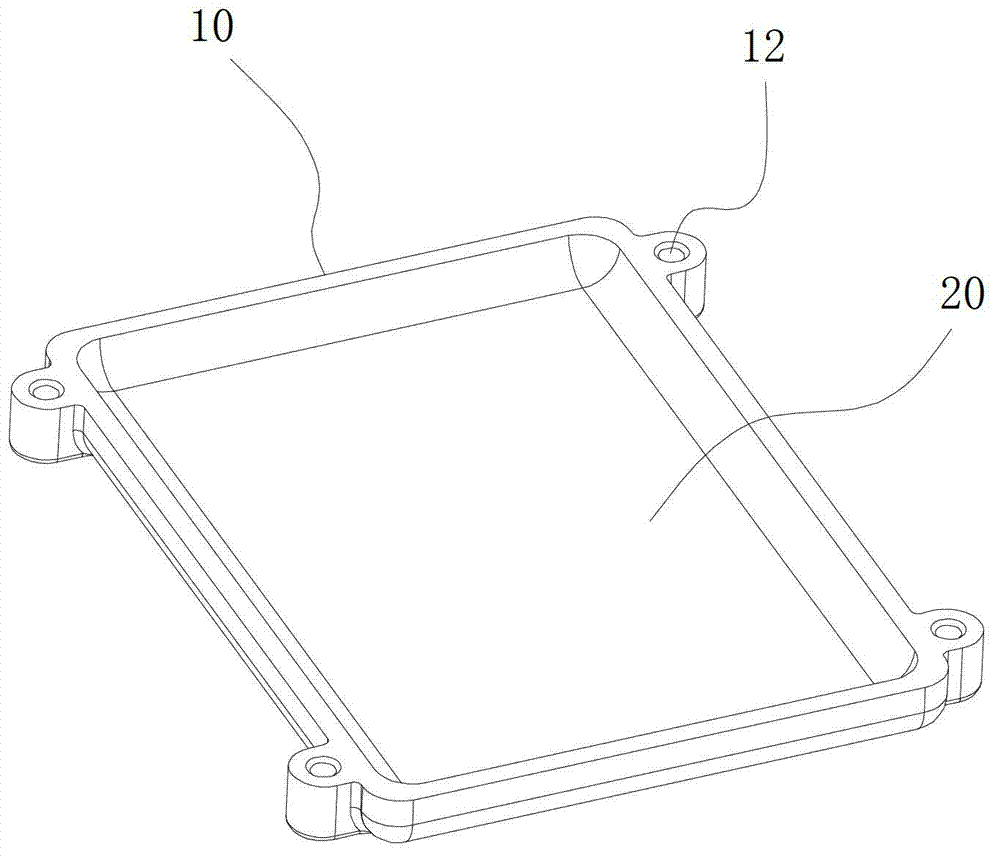

Near field communication antenna device adopting metal shell terminal equipment

PendingCN106848537ASimple and practical structureReduce thickness and assembly difficultyAntenna supports/mountingsAntenna equipments with additional functionsNear field communicationMetal

The invention discloses a near field communication antenna device adopting metal shell terminal equipment. The device comprises a metal shell and magnetic material arranged at the lower side of the metal shell. A seam belt is formed in the metal shell, and comprises two parts, one part is a random shape seam belt which is either closed or non-closed arranged in the metal shell, the other part is a long strip seam belt connected with the random shape seam belt and the metal shell edges. The seam belts are filled with dielectric material. The metal shell is connected with a matching circuit as a radio frequency radiation body. The edges of the metal shell are grounded. According to the near field communication antenna device adopting metal shell terminal equipment, the metal shell antenna function is achieved through a seam belt in the metal shell surface, the dielectric material in the seam belt achieves the integral forming of the metal shell and avoids the installation and configuration difficulties brought by the additional arrangement of antenna plug-in parts, the shielding function of the metal shell to the antenna is completely eliminated, and the device has a good performance.

Owner:ZHONGTIANXUN COMM TECH

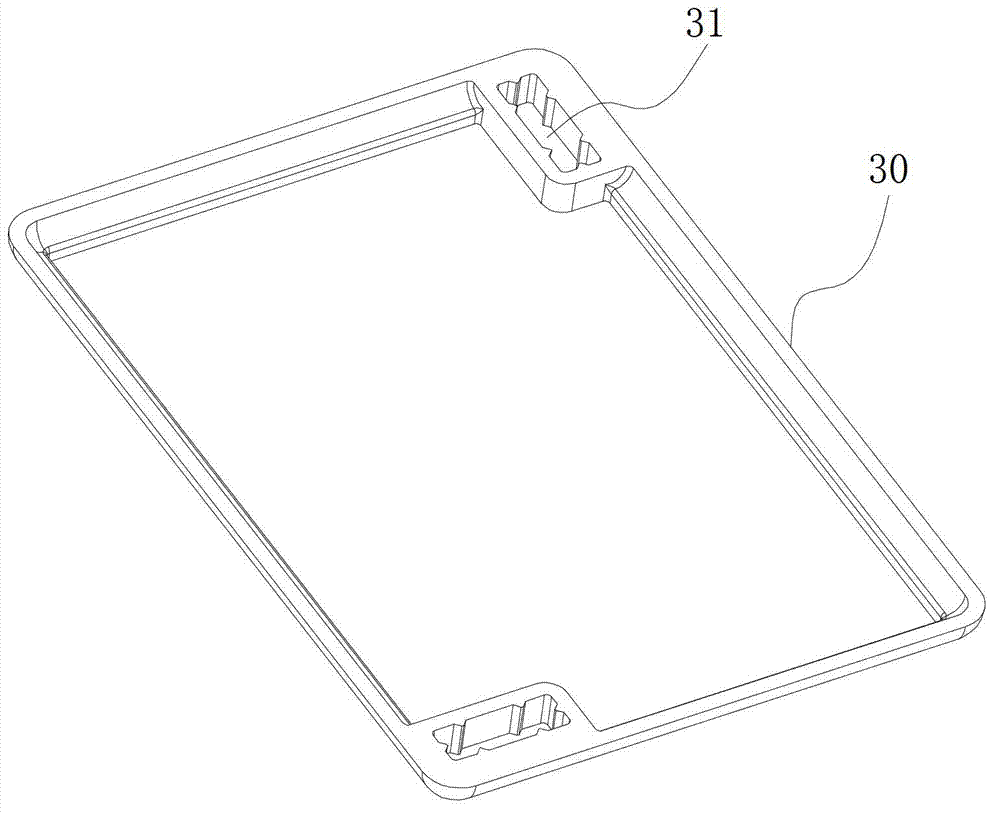

Plastic casing structure provided with protective circuit, as well as forming die and manufacture method thereof

InactiveCN103249271AShorten molding processing timeImprove yieldElectrical apparatus casings/cabinets/drawersInsulation layerEngineering

The invention discloses a plastic casing structure provided with a protective circuit, as well as a forming die and a manufacture method thereof. The plastic casing structure provided with the protective circuit comprises a plastic casing body, wherein a thin film layer is arranged on the inner side of the plastic casing body, and comprises an adhesive layer, a base layer, a winding layer and an insulation layer which are arranged sequentially; and the adhesive layer is connected with the plastic casing body. According to the invention, the thin film layer provided with a protective conducting wire is arranged on the inner side of the plastic casing body, so that the production and processing procedure can be simplified, and the manufacturing cost can be reduced. The forming die disclosed by the invention is provided with a positioning mechanism on a punch, quick positioning of the thin film layer is achieved in a locating pin manner, so that the forming processing time of the plastic casing body can be saved. In order to facilitate the quick positioning of the thin film layer, when placed to the punch, the thin film layer is prepressed in a shape matched with the punch through a prefabricate die, so that the thin film layer is no longer integrally formed with the plastic in the forming die; and further, the yield of plastic products is improved, and defective product loss in a production process is reduced.

