Semi-closed oil injection screw supercharger

A supercharger and screw technology, applied in the field of mechanical power, can solve the problems affecting the normal use of users, high maintenance costs, and large noise of the piston engine, so as to improve the service life of bearings and compressor efficiency, improve service life, improve The effect of bearing life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

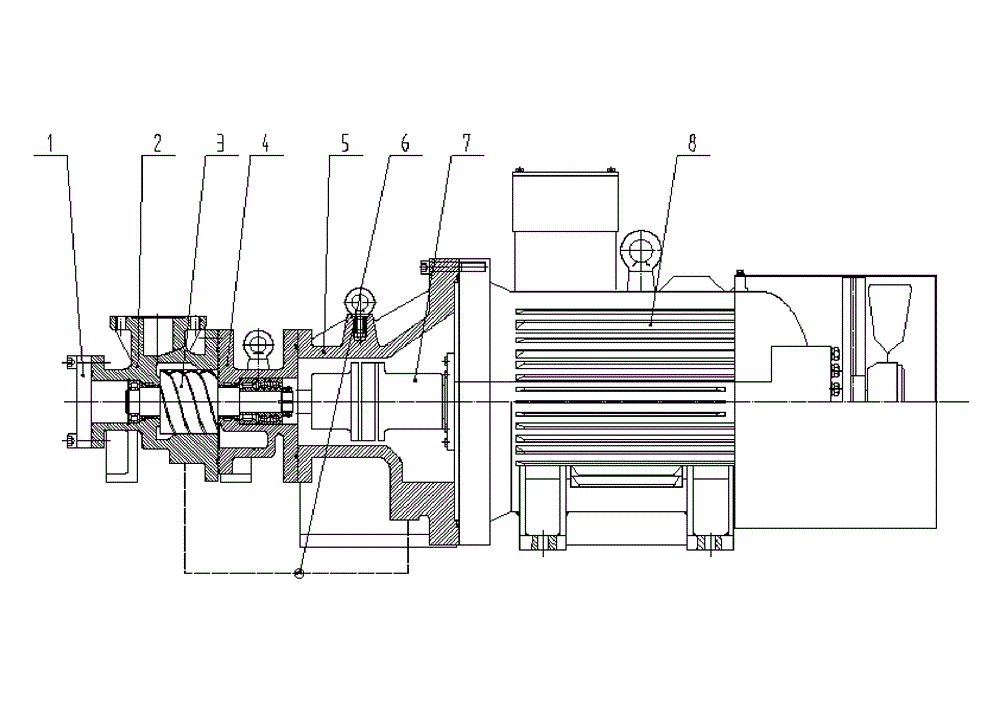

[0021] Such as figure 1 As shown, the present invention includes a body 2, the outer end of the body 2 is equipped with a suction end cover 1, the inner end of the body 2 is equipped with an exhaust end seat 4, and the other end of the exhaust end seat 4 is connected with a motor connecting body 5, The motor connection body 5 is connected with a motor 8 . Adjacent parts in the suction end cover 1, the body 2, the exhaust end seat 4, the motor connecting body 5, and the motor 8 are respectively sealed with O-rings and fastened by screws. The suction adopts radial suction, the suction hole is opened on the body 2 top, the exhaust is lateral exhaust, and the exhaust port is opened on the exhaust end seat 4.

