Special forging and pressing mold for cylinder barrel in hydraulic support of coal mine and forging and pressing method

A coal mine hydraulic, outer cylinder technology, applied in forging/pressing/hammering machinery, manufacturing tools, forging/pressing/hammer devices, etc., can solve the problems of inconvenient heat treatment, insufficient strength, short service life, etc., and achieve structural design Reasonable, save heating cost, reduce the effect of processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

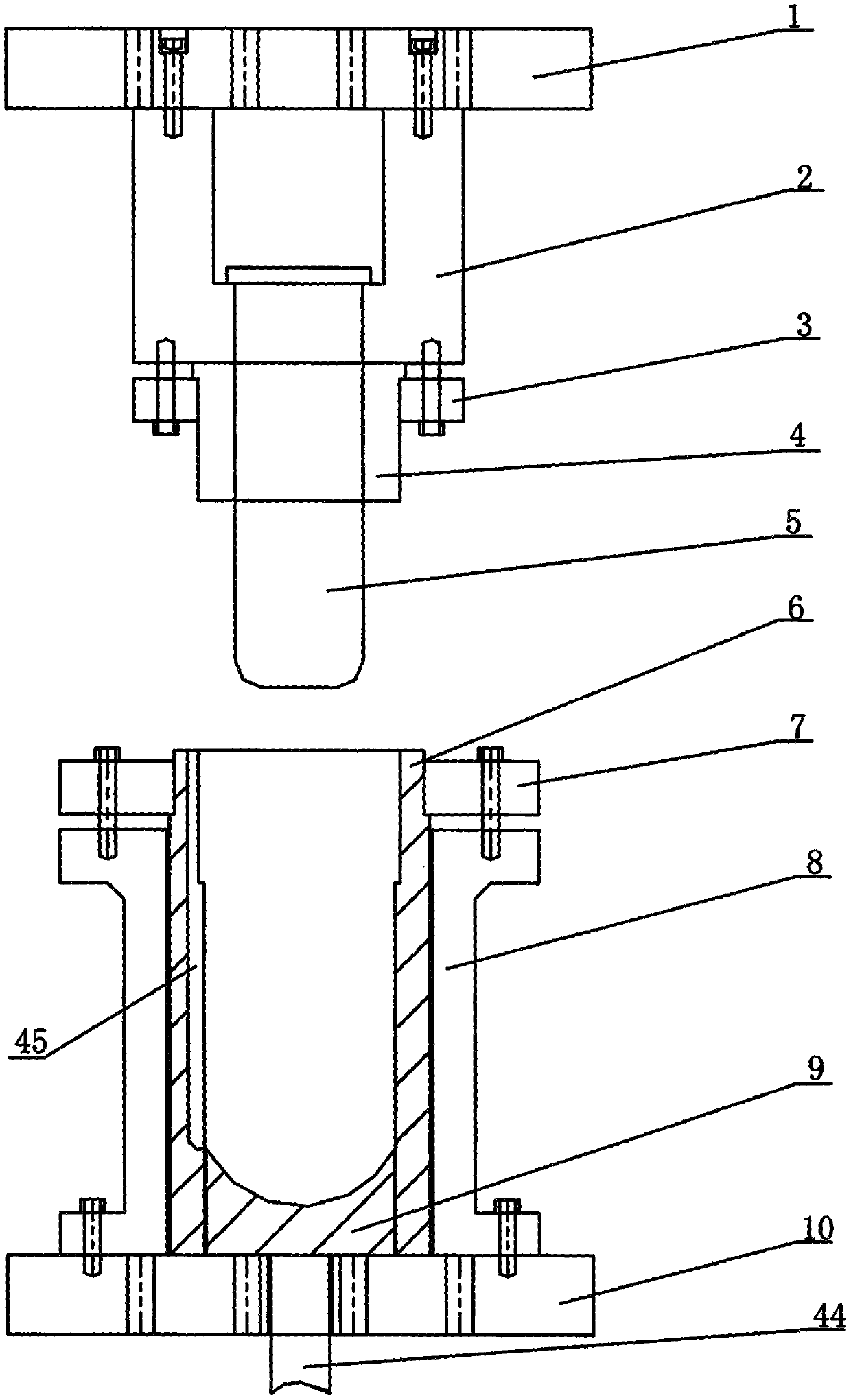

[0044]A special forging die for the outer cylinder of a coal mine hydraulic support. The forging die described in the forging die includes a forging punch and a forging die, and a forging punch includes an upper die fixing plate I1, and the bottom of the upper die fixing plate I1 passes The punch support seat 2 is connected with the pressure head 4, and the inside of the punch support seat 2 and the pressure head 4 is equipped with a punch I 5; a forging die includes a lower mold fixed plate I 10, and the top of the lower mold fixed plate I 10 The middle position is provided with a plug I 9, and the bottom of the plug I 9 is connected with the ejector rod I 44 which is installed in the middle position of the lower mold fixing plate I 10; Die I 6, the outside of lower die I 6 is provided with the die cover I 8 that is fixedly connected with lower die fixed plate I 10, and the upper outer side of described lower die I 6 is fixedly connected with die cover I 8 through lower pressi...

