Patents

Literature

40results about How to "Overcome tightness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

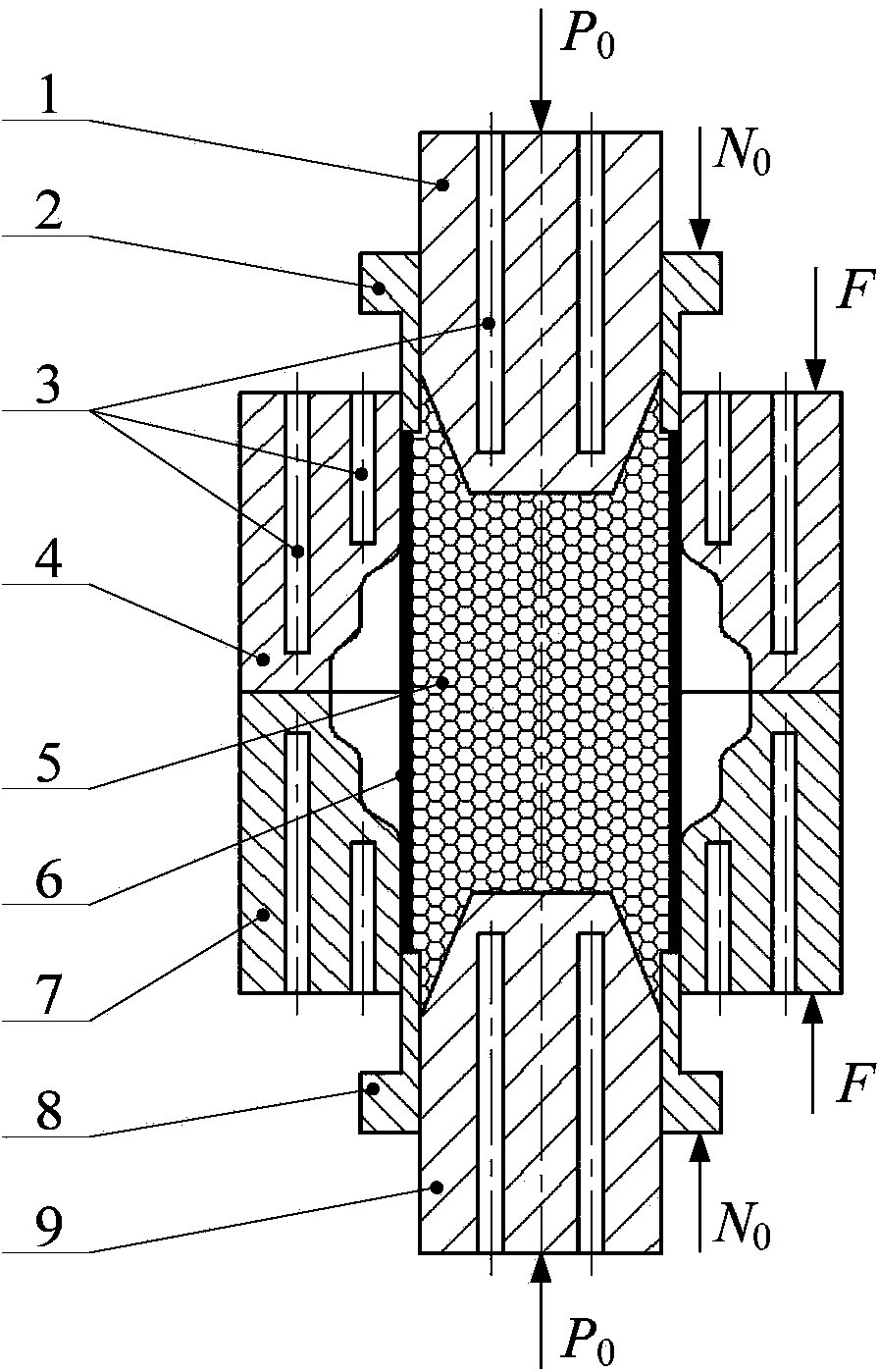

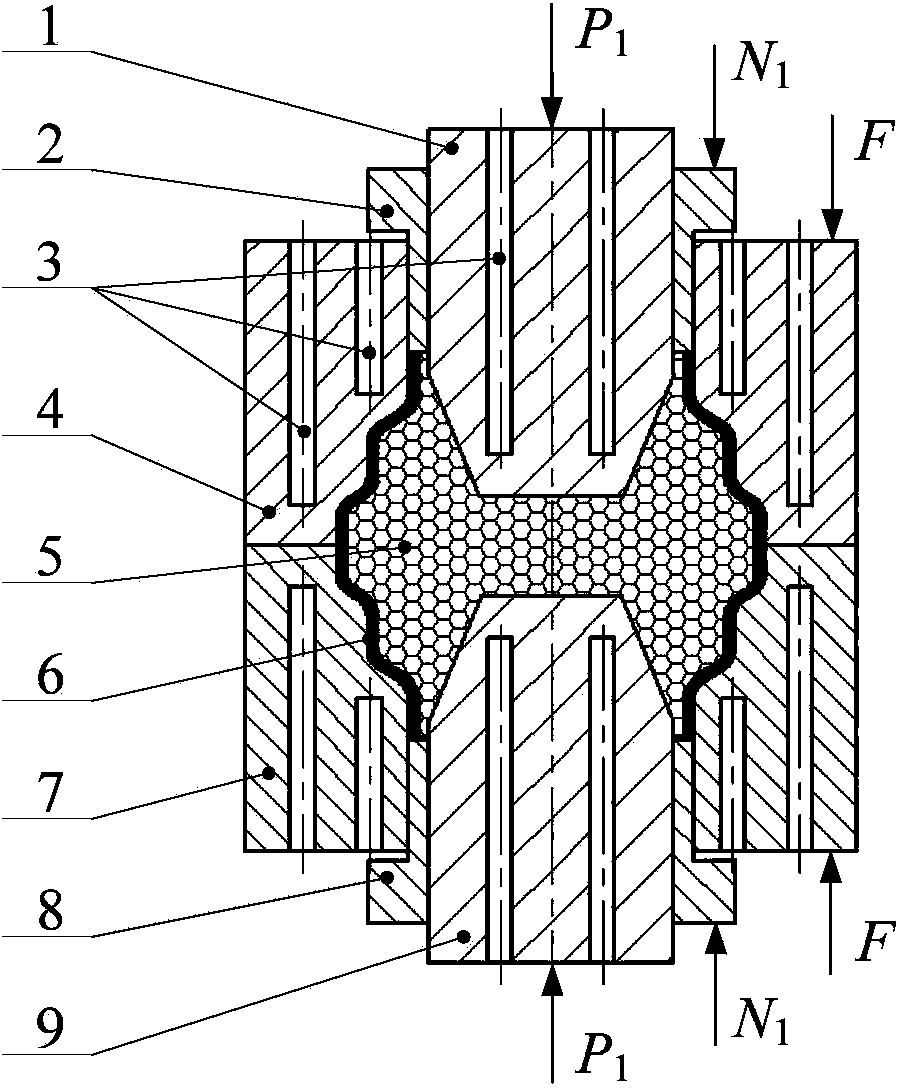

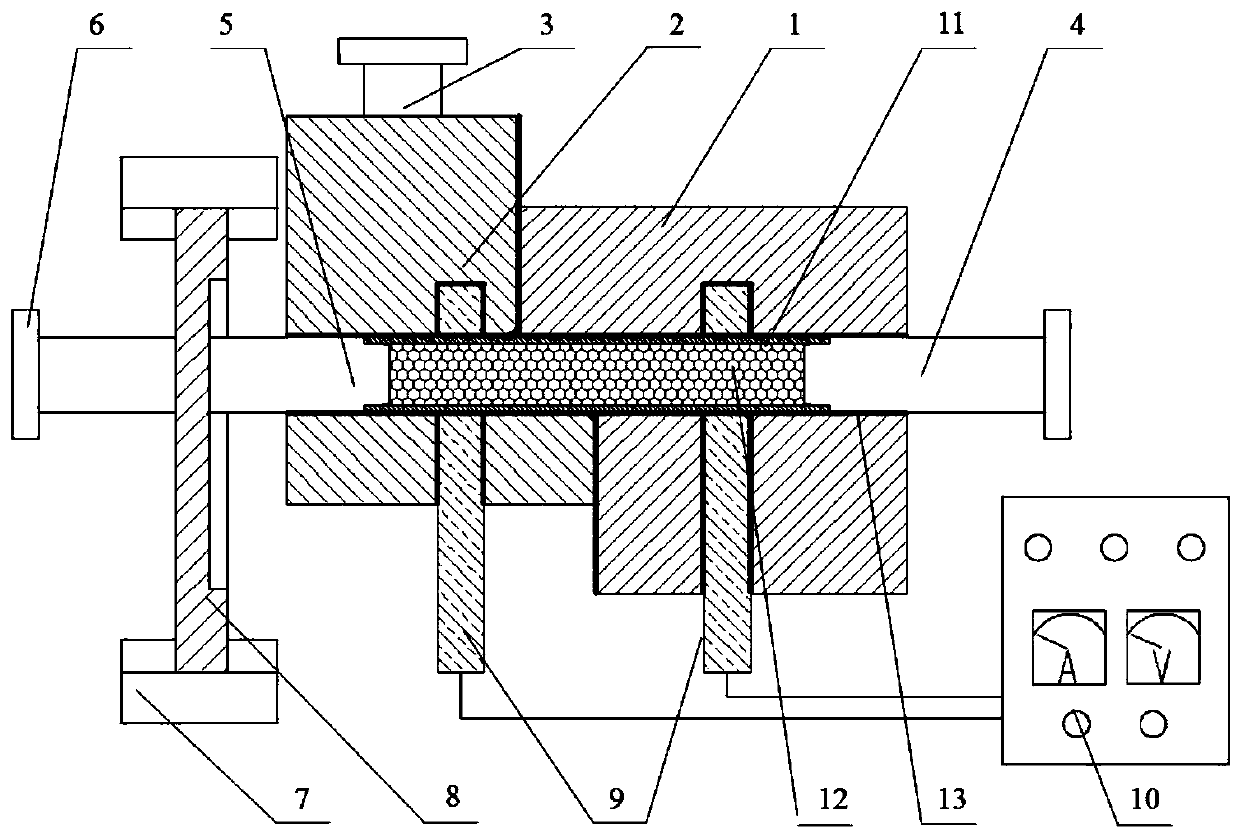

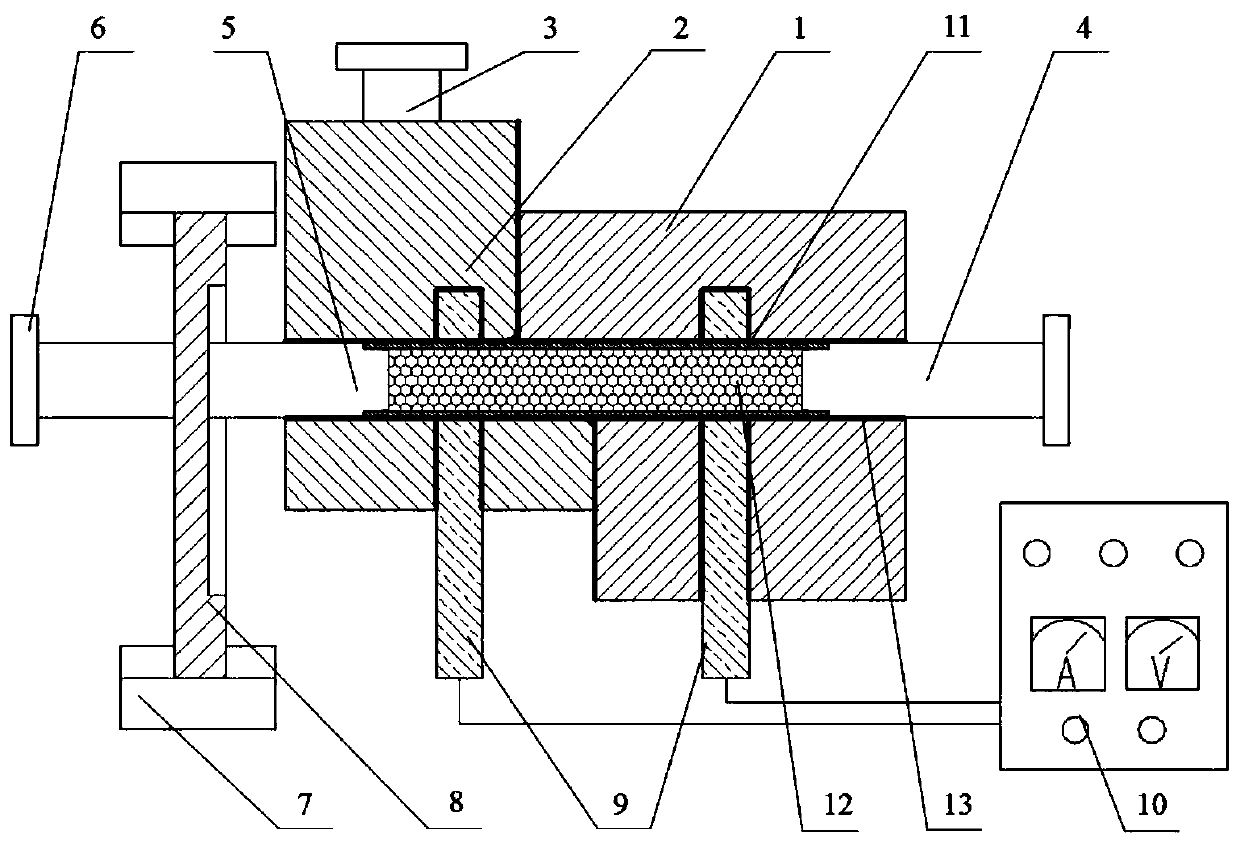

Solid particle medium thermal expansion forming method for light alloy tubular component

InactiveCN103894469ASimple process controlLow input costShaping toolsEnvironmental resistanceThermal expansion

Owner:YANSHAN UNIV

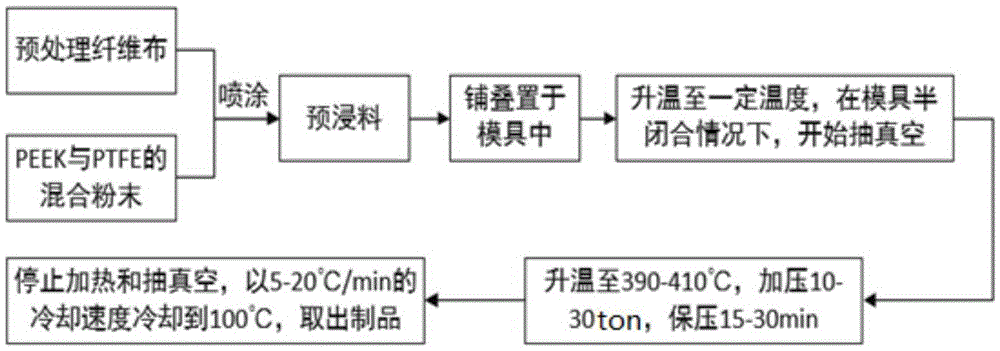

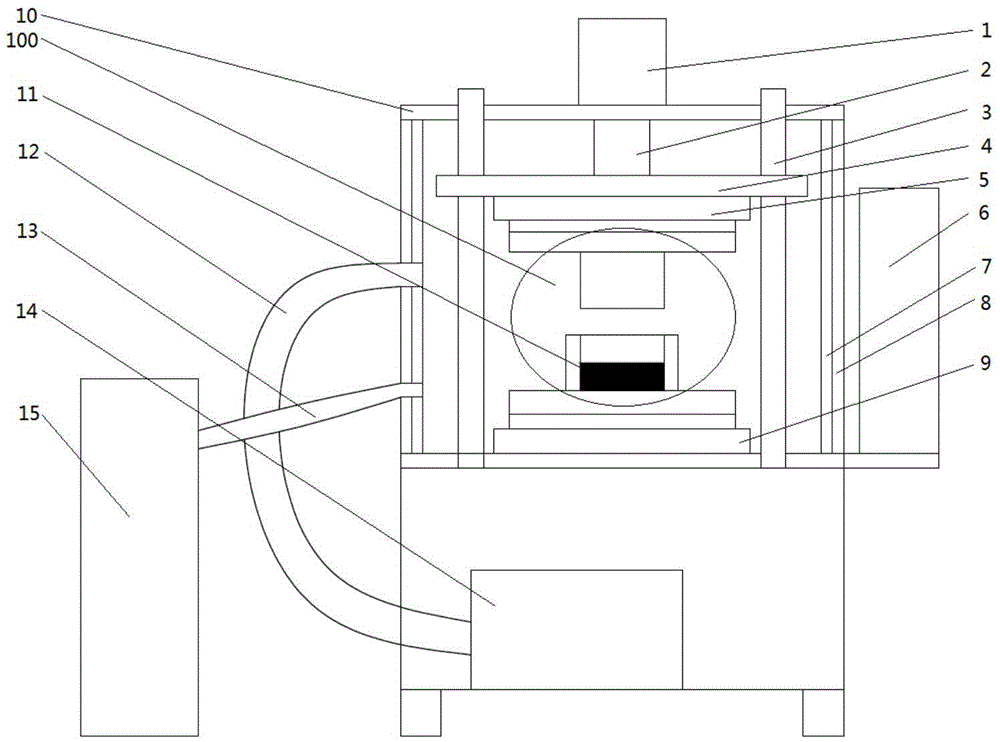

Hot press molding device for carbon fiber enhanced polyether-ether-ketone (PEEK) composite material and technological method thereof

The invention provides a hot press molding device for a carbon fiber enhanced polyether-ether-ketone (PEEK) composite board. The hot press molding device comprises a hydraulic machine, a molding die and a vacuum system. According to the device, a heating unit is separated from the hydraulic machine, and a heating pipe is used for heating the die to achieve a high temperature hot pressing function; by carrying out hot press molding in a vacuum environment, the content of bubbles in resin can be greatly reduced, and the test piece surface smoothness and workpiece performances are improved; a cooling unit is arranged in the die, and cooling speed is regulated by regulating the flow and temperature of high pressure cold air, so as to control the crystallinity of matrix resin and realize flexible selection between high strength and high toughness. Correspondingly, the invention also provides a hot press molding method for the carbon fiber enhanced polyether-ether-ketone (PEEK) composite board. A carbon fiber enhanced polyether-ether-ketone (PEEK) composite board produced by adopting the device and the method disclosed by the invention through hot press molding is simple in production equipment and solves the problems that material internal porosity is large, resin impregnation fiber is insufficient, test piece performance is insufficient, molding cycle is long and the like during production of polyether-ether-ketone resin with high melting point and high viscosity.

Owner:HUAZHONG UNIV OF SCI & TECH

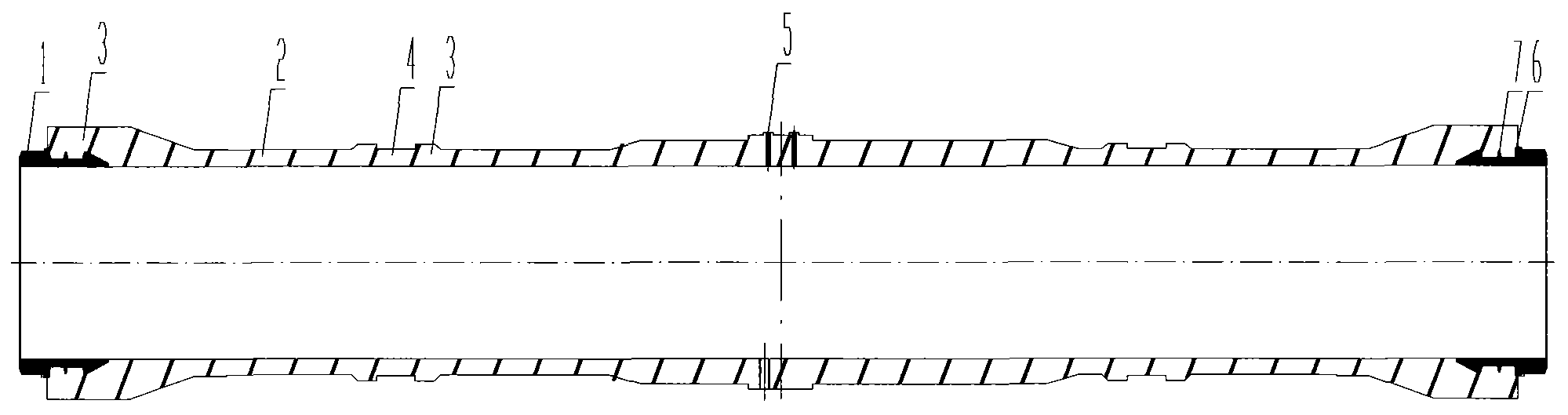

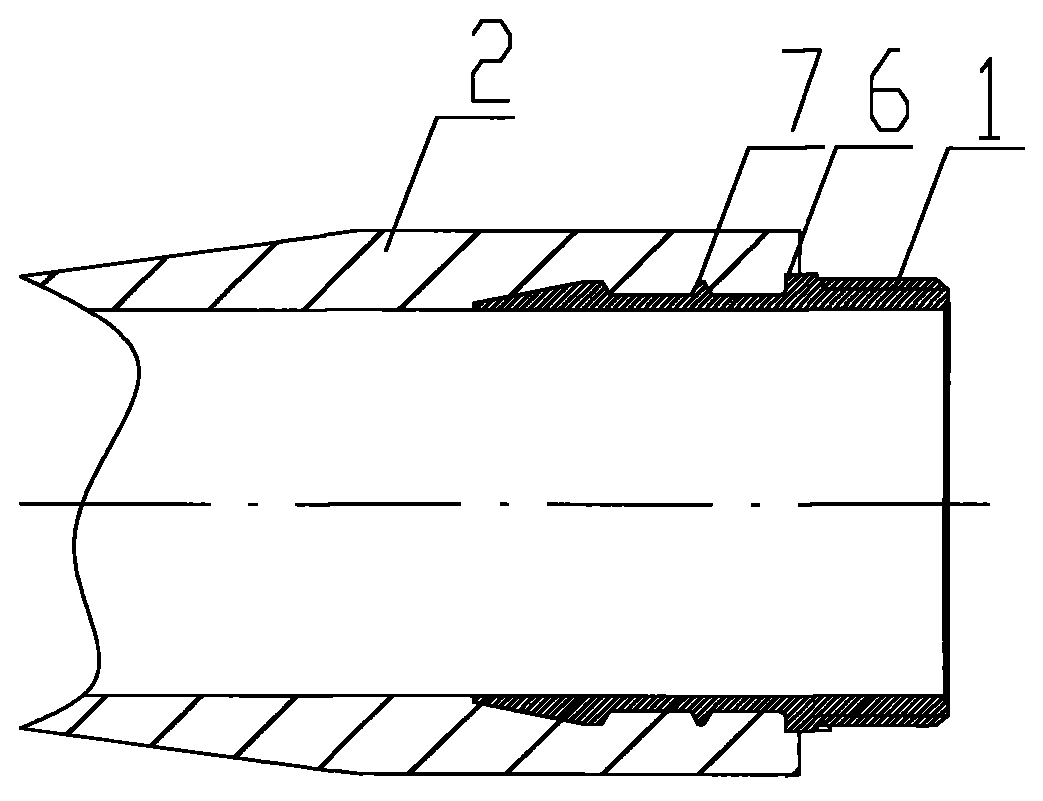

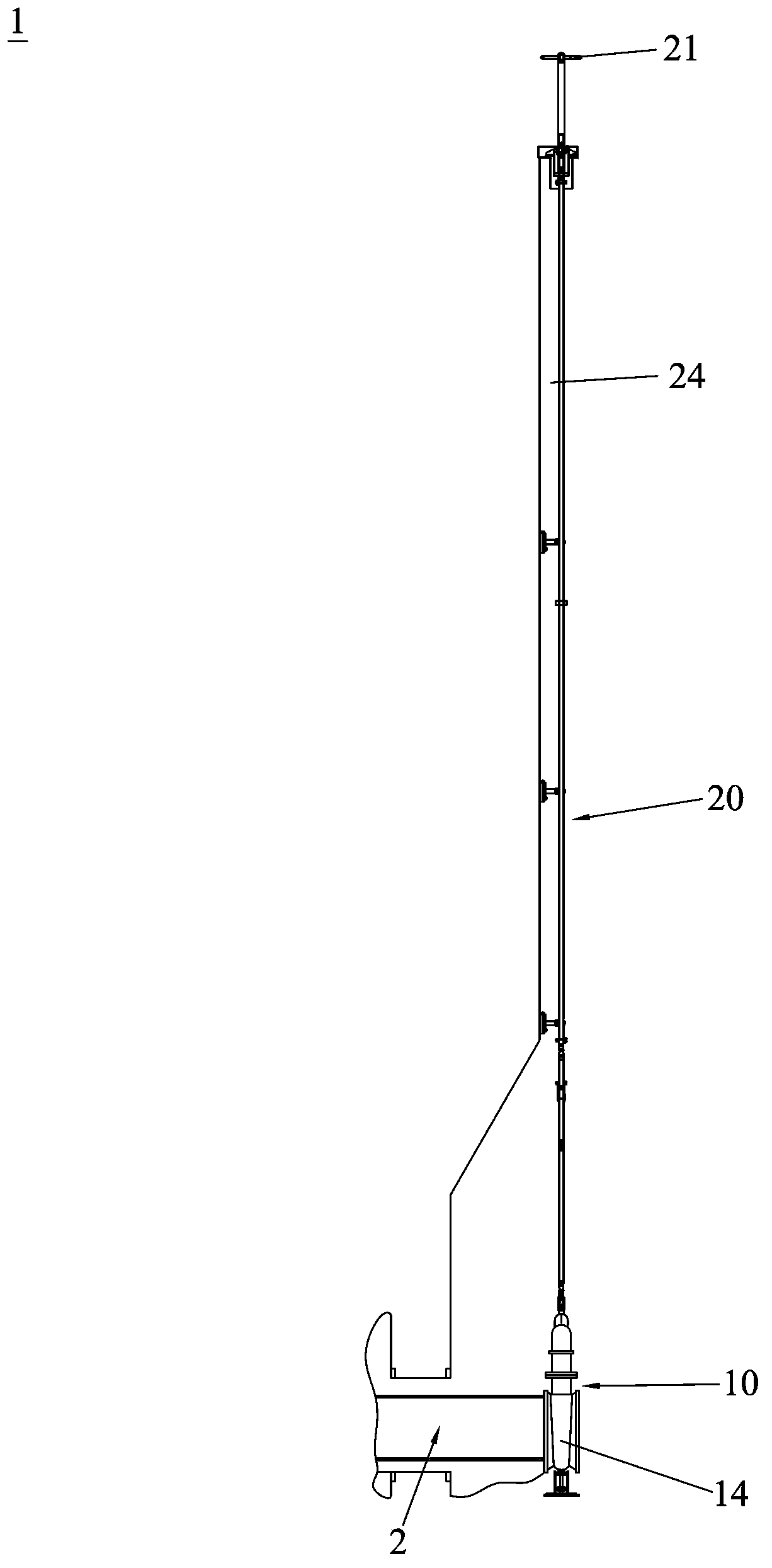

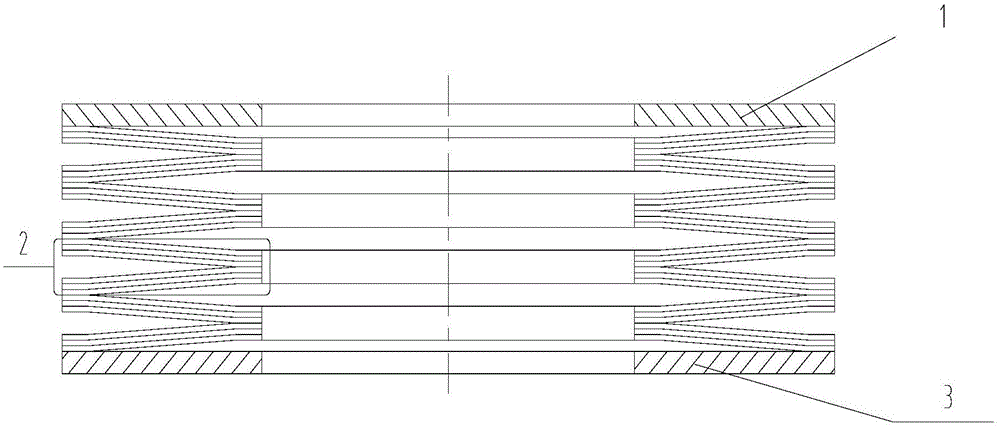

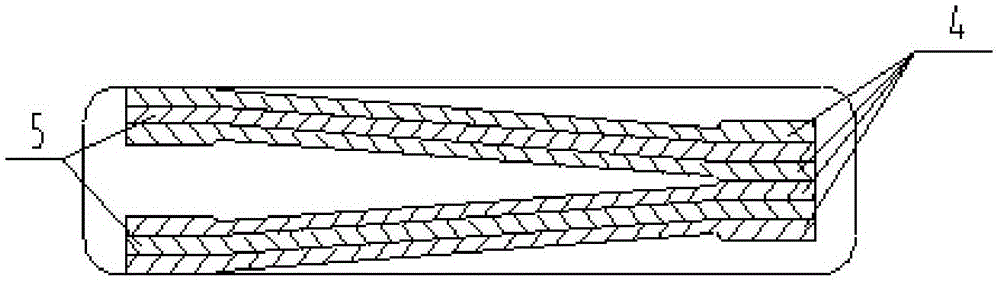

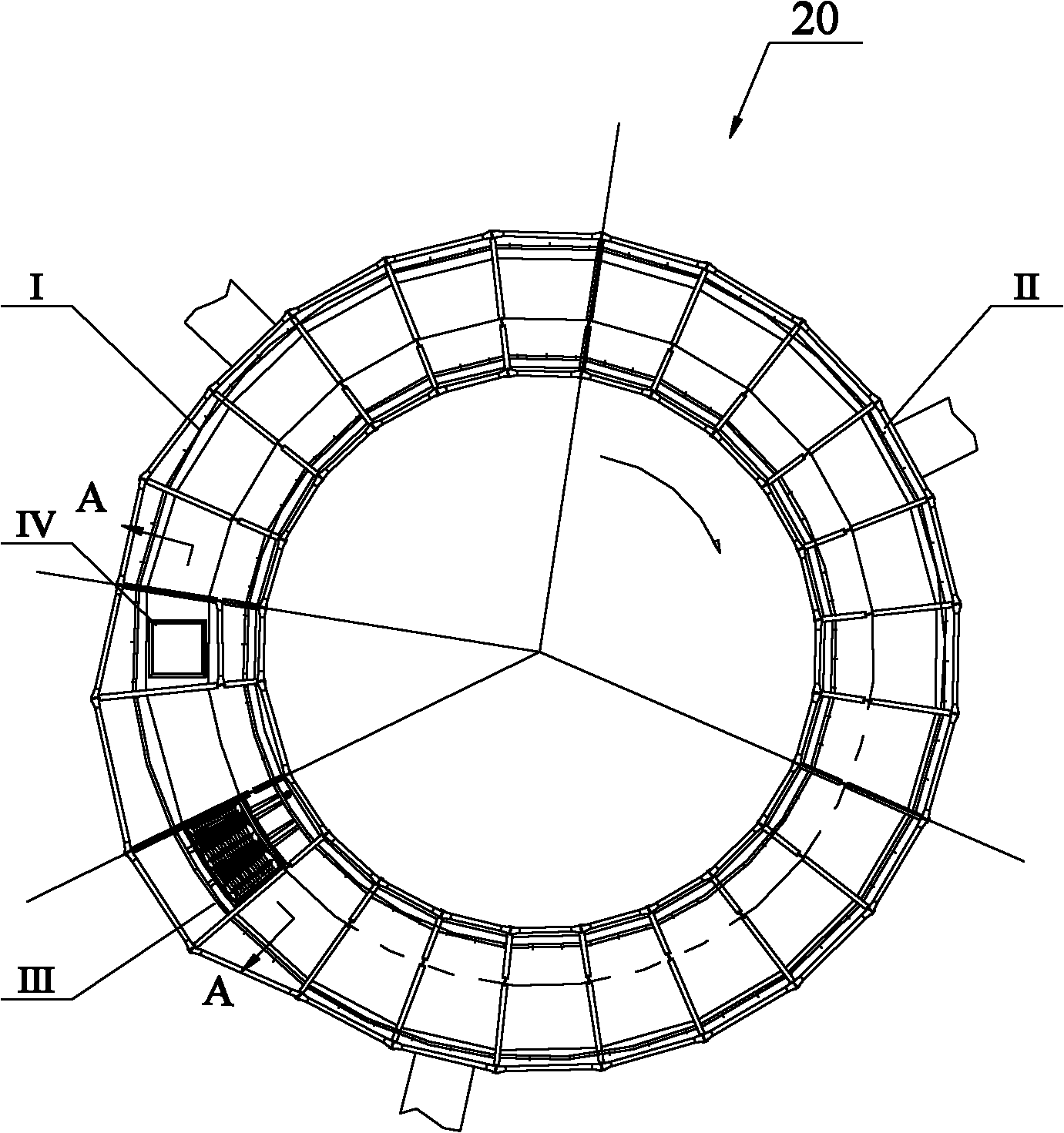

Manufacture method for composite-material launch canister of high-altitude fire-extinguishing rocket

The invention relates to a manufacture method for a composite-material launch canister of a high-altitude fire-extinguishing rocket. The launch canister comprises two metal bushings (1) and a composite-material canister body (2), and each of the two ends of the composite-material canister body (2) is hermetically connected with one metal bushing (1). The manufacture method is characterized by comprising the following steps: 1) making a cylindrical mould with smooth surface according to the structure of the launch canister inner chamber; ... 10) machining the external diameters of the canister body and a reinforcement hoop prepared in the 1)-9) steps. The prepared composite-material launch canister of the high-altitude fire-extinguishing rocket by employing the manufacture method of the invention has light weight, strong bearing capability, high-temperature flame sweep resistance, high pressure resistance, good seal performance, strong corrosion resistance, multi-time reuse and low maintenance cost.

