Ratchet wheel angle monitoring device for overhead contact mesh system

A technology of angle monitoring and catenary, applied in the direction of overhead lines, etc., can solve the problem of weight sticking and other problems, achieve the effects of increasing hardness, simplifying the overall structure, and improving reliability and safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in detail below in combination with specific embodiments.

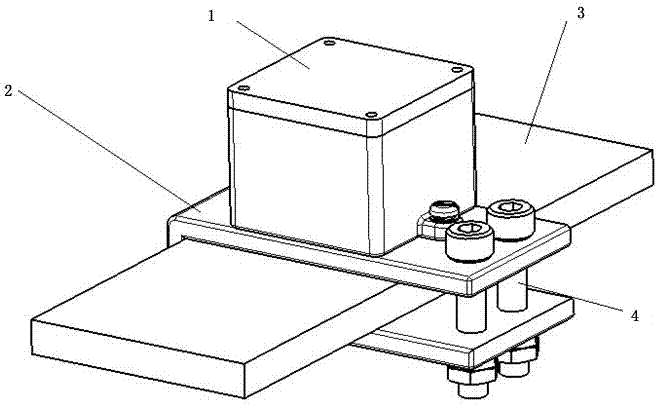

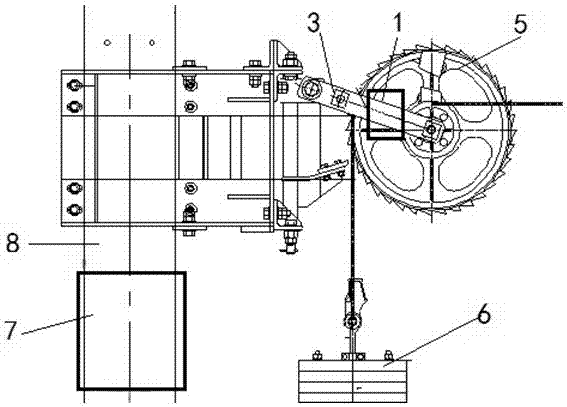

[0023] The invention relates to a ratchet angle monitoring device for a catenary system, which includes a housing 1 installed on a ratchet compensation bracket 3, and an angle sensor based on an accelerometer, an anti-electromagnetic interference circuit, an angle sensor, and an anti-electromagnetic interference circuit are installed in the housing 1 The circuit communicates with the concentrator 7 installed on the compensating lower anchor post 8 through a flexible cable, and the communication interface adopts RS485 to realize data communication and equipment power supply.

[0024] The housing 1 has a base 2 with a U-shaped structure, and the ratchet compensation bracket 3 is inserted into the U-shaped groove of the base 2 and clamped and fixed by bolts 4 .

[0025] This product can be installed in the middle of the ratchet compensation bracket 3, and the concentrator 7 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com