Owner:SHENZHEN XINGUODU TECH

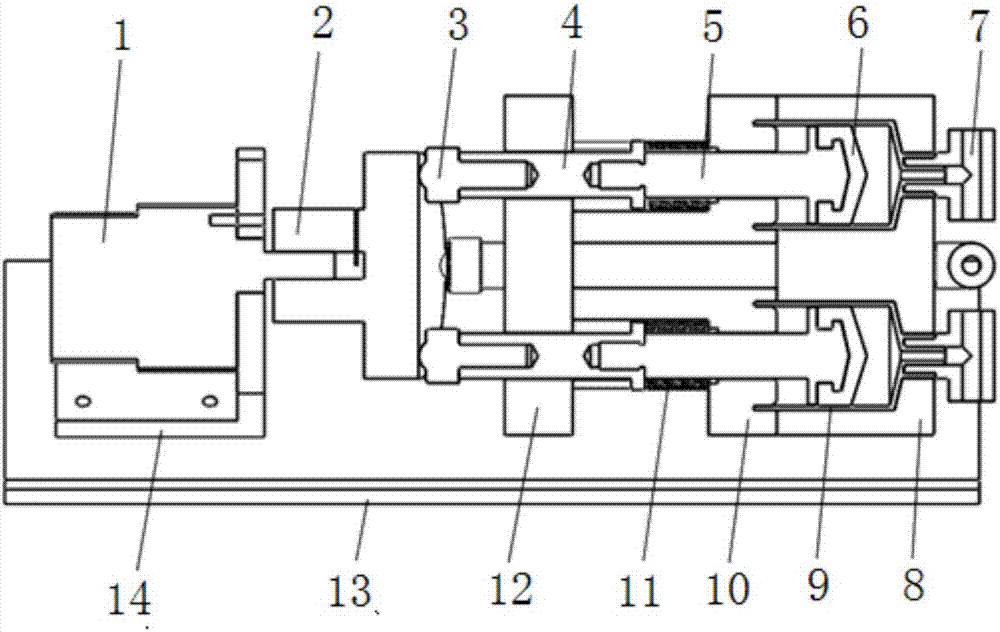

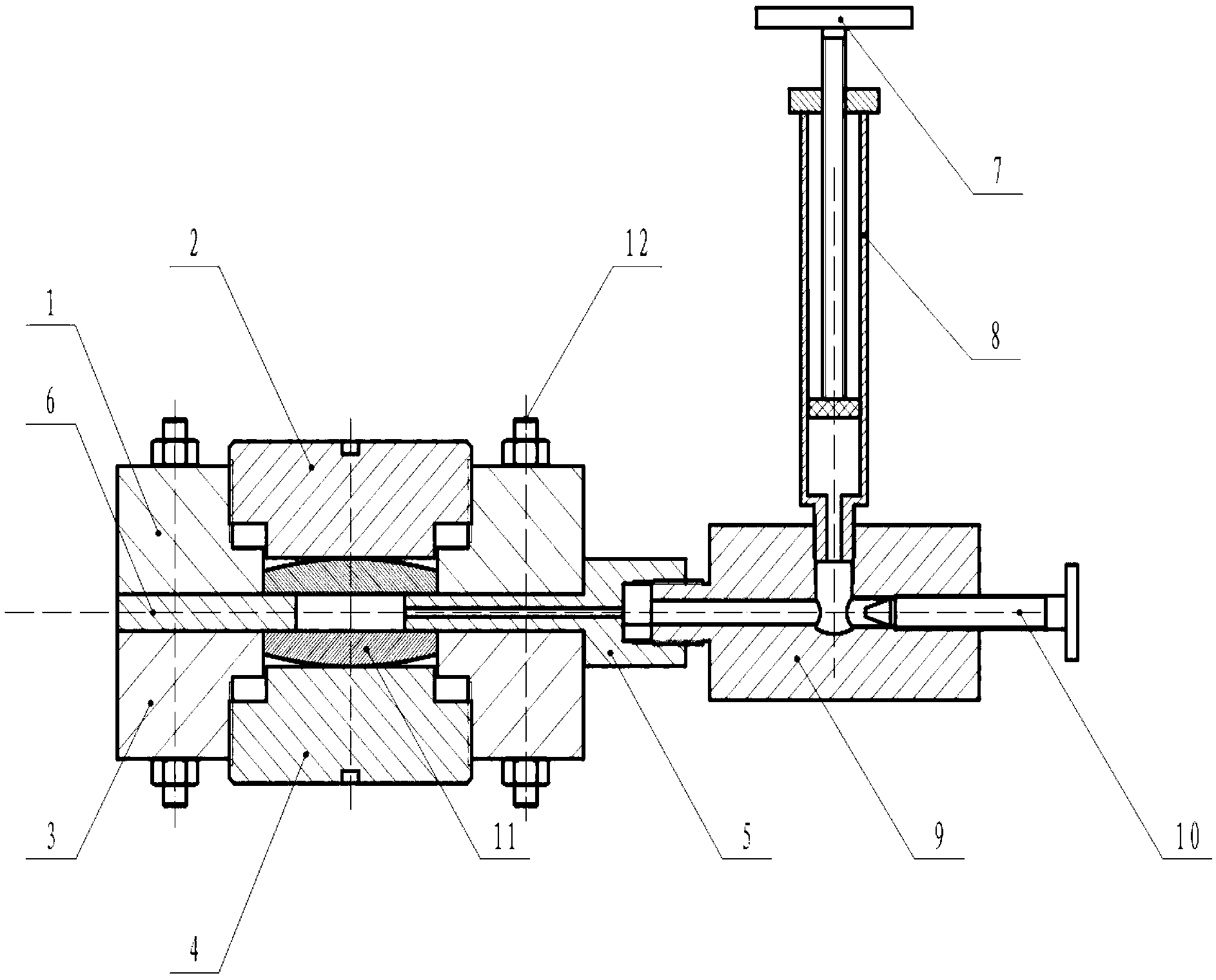

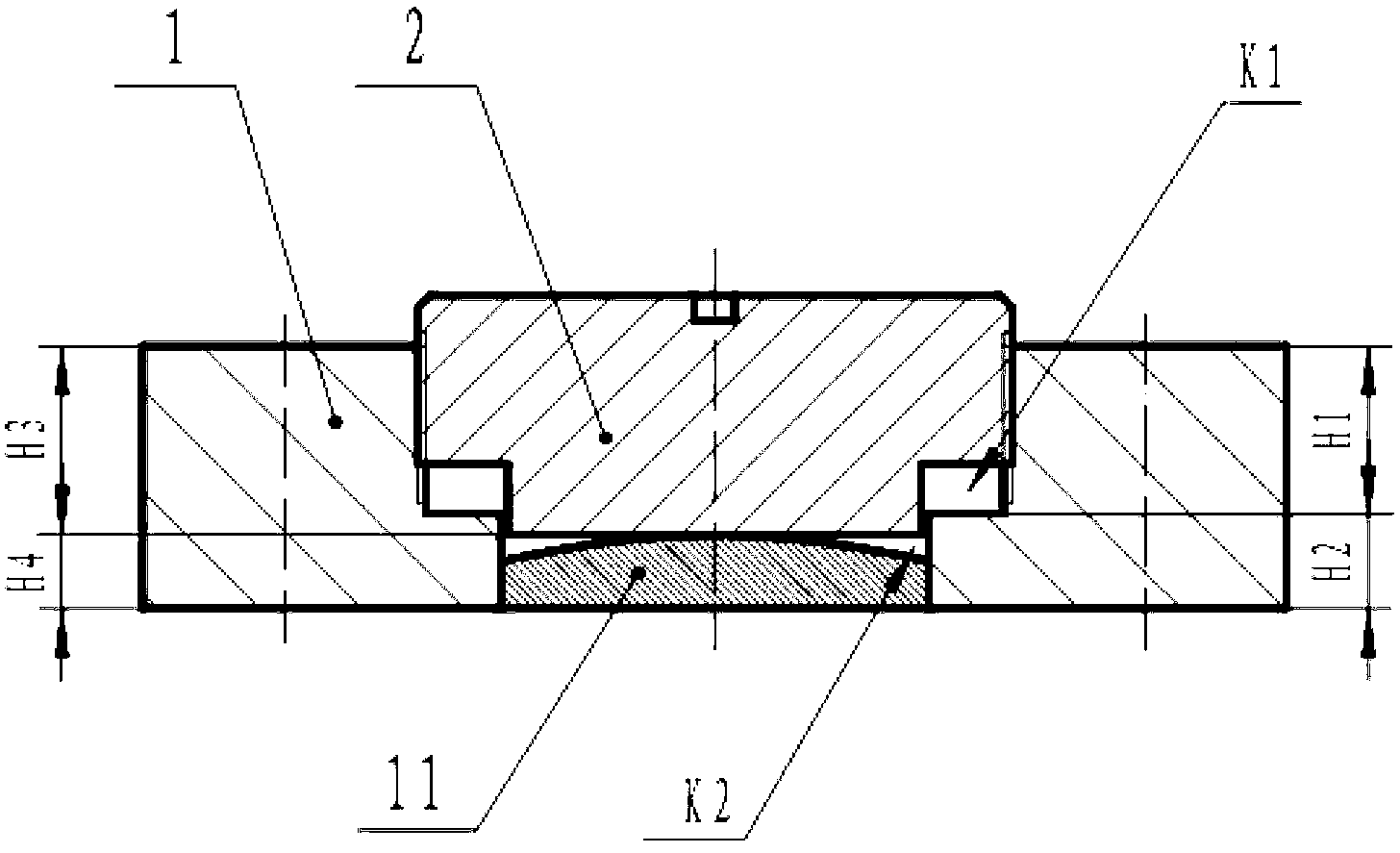