Owner:HEBEI DONGHENGYU FUNCTIONAL MATERIAL NEW TECH +1

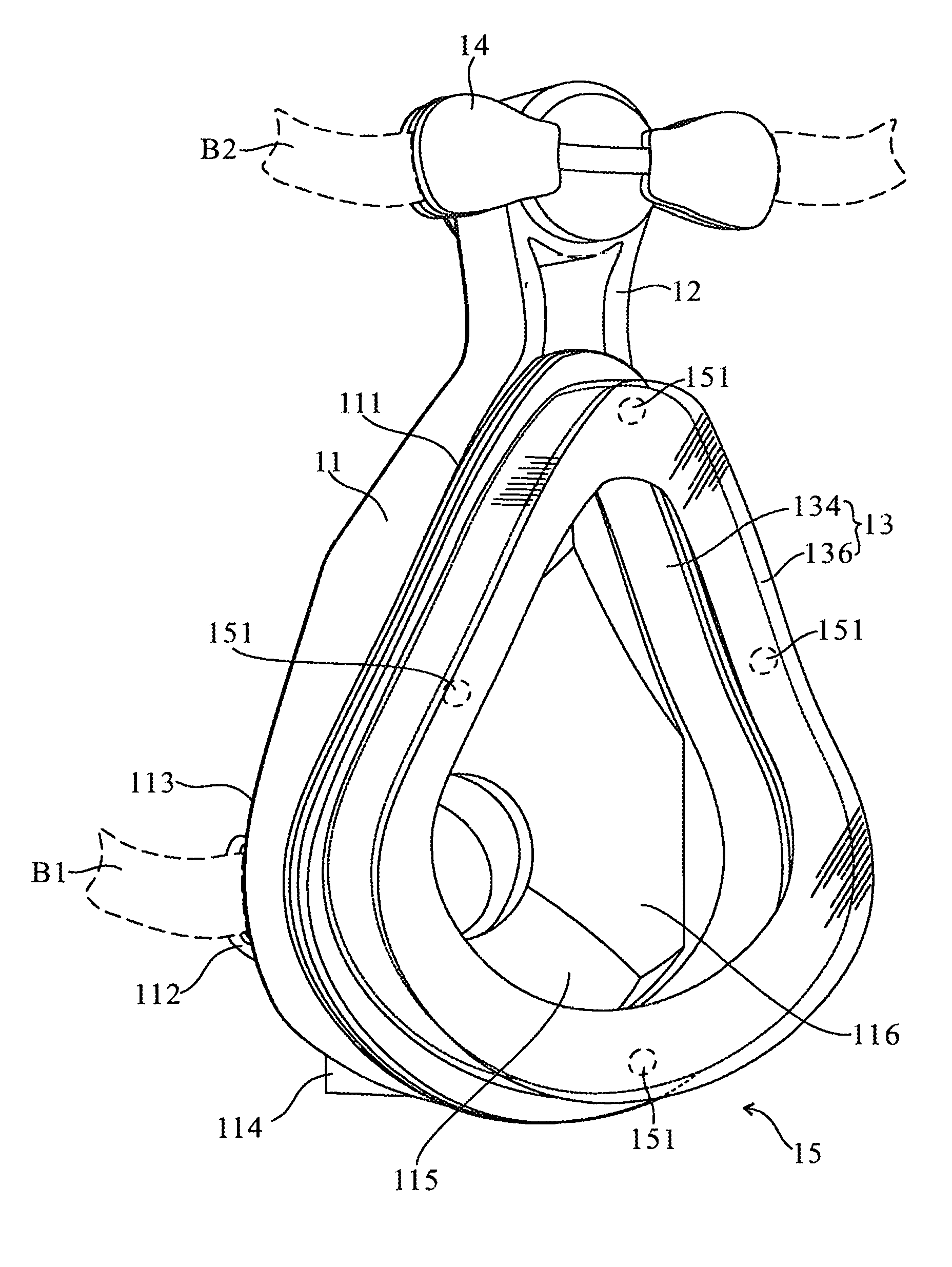

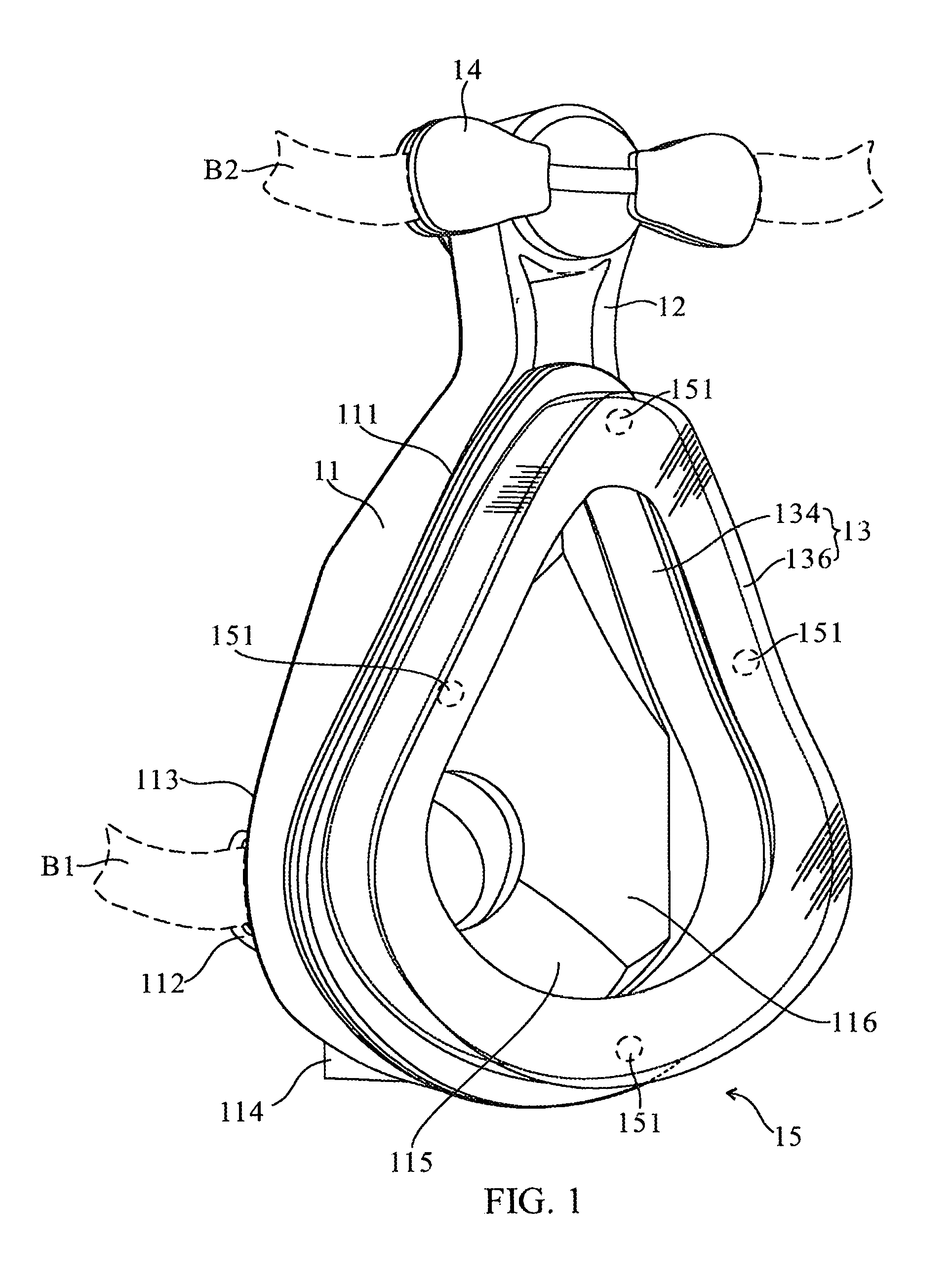

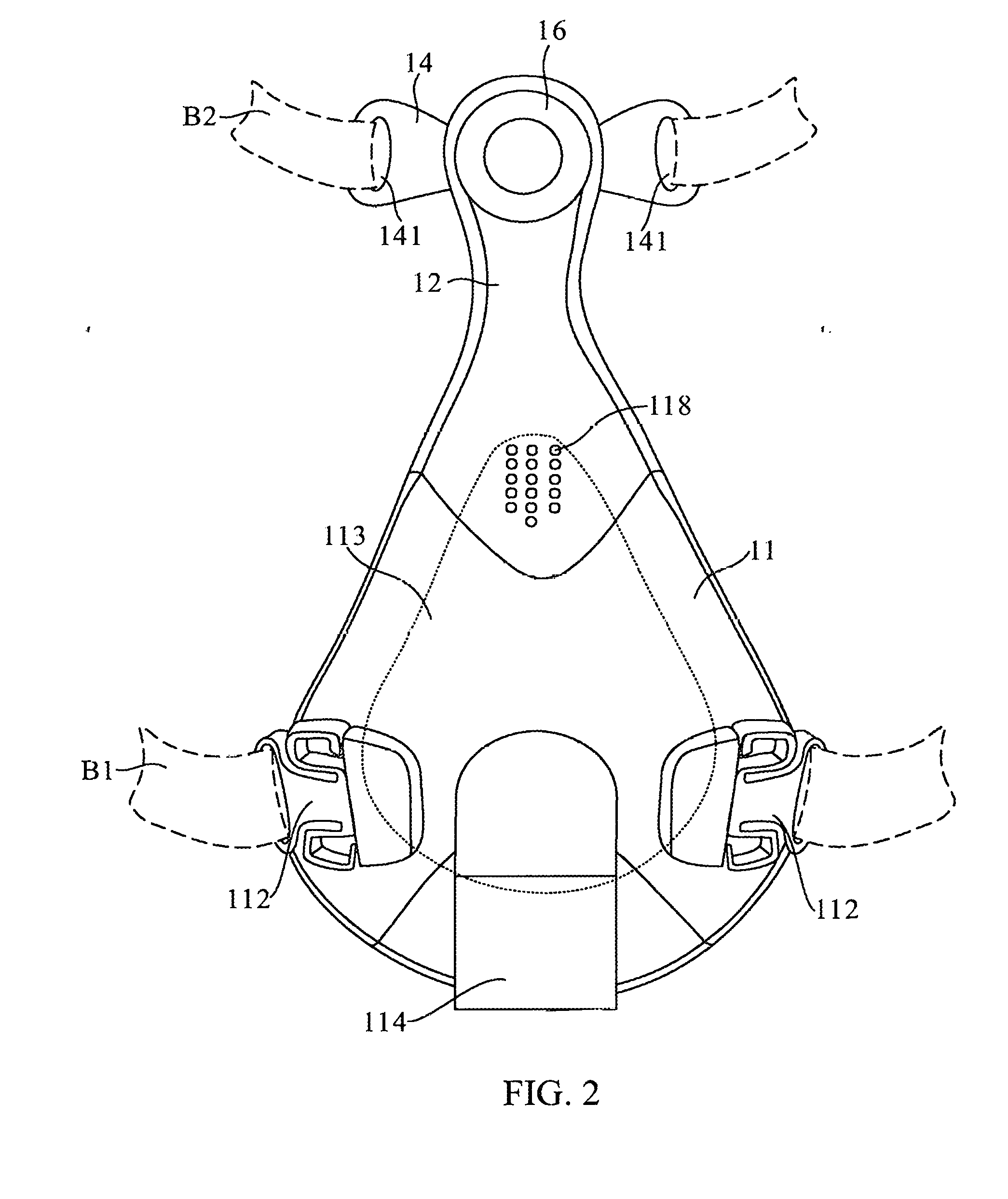

Inductive Breathing Mask and Respiratory Care System Thereof

InactiveUS20160279359A1Overcome tightness issueReduce morbidityRespiratory masksMedical devicesChinNasion

An inductive breathing mask is provided, which comprises a covering shell, a mask pad, and a pressure inductive unit, wherein the pressure inductive unit comprising at least one pressure inductive part, and the pressure inductive part is disposed on the mask pad where corresponds to at least one of the user's nasion, left cheek beside nose, right cheek beside nose, and chin for detecting the pressure of the user's nasion, left cheek beside nose, right cheek beside nose, and chin generated by the mask pad. In addition, the inductive breathing mask of the present invention may further be integrated with other functional elements for constructing a respiratory care system having warning and / or monitoring functions.

Owner:TAICHUNG VETERANS GENERAL HOSPITAL

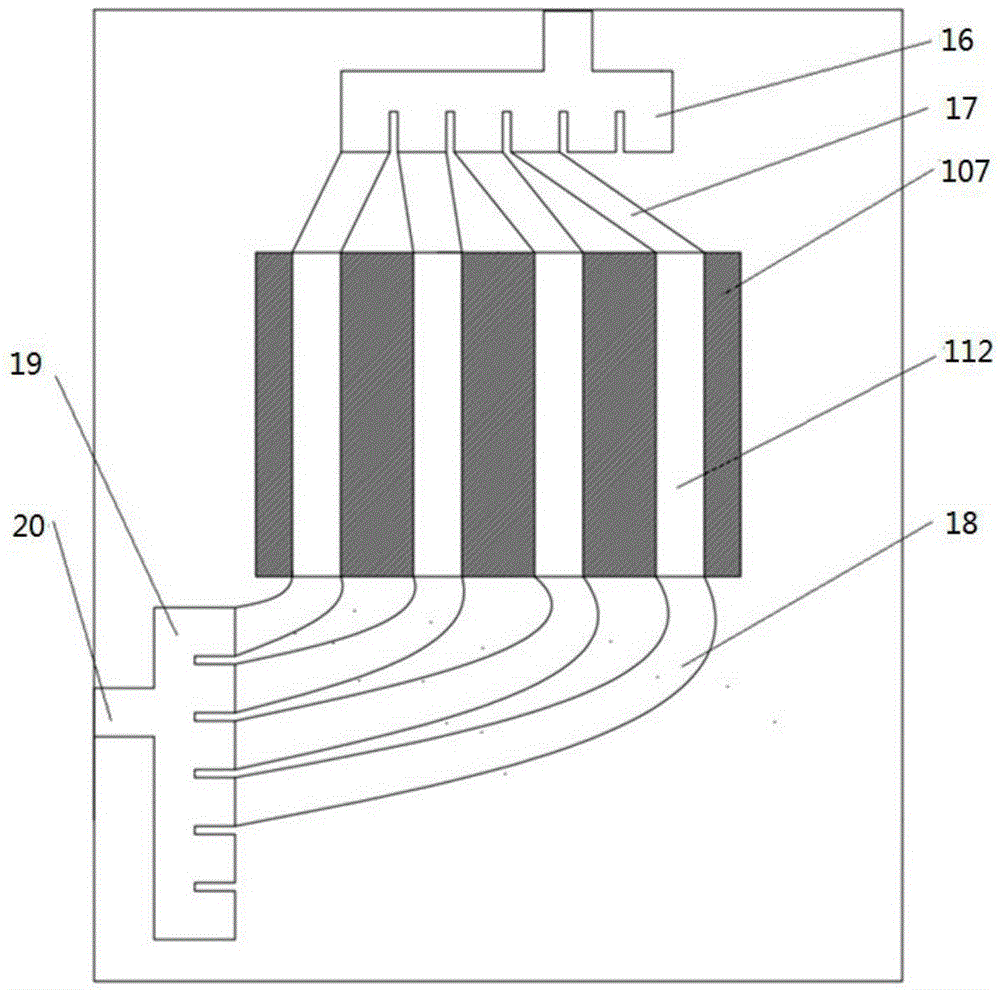

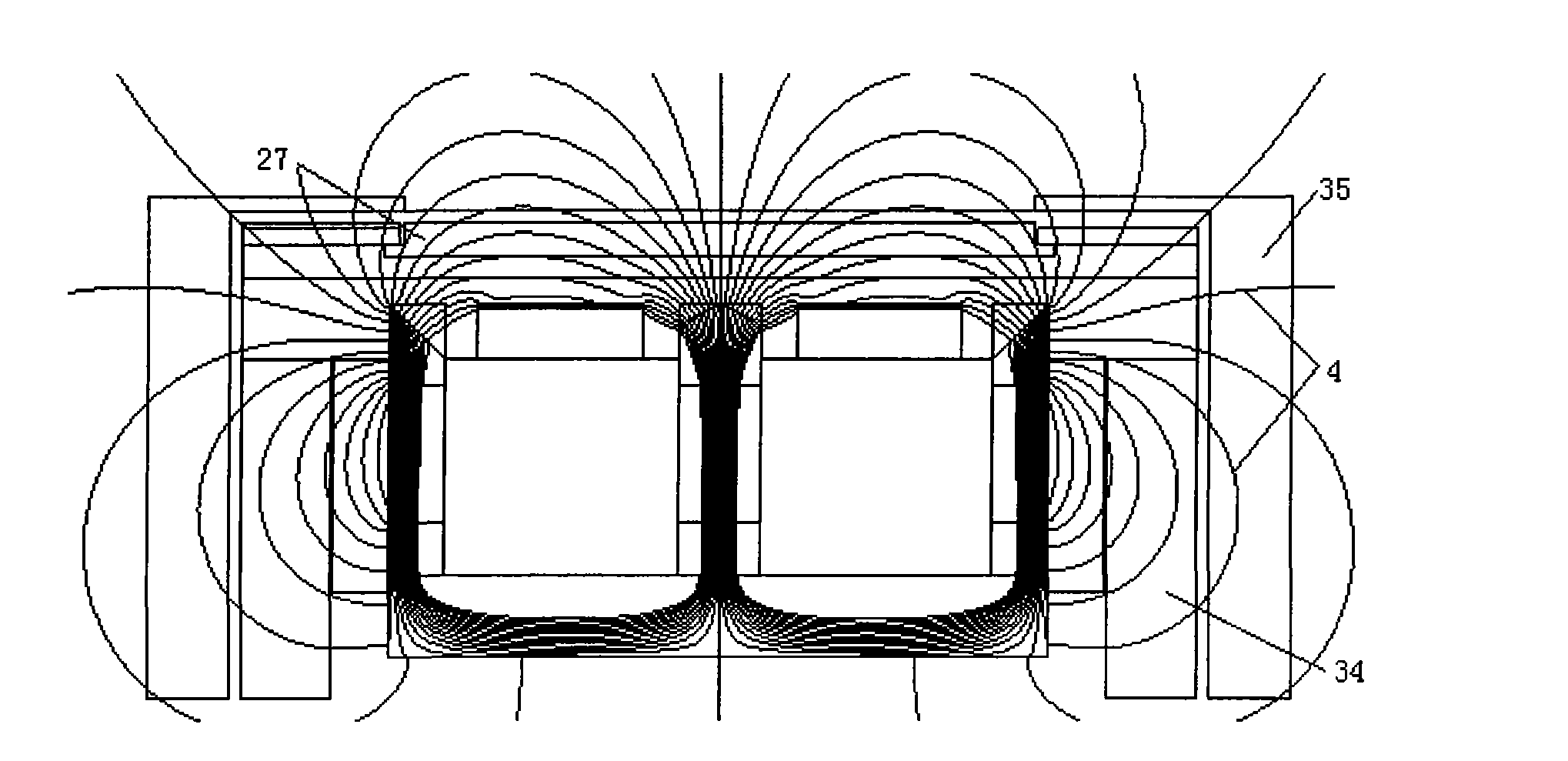

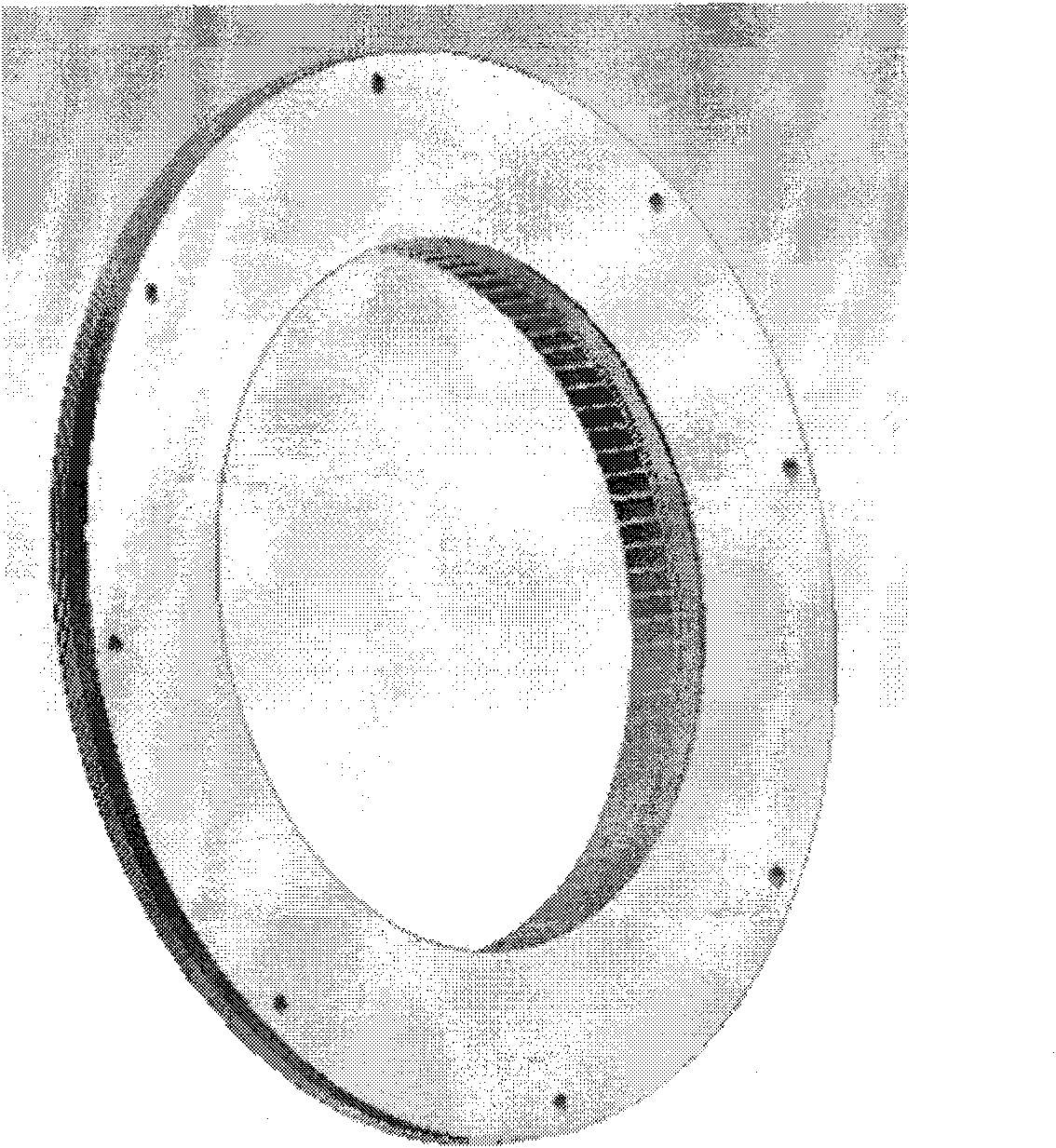

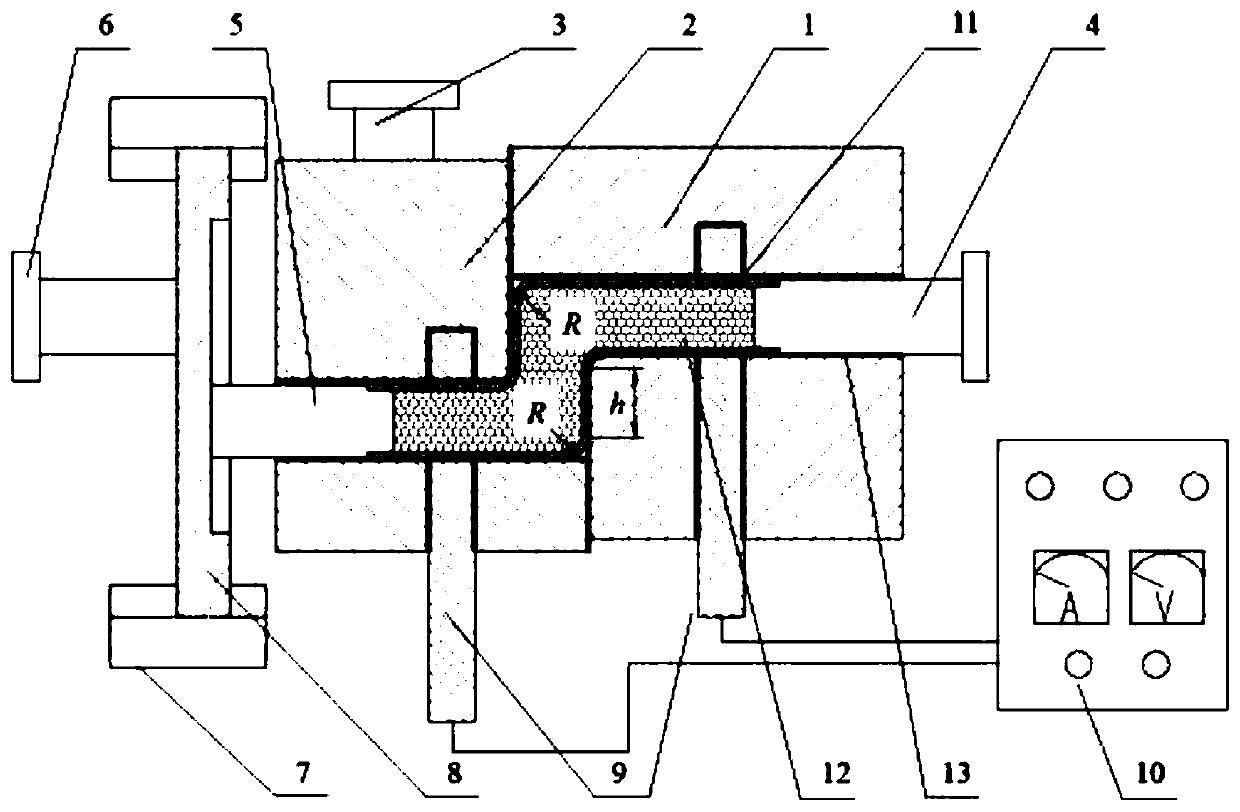

Rectangle plane magnetron sputtering cathode

InactiveCN101250687AIncrease widthAvoid discharge phenomenonVacuum evaporation coatingSputtering coatingSputteringEngineering

The invention relates to a rectangular plane magnetically controlled sputtering cathode, which is provided with a target, a cathode component and a shielding case which is arranged on the periphery of the cathode component, wherein a magnetic circuit mechanism is fixedly arranged on a target seat and is located inside a cathode body, the target is fixedly arranged on the lower portion of the target seat, and the cathode is characterized in that a magnetic conductive plate is arranged on the periphery of the cathode component and located on the inner side and the outer side of the shielding case in a whole circumference mode. The cathode of the invention can effectively increase the stability of a sputtering process and can increase the availability ratio of the target.

