Forming mold and forming method of micro composite plastic part

A technology for forming molds and plastic parts, applied in the direction of coating, etc., can solve the problems of difficult finishing, complex precise assembly of different tiny components, and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

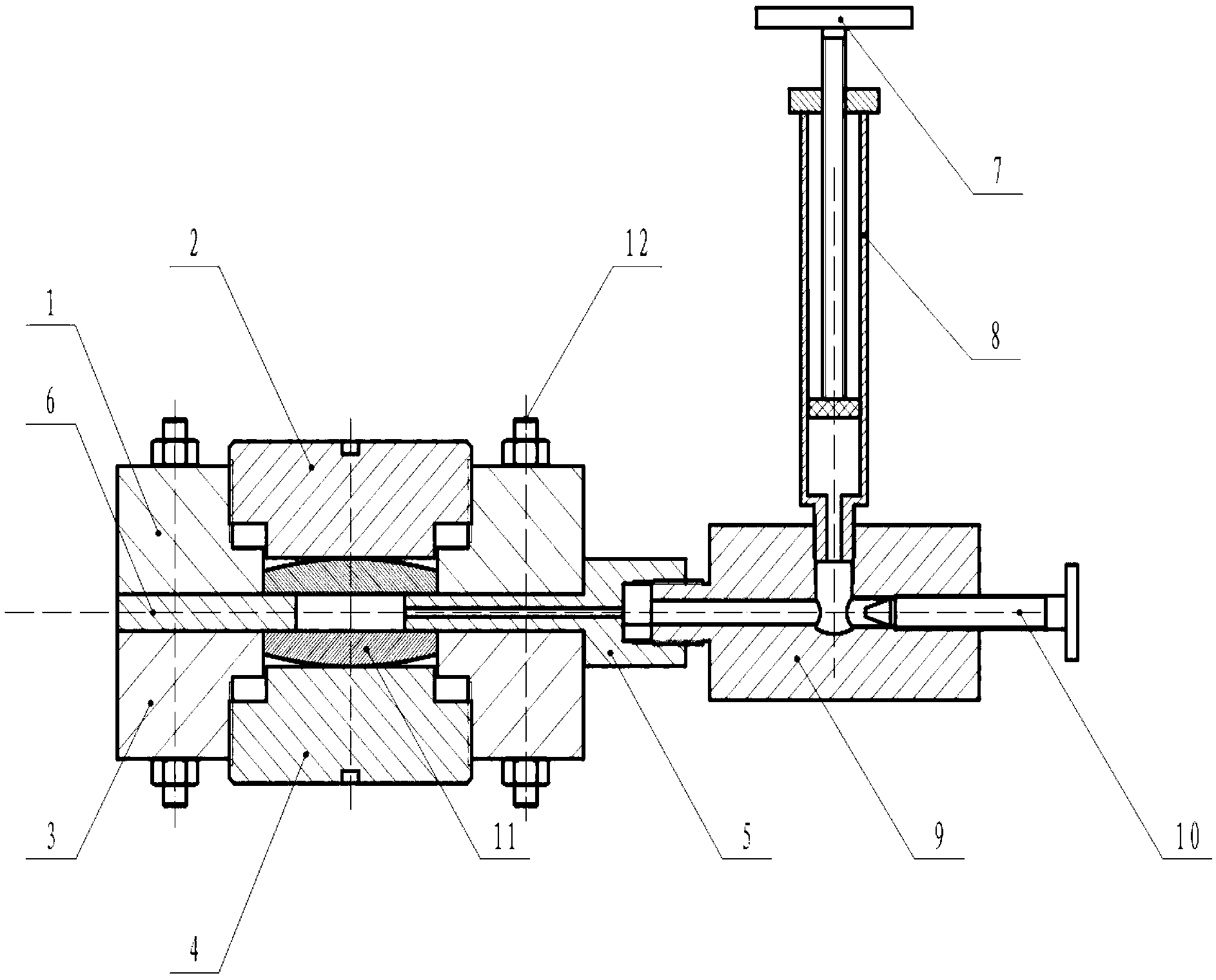

[0023] The second object of the present invention is to provide a molding method for injection molding micro-composite products using the above-mentioned molding mold, which can realize injection molding by hand or by an injection molding machine. A preferred embodiment is:

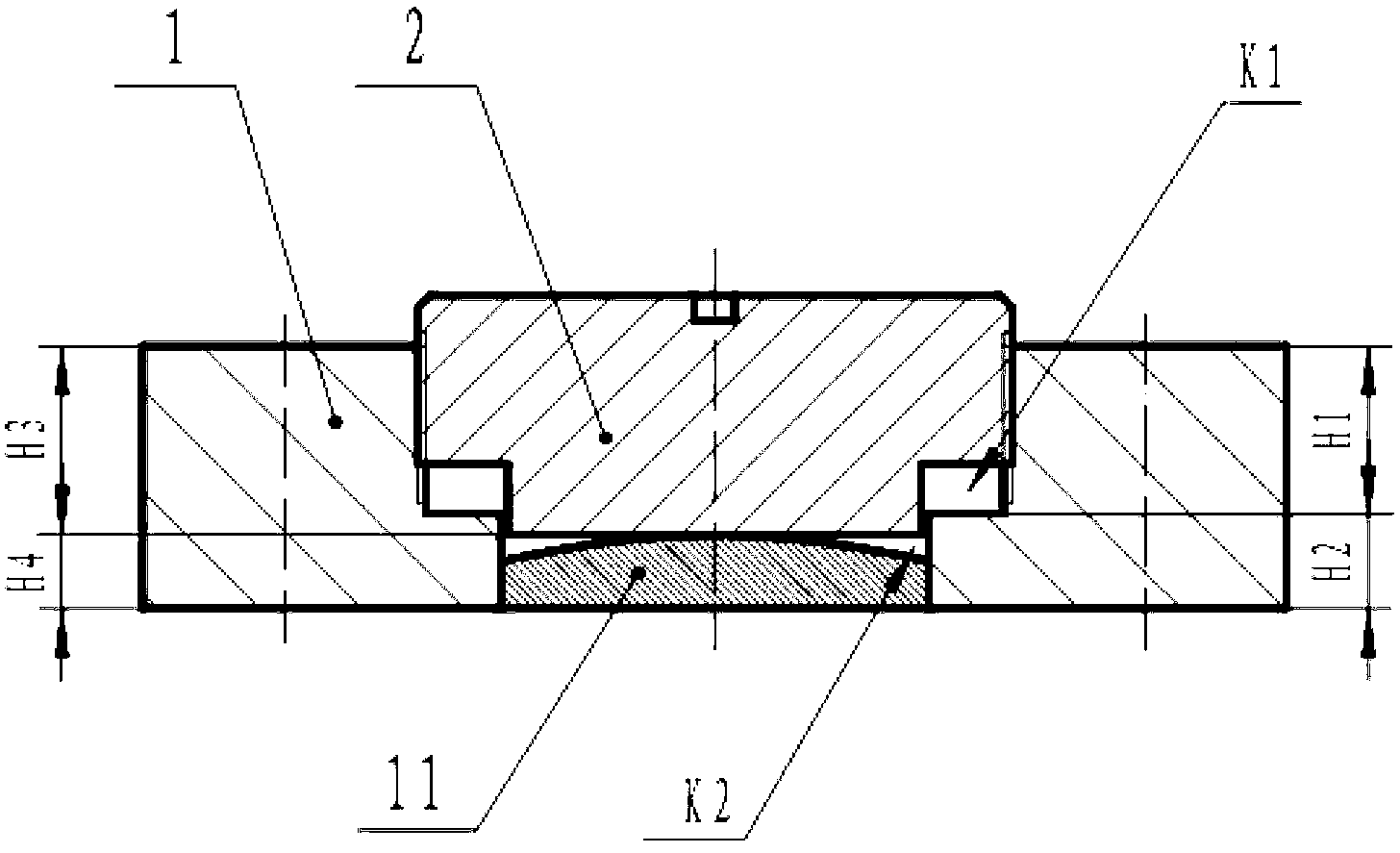

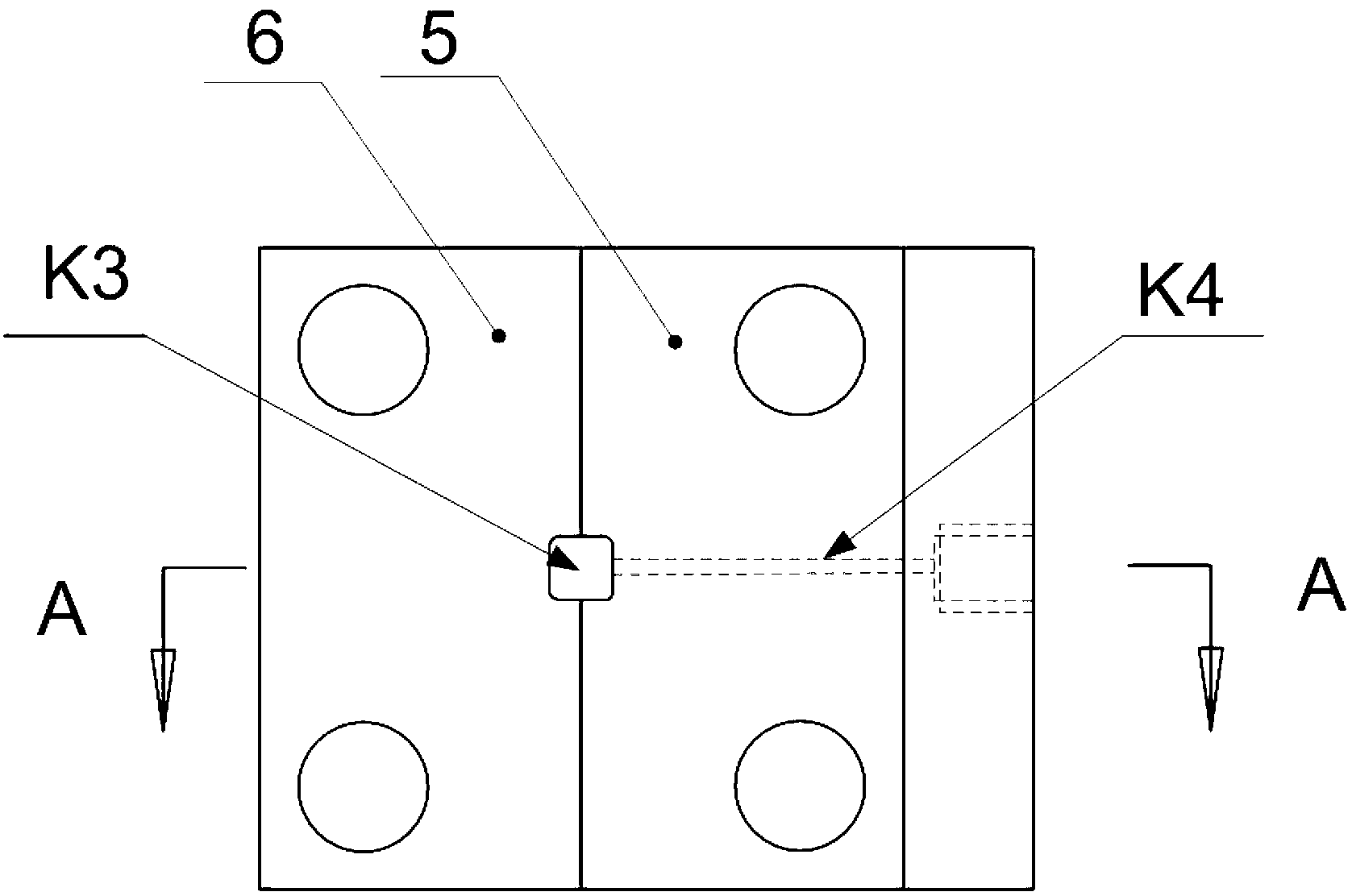

[0024] 1) Preload the rigid member 11 of the miniature composite plastic part into a specific position of the mold cavity, such as the installation hole of the upper and lower templates, adjust the position of the rigid member by changing the height of the threaded adjustment block screwed into the threaded hole, and place the upper mold , the middle mold, the lower mold part and the injection molding system are assembled separately, and the mold is closed;

[0025] 2) Unscrew the closed valve 10 to a suitable position, accurately measure and inhale and inject the flexible material into the runner cavity through the injection molding piston 7 and the barrel 8, and enter the mold cavity to fill it up, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com