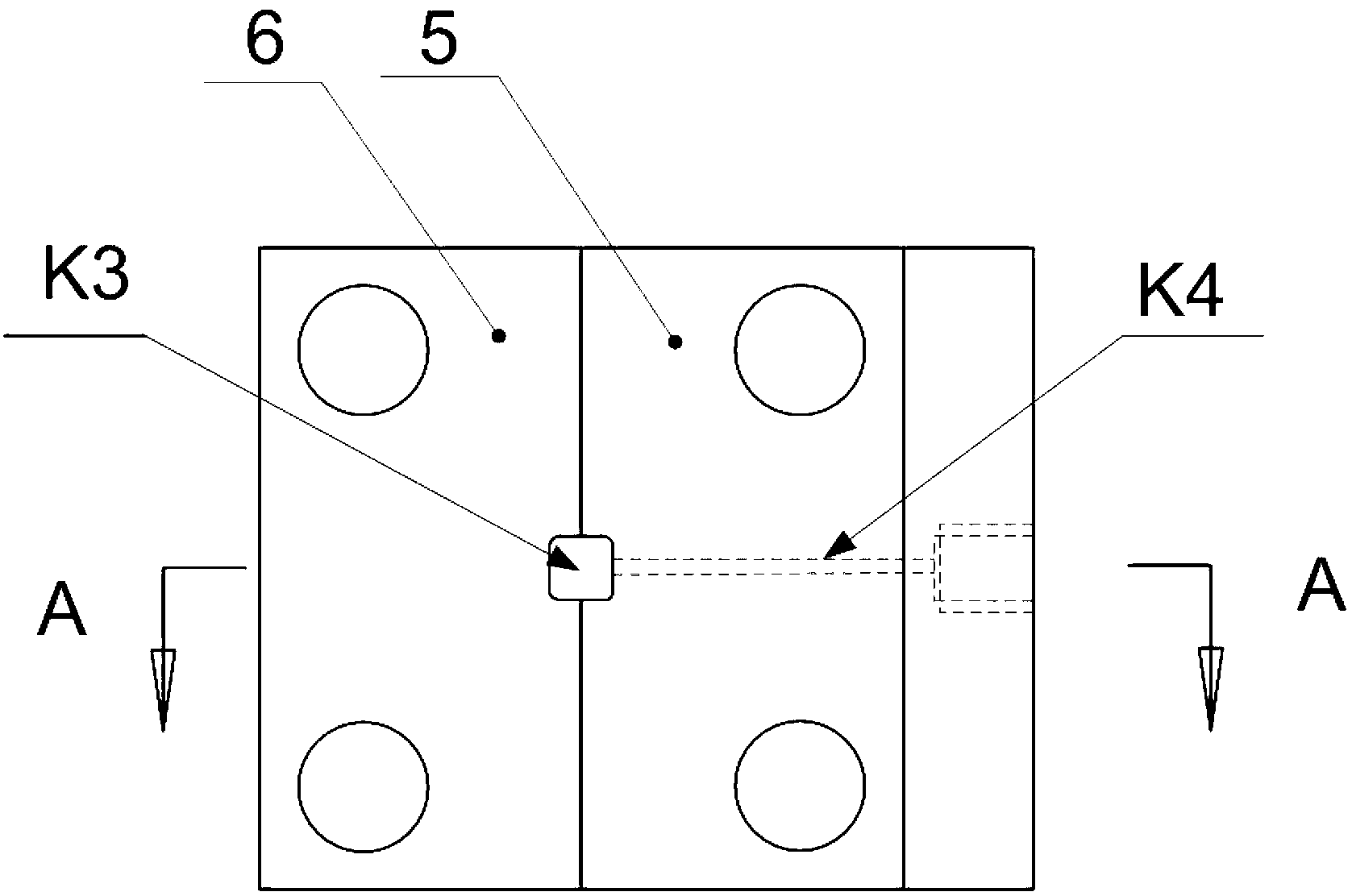

Special forging and pressing mold for cylinder barrel in hydraulic support of coal mine and forging and pressing method

