Preparation method of seven-electrode conductivity sensor

A conductivity sensor and seven-electrode technology, which is applied in the field of sensor research, can solve the problems of complex preparation process of the seven-electrode conductivity sensor, the inability to integrate the conductivity cell and metal electrodes, and the inability to effectively control the performance of the sensor in a wide range, etc., to achieve Multifunctional integration, low cost, and adjustable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

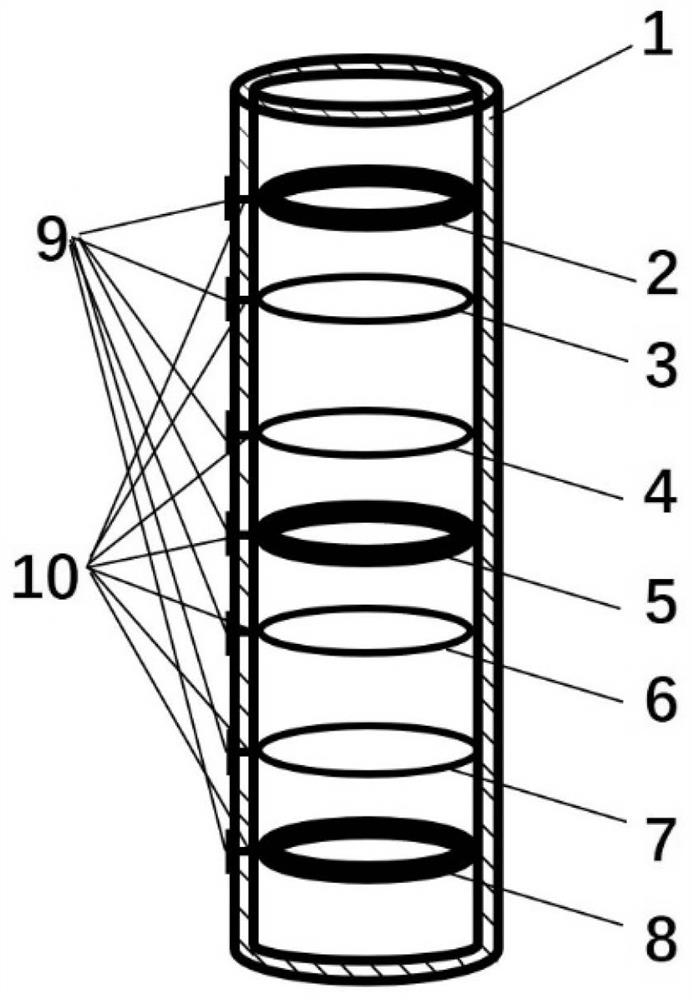

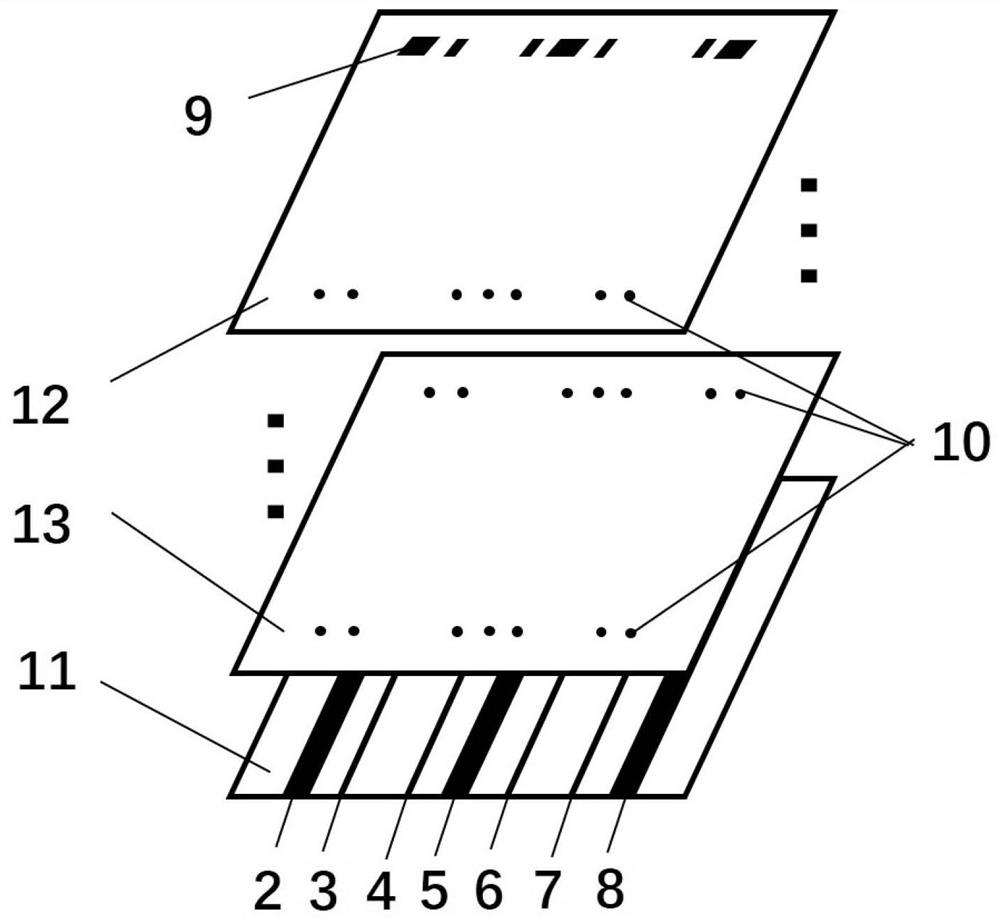

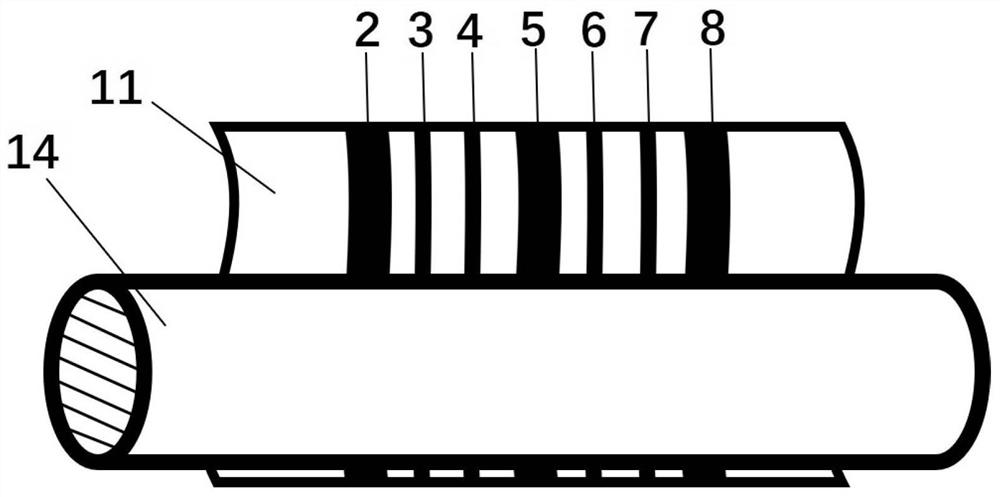

[0046] Example 1: Preparation of LTCC seven-electrode conductivity sensor

[0047] (1) LTCC ceramic raw porcelain tape is obtained by tape casting of LTCC ceramic slurry. The components of the LTCC ceramic slurry include: 50wt% calcium borosilicate glass-ceramic powder, 38wt% xylene solvent, 6wt% PVB binder, 4wt% castor oil dispersant and 2wt% polyethylene Diol plasticizer. The thickness of the obtained LTCC ceramic green tape is 50 μm;

[0048] (2) According to the designed punching position, punch holes on the surface of the LTCC ceramic green tape material, and then fill the holes with commercial gold electrode slurry to form a LTCC ceramic green tape with through holes; then, use screen printing Process The gold electrode paste is printed on the surface of the LTCC green ceramic belt material with through holes according to the planar pattern of the annular inner electrode and the outer electrode, and then placed in an oven at 80°C for drying. Among them, the LTCC ceram...

Embodiment 2

[0052] Example 2: Preparation of HTCC seven-electrode conductivity sensor

[0053] (1) HTCC ceramic raw porcelain tape is obtained by tape casting of HTCC ceramic slurry. The components of the HTCC ceramic slurry include: 50wt% alumina ceramic powder, 38wt% xylene solvent, 6wt% PVB binder, 4wt% castor oil dispersant and 2wt% polyethylene glycol plasticizer. ; The thickness of the resulting HTCC ceramic raw porcelain tape is 50 μm;

[0054] (2) According to the designed punching position, punch holes on the surface of the HTCC ceramic green tape material, and then fill the holes with commercial platinum electrode slurry to form a HTCC green tape with through holes; then, use the screen printing process The platinum electrode paste was printed on the surface of the LTCC green ceramic belt material with through holes according to the planar pattern of the ring-shaped inner electrode and the outer electrode, and then placed in an oven at 80°C to dry for use. Among them, the mat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com