Embodiment 2

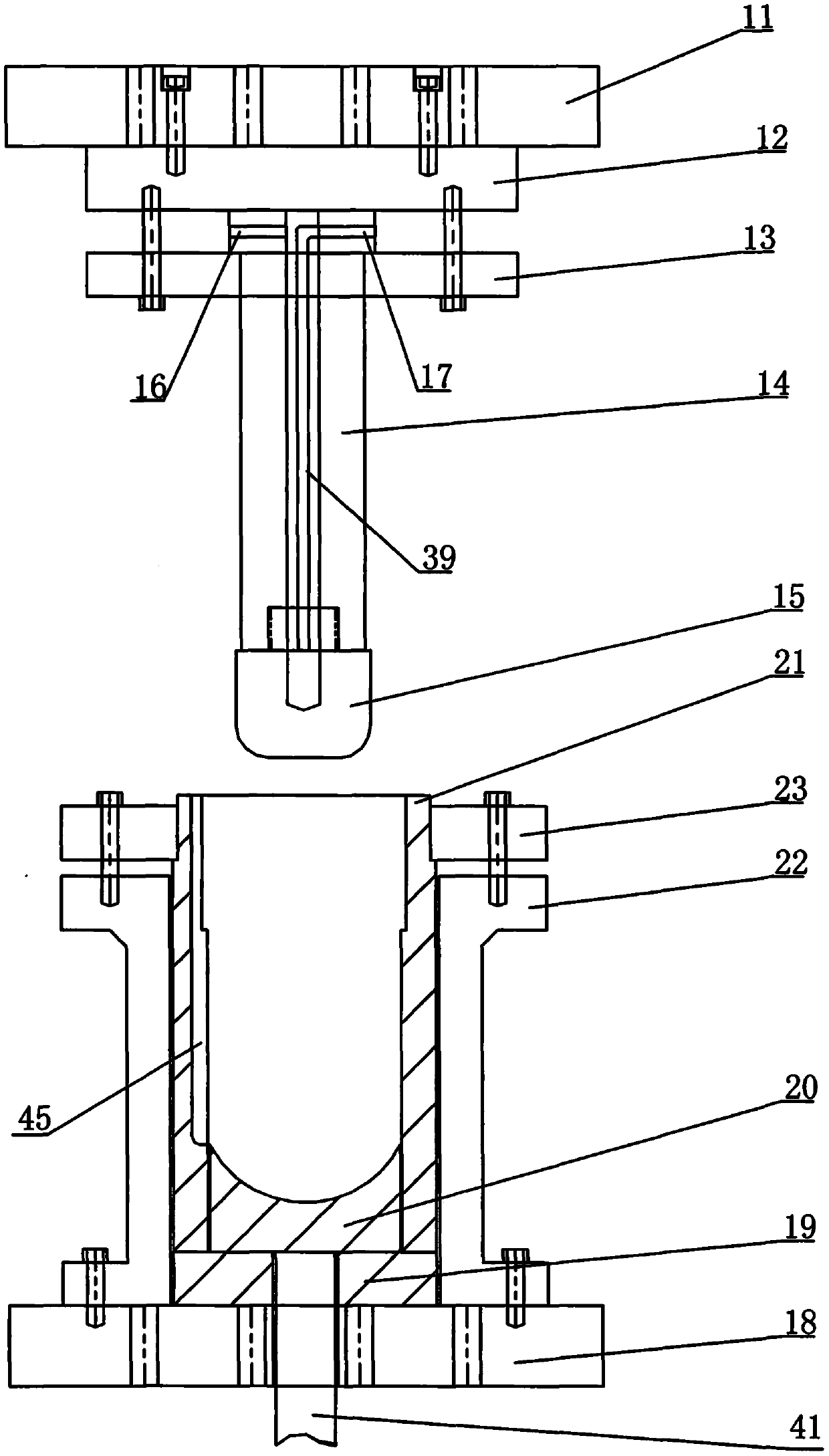

[0055] A special forging die for the outer cylinder of a coal mine hydraulic support, including a forging die, a second forging die and a final forging die; the first forging die includes a forging punch and a forging die, and the first forging punch includes an upper die fixing plate I 1, the bottom of the upper mold fixing plate I 1 is connected to the press head 4 through the punch support seat 2, and the punch support seat 2 and the press head 4 are equipped with a punch I 5 inside; a forging die includes a lower die fixing plate I 10, the top middle position of the lower mold fixed plate I 10 is provided with a top I 9, and the bottom of the top I 9 is connected to the push rod I 44 that is installed in the middle position of the lower mold fixed plate I 10; the outside of the top I 9 is provided with The lower mold I6 fixedly connected with the lower mold fixed plate I10, the outer side of the lower mold I6 is provided with the mold cover I8 fixedly connected with the low...