ActiveCN110125302ARealize one-piece moldingLess consumablesForging/hammering/pressing machinesUltimate tensile strengthCoal

The invention relates to a special forging and pressing mold for a cylinder barrel in a hydraulic support of a coal mine and a forging and pressing method. The mold comprises a first forging mold, a second forging mold and a final forging mold. The first forging mold comprises a first forging terrace die and a first forging concave die; the first forging terrace die comprises an upper die fixing plate I, the bottom of the upper die fixing plate I is connected to a punch through a punch supporting seat, and a punch I is mounted in the punch supporting seat and a pressure head in a penetrating manner; the first forging concave die comprises a lower die fixing plate I, an ejecting head is arranged in the middle position of the top of the lower die fixing plate I, and the bottom of the ejecting head I is connected to an ejector rod I mounted in the middle position of the lower die fixing plate I in a penetrating manner. The special forging and pressing mold provided by the invention has the advantages of being reasonable in structural design, low in cost, high in integral density, good in metallographic structure, small in margin, raw material-saving and high in strength and capable ofachieving waste heat tempering and integrally forming an outer cylinder barrel.

Owner:邓州市良机锻压设备制造有限公司

Post-processing mechanism and production system for instant laminaria japonica noodles

ActiveCN110495481AOptimize production flowAchieve continuous completionDrying gas arrangementsDrying machines with progressive movementsLaminaria japonicaAssembly line

The present invention discloses a post-processing mechanism for instant laminaria japonica noodles. The post-processing mechanism for the noodles comprises a noodle cooking machine, a noodle cutting machine, a noodle hanging and conveying mechanism and a drying device. The noodle cooking machine is used for cooking strip-cut raw noodles, the noodle cutting machine is used for cutting the noodles after cooking, the noodle hanging and conveying mechanism is used for conveying the noodles after cutting, and the drying device is used for drying the conveyed noodles. The present invention also discloses a production method. The instant laminaria japonica noodles are high in nutritional value and good in mouthfeel. The post-processing mechanism fully mixes materials, is strong in production assembly line, good in drying efficiency and high in heat utilization rate.

Owner:FUJIAN JIEFENG CHOICE RARE SEA FOOD DEV

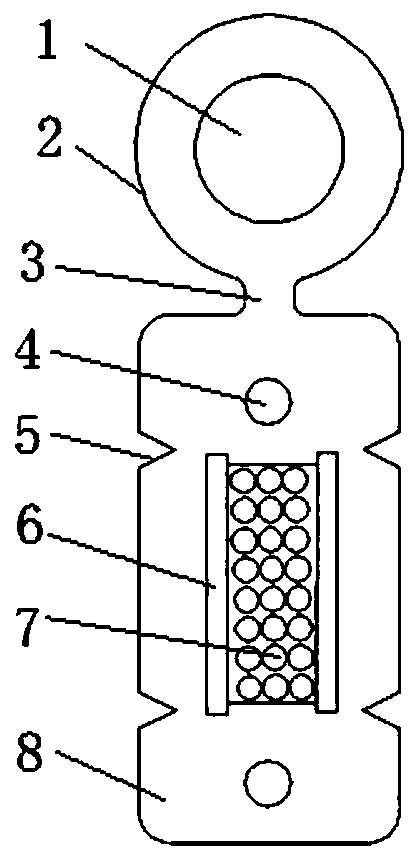

Continuous pressing device for composite materials

The invention discloses a continuous pressing device for composite materials, and particularly relates to a continuous pressing device for wood-plastic composite door production. The continuous pressing device for the composite materials comprises a support part, a steel belt and driving roller system and a pressure applying system. Pressure in the vertical direction provided by pressure oil cylinders is converted into direct continuous pressure of upper and lower steel belts through pressure transfer roller columns rolling in situ, and pressure of the steel belts is controlled through the relative distance between a roller barrel support and a stand column. The continuous pressing device is used for producing wood-plastic plates, is high in efficiency and low in energy consumption, and can reduce the cost of composite material products, reduce the labor intensity and achieve integral forming of a local structure.