Owner:HEFEI UNIV OF TECH

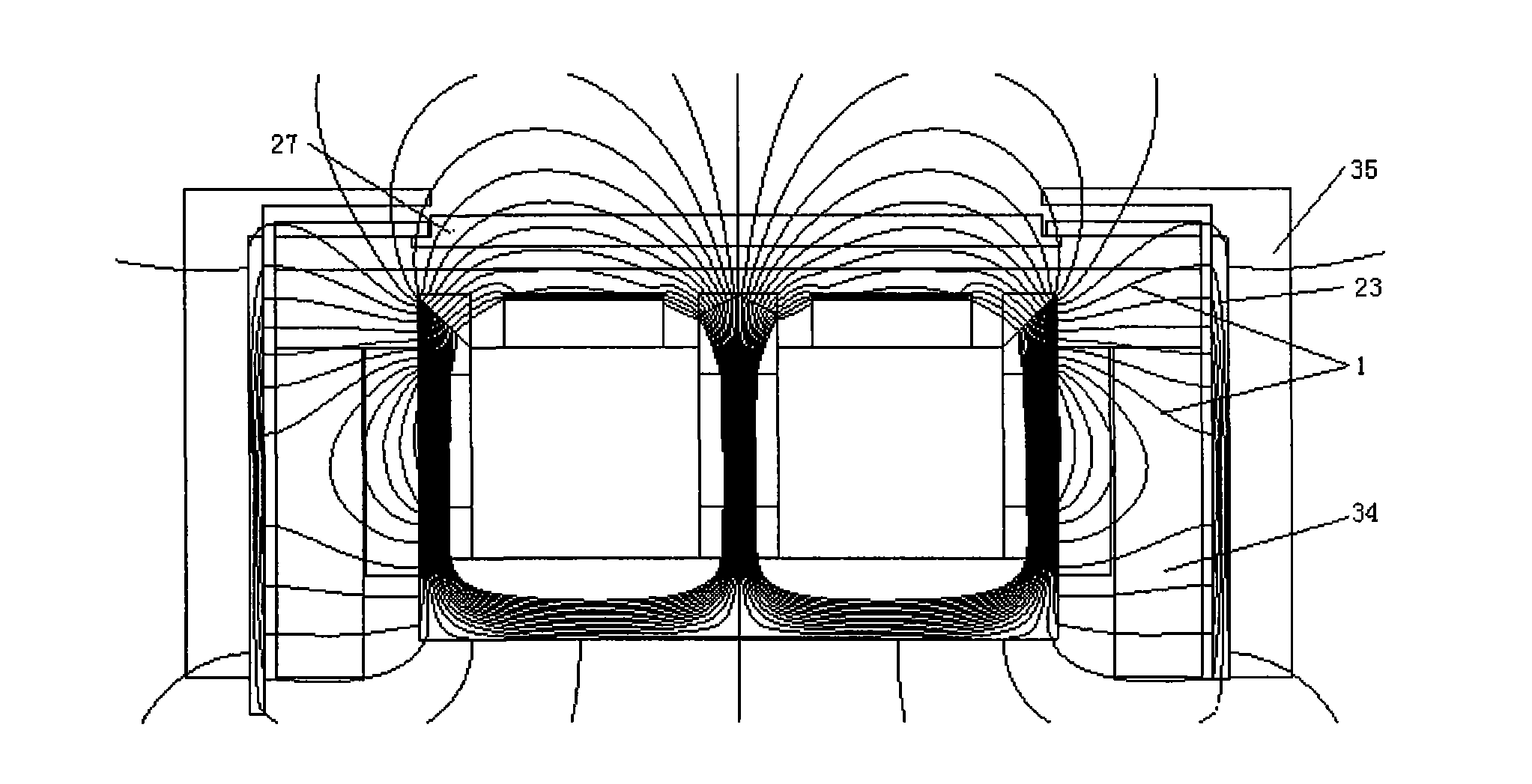

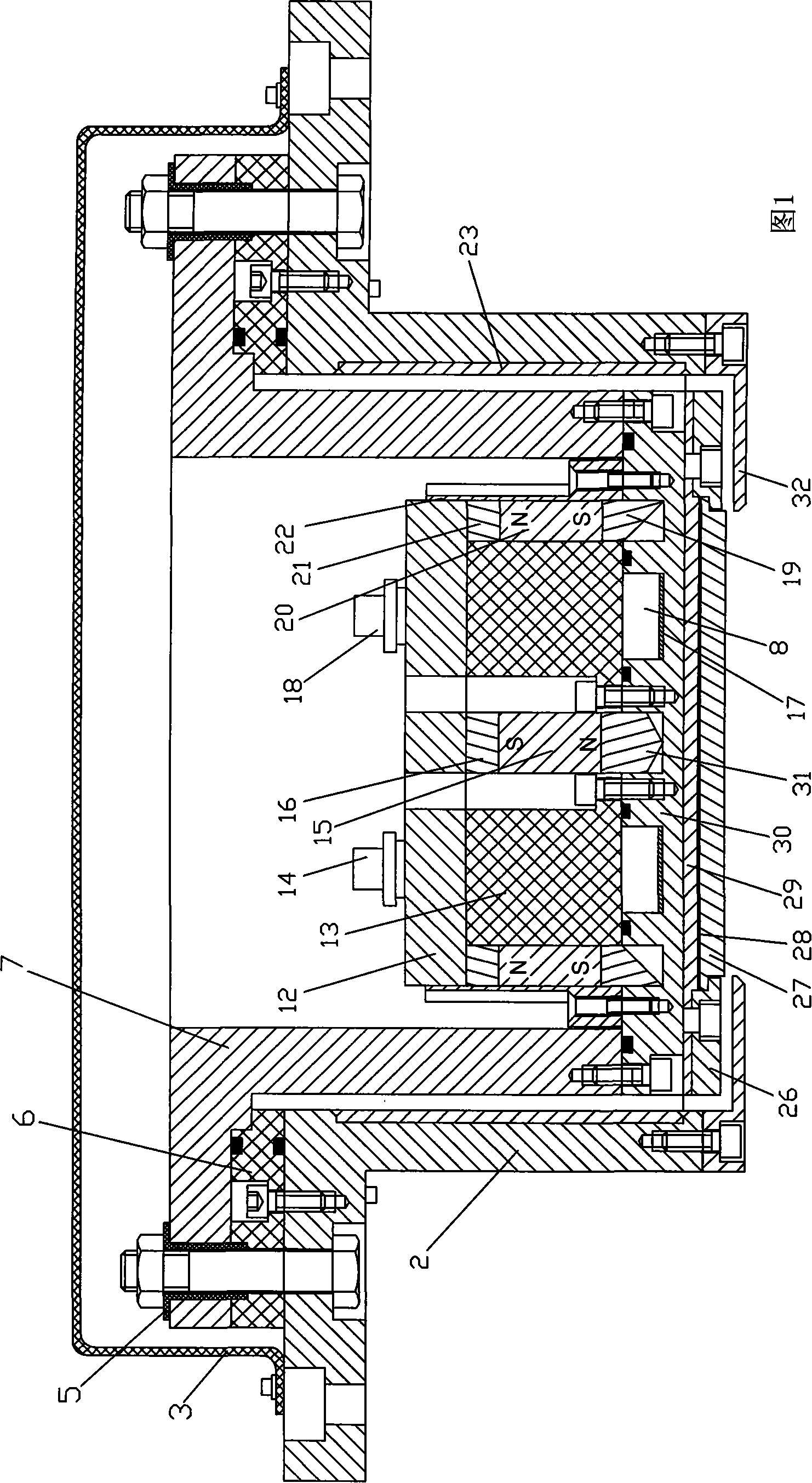

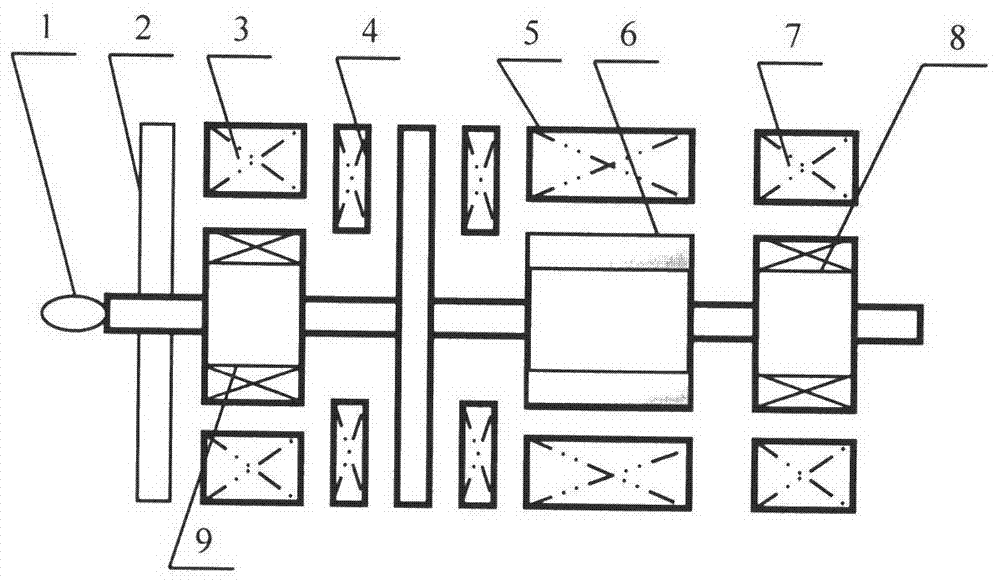

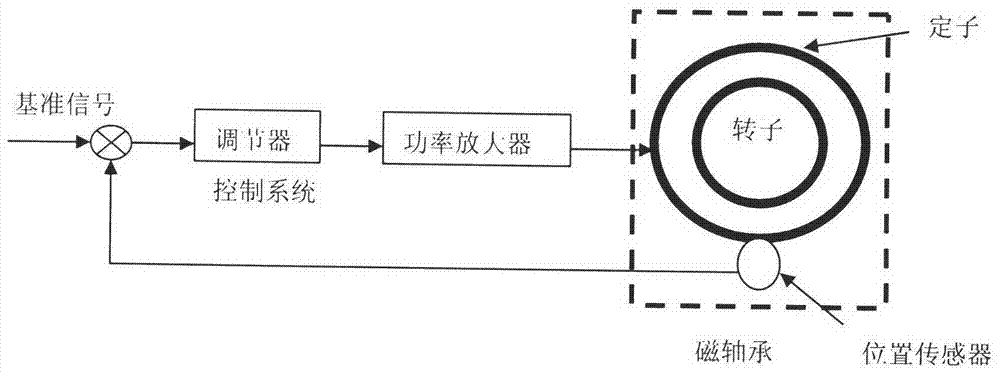

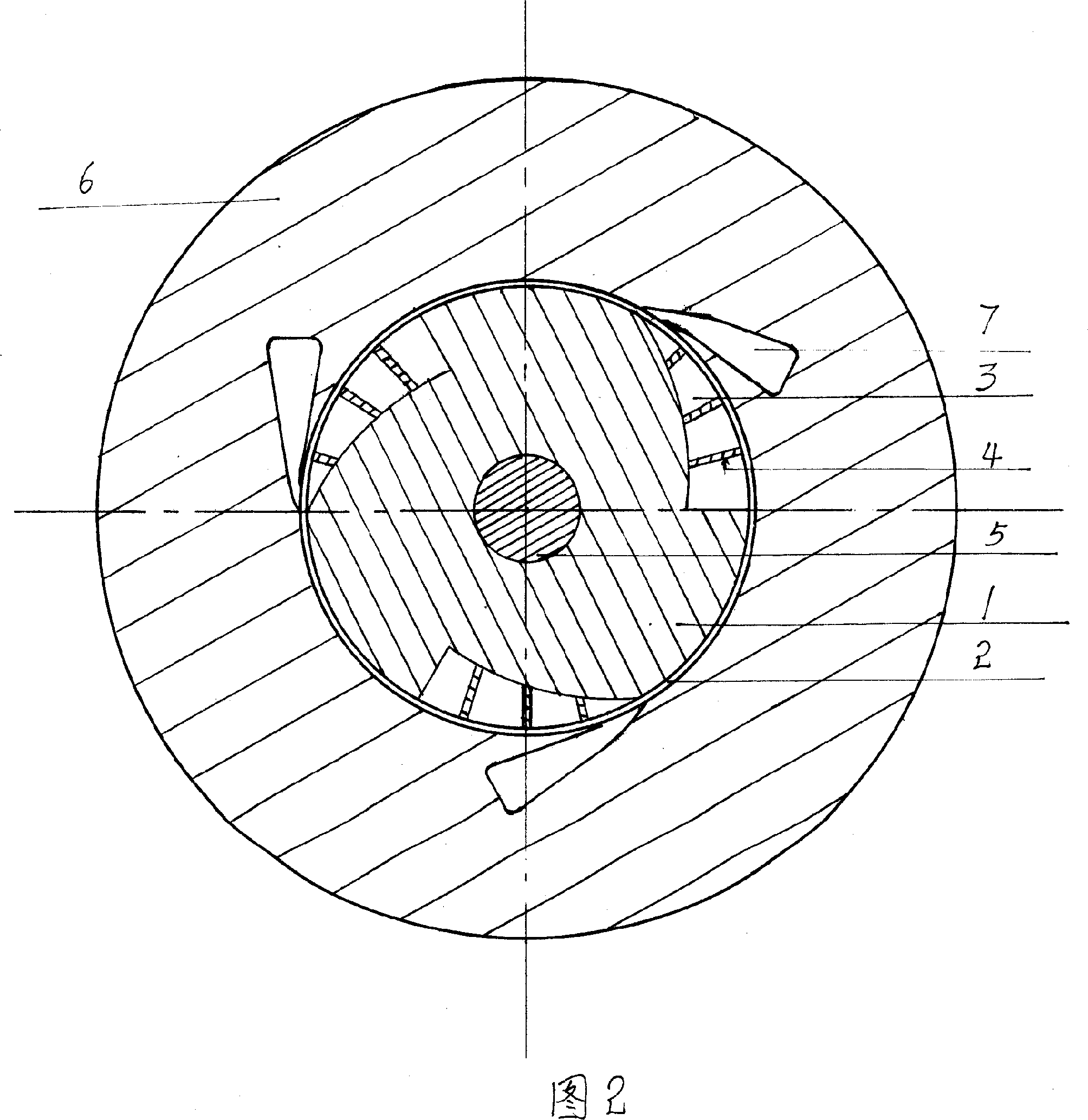

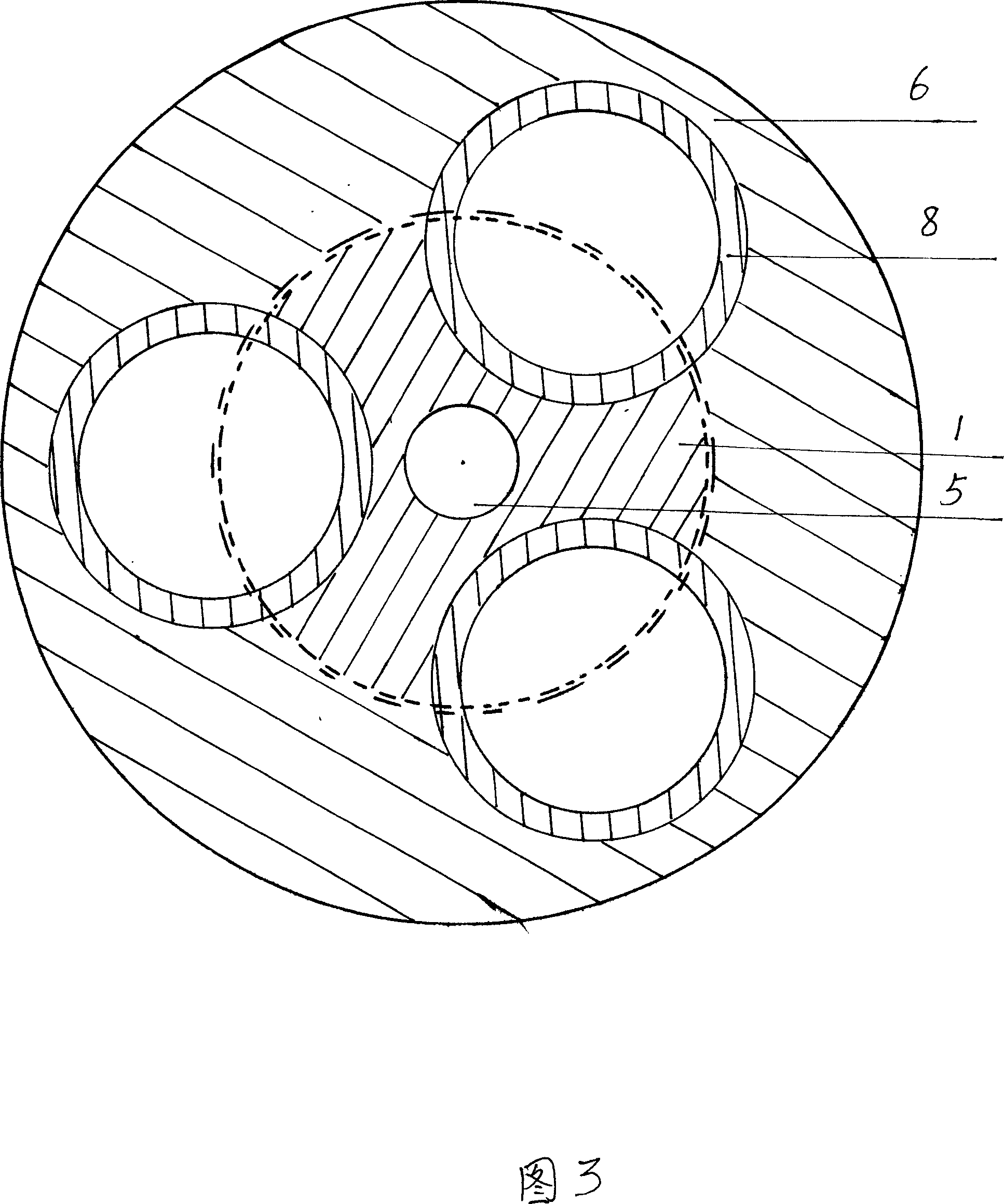

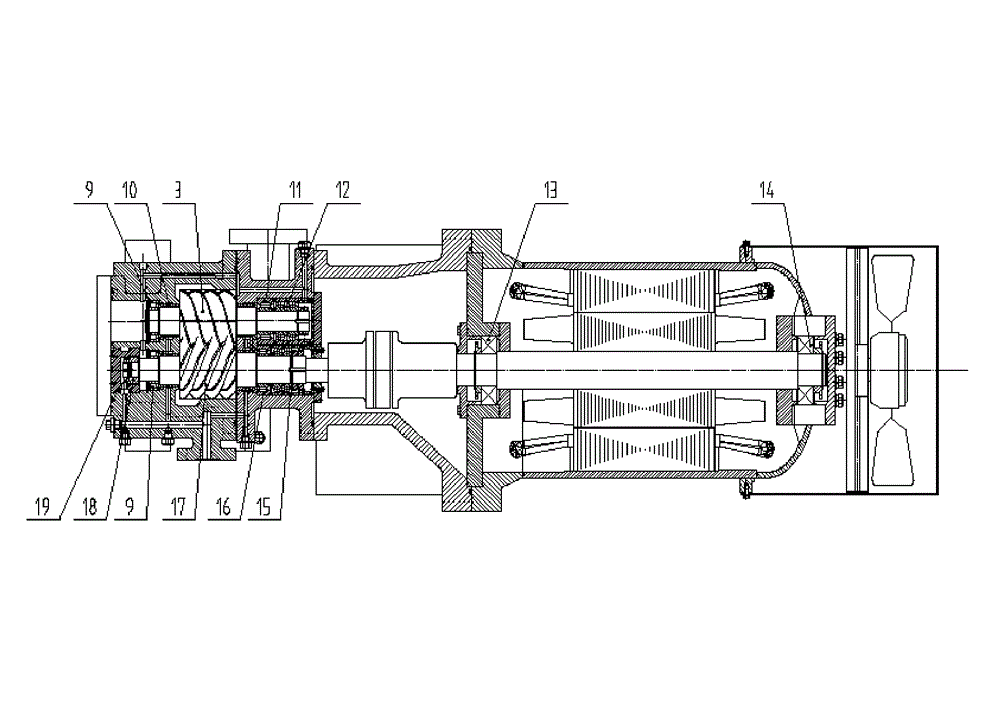

Active electromagnetic bearing impeller pump

InactiveCN104514726AOvercoming wear and tearOvercome tightnessPump componentsPump installationsCorrosion resistantImpeller

The invention discloses an active electromagnetic bearing impeller pump. The active electromagnetic bearing impeller pump is mainly composed of a radial direction electromagnetic bearing rotor, a stator, a thrust bearing, a sensor and a bracket thereof, an impeller and a pump shell. The bearing seat and the impeller are made as an integrated body, the impeller (rotor) of the pump is embedded with the soft magnetic material (magnetic steel and the like) with good permeability, the pump shell (stator) is provided with a coil, which is connected with the electric current for generating the rotating magnetic field, driving the impeller for rotating and realizing the action of the pump. Another magnetic bearing (in radial direction and axial direction) is used for rotating and locating the main shaft and stopping the displacement in radial direction and axial direction. The rotor is soaked in the medium for rotating; the surface contacting the fluid is covered by the corrosion-resistant material, so that the pump has no sealing element of any type inside. The active electromagnetic bearing impeller pump is simple in function, the defect of the common impeller pump, which is easily worn and required to be sealed can be greatly overcome and the active electromagnetic bearing impeller pump has good application prospect.

Owner:SHAZHOU PROFESSIONAL INST OF TECH

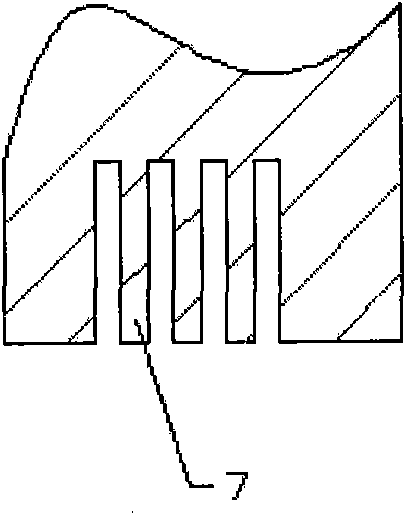

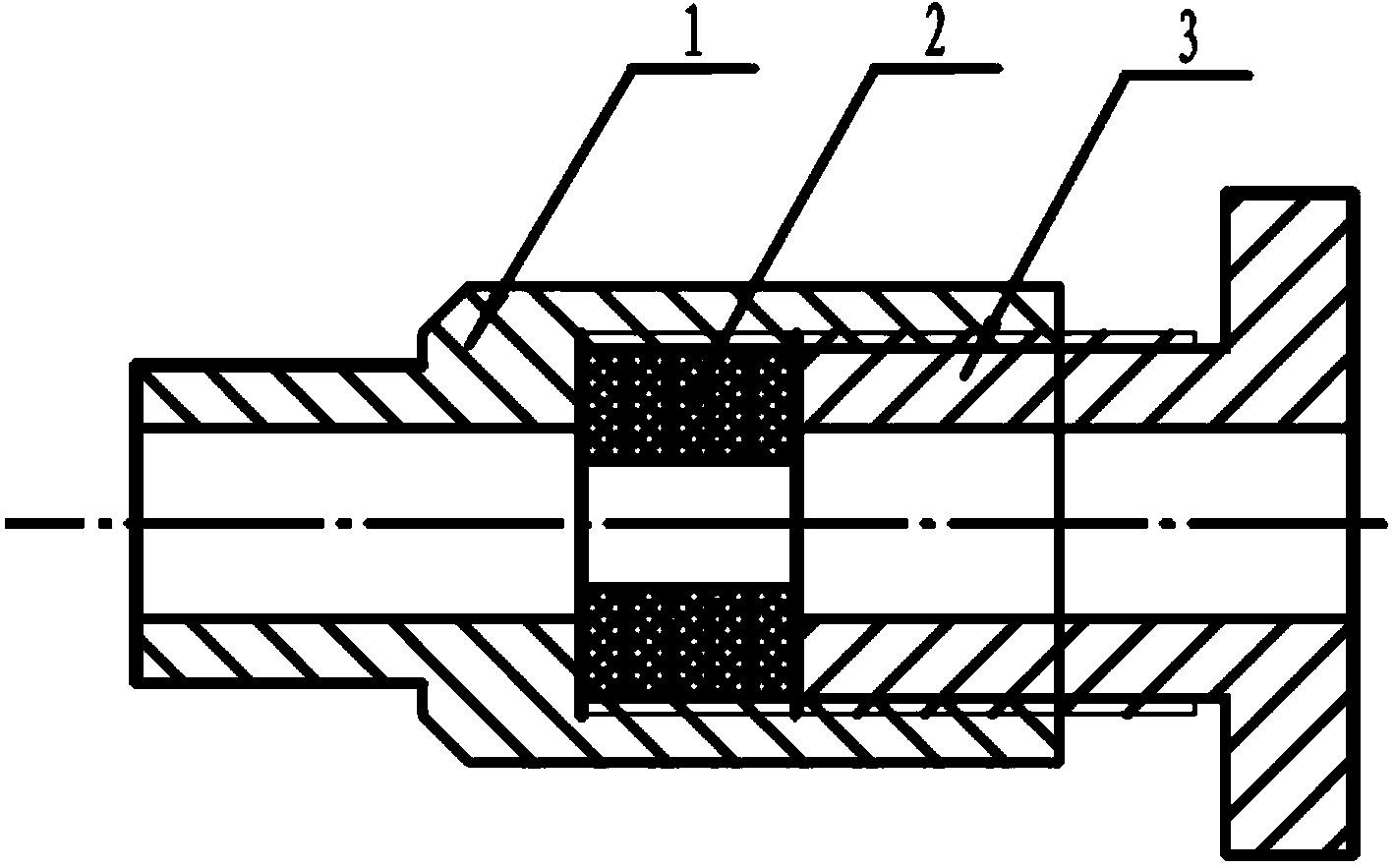

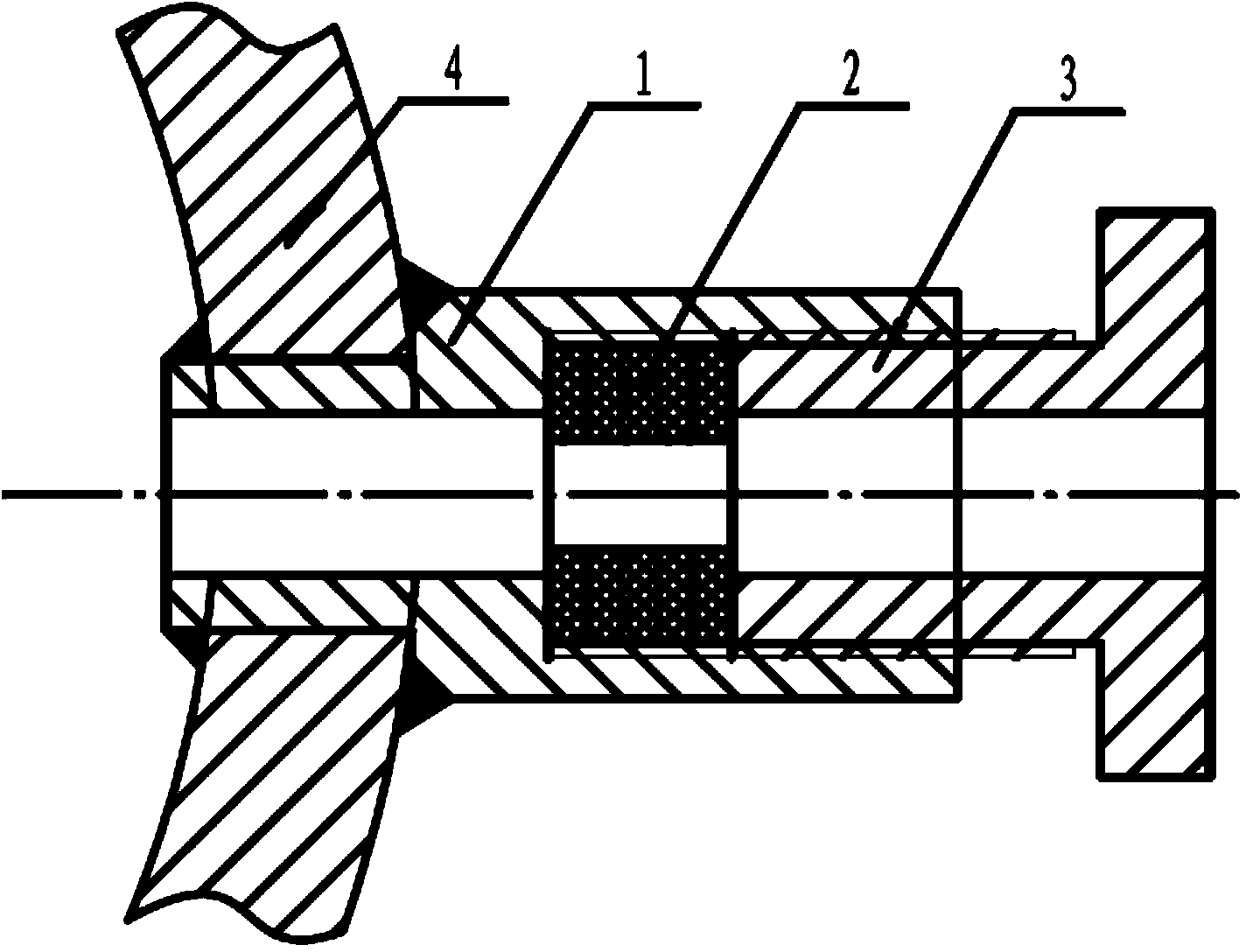

Labyrinth and fingertip combined type seal structure

The invention provides an improved labyrinth and fingertip combined type seal structure which adopts a fingertip seal and a fingertip seal front baffle plate as main bodies, wherein the fingertip sealfront baffle plate is improved into a labyrinth seal structure, the fingertip seal comprises two high-pressure seal grade fingertip pieces and a low-pressure seal grade fingertip piece with a fingertip shoe, arc-shaped gaps are arranged on the fingertip pieces, the three fingertip pieces are fixed together, the front baffle plate is arranged in front of the high-pressure seal grade fingertip pieces, a rear baffle plate is arranged at the rear of the low-pressure seal grade fingertip piece with a fingertip shoe, and the labyrinth seal is a seal tooth which is inlaid in the front baffle plate.The labyrinth and fingertip combined type seal structure is used for axially sealing a mechanical rotor of an impeller and can effectively prevent the axial gas leakage of an engine; and if the direction of the seal tooth is changed, the labyrinth and fingertip combined type seal structure can be used for sealing holes.