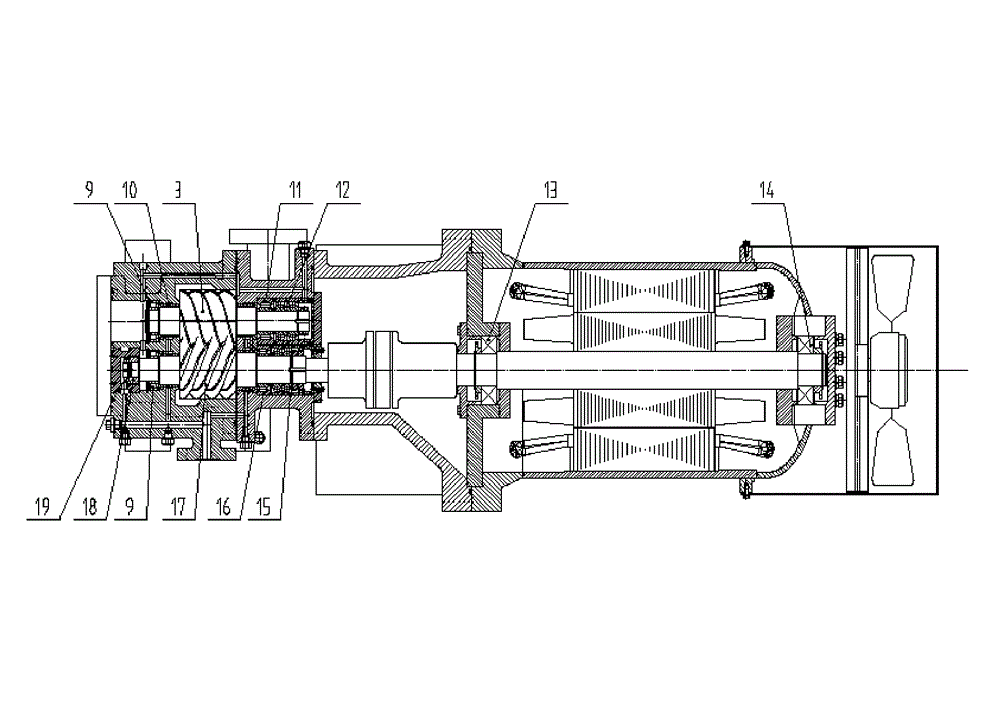

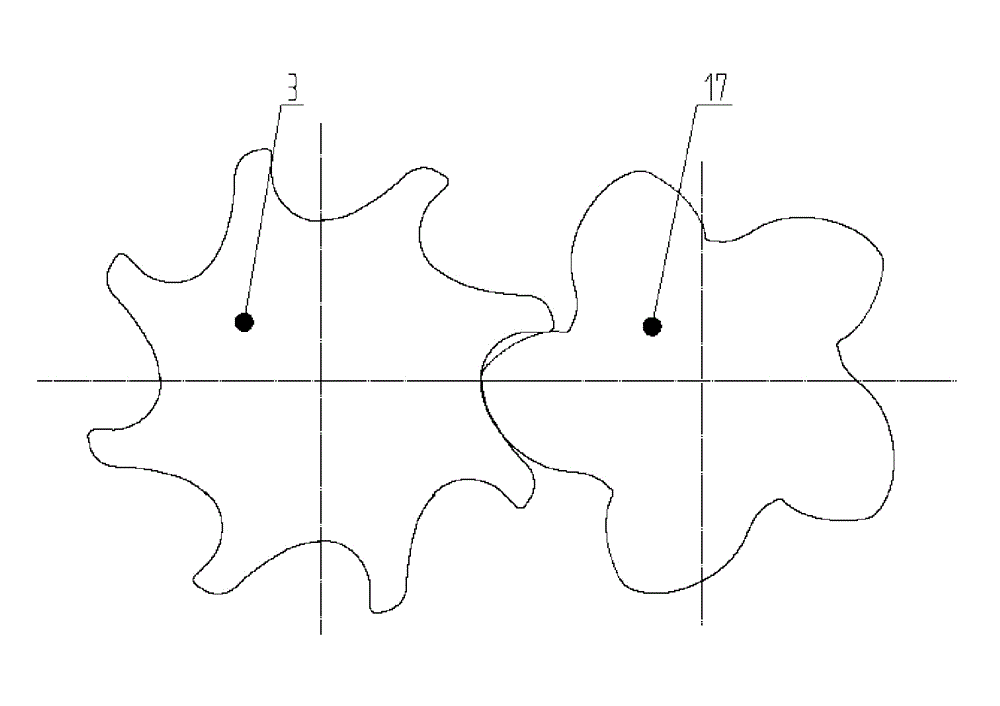

[0022] Such as figure 2 As shown, the body 2 is provided with a female rotor 3 and a male rotor 17, the suction ends of the female rotor 3 and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com