Owner:珠海市华衍木业有限公司

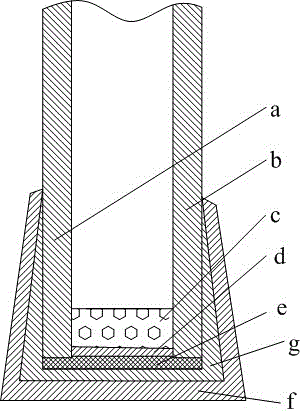

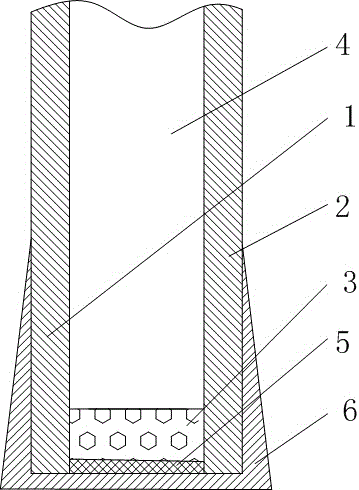

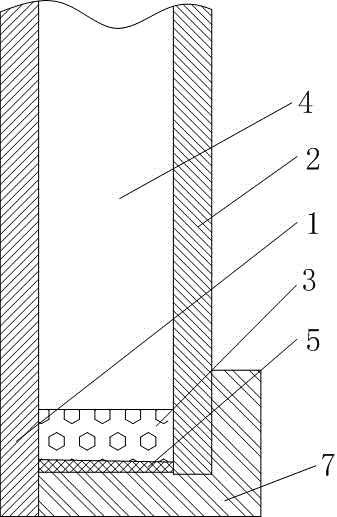

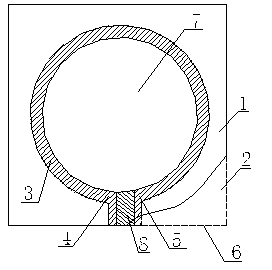

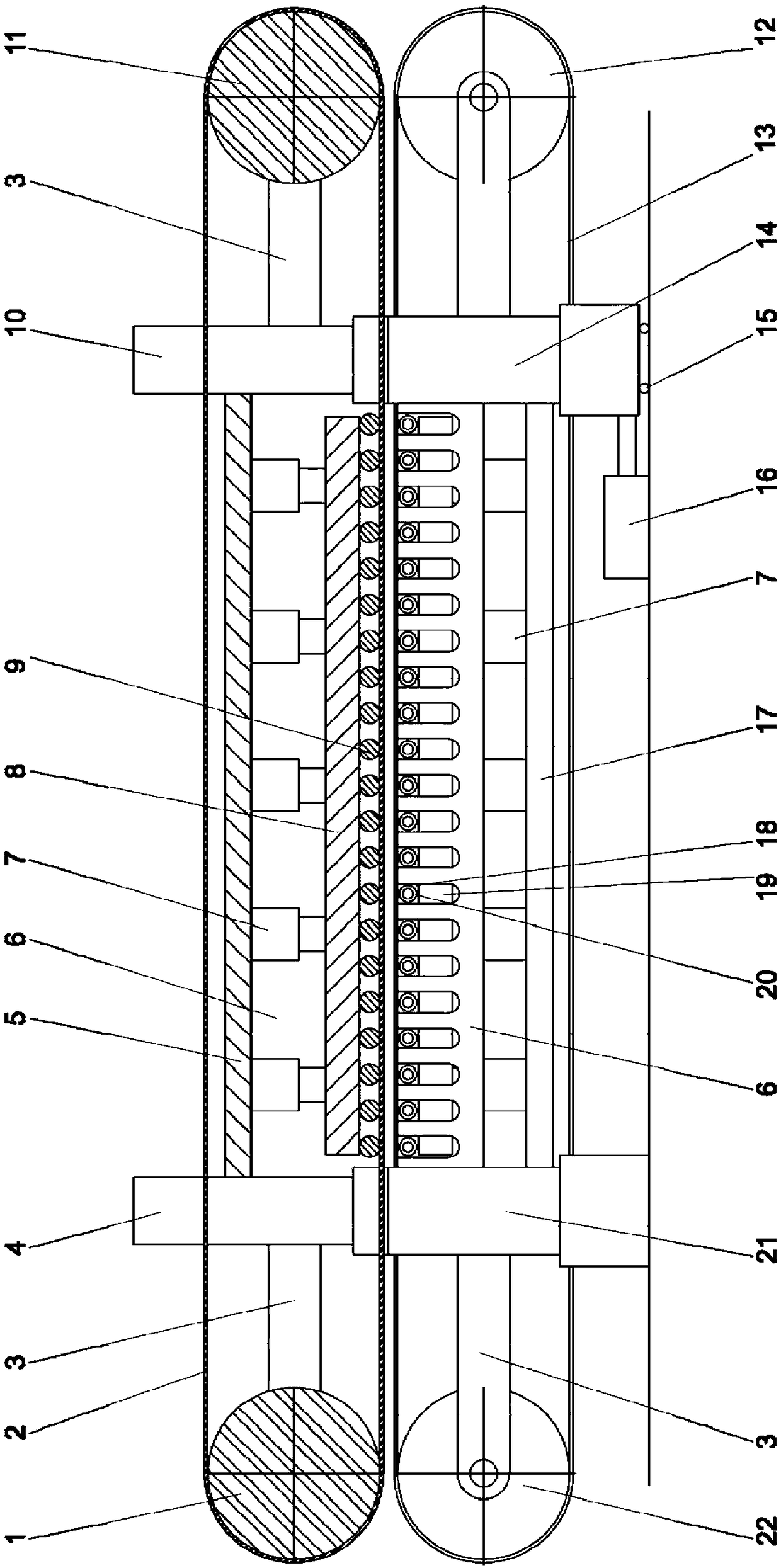

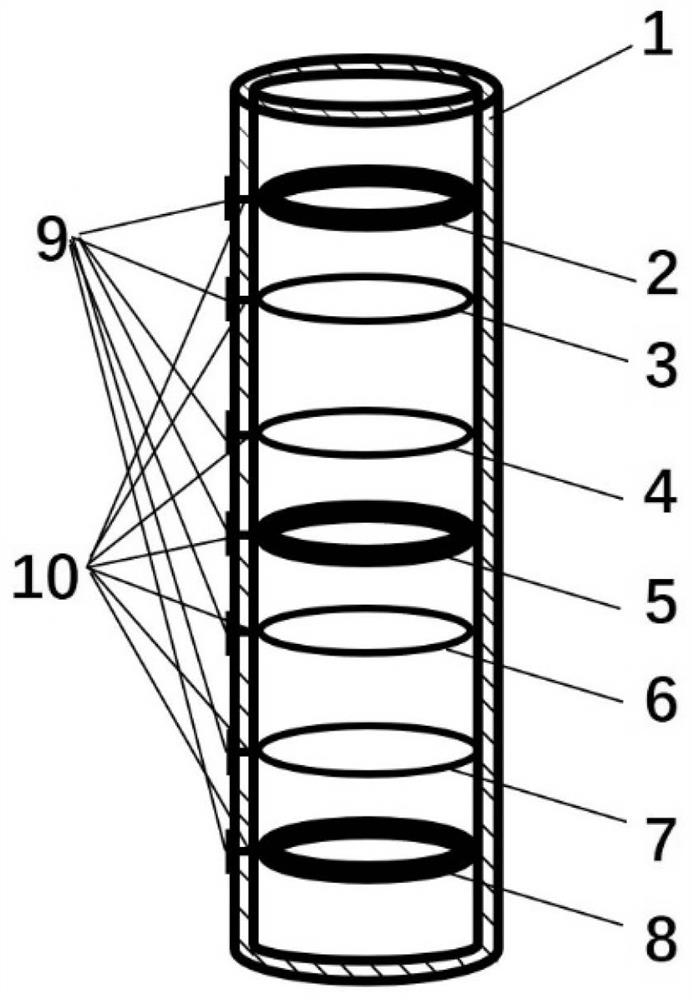

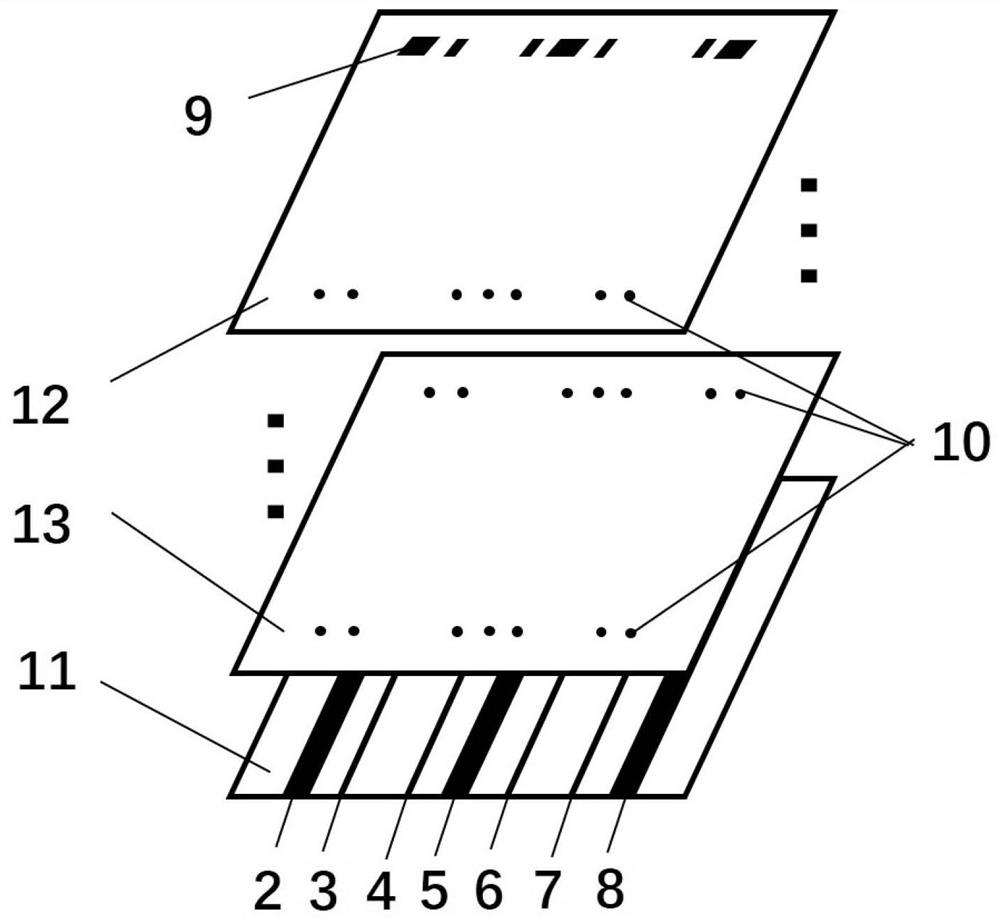

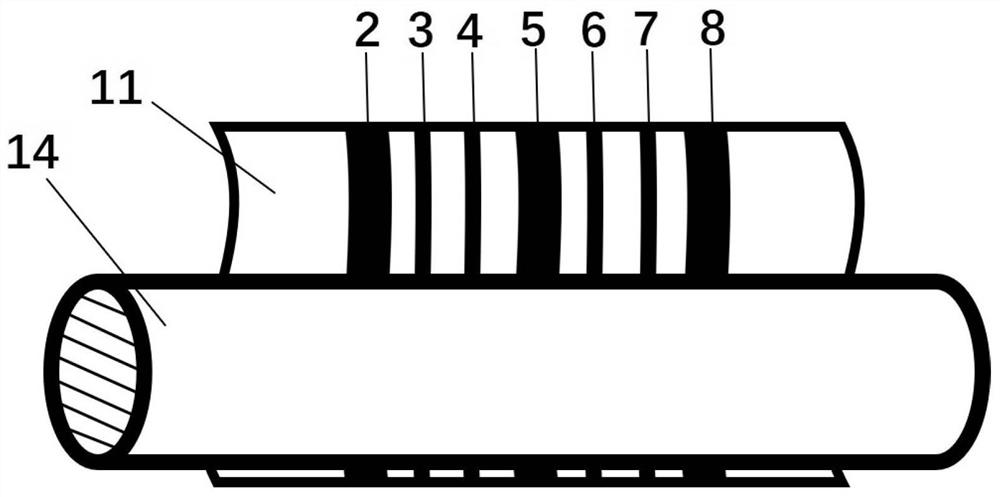

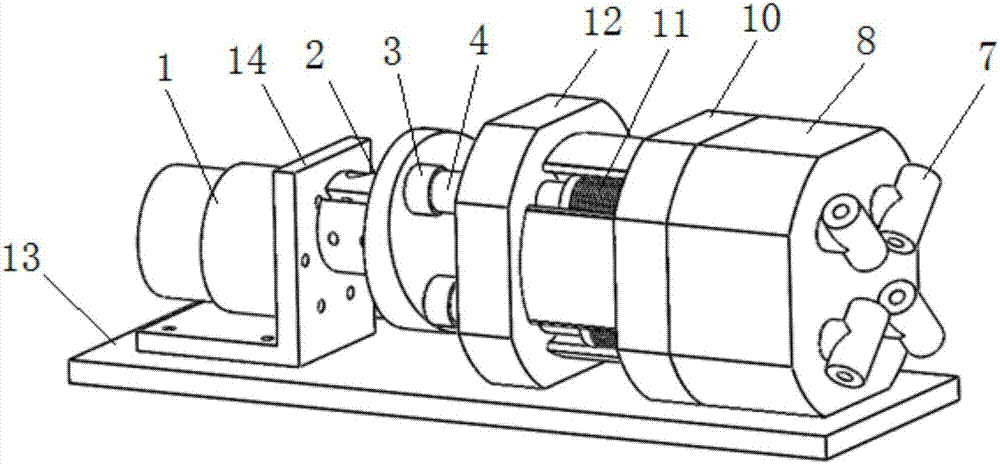

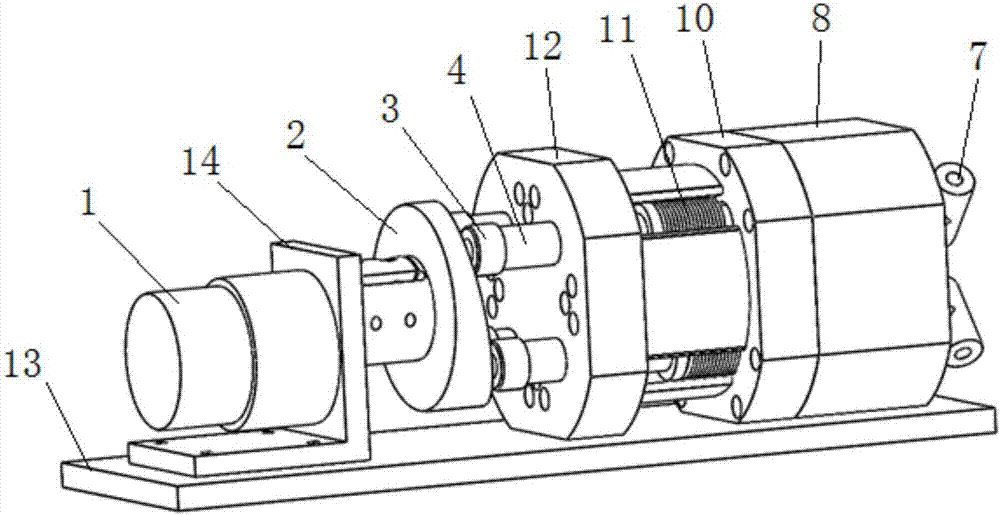

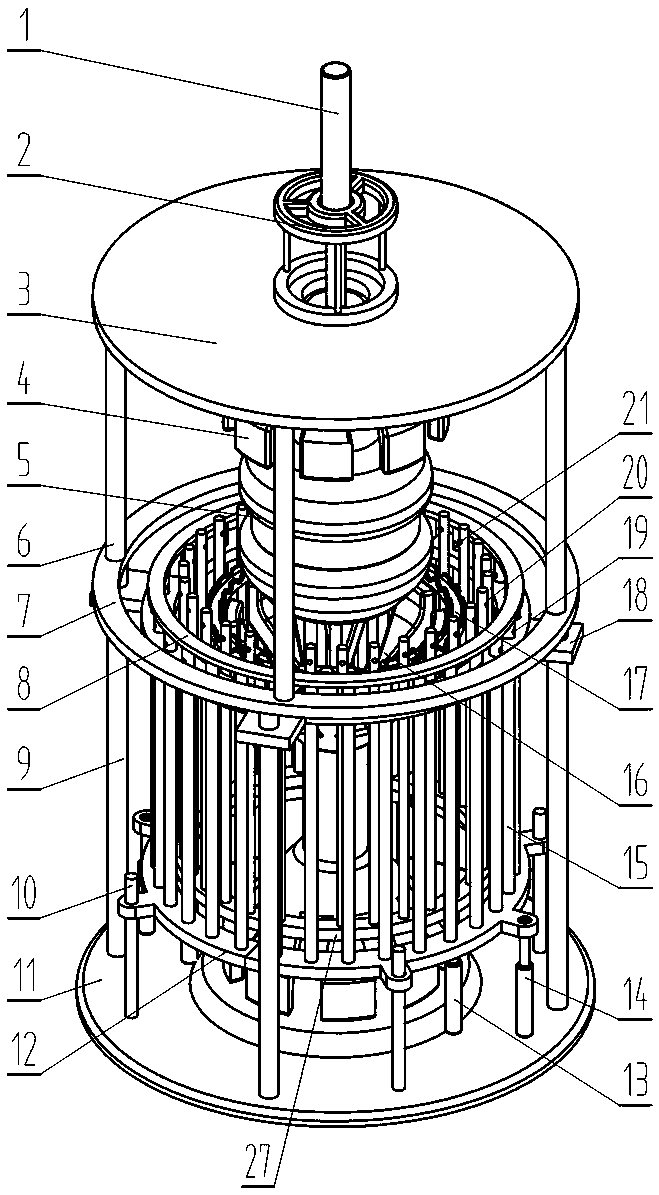

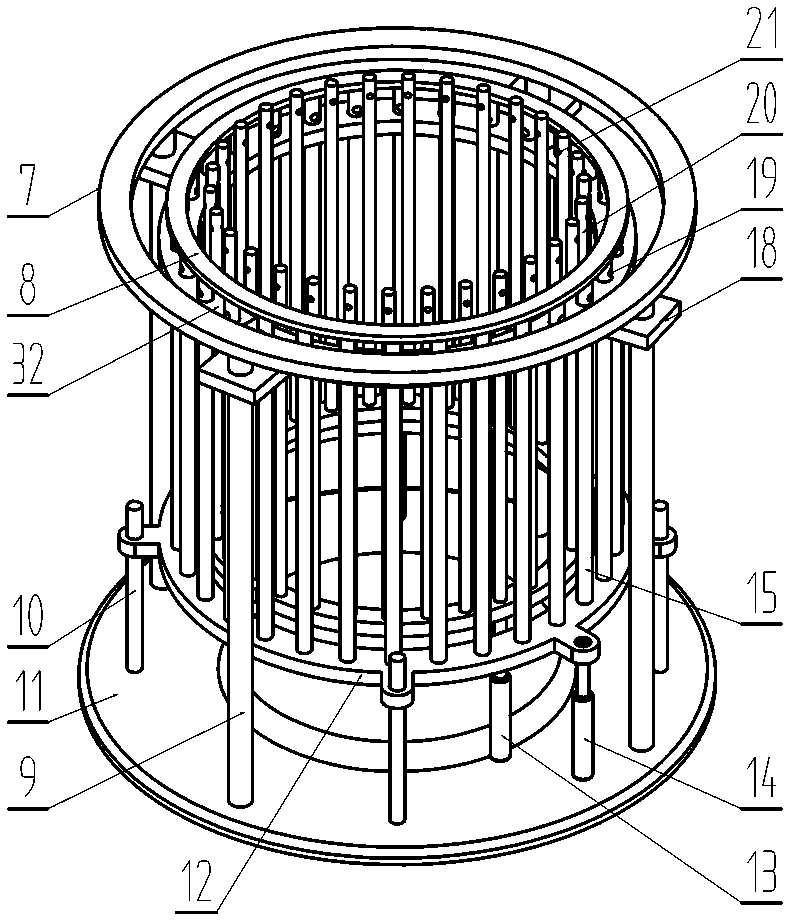

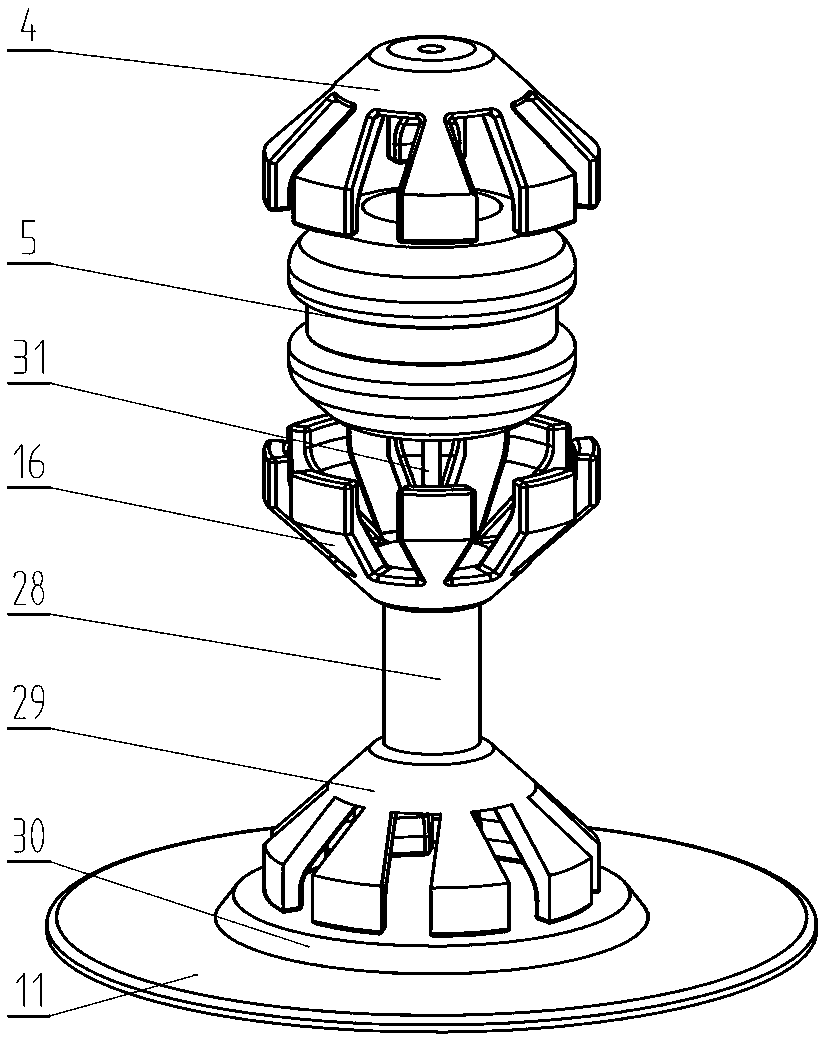

Preparation method of seven-electrode conductivity sensor

ActiveCN113495191ARealize one-piece moldingOvercoming splicingPrecision positioning equipmentSoldering apparatusMetal electrodesElectronic conductivity

The invention relates to a preparation method of a seven-electrode conductivity sensor, in particular to the seven-electrode conductivity sensor and the preparation method of the seven-electrode conductivity sensor. The seven-electrode conductivity sensor comprises a circular-tube-shaped conductivity cell made of a ceramic material, seven metal circular ring inner electrodes which are sequentially distributed on the inner wall of the ceramic circular-tube-shaped conductance cell in parallel, seven metal outer electrodes which are located on the outer wall of the ceramic circular-tube-shaped conductance cell, and through hole metal electrodes which are used for connecting the metal circular ring inner electrodes and the metal outer electrodes. The ceramic material is an HTCC ceramic material or an LTCC ceramic material which can be co-fired with metal.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