Owner:HARBIN ENG UNIV

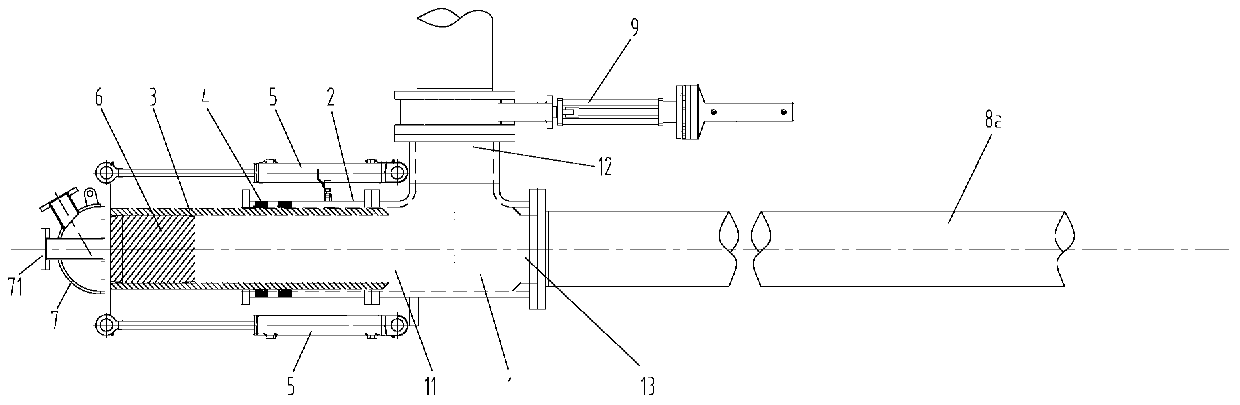

Shield machine pipe extension device and connecting method for slurry pipeline in tunnel

ActiveCN110145324AGuaranteed not to leakPrevent leakageTunnelsArchitectural engineeringSlurry pipeline

The invention discloses a shield machine pipe extension device and a connection method for a slurry pipeline in a tunnel. The device comprises a three-way pipe with a first port, an outer sleeve pipewith one end connected with the first port, a telescopic pipe with one end telescopically inserted and stretches into the three-way pipe from the other end of the outer sleeve pipe, a sealing elementarranged between the telescopic pipe and the outer sleeve pipe, a driving device for driving the telescopic pipe to move and a blocking ball capable of entering or disengaging from the telescopic pipeunder the effect of pressure. The three-way pipe is further provided with a second port which is connected with the slurry pipeline of a shield machine in a blocking manner, and a third port which isconnected with the slurry pipeline in the tunnel in a disengaging manner. According to the shield machine pipe extension device and the connection method for the slurry pipeline in the tunnel, slurrydoes not need to be transported backwards, the mechanism is simple, the economy is good, and operation and maintenance are convenient.

Owner:TIANHE MECHANICAL EQUIP MFG

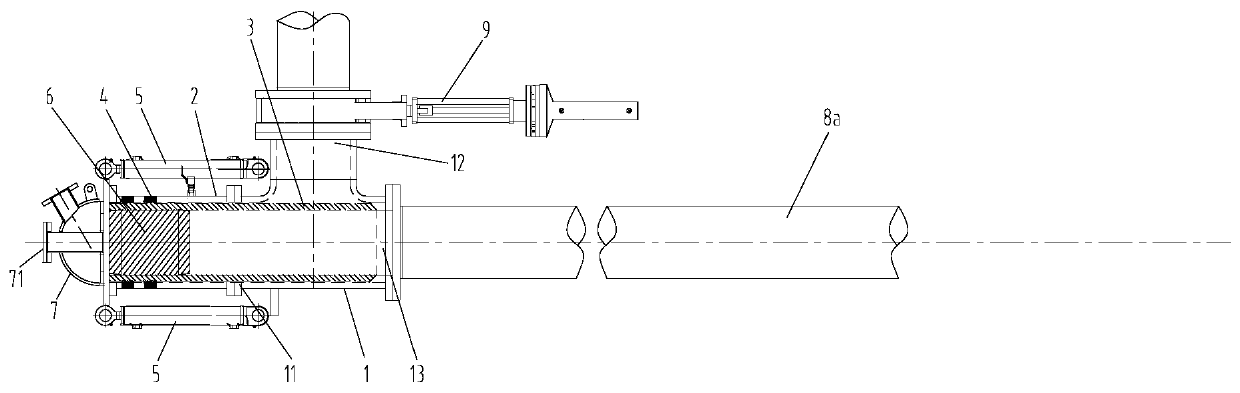

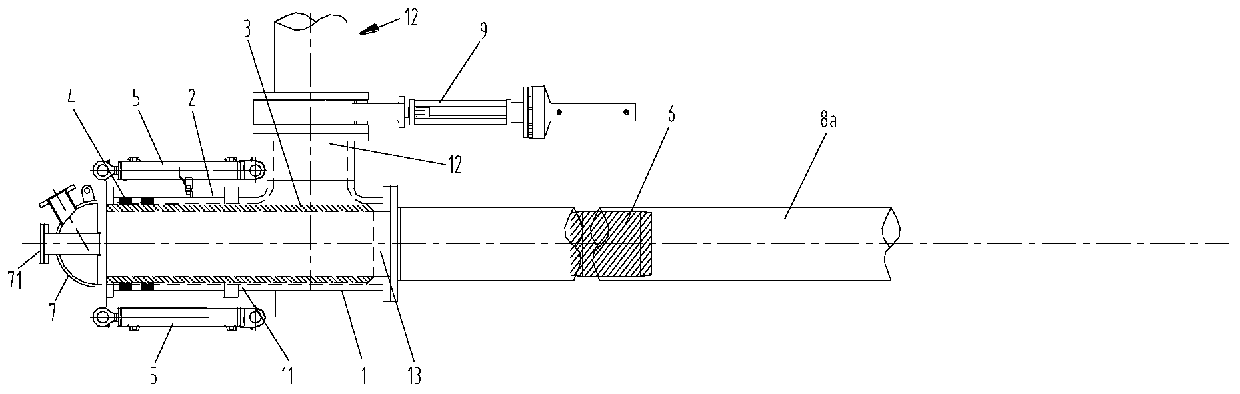

Bending forming method for small bending radius tube

ActiveCN110064689ASolve the problem of low forming limitRaise the forming limitPower flowSolid particle

The invention discloses a bending forming method for a small bending radius tube. The method comprises the following steps that S1, a tube blank is filled with a solid particle medium; S2, the tube blank is put into a forming die and sealed; S3, current is applied to the tube blank, and electrifying is stopped after the temperature of the tube blank reaches an experiment required temperature; S4,the right end of the tube blank is driven to move inwards in the axial direction, the left side of the tube blank is driven to move in a tangential direction, shear-bending deformation of the tube blank occurs, and the left end of the tube blank is driven to move inwards in the axial direction; S5, when the forming size of the tube blank reaches a set value, feeding is stopped, and a formed tube is obtained; and S6, a punch is reset, the forming die is opened, the formed tube is taken out, the solid particle medium in the tube blank is removed, and the small bending radius tube is obtained. The problem of low forming limit in existing tube bending forming technologies at normal temperature can be solved, and the obtained formed tube has the characteristics such as small bending radius, high forming precision and excellent shaping performance.

Owner:HARBIN INST OF TECH

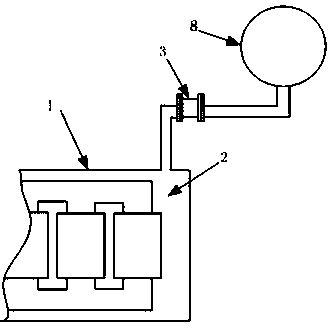

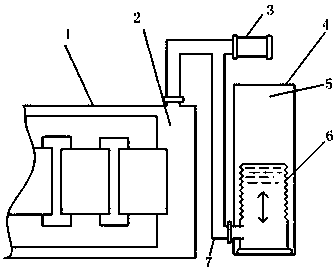

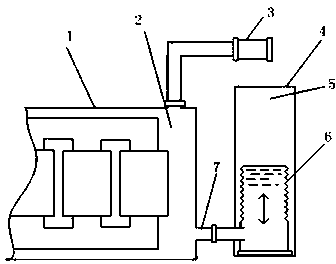

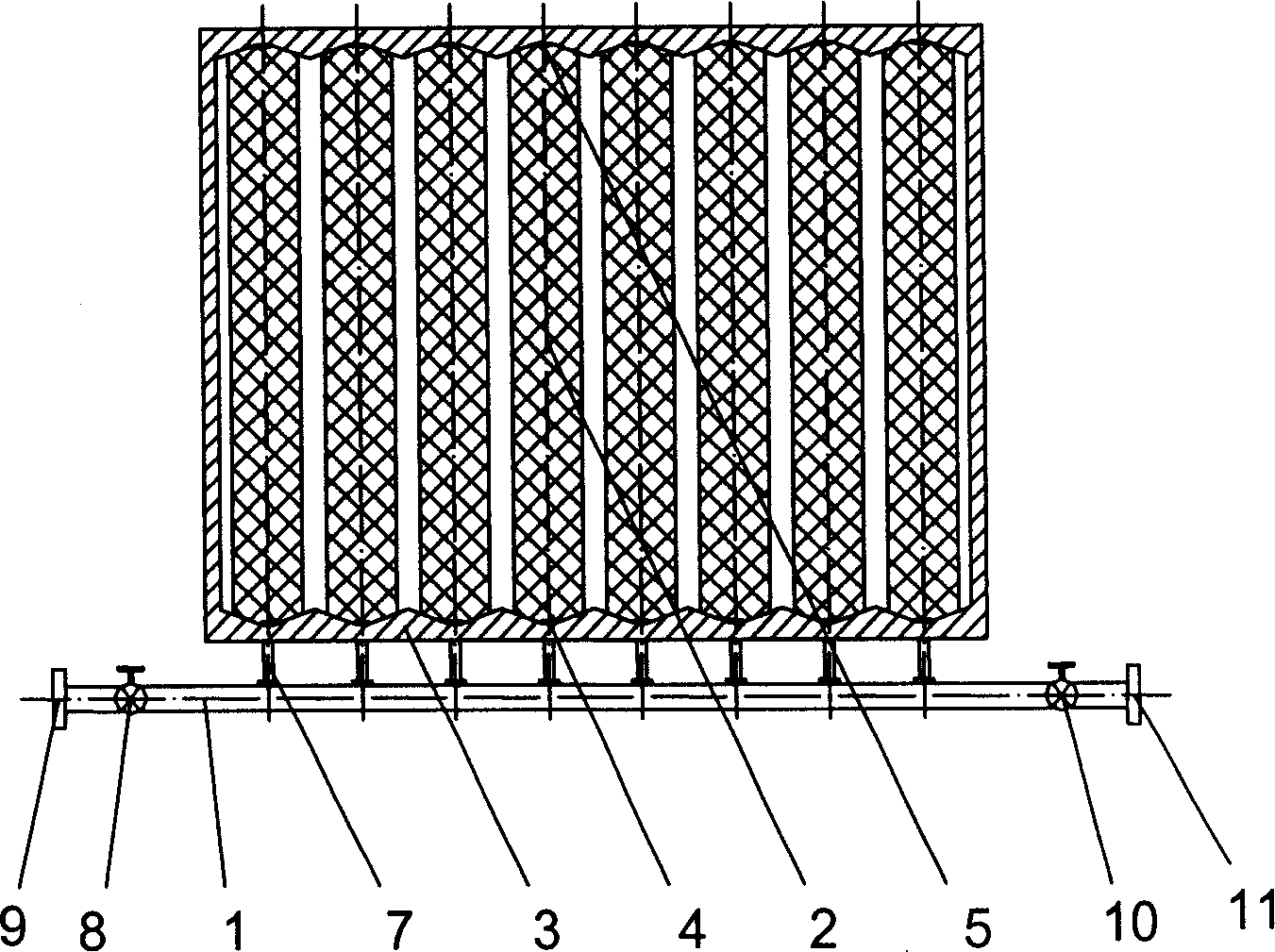

Insulating oil volume compensation device system for oil immersed electrical device

InactiveCN103971886ASimplify the external structureImprove reliabilityTransformers/inductances coolingThermodynamicsElectric power equipment

The invention discloses an insulating oil volume compensation device system for an oil immersed electrical device. The insulating oil volume compensation device system comprises an electrical device body filled with insulating oil. An oil volume compensation device is arranged in a low position on the side face of the electrical device and connected with the electrical device through an oil way system. The oil volume compensation device is a volume expansion heat dissipation device. An insulating oil inlet and an insulating oil outlet which are communicated with the oil way system are formed in the volume expansion heat dissipation device. The oil volume compensation device is composed of a plurality of elastic elements and a shell arranged outside the elastic elements. According to the insulating oil volume compensation device system for the oil immersed electrical device, the external structure of the electrical device is greatly simplified, and space is saved; real fuel tank tight welding and sealing can be achieved for the electrical device, and therefore a user does not need to maintain the electrical device, reliability of the electrical device is improved, and manufacturing cost and maintenance cost are saved.

Owner:苏州翰为电气科技有限公司

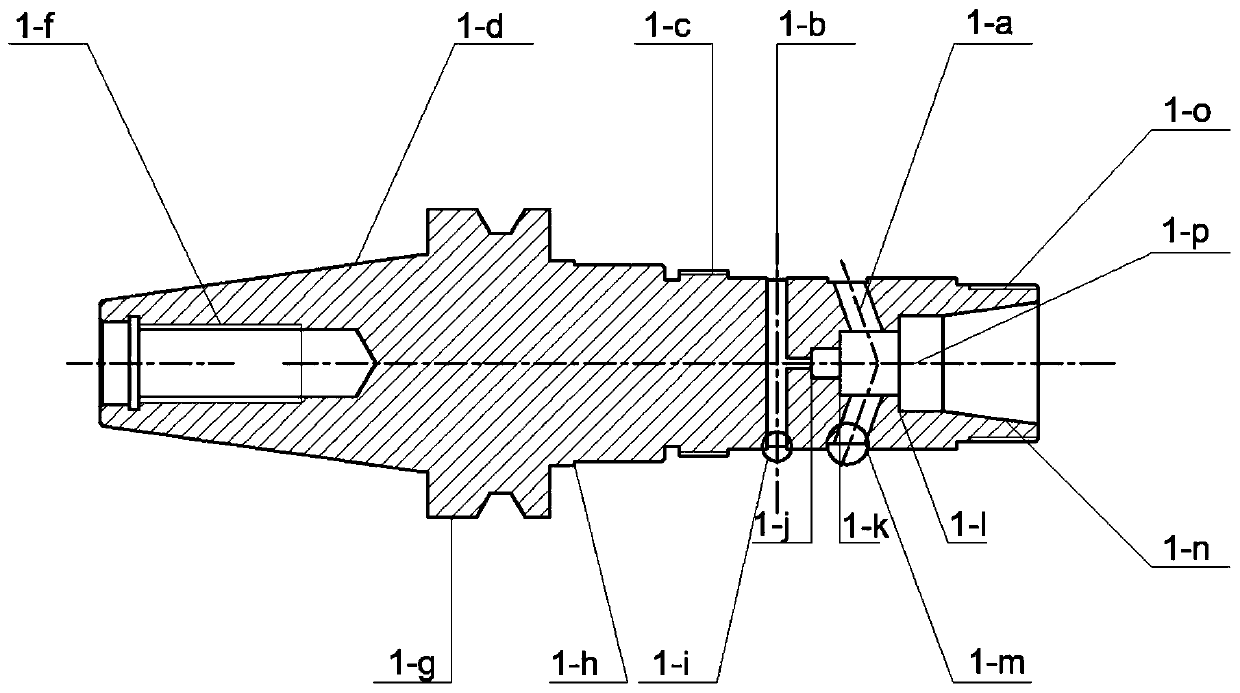

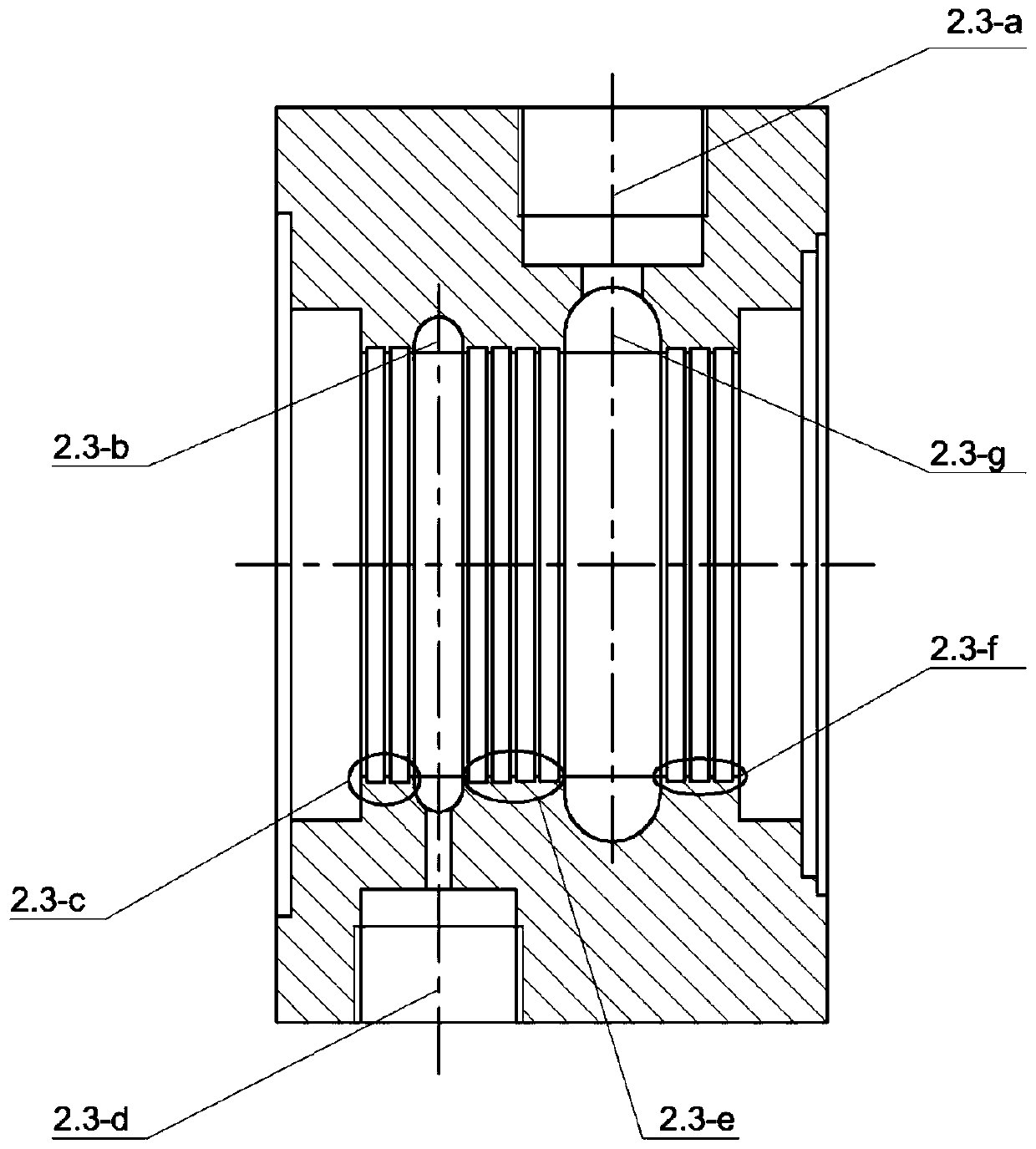

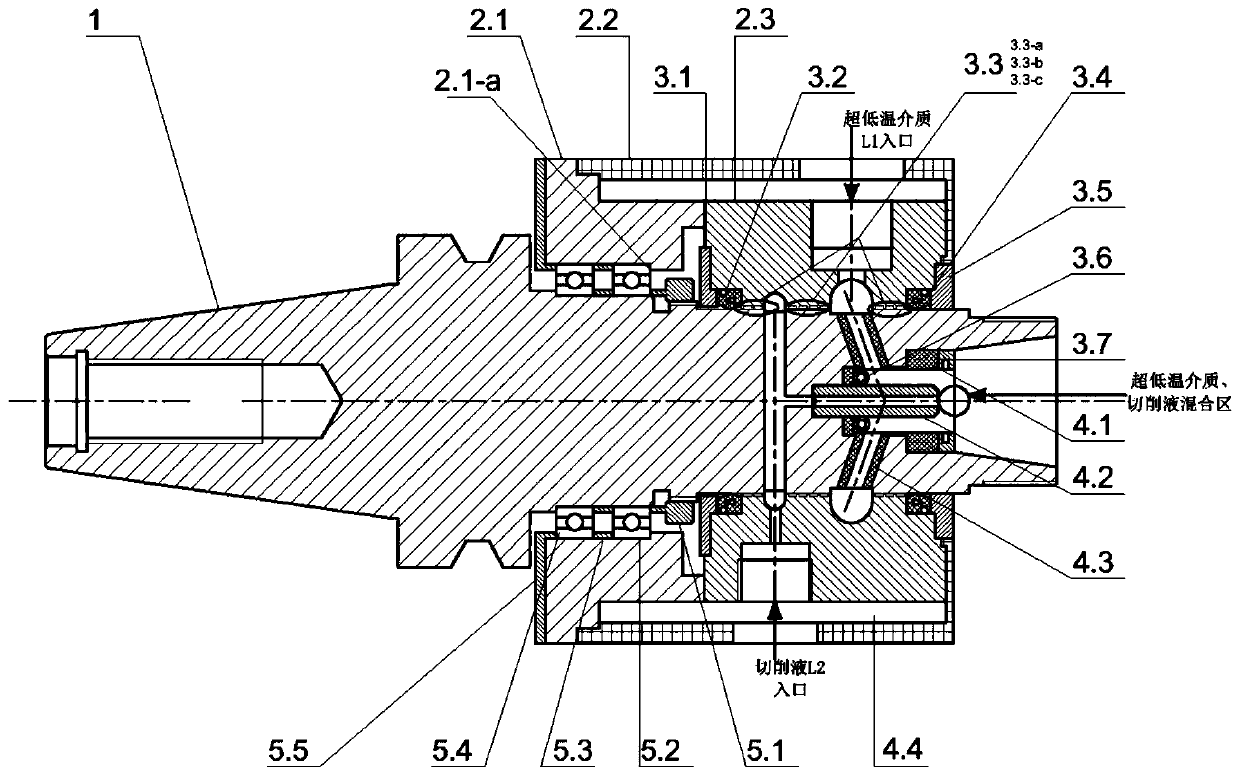

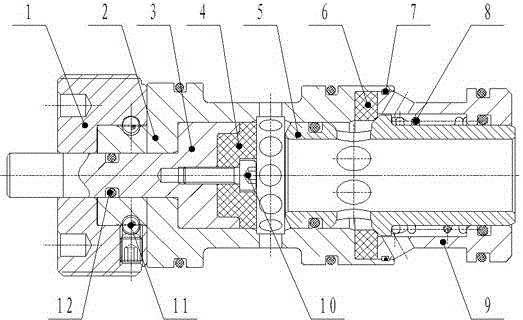

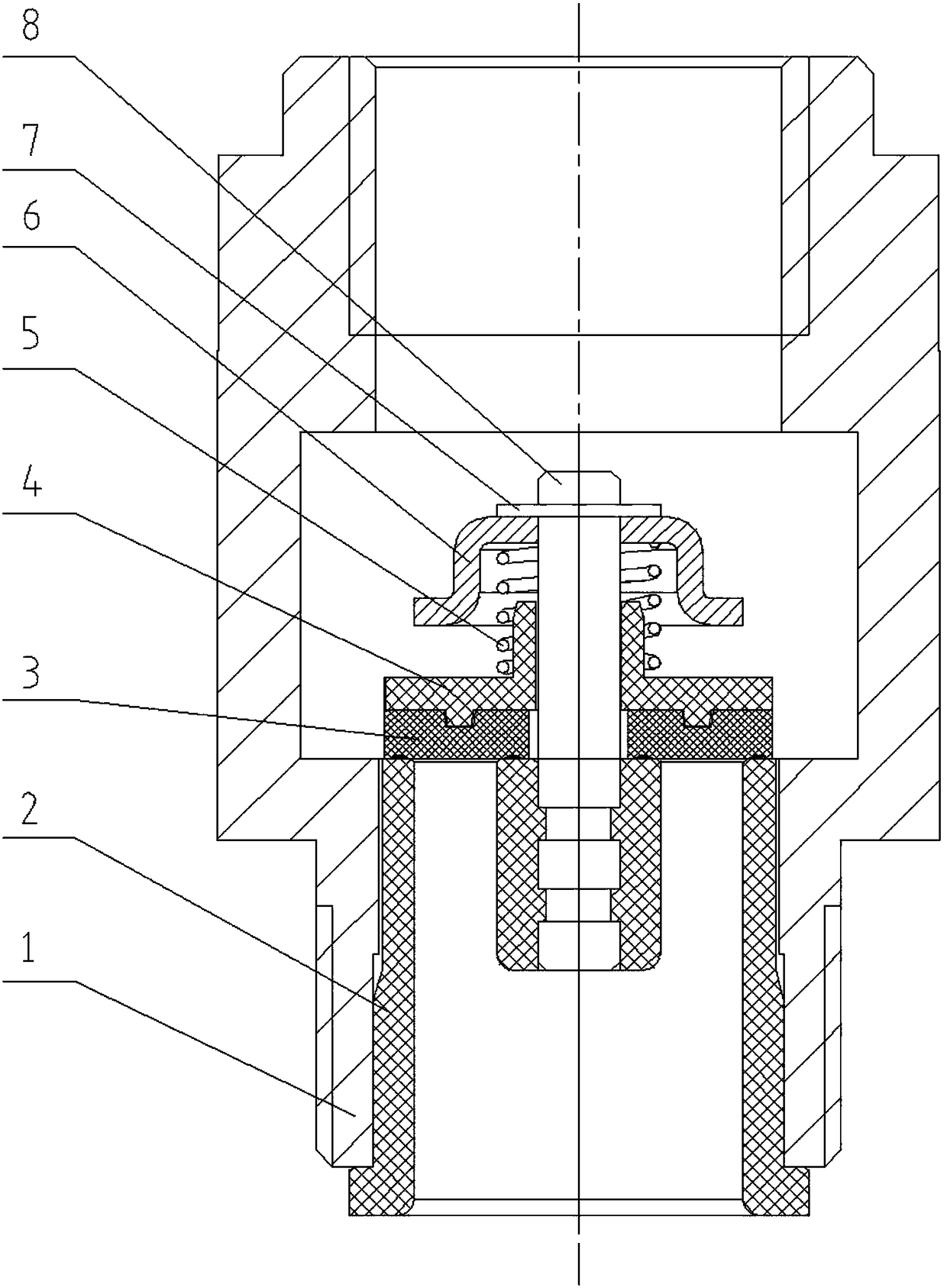

Knife handle suitable for low-temperature minimal quantity lubrication

ActiveCN110883591ASolve problems not suitable for low temperature MQL cuttingOvercome tightnessMilling cuttersAdverse effect compensationNumerical controlCooling effect

The invention provides a knife handle suitable for low-temperature minimal quantity lubrication, and belongs to the technical field of cooling and lubrication of numerical control machine tools. The knife handle comprises a knife handle body, a peripheral static structure, a multi-layer sealing structure, a heat insulation structure and a bearing supporting structure. The problems that in the minimal quantity lubrication technology, the cooling performance is insufficient, and lubrication is insufficient in the low-temperature cooling machining technology are solved, the oxygen isolation protection effect of an ultralow-temperature medium, the cooling effect of the ultralow-temperature medium and the anti-attrition lubrication effect of minimal quantity lubrication are integrated, and therefore a good machining effect is achieved on the aspect of materials difficult to machine. The knife handle can be used for machining the materials difficult to machine through a traditional numericalcontrol machine tool, the application range of an outer rotating inner knife handle is widened, the cutting heat of the materials difficult to machine in the cutting machining process is effectivelyreduced, the service life of a knife is prolonged, traditional cutting fluid is replaced, and green manufacturing is achieved.

