Efficient self-recycling system for continuously preparing sodium bichromate by wet method

A self-circulating, sodium red alum technology, applied in the direction of sustainable manufacturing/processing, climate sustainability, chromate/dichromate, etc., can solve the problem of increased labor intensity, low heat recovery utilization rate, and incomplete resources. Use and other issues to achieve the effect of reducing environmental pollution, reducing manufacturing costs, and reducing waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it with reference to the description.

[0026] It should be understood that terms such as "having", "comprising" and "including" as used herein do not entail the presence or addition of one or more other elements or combinations thereof.

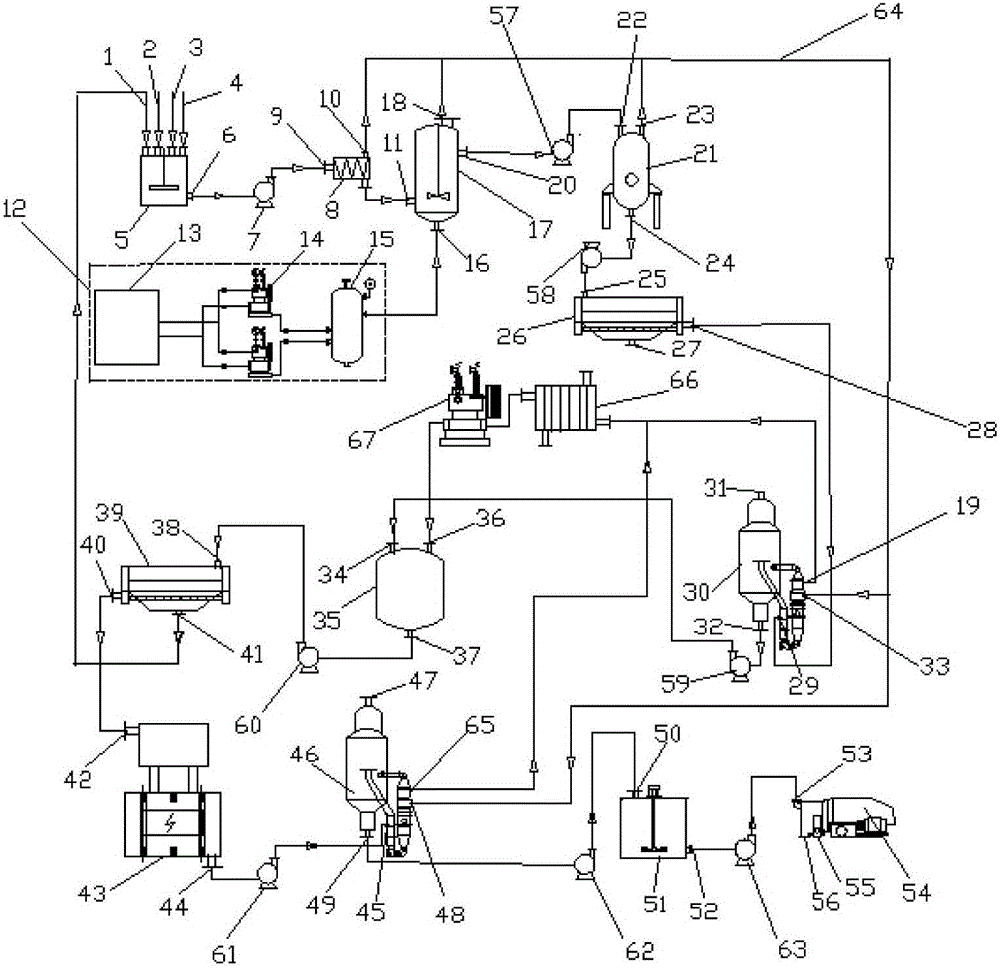

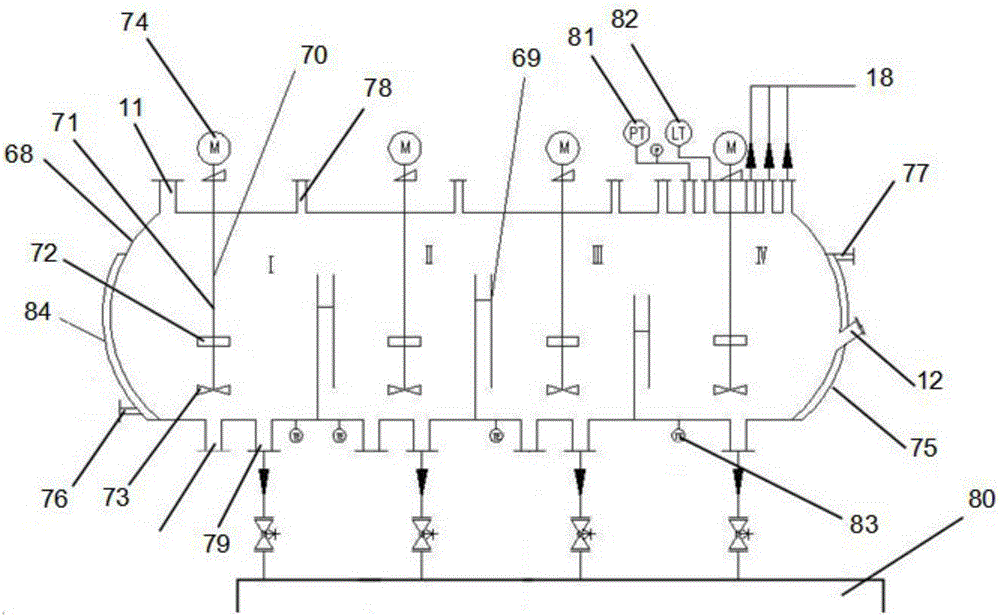

[0027] figure 1 Show a kind of high-efficiency self-circulation wet method of the present invention to continuously prepare the system of sodium rufium, comprising:

[0028] A beating tank 5 is provided with a sodium bicarbonate inlet 1, a ferrochrome powder inlet 2, a sodium carbonate inlet 3 and a water inlet 4 for inputting raw materials;

[0029] The beating tank 5 is sequentially connected to the first delivery pump 7, the preheating device 8, the liquid phase oxidation reaction device 17, the flash evaporation device 21, the first separation device 26, the first concentrat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com