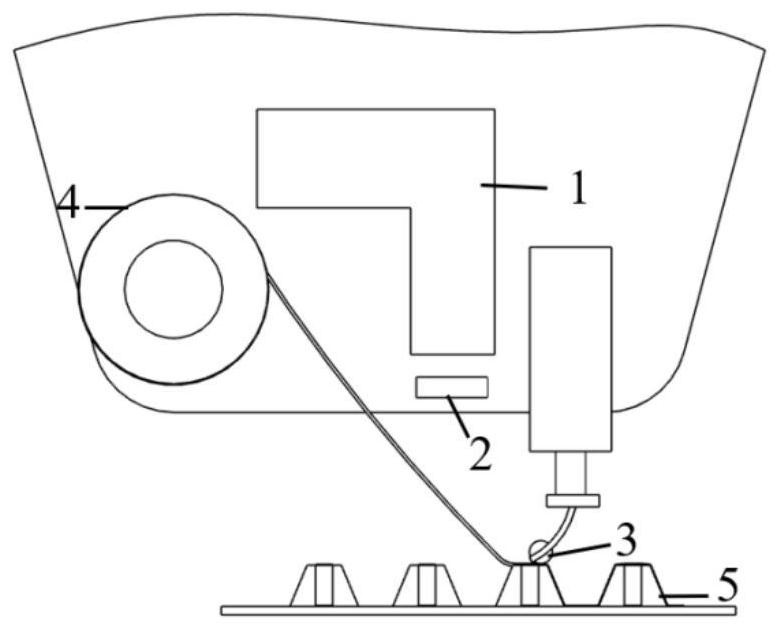

Flux adjustable type liquid-gas universal mute pump

ActiveCN107191366AReduce noiseImprove mute effectPositive displacement pump componentsPumpsEngineeringCam

The invention relates to the field of pumps, in particular to a flux adjustable type liquid-gas universal mute pump. The flux adjustable type liquid-gas universal mute pump comprises a motor, a cam, cam push rods, a cam push rod supporting part, an injector fixing part, elastic parts, a one-way valve, a bottom plate and injectors. The motor, the cam push rod supporting part and the injector fixing part are sequentially arranged on the bottom plate, an output shaft of the motor is connected with the cam, the multiple cam push rods making contact with the cam are arranged on the cam push rod supporting part in a slidable manner, the multiple injectors are arranged on the injector fixing part, the multiple injectors are connected with the multiple cam push rods, the elastic parts are arranged between the cam push rods and the injectors, and the one-way valves are arranged at the positions of end openings of all the injectors. Noise is low during operation, a mute effect better than that of other pumps can be achieved within a certain flux range, and the pump can be well integrated in equipment with the high requirement on mute indicators.