Owner:DALIAN UNIV OF TECH

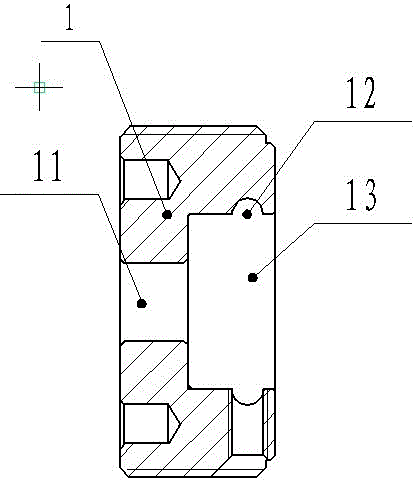

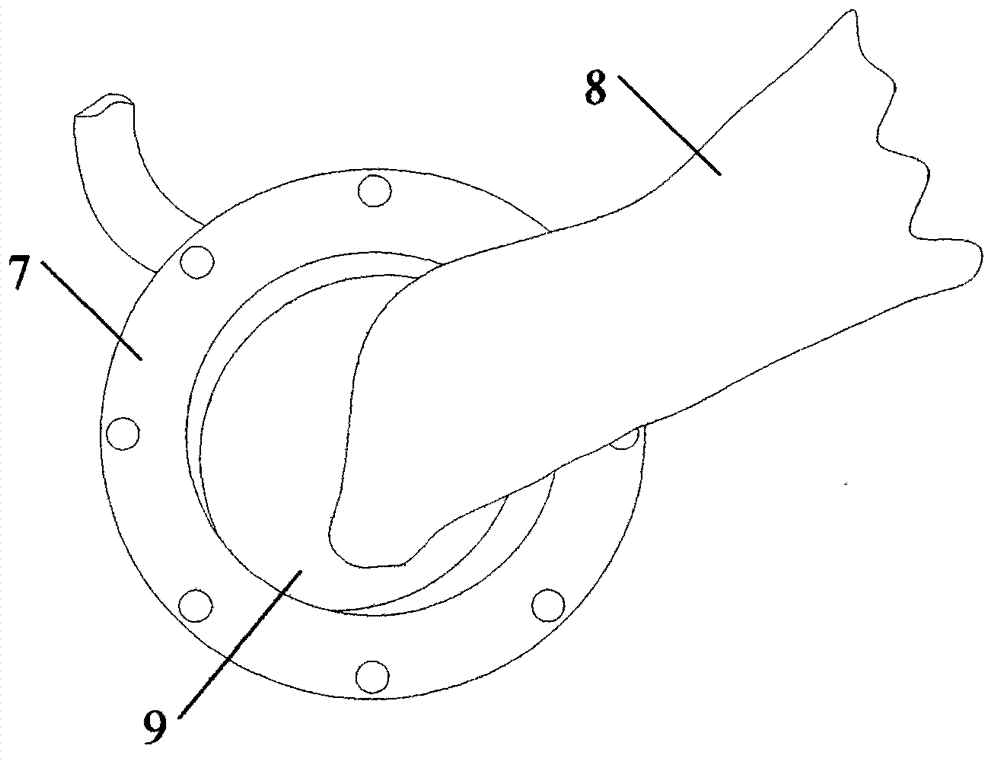

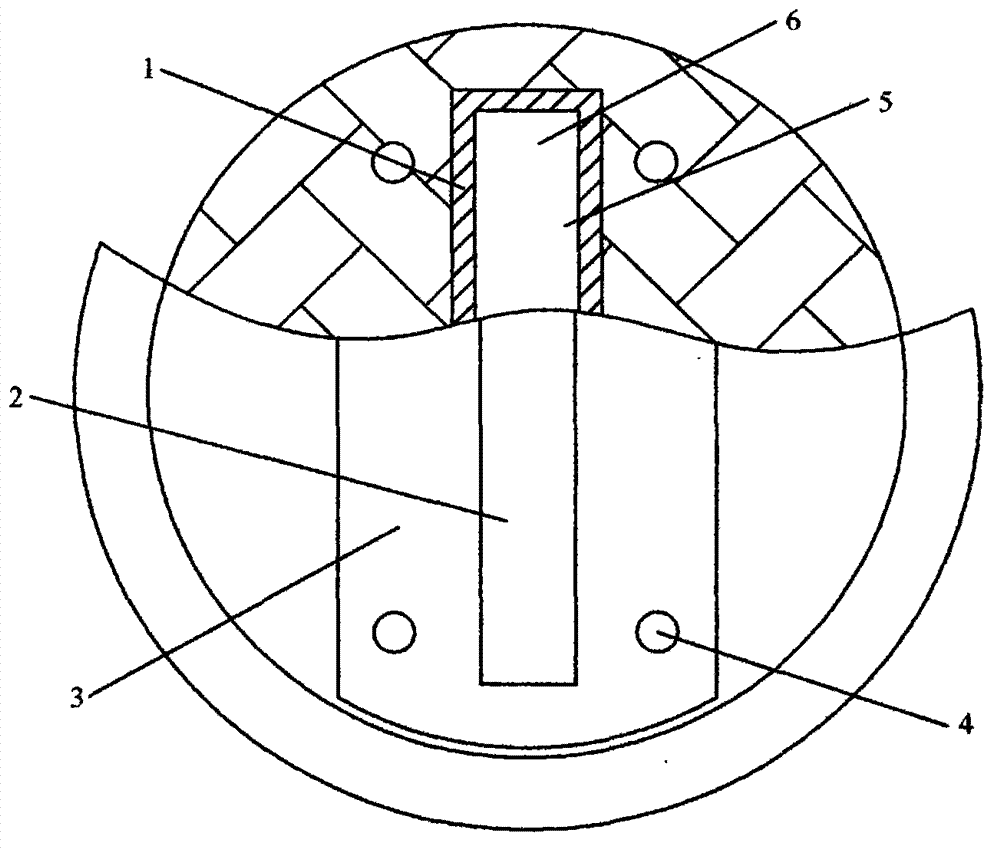

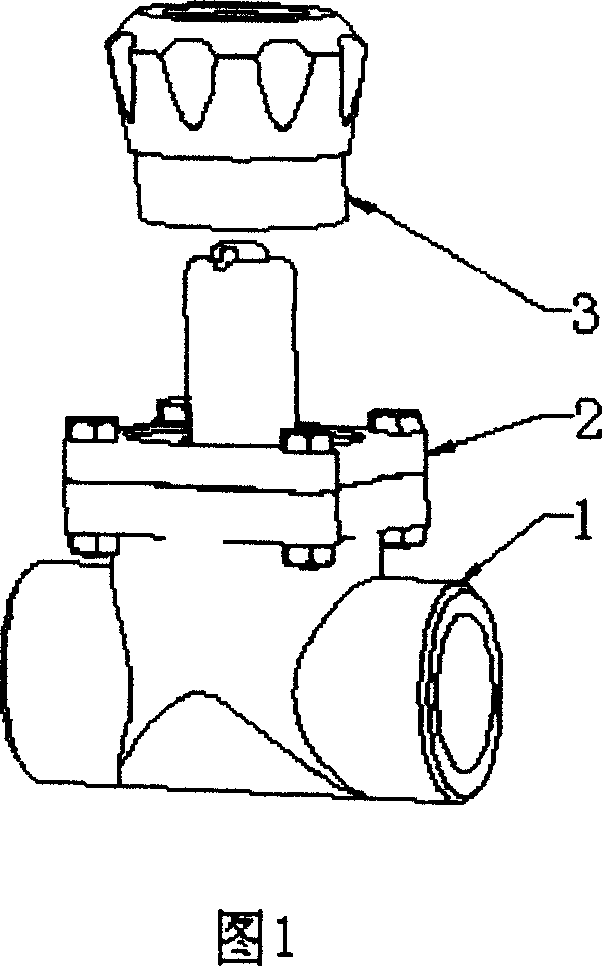

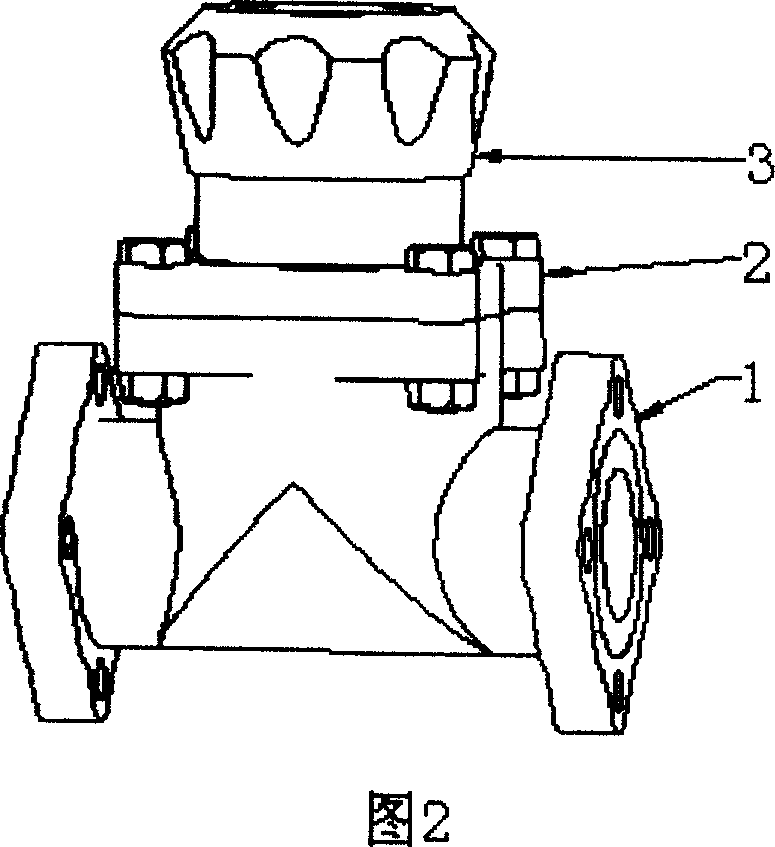

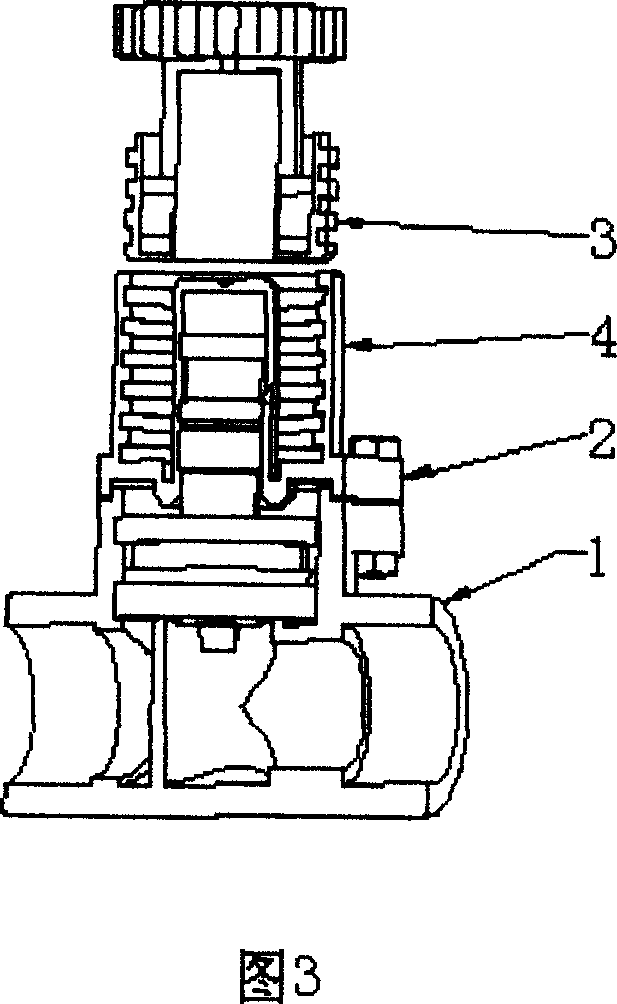

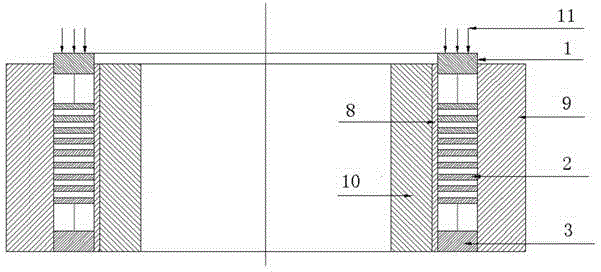

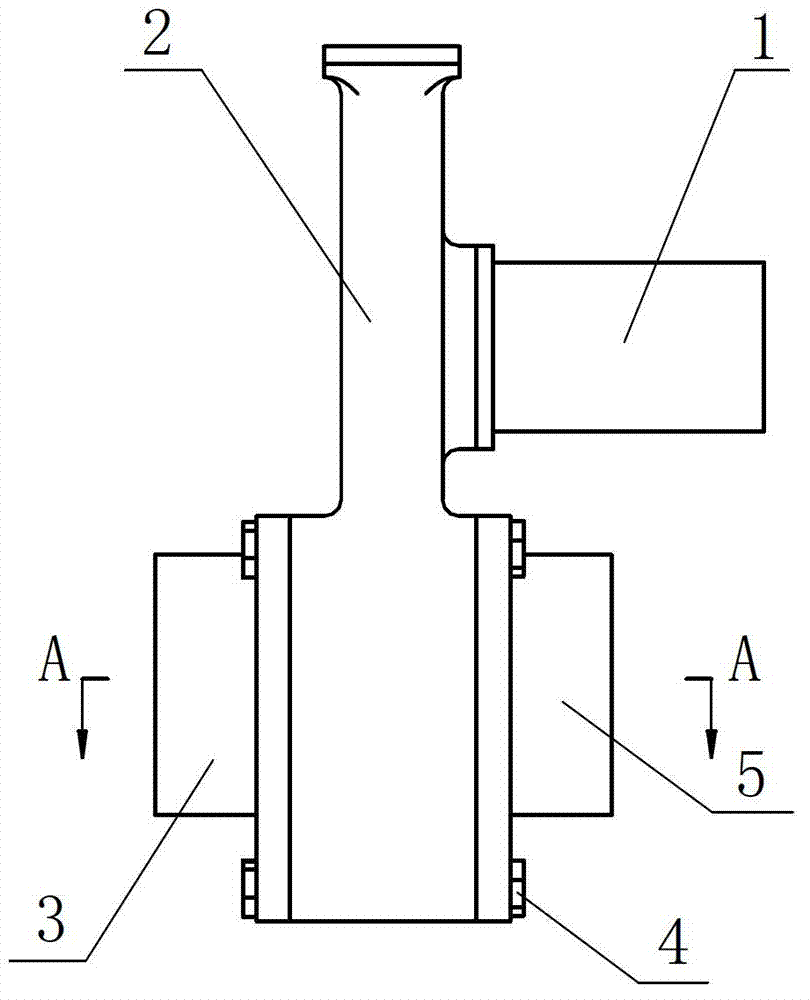

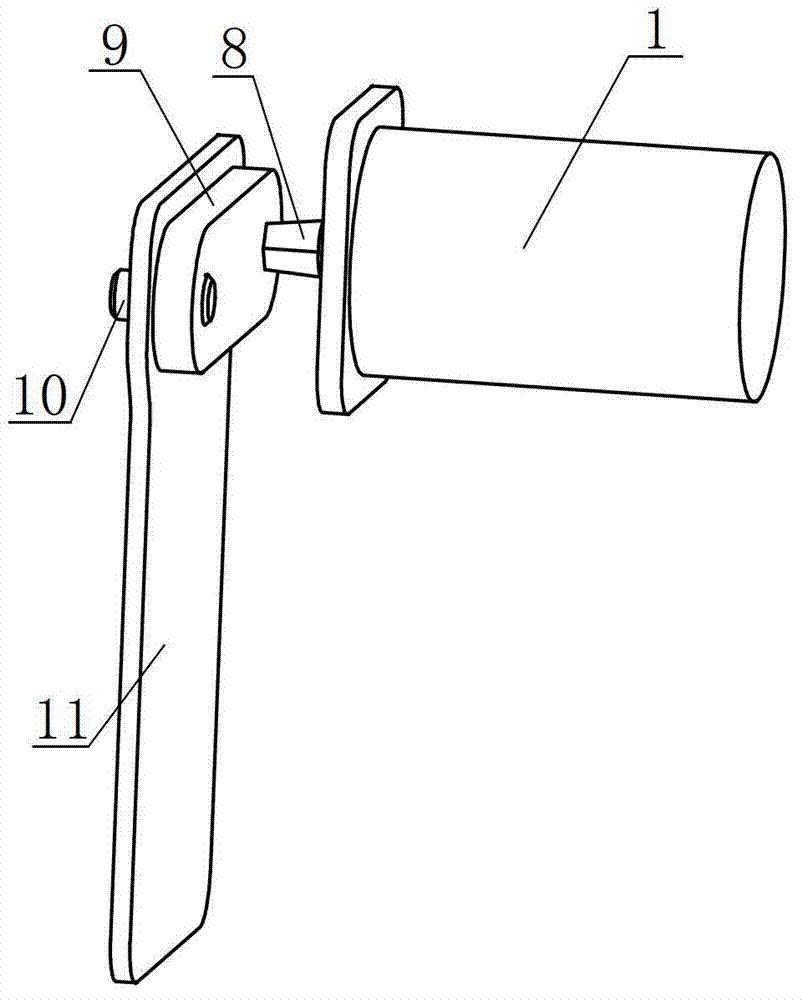

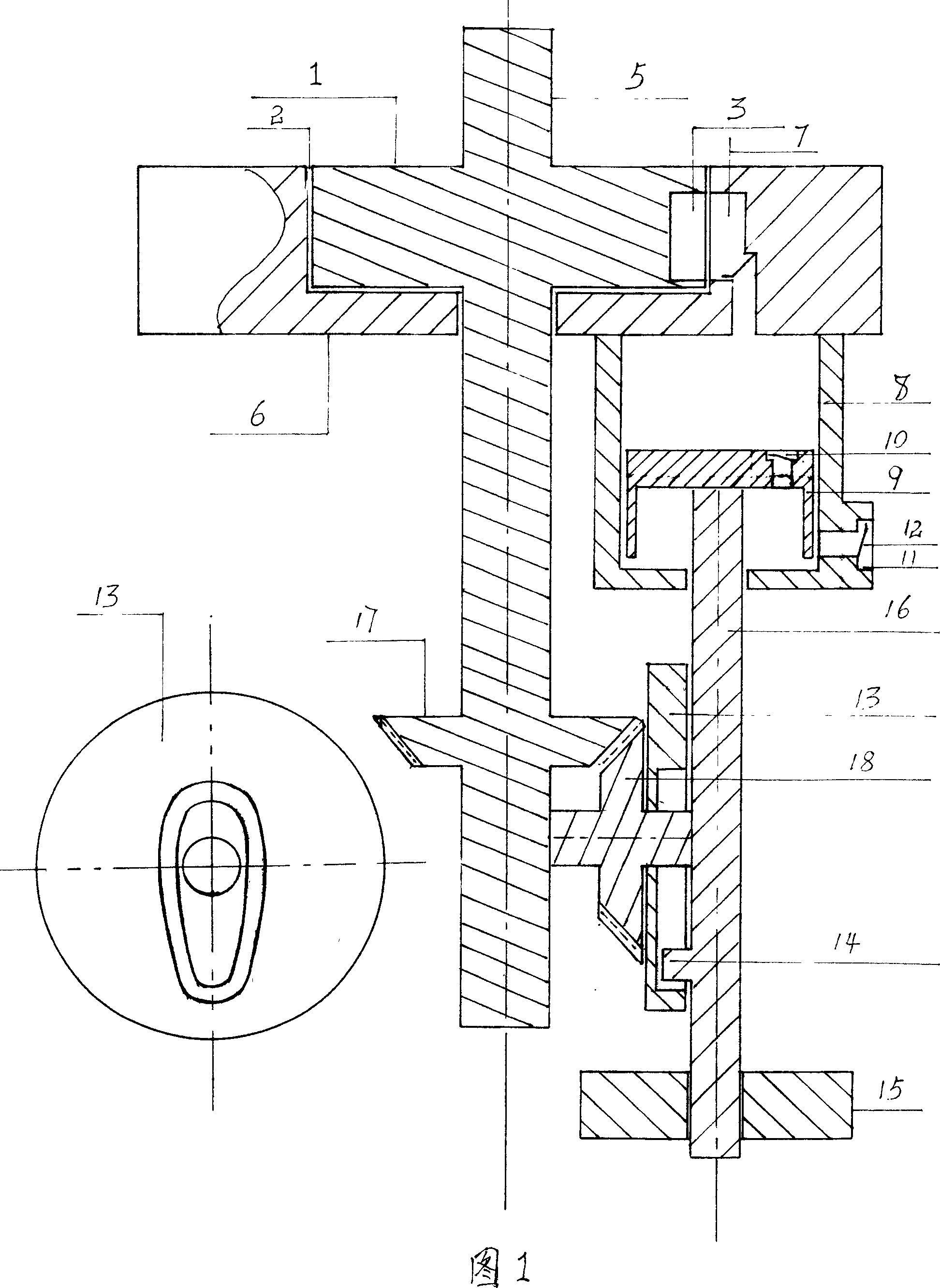

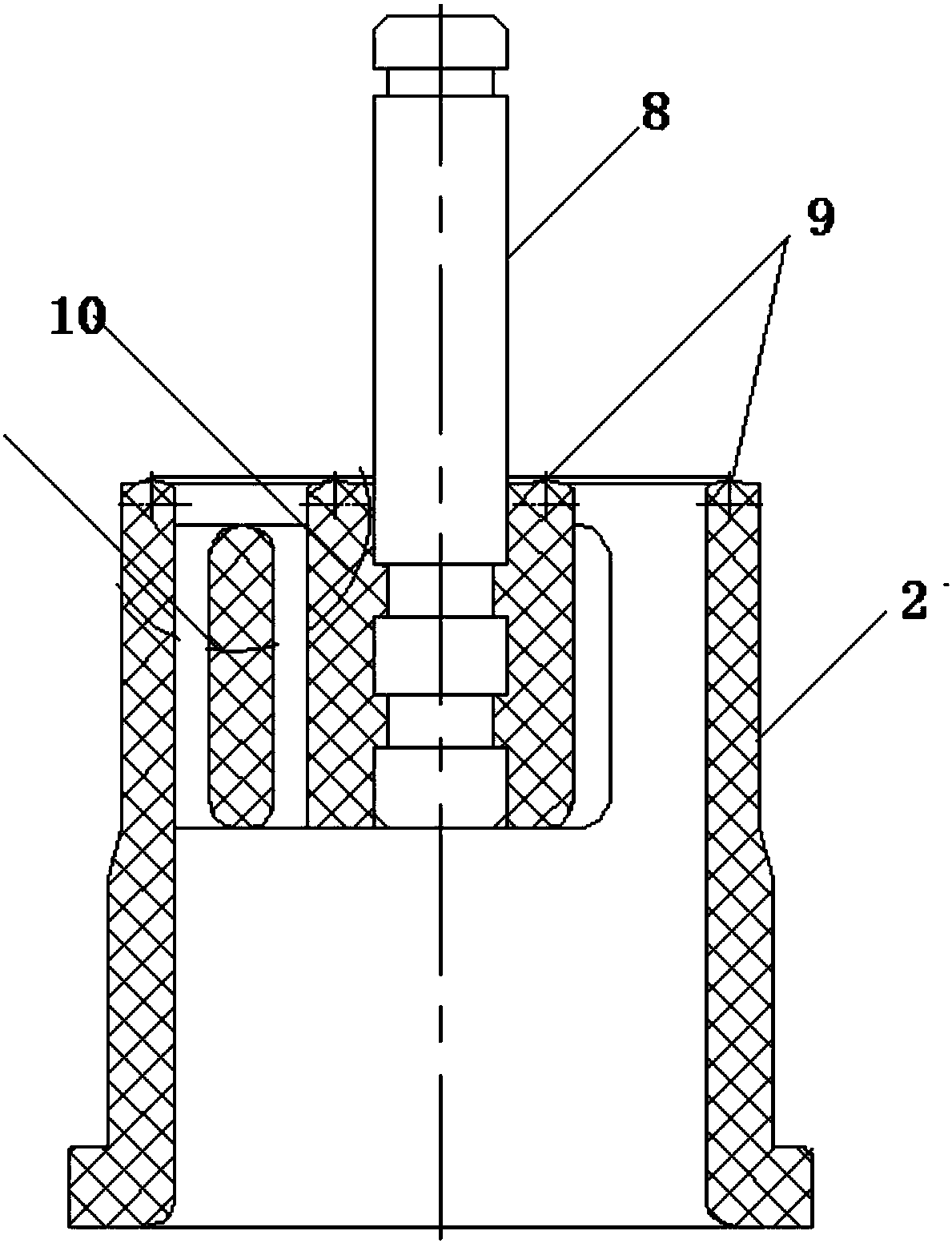

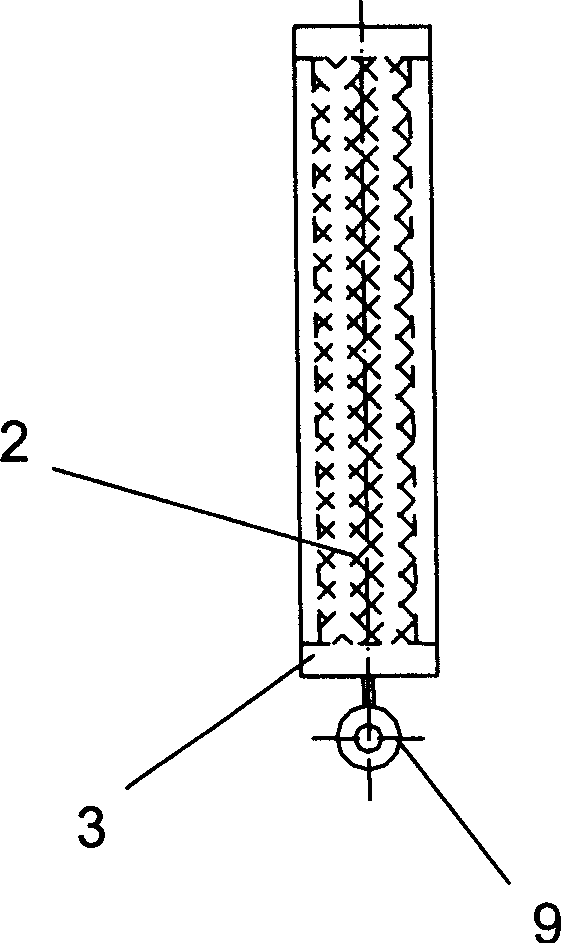

Integral plug-in valve core assembly for hand-operated direction valve

InactiveCN103334776AEasy to replaceEasy maintenanceMine roof supportsProps/chocksSteel ballEngineering

The invention relates to an integral plug-in valve core assembly for a hand-operated direction valve. A plug (1) consists of a left cavity (11), a right cavity (13) and a groove (12) along the circumference of the right cavity (13), which are communicated axially and sequentially; the plug (1) is rotationally connected with a valve bush (2) by a steel ball (11); the valve bush (2) is connected with a high-pressure valve bush (9) by a steel wire key (7); a valve seat (6) is arranged at a connecting part between the valve bush (2) and the high-pressure valve bush (9); the valve seat (6) and a valve core (5) form linear sealing; a spring (8) is mounted on the external circumference of the valve core (5) in a sleeving manner; a valve rod assembly and the valve core (5) are mounted on the left side and the right side of an inner cavity formed by the valve bush (2) and the high-pressure valve bush (9) respectively; and sealing rings (13) are mounted at the left ends of the valve rod assembly and the valve core (5) in a sleeving manner. The integral plug-in valve core assembly adopts floating integral plug-in valve design, is more compact in structure, smoother in liquid way, more reliable in sealability, and quick to assemble, and facilitates underground replacement and maintenance.