Embodiment 3

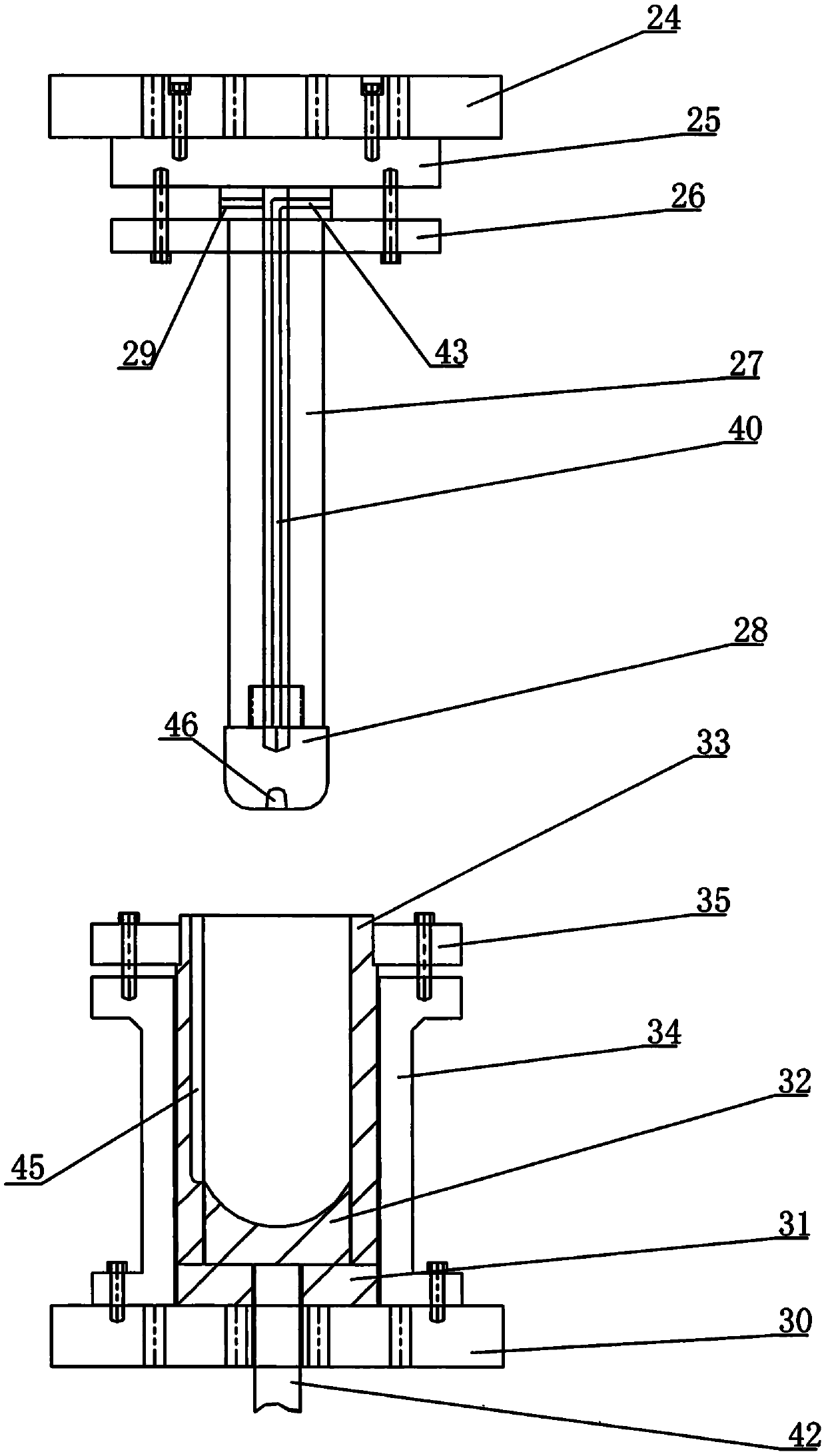

[0067] A special forging die for the outer cylinder of a coal mine hydraulic support, including a forging die, a second forging die and a final forging die; the first forging die includes a forging punch and a forging die, and the first forging punch includes an upper die fixing plate I 1, the bottom of the upper mold fixing plate I 1 is connected to the press head 4 through the punch support seat 2, and the punch support seat 2 and the press head 4 are equipped with a punch I 5 inside; a forging die includes a lower die fixing plate I 10, the top middle position of the lower mold fixed plate I 10 is provided with a top I 9, and the bottom of the top I 9 is connected to the push rod I 44 that is installed in the middle position of the lower mold fixed plate I 10; the outside of the top I 9 is provided with The lower mold I6 fixedly connected with the lower mold fixed plate I10, the outer side of the lower mold I6 is provided with the mold cover I8 fixedly connected with the low...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com