Owner:SHENYANG INST OF AUTOMATION - CHINESE ACAD OF SCI

Forming mold and forming method of micro composite plastic part

The invention discloses a forming mold and a forming method of a micro composite plastic part, belonging to the field of injection molds and forming. The mold comprises an upper mold, a middle mold, a lower mold and an injection molding system, wherein a forming cavity is formed by the upper mold, the middle mold and the lower mold; a rigid member is embedded into the forming cavity and then a flexible member is formed in an injection molding mode, so as to obtain the micro composite plastic part with the rigid member and the flexible member; a through hole formed by a threaded hole and a mounting hole is formed in each of the centers of upper and lower mold plates of the upper and lower molds; a thread adjusting block is arranged into the threaded hole; the rigid member is embedded into the mounting hole; the middle mold part is formed by two middle mold plates the centers of which are provided with symmetric forming cavity through holes; one of the middle mold plates is provided with a flowing channel hole and is connected with the injection molding system; the upper mold, the middle mold and the lower mold are connected to form a whole body through fixing bolts; the injection molding system comprises an injection molding piston with scales, a transparent cylinder with scales, an injection molding flowing channel cylinder and a sealing valve. The forming mold is compact in structure, the integral forming of the rigid member and the flexible member is realized, materials are precisely measured and fed, and one multipurpose mold is achieved.

Owner:BEIJING UNIV OF CHEM TECH

Knitting machine used for integrated formation of cylindrical braided fabric

PendingCN109853111ARealize one-piece moldingAffect aestheticsCircular loomsEngineeringMechanical engineering

The invention discloses a knitting machine used for integrated formation of a cylindrical braided fabric, and belongs to the field of knitting machines. The knitting machine is used for cylindrical knitting, and comprises a base, an internal thread feeding rod and an external thread feeding rod which move up and down through a jacking cylinder and a guide rod are installed on the base, rails are installed in the internal and external thread feeding rods, tatting devices are arranged on the rails, a middle inner die and a lower outer die are installed on the central axes of areas in the rails,and the middle inner die cooperates with the lower outer die to complete knitting of the three-dimensional cylindrical braided fabric. According to the technical scheme, through linkage of the dies and a flat knitting machine, three-dimensional knitting of the cylindrical braided fabric is completed under the cooperation of the dies and the flat knitting machine.

Owner:山东绿城家居有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com