Owner:SHANXI PINGYANG GUANGRI ELECTROMECHANICAL

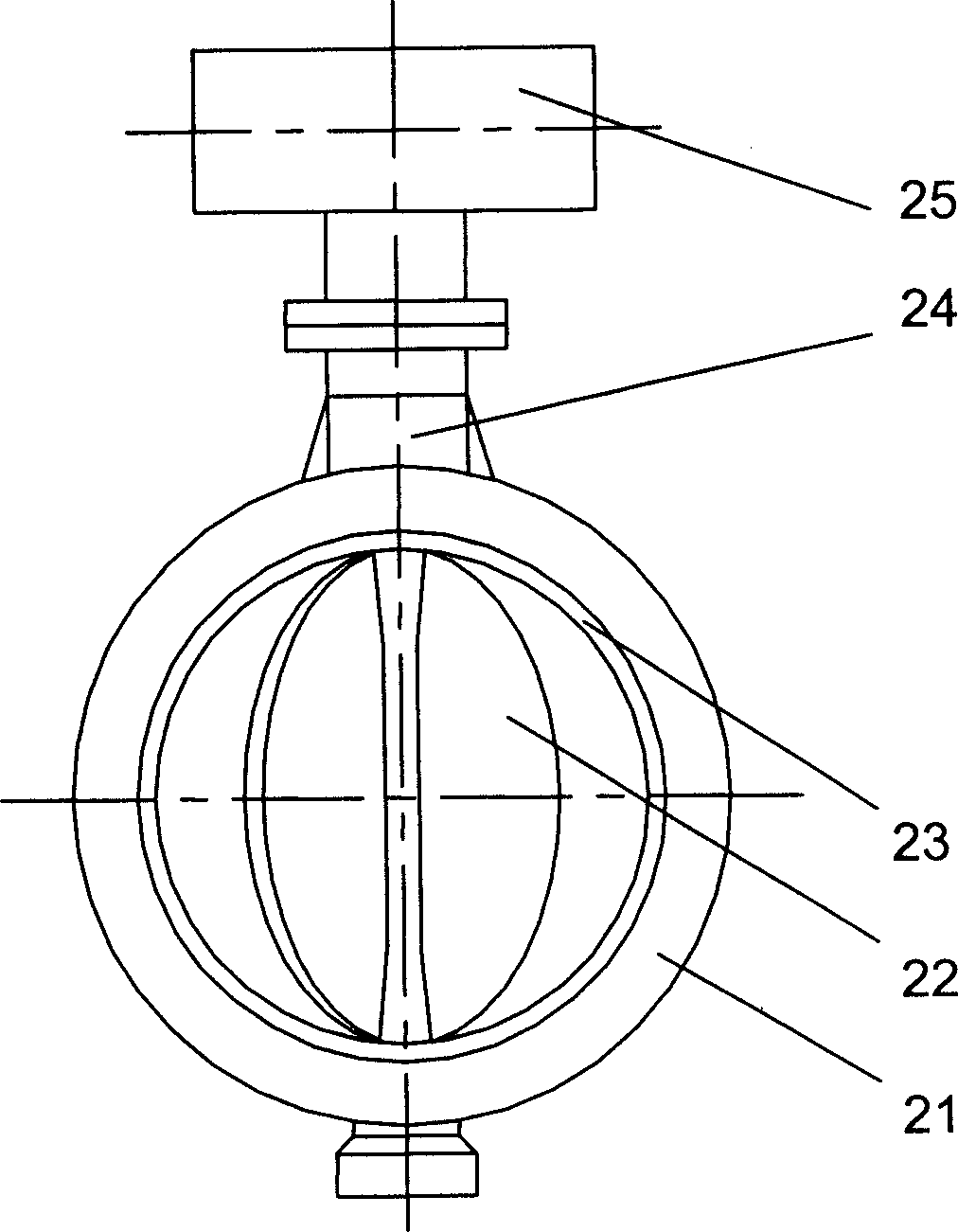

Novel pressurizing sealing ball valve

InactiveCN103352990AOvercome difficult to adjustOvercoming the difficulty of disassembly and assembly during maintenancePlug valvesCleaning using gasesTime alignmentEngineering

Provided is a novel pressurizing sealing ball valve. The novel pressurizing sealing ball valve is mainly characterized by comprising a sealing clearance aligning device, a valve core hemispheroid adjusting mechanism and a deposited dust clearing device. The sealing clearance aligning device is composed of a valve body, a sealing assembly, a tension bolt and a compression bolt and can directly align sealing clearances. The valve core hemispheroid adjusting mechanism is connected by a valve cover, an adjusting bolt, a locating shaft, a valve core hemispheroid and a snap spring and can adjust the moving positions of the valve core hemispheroid, and the deposited dust clearing device is connected with a high-pressure air source to directly clear deposited dust inside the valve body. The novel pressurizing sealing ball valve has the advantages of conveniently assembling, maintaining and replacing sealing rings, conducting real-time alignment on the sealing clearances, prolonging the service life of the sealing rings, and reducing production, maintenance and use cost of products.

Owner:QIDONG METALLURGICAL MASCH CO LTD

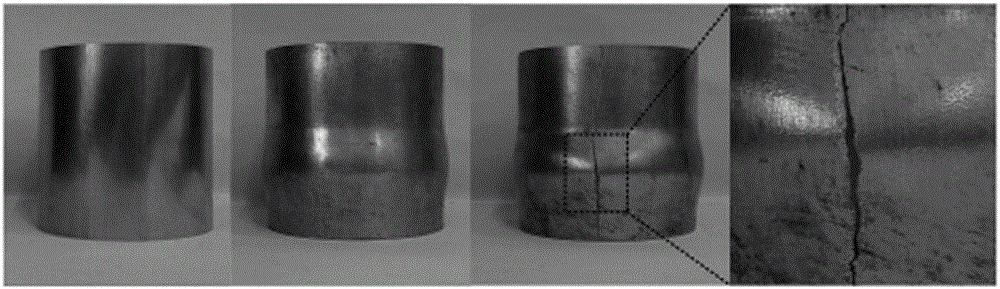

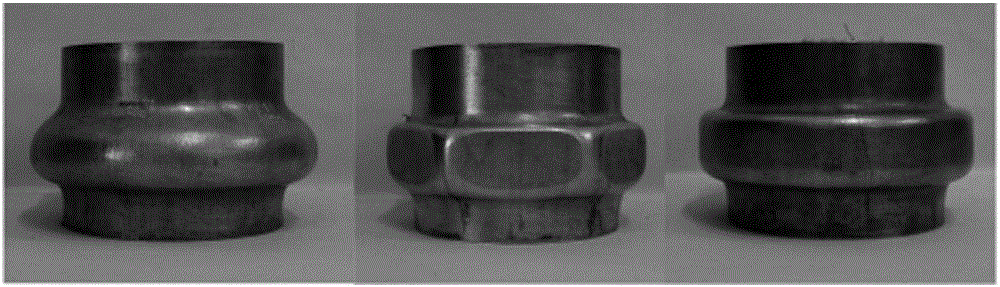

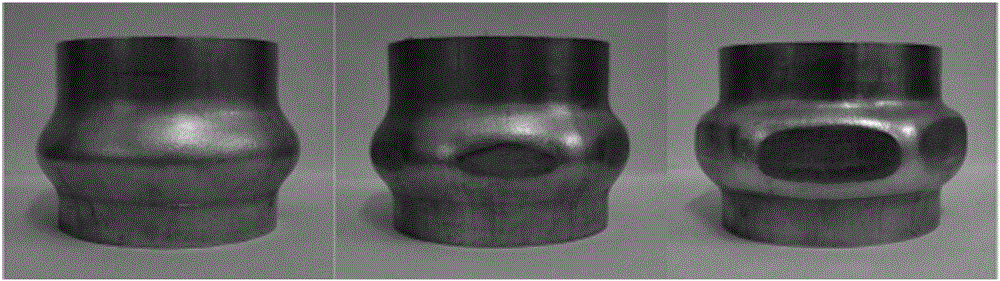

Solution treatment and granular medium cold forming method for high-strength aluminum alloy pipe fitting

ActiveCN105964722ASimple process controlLow input costFurnace typesProcess efficiency improvementSolid particleArtificial aging

Disclosed is a solution treatment and granular medium cold forming method for a high-strength aluminum alloy pipe fitting. Forming of complex parts from a high-strength aluminum alloy extruded pipe at a room temperature is realized through the process of solution treatment, granular medium pressure forming and artificial aging. The process is easy and convenient to control, the input cost is low, product design is flexible, energy consumption is low, production efficiency is high, the size of a target workpiece is precise, and high use strength and stability are achieved. After a pipe blank is subjected to solution treatment, the strength and hardness are lowered, the plasticity is remarkably improved, parts in complex shapes can be formed only at the room temperature, and the bearing capacity requirement for equipment is low. The strength of the formed pipe fitting is low, the strength of the pipe fitting can be recovered to the original state through artificial aging, and the service life of the target pipe fitting is prolonged. Solid granular media are stable in chemical property, environmentally friendly, free of pollution and reusable, and have the characteristic of uneven distribution of internal pressure, and the use strength of the formed pipe fitting is guaranteed while the plastic processing capacity of the pipe blank is improved.

Owner:YANSHAN UNIV

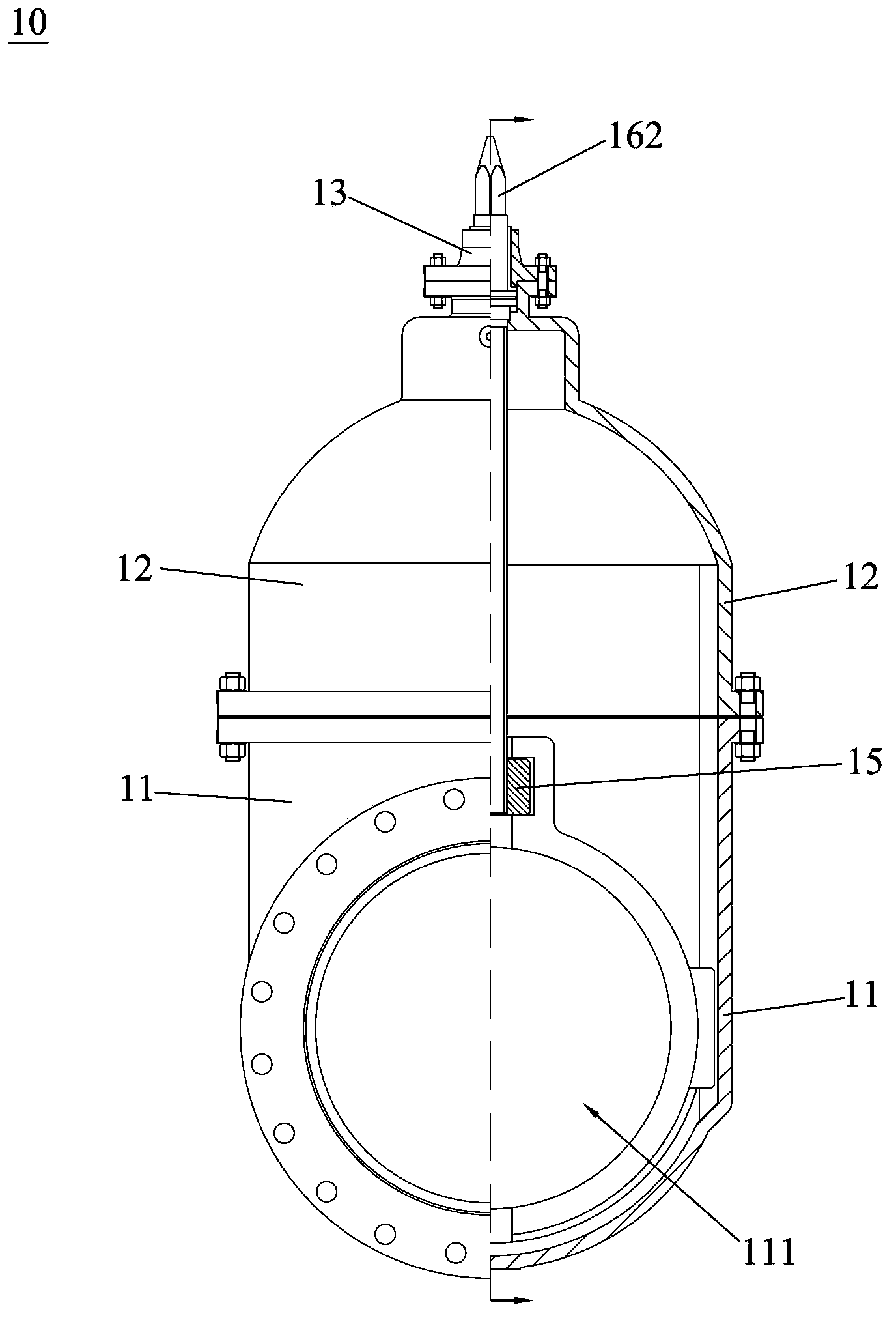

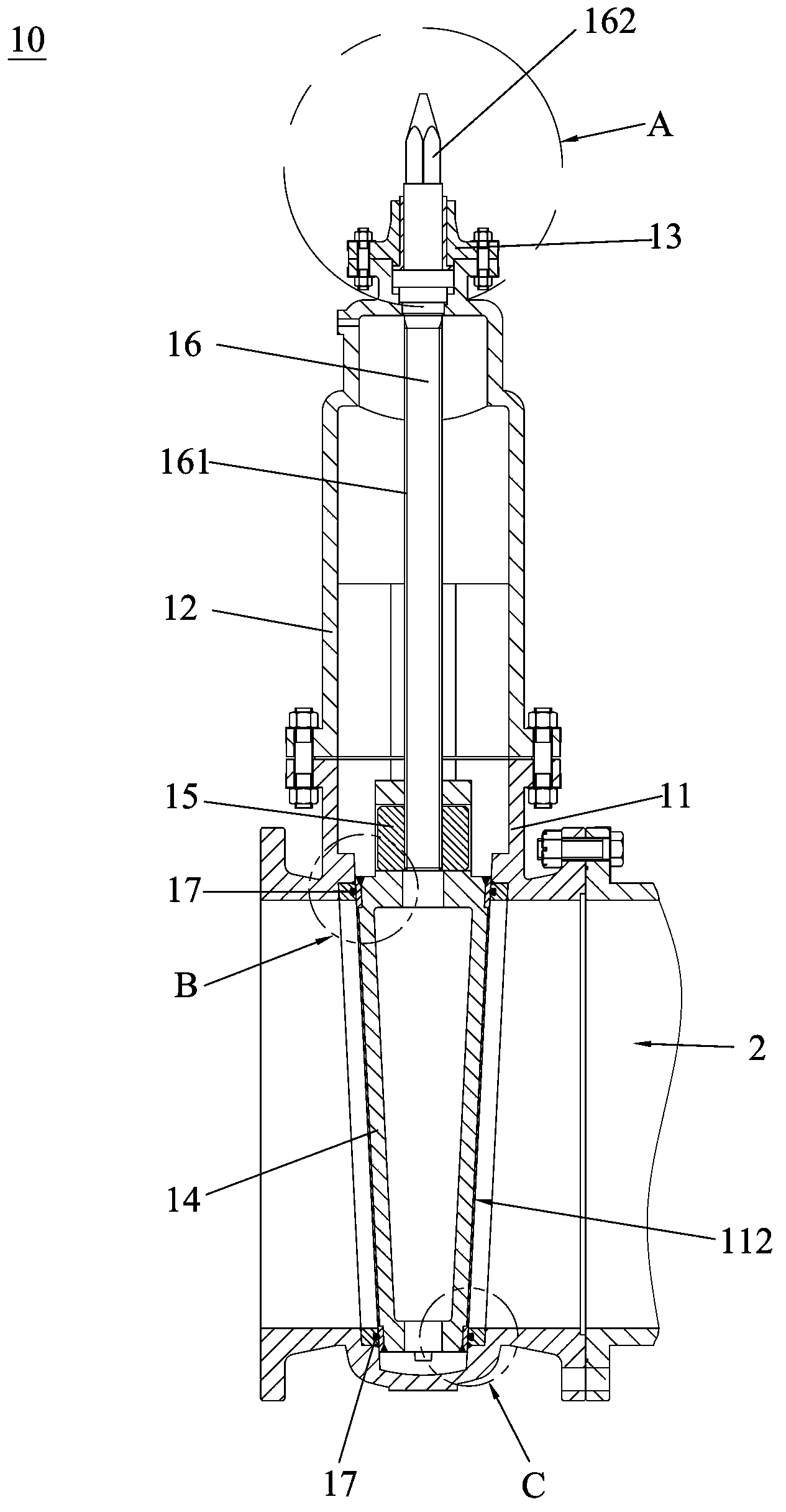

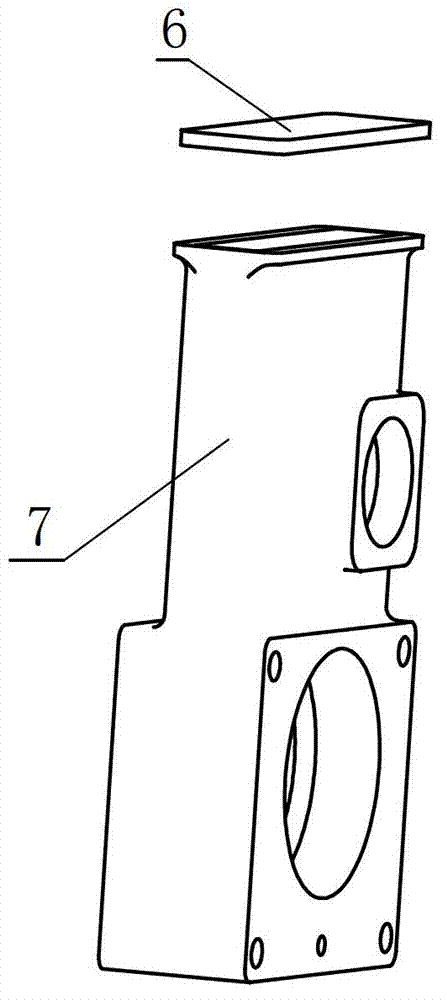

Gate valve of nuclear fuel transfer device

ActiveCN103410993ASimple structureReduce weightOperating means/releasing devices for valvesSlide valveWater leakageRemote control

The invention discloses a gate valve of a nuclear fuel transfer device. The gate valve of the nuclear fuel transfer device comprises a gate valve component and an operating rod component in detachable connection, the gate valve component comprises a valve plate, a valve rod and a valve housing of an oval cavity structure, the valve plate is of a wedge-shaped structure, a wedge-shaped groove matched with the valve plate is formed in the inner wall of the valve housing, the valve plate is slidably embedded in the wedge-shaped groove and connected onto the valve rod in a threaded manner, the valve rod is accommodated in the valve housing, and the upper end of the valve rod extends out of the valve housing and is detachably connected with the operating rod component. The valve rod is driven to rotate through the operating rod component, so that the valve plate ascends or descends along the valve rod so as to open or close a transfer passage; the valve plate and the valve housing are in wedge-type soft seal, a sealing effect is good, the problem of poor seal or water leakage is solved, and lubrication is not required; the wall thickness of the valve housing of the oval cavity structure is unequal, strength and rigidity of the valve housing are guaranteed, weight of the gate valve component is reduced, and decontamination is facilitated; the operating rod component is small in friction and operating torque of remote control, and the gate valve is simple in structure.

Owner:CHINA NUCLEAR POWER TECH RES INST CO LTD +1

Cable bundle flange filling and sealing method

The invention discloses a cable bundle flange filling and sealing method which mainly includes the steps: a, sealing a flange needing filling by the aid of a silicon rubber sealing ring; and b, filling fluid silicon rubber into the flange in a layered manner through a hole on the sealed flange until a filling rubber surface is parallel and level to the inner surface of the flange. The cable bundle flange filling and sealing method can overcome the defects of uneven rubber surface, easy leakage, poor sealing performance, low reliability and the like in the prior art, and accordingly has the advantages of even rubber surface, difficulty in leakage, fine sealing performance and high reliability.

Owner:BEIJING XINLI MACHINERY

Preparation method of PPR plastic permanent magnet cut off valve

InactiveCN1948794AKeep static closedNo wearing partsLift valveValve housingsSingle injectionEngineering plastic

A PPR plastics permanent-magnet stop valve comprises a valve seat single-injection moulded of PPR plastics, a valve deck made of high-strength engineering plastics and metal connected with the valve seat via a flange plate and a bolt and an operating handle forming a threaded connection with the outside guide cover on the valve deck.

Owner:钟荷清

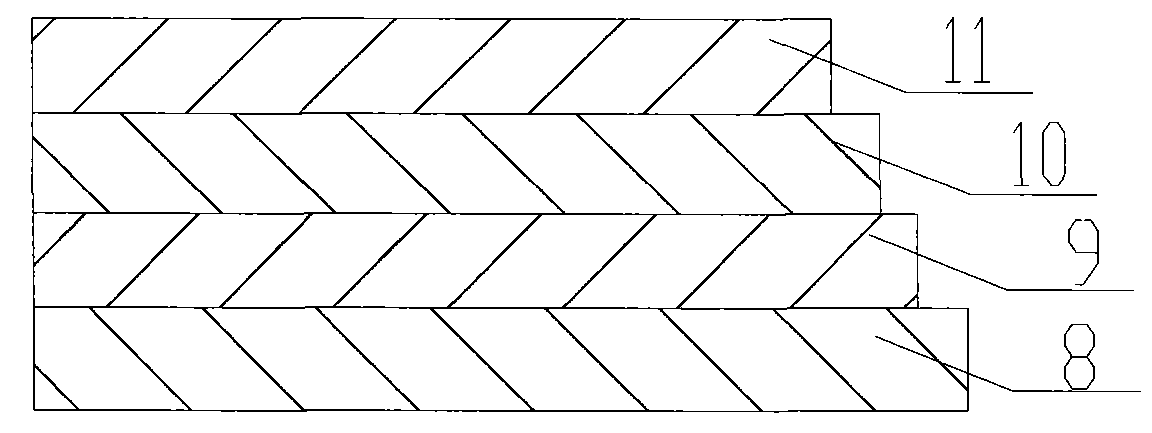

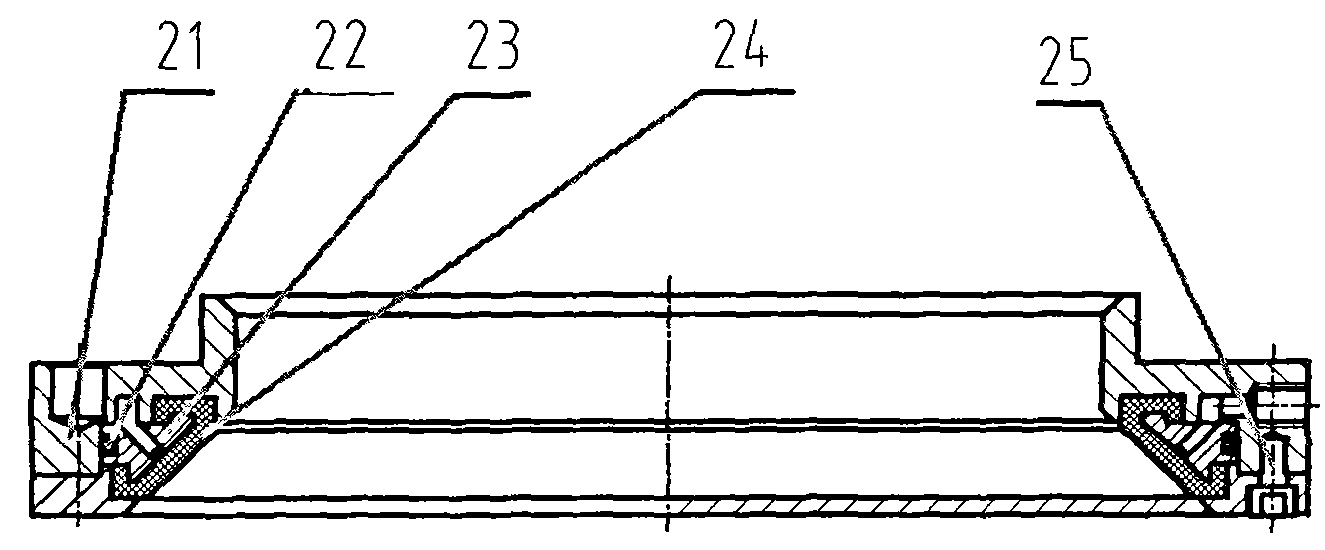

Machining method and device for multi-layer membrane structure corrugated pipe

The invention discloses a machining method and device for a multi-layer membrane structure corrugated pipe, and belongs to the technical field of corrugated pipe manufacturing. The method and device overcome the defects that a corrugated pipe manufactured through a conventional method has the short fatigue life, and is low in strength and compression rate, poor in geometric accuracy and the like. The method comprises the following steps that firstly, an annular membrane is obtained through machining; secondly, chemical milling is carried out on the surface of one side of one part of the annular membrane to form an annular concave part, and a stress concentration weakening membrane is formed; thirdly, the accurate definition of a diffusion bonding area and a non-diffusion bonding area is ensured through the sample plate shape carving step; and thirdly, an upper corrugated pipe flange, a lower corrugated pipe flange, an original specification membrane and the stress concentration weakening membrane are assembled according to a certain sequence, and diffusion bonding is finished. According to the machining method and device, machining of the multi-layer membrane structure corrugated pipe is achieved through the diffusion welding and stress relaxation combining technology method; and meanwhile the stress concentration weakening processing method is adopted for eliminating the stress concentration phenomenon produced in the corrugated pipe working process, and the fatigue life of the corrugated pipe is greatly prolonged.

Owner:BEIJING XINGHANG MECHANICAL ELECTRICAL EQUIP

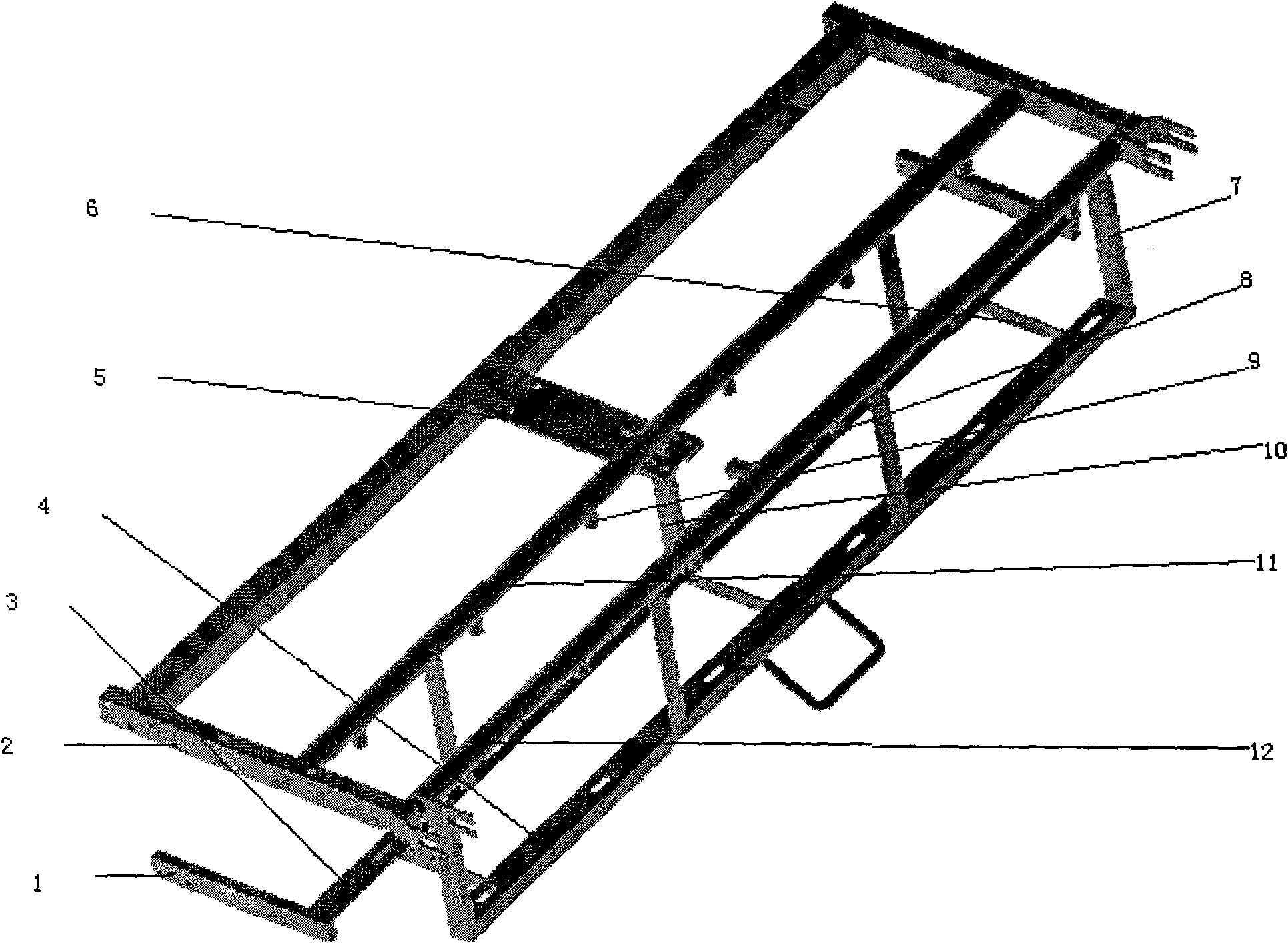

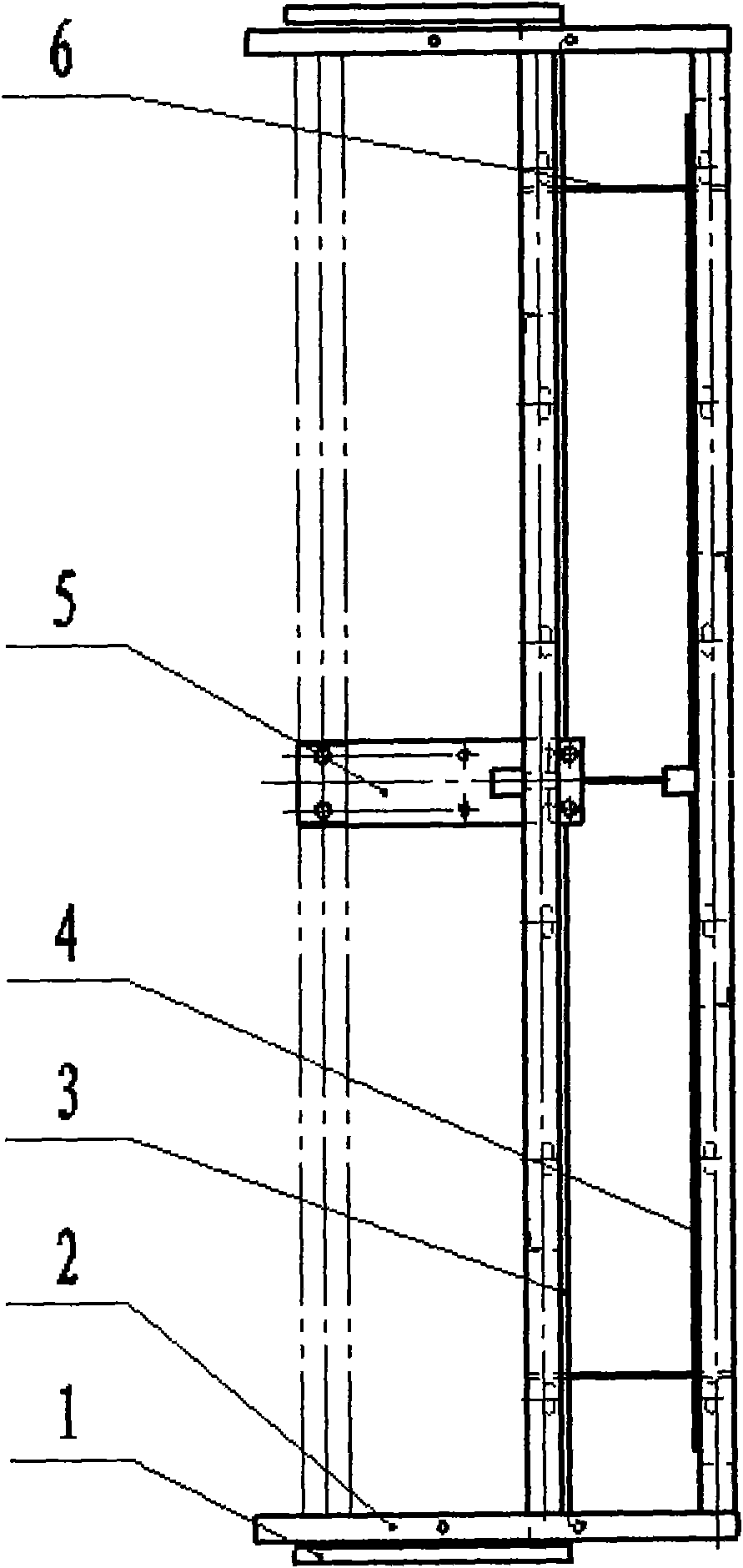

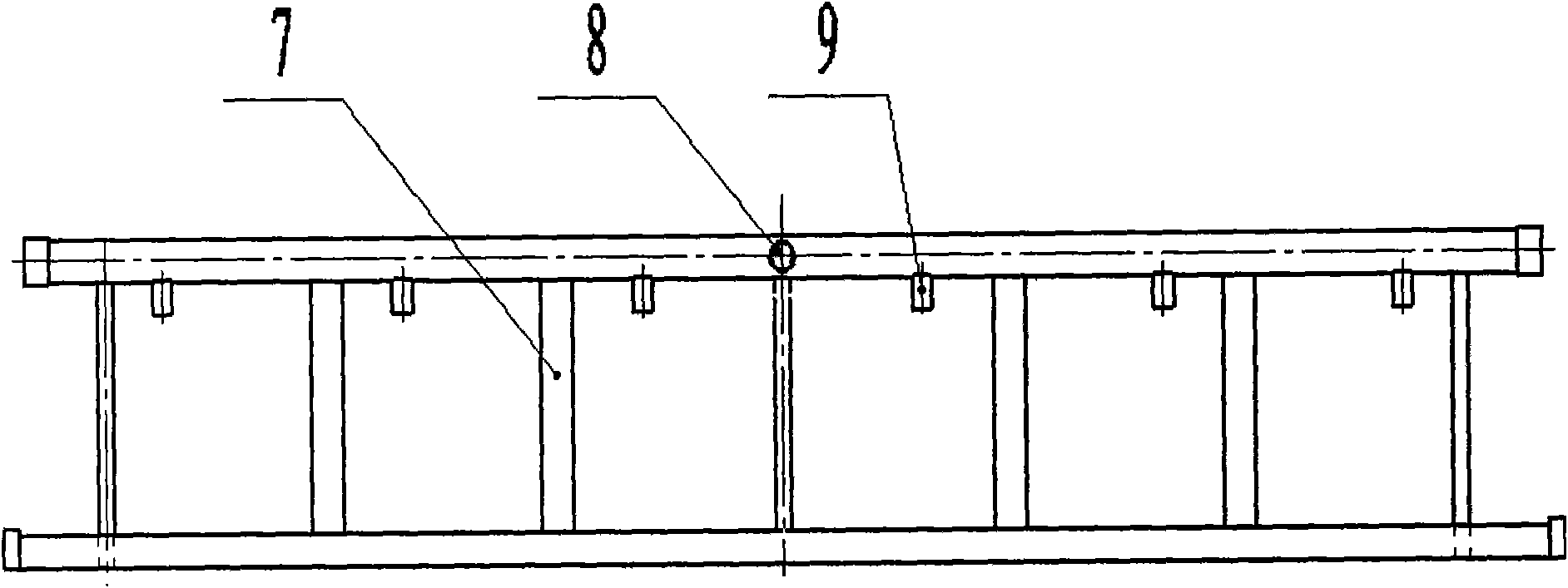

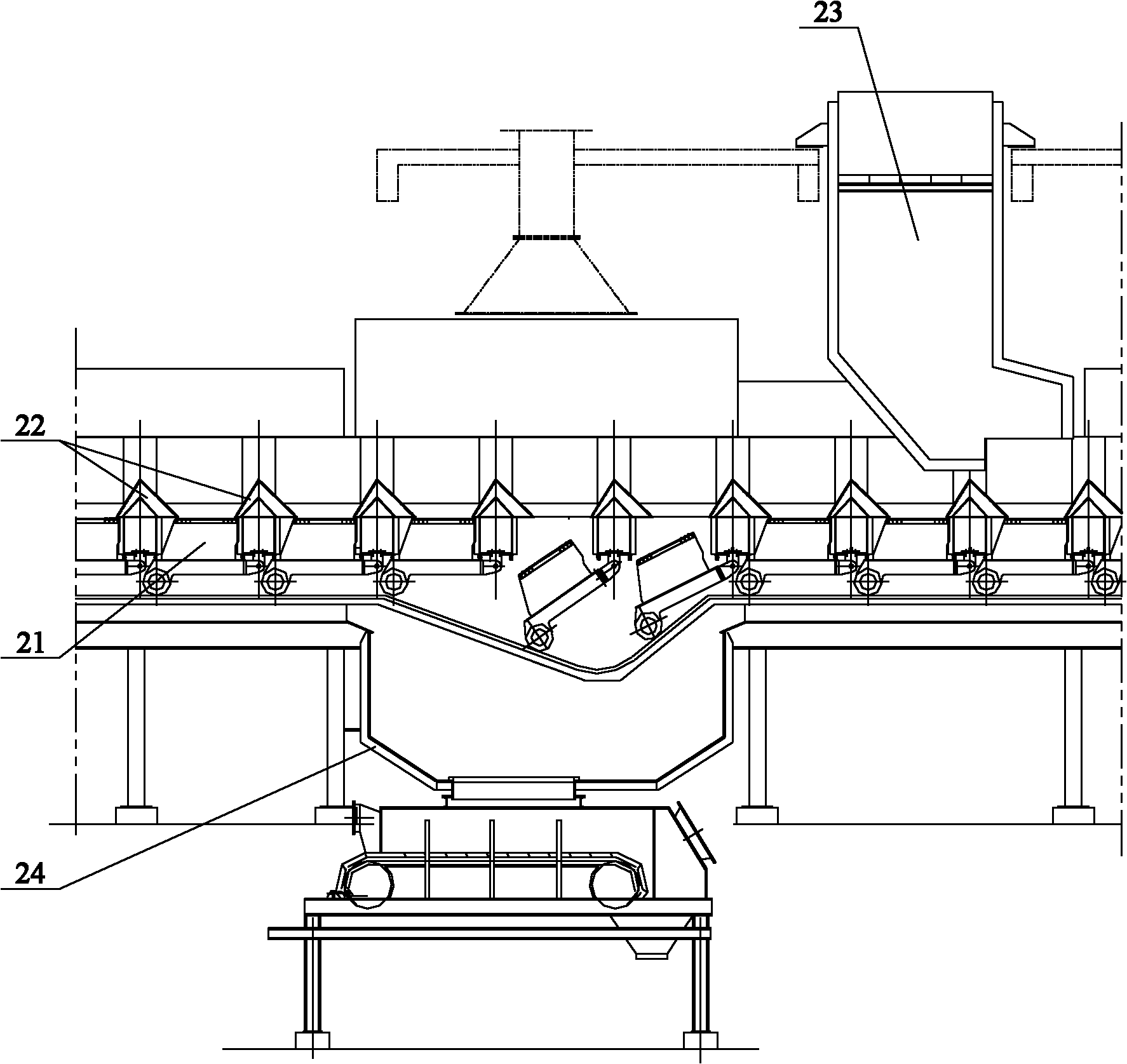

Auxiliary machine frame matched with positive and negative air pressure combined type pneumatic seeding unit

InactiveCN101637077AOvercome clutterOvercome tightnessSeed depositing seeder partsPositive pressureEngineering

The invention discloses an auxiliary machine frame matched with a positive and negative air pressure combined type pneumatic seeding unit, wherein the lower side beams and the upper side beams are connected by bolts and fixed on a side plate of a main machine frame; a lower front beam is welded on the lower side beams at the two sides; a front supporting rod connects the lower front beam and a positive pressure air pipe into one body by welding, is welded with a connecting plate, is connected with the main machine frame with bolts used by the connecting plate, is matched with the connection ofthe lower side beams and the upper beams as well as the side plate of the main machine frame, and fixedly connects the positive and negative air pressure combined type pneumatic seeding unit by bolts; the positive pressure air pipe and the negative pressure air pipe are integrally connected with the upper side beams at the left end and the right end by welding; a rear supporting rod connects a lower rear beam and the negative air pipe by welding; and a cross supporting rod is connected with the lower front beam and the lower rear beam by welding. The auxiliary machine frame has simple structure and convenient operation, adopts bolt connection, has convenient disassembly, is applicable to the positive and negative air pressure combined type rape seed seeding unit in precise quantity and solves the problem of arrangement and installation of air pipes of the positive and negative air pressure combined type pneumatic seeding unit.

Owner:HUAZHONG AGRI UNIV

Sealing switch of fuel system

The invention discloses a sealing switch of a fuel system, wherein an outer head face of a first fixing sealing ring is attached with an inner surface of a flange joint of an oil pipe at one side, and an outer head face of a second fixing sealing ring is attached with an inner surface of a flange joint of an oil pipe at the other side; a movable inserting plate in a link rod mechanism is arranged between the first fixing sealing ring and the second fixing sealing ring; one surface of the movable inserting plate is attached with an inner head face of the first fixing sealing ring, and the other surface keeps a clearance of 2-3mm with an inner head face of the second fixing sealing ring. Both a movable ring and a spring are sleeved on an outer circular surface of the second fixing sealing ring, and the movable ring is adjacent to the movable inserting plate. Under the function of the spring, the movable ring is capable of sliding on the sealing rings; meanwhile, the movable inserting plate is firmly attached with the first fixing sealing ring when the movable inserting plate is exerted with the pressure, to reduce the requirement on the processing precision. The sealing switch is simple in structure, high in sealing performance and excellent in technology, and is capable of effectively reducing the production time and the cost.

Owner:XIAN AIRCRAFT IND GROUP

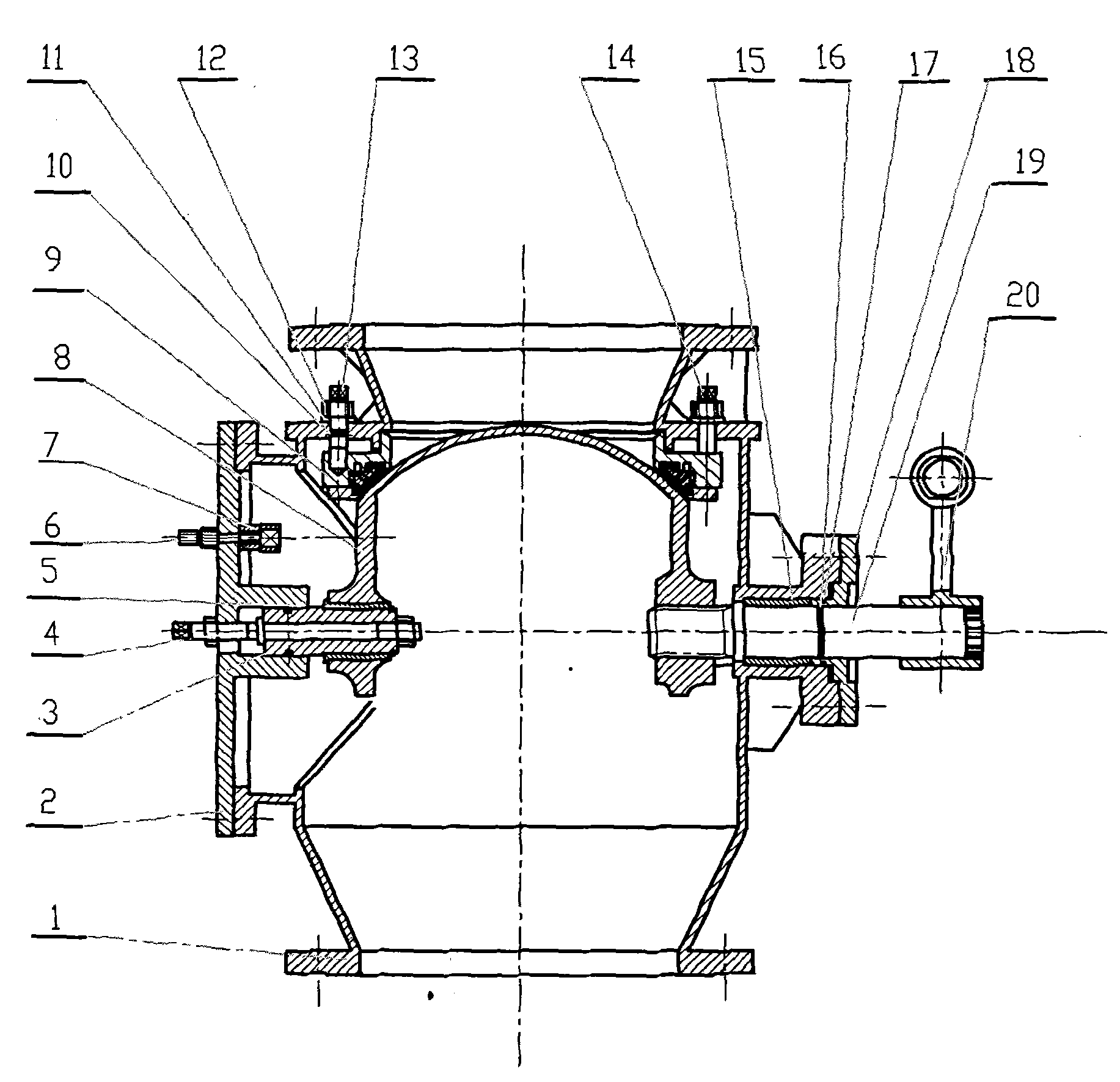

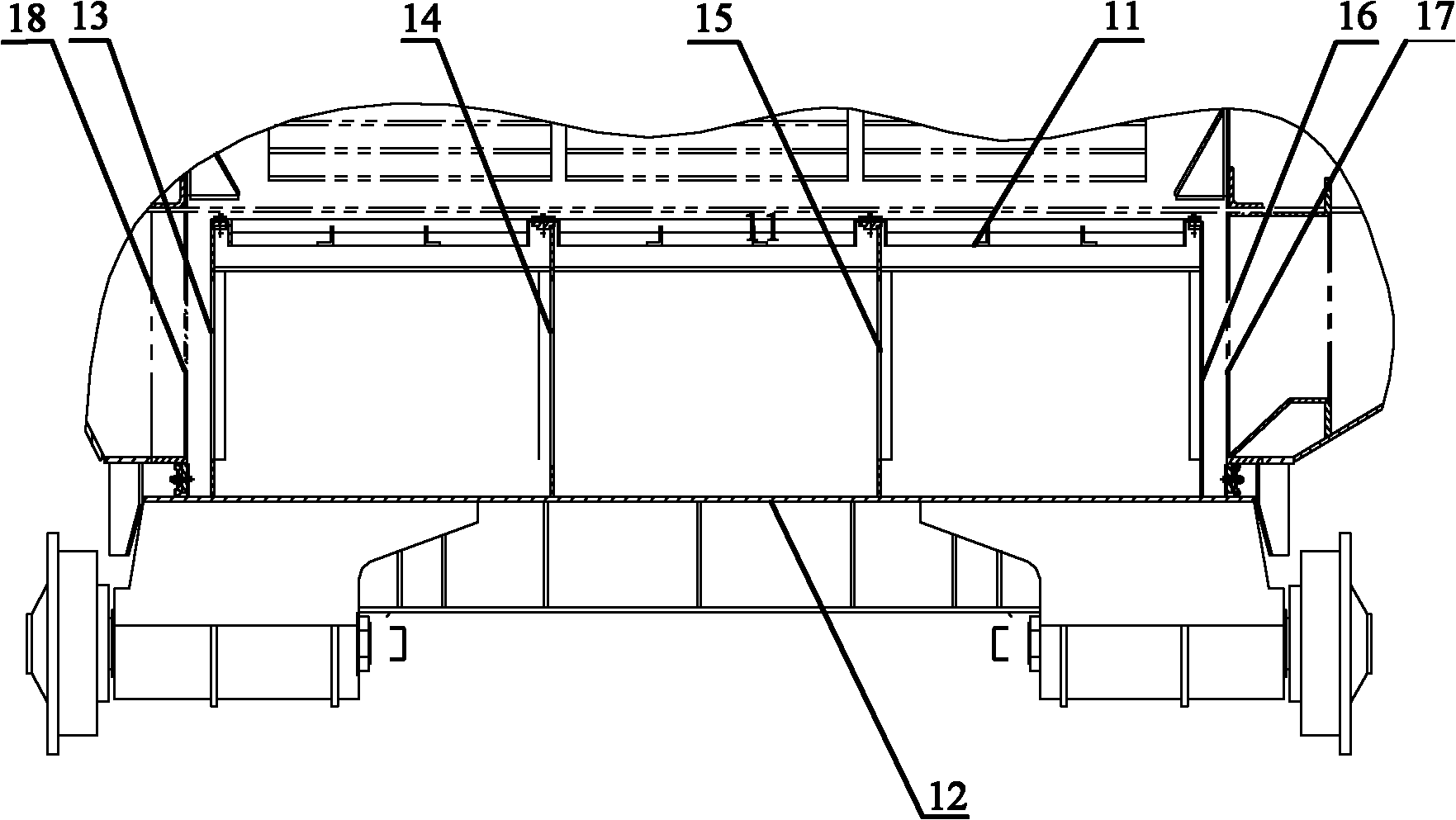

Ring cooling machine trolley and ring cooling machine with trolley

ActiveCN102121796AOvercome tightnessOvercoming the problem of the lower plate of the trolleyHandling discharged materialEngineeringMechanical engineering

The invention discloses a ring cooling machine trolley. Two vertical support plates vertical to the running radius direction of the ring cooling machine trolley are arranged between a grate plate and a lower flat plate of the ring cooling machine trolley. The bottoms of the preposed ends of the two vertical support plates are provided with a buildup accommodation space respectively. A connecting part is fixedly arranged between the two vertical support plates. A radial distance between the inner vertical support plate and an inner sealing plate of the trolley, the radial distance between the outer vertical support plate and an outer sealing plate of the trolley, a vertical distance between the connecting part and the lower flat plate of the trolley, a peripheral distance between the root part of the buildup accommodation space on each vertical support plate and a static sealing device of a preposed support beam of the trolley, and the height dimension of the buildup accommodation space are all more than a preset distance. The lower flat plate of the trolley can realize smooth discharging in the local area range of the static sealing device of the trolley, and effectively overcomes the shortcoming that the preposed ends of the vertical plates block materials to cause damages to the static sealing and the lower flat plate of the trolley. Based on the ring cooling machine trolley, the invention also provides a ring cooling machine with the trolley.

Owner:ZHONGYE-CHANGTIAN INT ENG CO LTD

Rotary jet engine

InactiveCN1966939AOvercoming problems that degrade sealing performanceIncrease speedGas turbine plantsNon-positive displacement enginesFree-piston engineCombustion

A rotary motor is mainly composed of rotor and stator. On the stator, there is single direction valves equipped on the air inlet, cylinder and compression chamber, with the piston also having sing way valve and moving back and forth under the control of the guide drop center wheel. There are seal zone and combustion inflation zone on the rotor. With the compression and combustion separated, the compressed fuel goes to the compression chamber in the stator, and the ignited high temperature and high pressure gas entering into the combustion inflation zone of the rotor to push it spinning. It is finished in the rotor. It overcame the issues like too many components of the piston engine, poor sealing of the triangle piston rotary engine, and uneven force on the piston, high difficulty and cost of the manufacturing of jet engine. The above mention engine combines all the merits with simple structure, small size, light weight, big power, high rotation speed, low vibration, high efficiency, good sealing, and oil saving. It is an ideal engine.

Owner:毛世琨 +1

Block check valve for cutting off or recovering medium return of oil path of oil supply system

PendingCN108413099ASolution volumeSolve quality problemsCheck valvesEqualizing valvesDouble check valveLow resistance

The invention discloses a block check valve for cutting off or recovering medium return of an oil path of an oil supply system and provides a low-resistance backflow preventer which is reliable in sealing performance, durable, capable of closing a valve stably, and small in pressure fluctuation. According to the technical scheme, a valve rod is connected with a check valve seat located under a check valve body through a valve deck with an arched section and a reset spring arranged in the valve deck; in the return state, a flow medium entering a joint valve body tube downwards pushes the valvedeck, the reset spring is driven to reversely push the check valve body to the initial position, the sealing surface of the check valve body is attached to a flange sealing ring in linear contact withthe end direction of the check valve body, and thus, the flow medium is prevented from flowing back to an inlet of the valve from an outlet; and in this way, the flow direction of the flow medium ischanged, cut-off or recovery of the flow medium between an upstream valve cavity and a downstream cavity of the valve rod is controlled, and flow control for blockage or zero-pressure blockage is achieved. By adoption of the block check valve, the defects that in the prior art, a check valve body is large in size, high in weight, difficult to assemble and large in resistance are overcome.

Owner:成都威特电喷有限责任公司

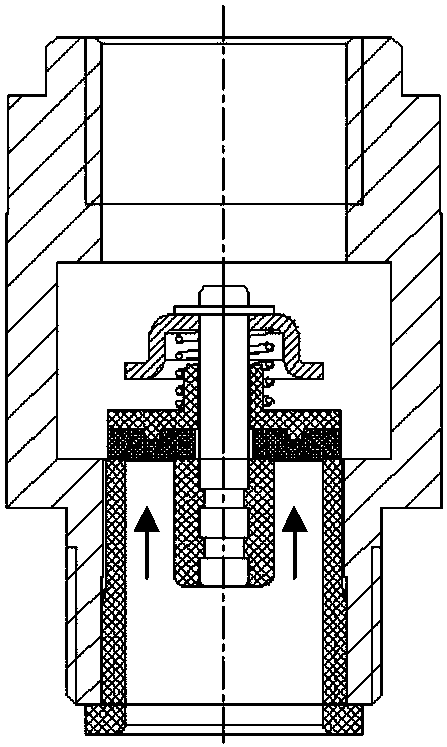

Pneumatic sealing device

InactiveCN104314911AReduce excessive frictionExtended service lifeEngine sealsPiston ringsReciprocating motionHigh pressure

The invention relates to a pneumatic sealing device which comprises a rubber body, a piston body and an air cylinder, wherein the piston body is arranged in the air cylinder, a groove is formed in the piston body, and the rubber body is mounted in the groove; a first sealing lip, a second sealing lip and a third sealing lip are arranged on the rubber body, the first sealing lip and the second sealing lip are in interference contact with the side wall of the groove of the piston, and the third sealing lip is in interference contact with the wall of the air cylinder. The force situation of the sealing lips is improved by applying compressed air, so that the reliability, the fatigue resistance, the pressure resistance and the abrasion resistance of a sealing ring are improved. The pneumatic sealing device can solve the problems of thin main sealing lip, small bearing pressure and short service life of the current sealing ring with a single structure, overcomes the defects of poor sealing effect, easiness in damage of a sealing piece, bad reciprocating motion and easiness in lip reversing, and is especially suitable for the demand of pneumatic high-pressure and fast-moving sealing.

Owner:QINGDAO TKS SEALING IND

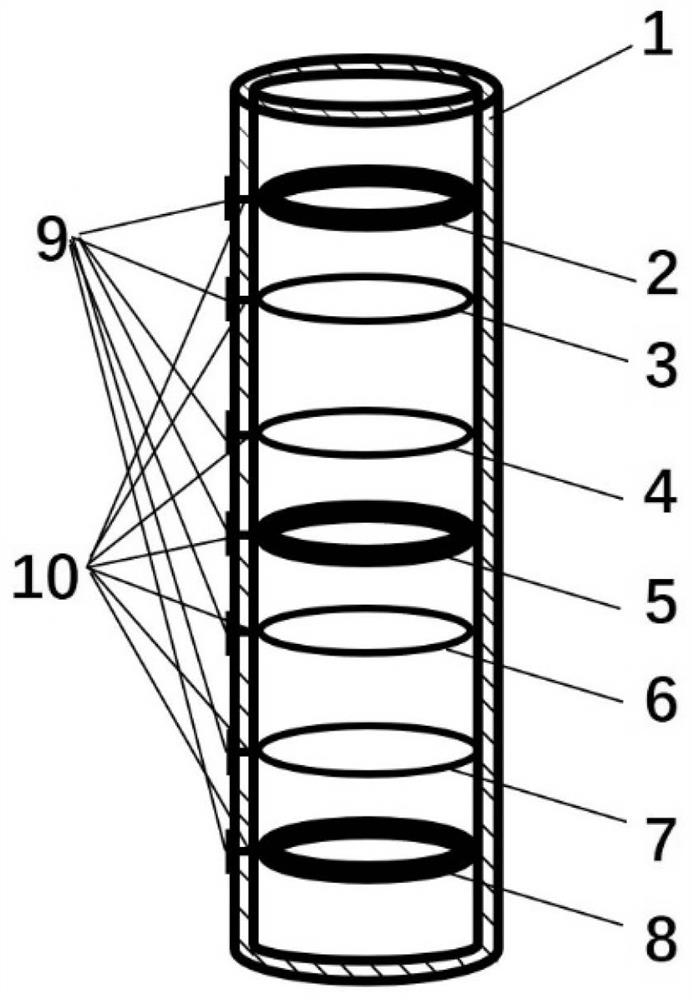

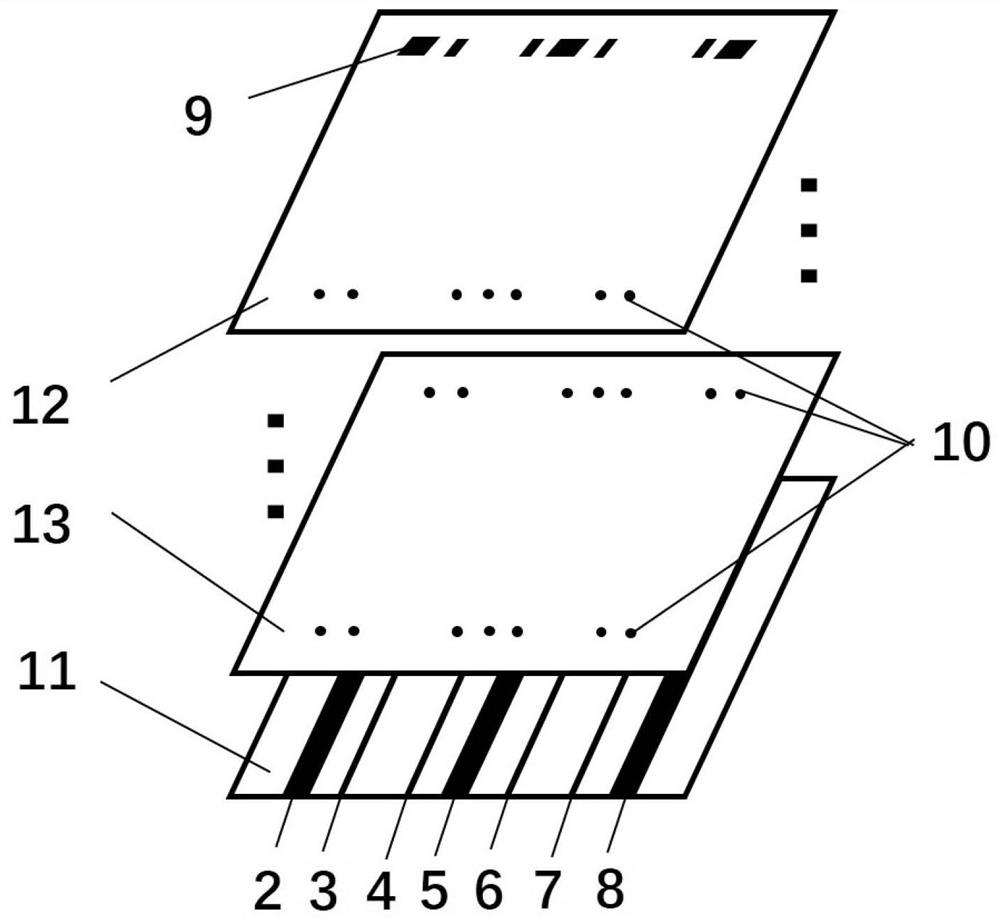

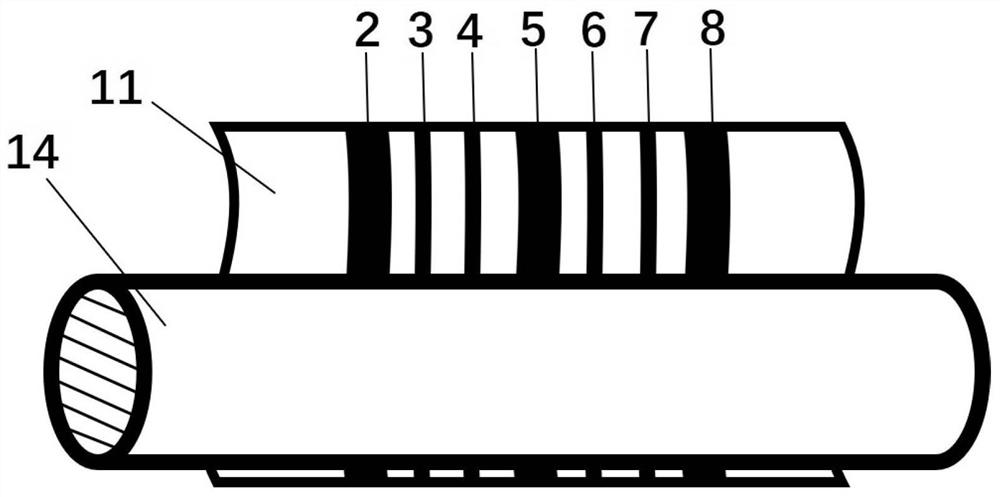

Preparation method of seven-electrode conductivity sensor

ActiveCN113495191ARealize one-piece moldingOvercoming splicingPrecision positioning equipmentSoldering apparatusMetal electrodesElectronic conductivity

The invention relates to a preparation method of a seven-electrode conductivity sensor, in particular to the seven-electrode conductivity sensor and the preparation method of the seven-electrode conductivity sensor. The seven-electrode conductivity sensor comprises a circular-tube-shaped conductivity cell made of a ceramic material, seven metal circular ring inner electrodes which are sequentially distributed on the inner wall of the ceramic circular-tube-shaped conductance cell in parallel, seven metal outer electrodes which are located on the outer wall of the ceramic circular-tube-shaped conductance cell, and through hole metal electrodes which are used for connecting the metal circular ring inner electrodes and the metal outer electrodes. The ceramic material is an HTCC ceramic material or an LTCC ceramic material which can be co-fired with metal.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

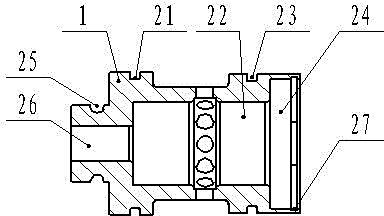

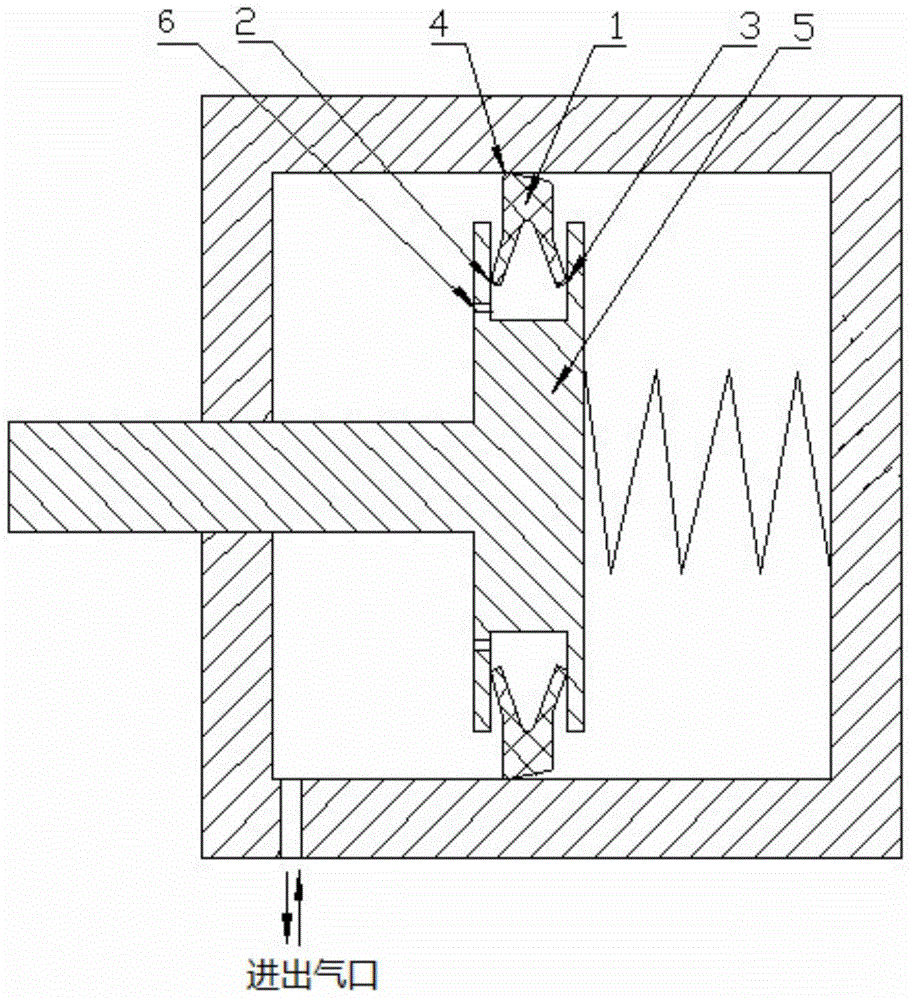

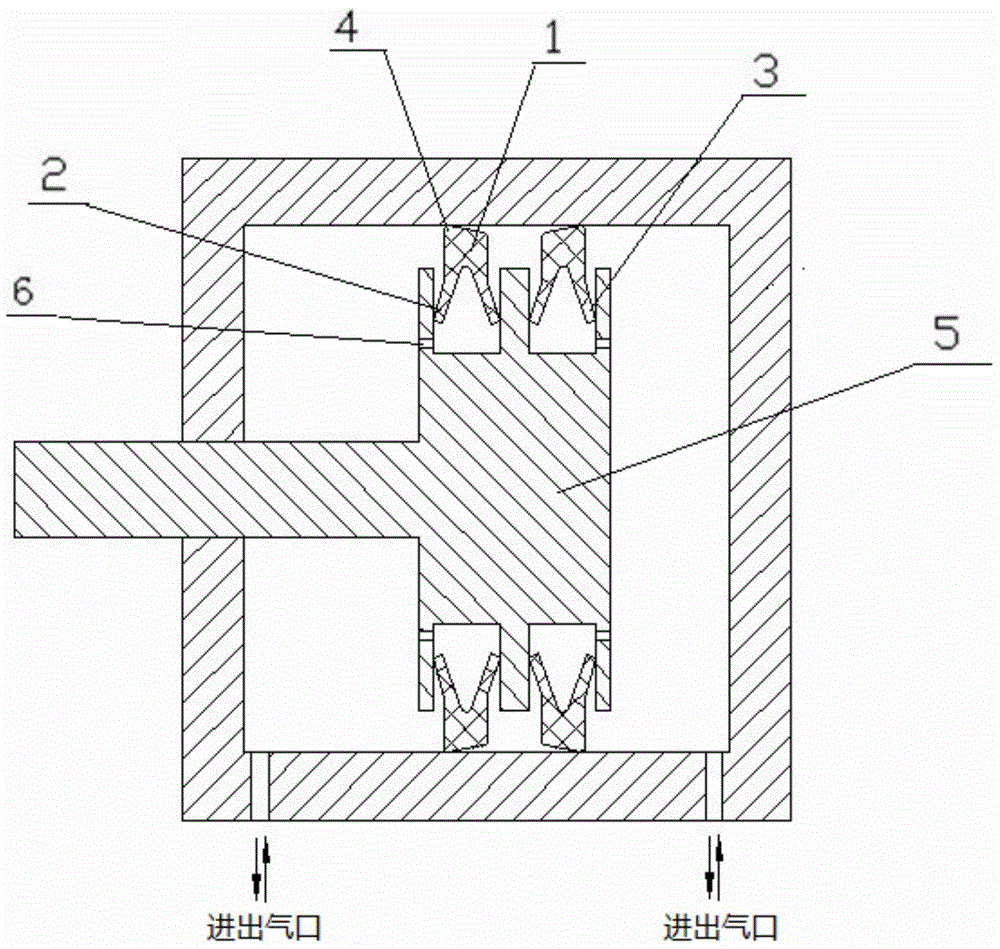

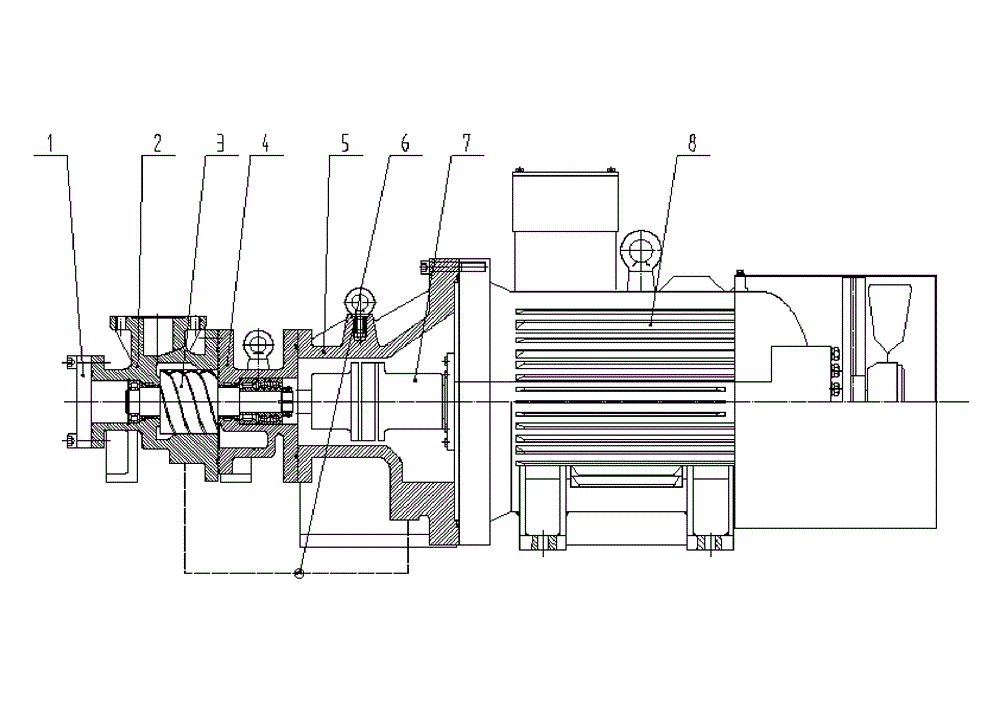

Semi-closed oil injection screw supercharger

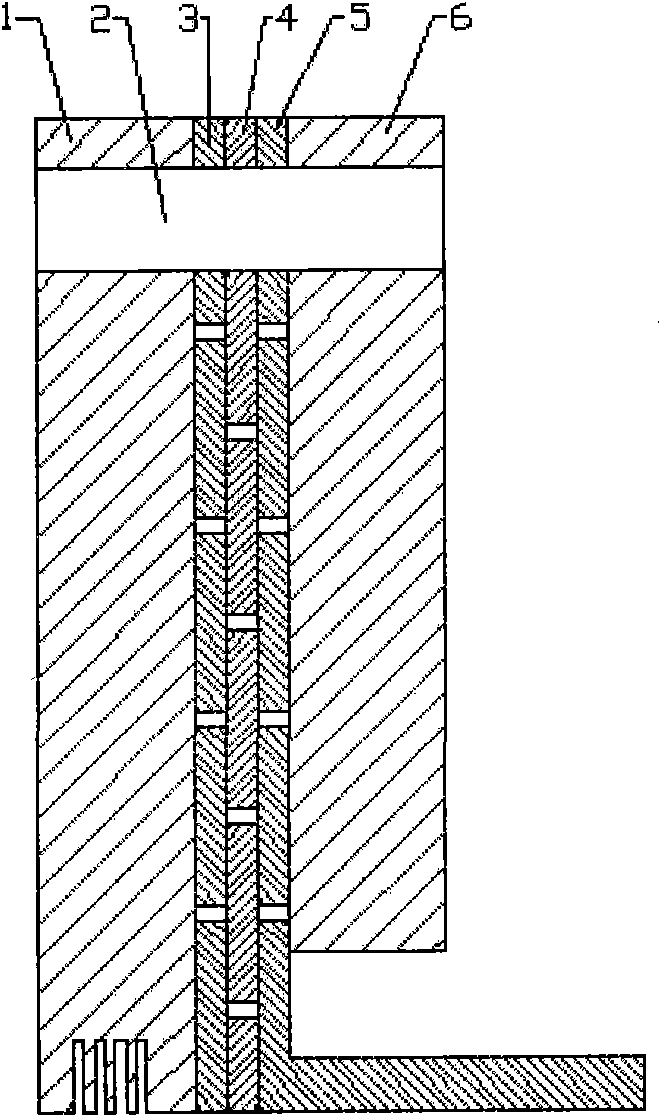

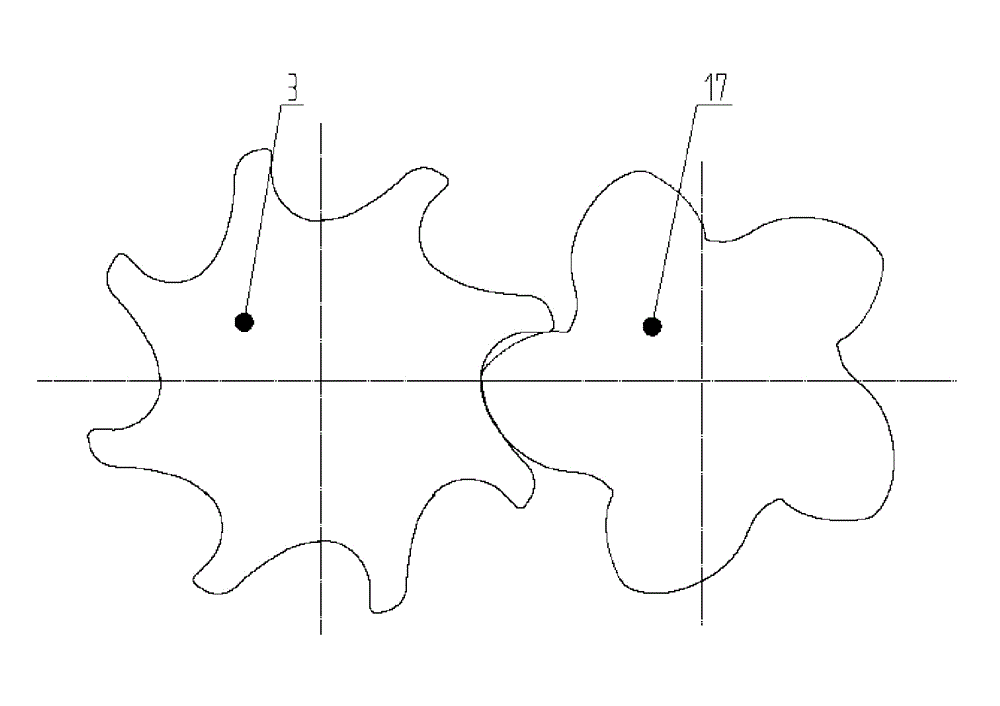

InactiveCN103334927AFully enclosedOvercome tightnessSealing arrangement for pumpsRotary piston pumpsEngineeringMechanical engineering

The invention discloses a semi-closed oil injection screw supercharger. A suction end cover (1) is mounted at the outer end of a supercharger body (2); an exhaust end seat (4) is mounted at the inner end of the supercharger body (2); the other end of the exhaust end seat (4) is connected with a motor (8) through a motor connecting body (5); a female rotor (3) and a male rotor (17) are mounted in supercharger body (2); and the male rotor (17) is connected with the motor (8) through a coupler (7). Low-pressure gas (0.7-1MPa) is compressed to medium-pressure gas (3-4MPa) at high volume efficiency; a maximum volume flow of one machine can reach 72Nm<3> / min; and the complete supercharger is totally closed, and is less in wasted work, high in efficiency, compact in structure, reliable in operation, low in noise, and convenient to maintain.

Owner:YANTAI MOON

Seal joint for pressurized wind tunnel

InactiveCN103852236AWide pressure rangeImprove sealing and insulation performanceAerodynamic testingEngineeringMechanical engineering

The invention discloses a seal joint for a pressurized wind tunnel. The seal joint comprises a base, a pressing screw and seal washers. The base is connected to the wall of the pressurized wind tunnel in a welded mode, a cable penetrates through a central through hole of the pressing screw, a central through hole of the base and central through holes of the seal washers, the five overlaid seal washers are located between the pressing screw and the base, mechanical extrusion formed by tightening force of threads for connection between the pressing screw and the base enables the seal washers to deform, hold the cable tightly, and meanwhile extrude an inner cavity of the base tightly, and seal problems caused when the cable passes through the wall of the pressurized wind tunnel. By the adoption of an embedded type seal joint design mode, contradiction between communication and seal is effectively overcome; by using the characteristics that the seal washers are high in elasticity and toughness, the technical problem that a traditional seal joint cannot be used under a dynamic pressure condition, and reliable and rapid connection of the measurement and control cable in the pressurized wind tunnel is achieved. The seal joint has a wide pressure resistant range and good airtightness and insulativity, and can be used repeatedly and installed rapidly.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

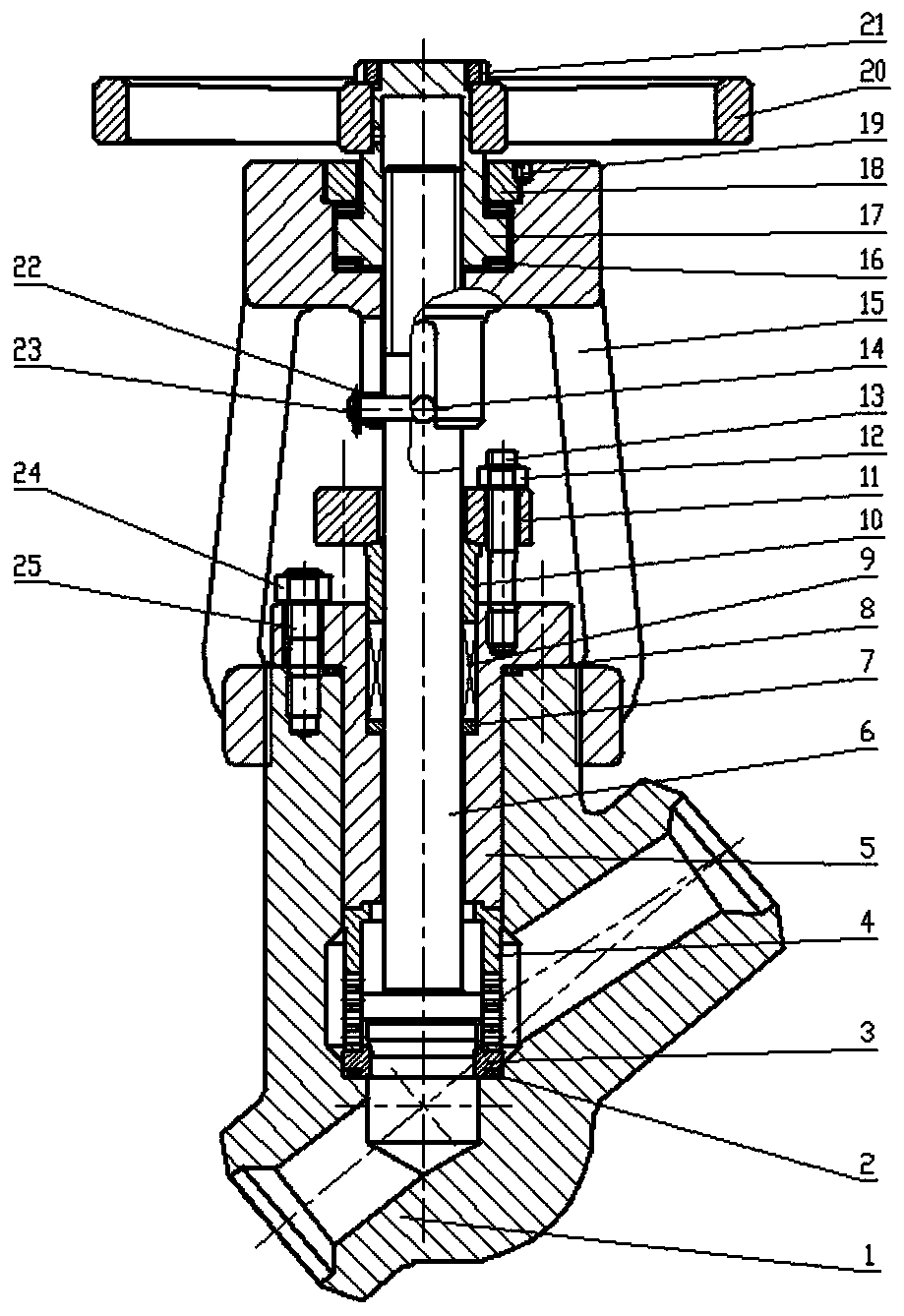

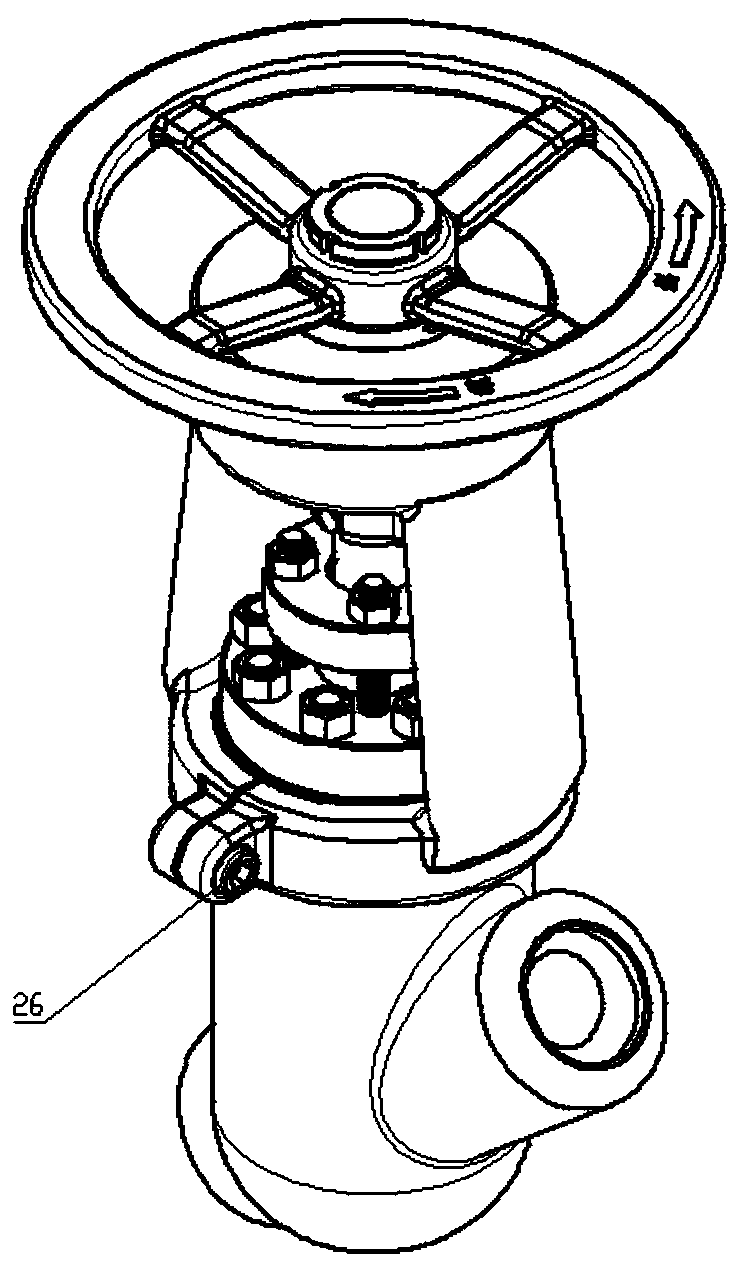

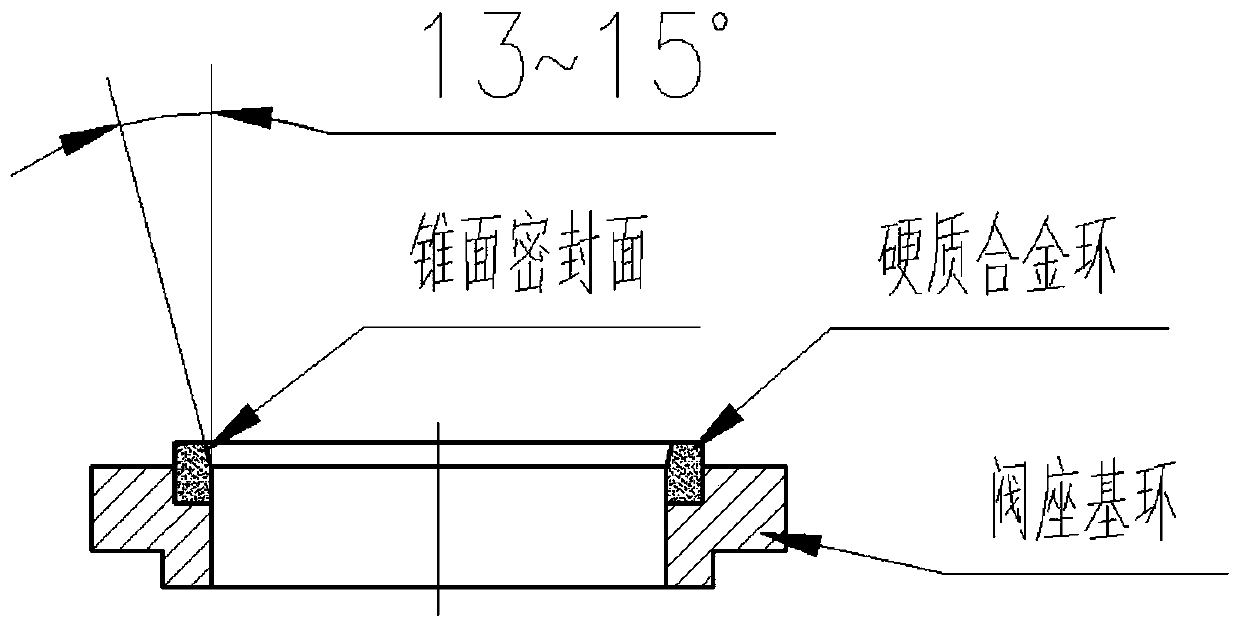

Detachable movable valve seat Y-type stop valve

ActiveCN111306306ALow fluid resistanceSolve and overcome tightnessSpindle sealingsLift valveValve seatPhysics

The invention relates to a detachable movable valve seat Y-type stop valve. The detachable movable valve seat Y-type stop valve comprises a valve body (1), an integrated valve element stem (6), a bracket (15) and a hand wheel (20); the valve body (1) is provided with a three-channel structure of a medium inflow channel, a valve body middle cavity and a medium outflow channel; a valve seat sealingpad (2), a valve seat (3), a sleeve (4) and a sleeve pressing cover (5) are arranged in the valve body middle cavity of the valve body (1) in sequence from bottom to top; the sleeve (4) is arranged onthe upper surface of a valve seat base ring; the integrated valve element stem (6) is inserted into the valve body through the sleeve (4); and the sleeve pressing cover (5) is installed above the sleeve (4); the outer circle of the lower end of the valve element stem is matched with the inner wall of the sleeve (4) to form a guide, and the upper end of the valve element stem penetrates through astuffing box hole formed in the sleeve pressing cover. A stuffing liner (7), a combined stuffing (9), a stuffing pressing cover (10) are arranged in the stuffing box hole in sequence, the bracket (15)is installed on the upper part of the valve body (1), a clamping design is adopted at the lower end of the bracket (15), and the lower end of the bracket (15) is fixed to the valve body (1) by threaded connection and fastened with a bracket locking screw (26).

Owner:WUZHONG ZHONGCHUANG VALVES

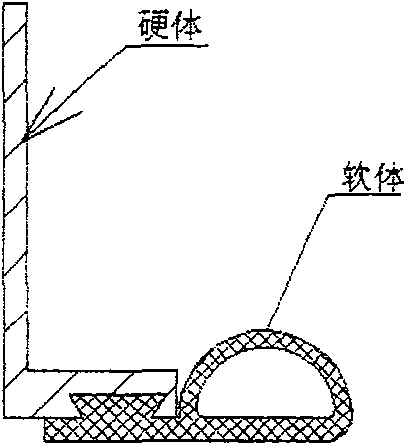

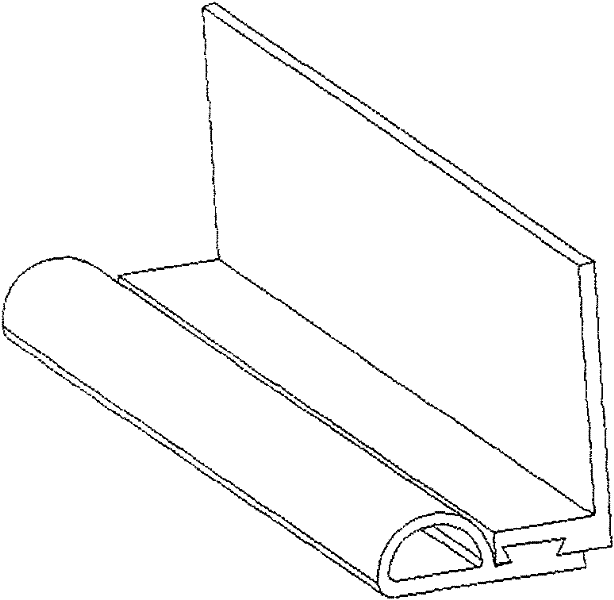

Double-body combined sealing strip for solid-shaped steel window

InactiveCN102220831AOvercome tightnessOvercome energy savingSealing arrangementsMetallurgyEnergy conservation

The invention provides a double-body combined sealing strip for a solid-shaped steel window. The sealing strip is formed by connecting a soft body (a rubber strip) and a hard body (a pressing strip) into a whole and is fixed on a window frame and a window stile of the solid-shaped steel window to solve the problem that the solid-shaped steel window is poorly sealed. By the double-body combined sealing strip, the performance of energy conservation and environment friendliness of the solid-shaped steel windows with large inventory in old buildings is improved. The double-body combined sealing strip has the characteristics of good sealing effect and long service life, is firmly installed, has a simple and novel structure, is convenient to modify and maintain, can keep the original window forms and building styles and is particularly suitable for repairing the solid-shaped steel windows of various excellent historic preservation buildings.

Owner:SHANGHAI WEIDA ART CASTING ENG

Valve of fluid bag

InactiveCN1854577AThe production process is simple and safeReliable manufacturingDiaphragm valvesEngine diaphragmsControl valvesBiomedical engineering

There is disclosed a fluid bag valve which includes a main fluid pipe, several fluid bags and a valve casing. Fluid inlet and outlet controlling valves are disposed on both ends of the main fluid pipe separately. The several fluid bags are disposed in the valve casing. Each fluid bag is connected with the main fluid pipe by a fluid branch pipe and there are spaces between fluid bags. When the fluid bags are filled with pressure fluid, each pair of fluid bags tightly contact, so the valve presents the closed state. When the fluid in the bag is discharged, the fluid bags are separated each other, so the valve presents the open state.

Owner:杨小明

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com