Patents

Literature

96results about How to "Reduce radial load" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

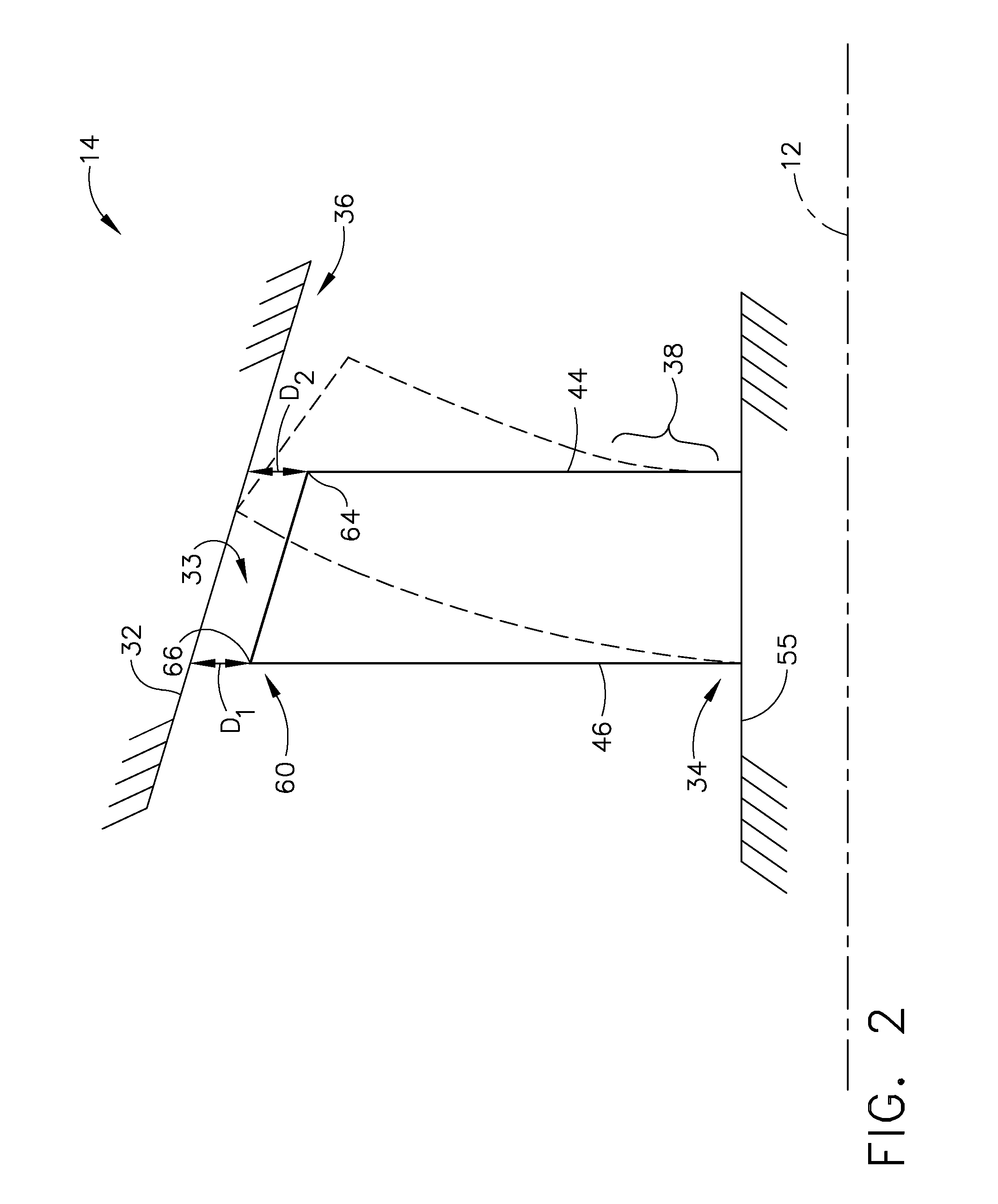

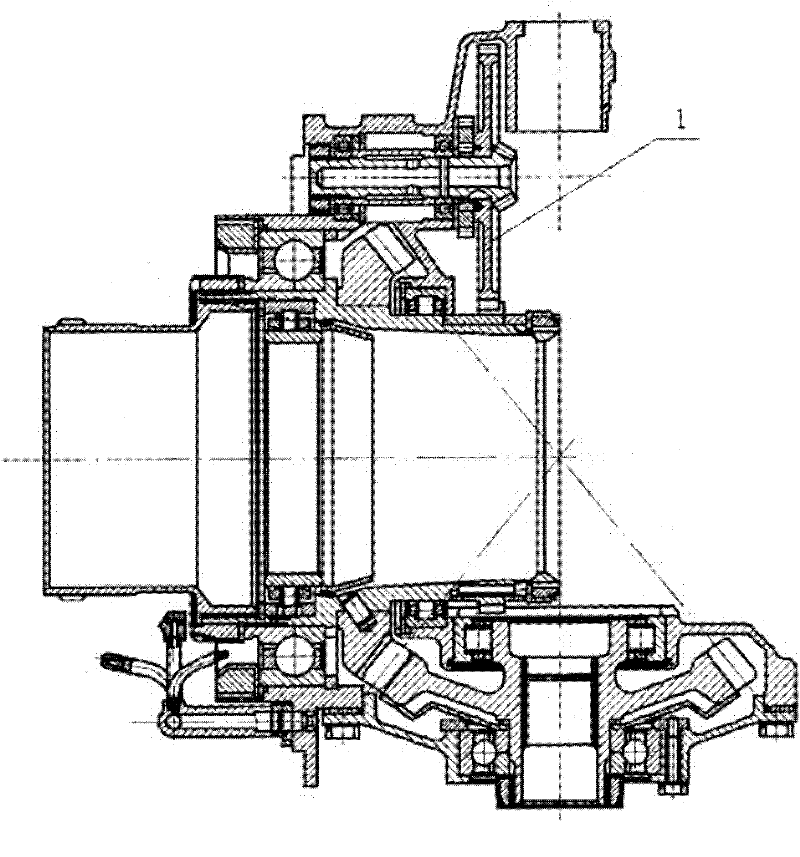

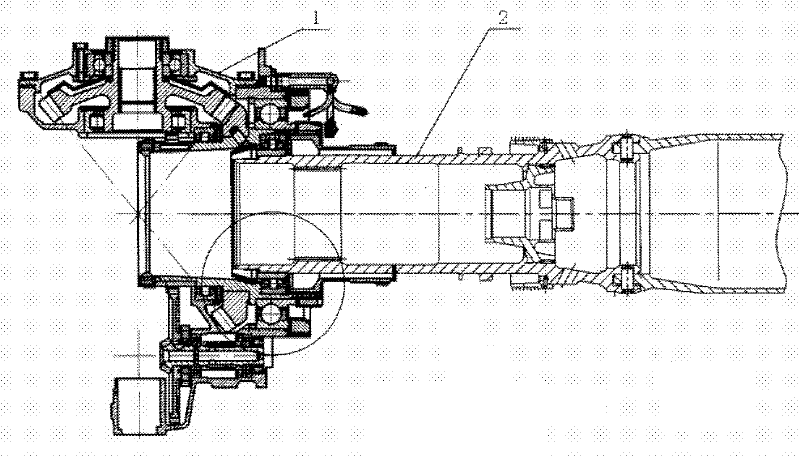

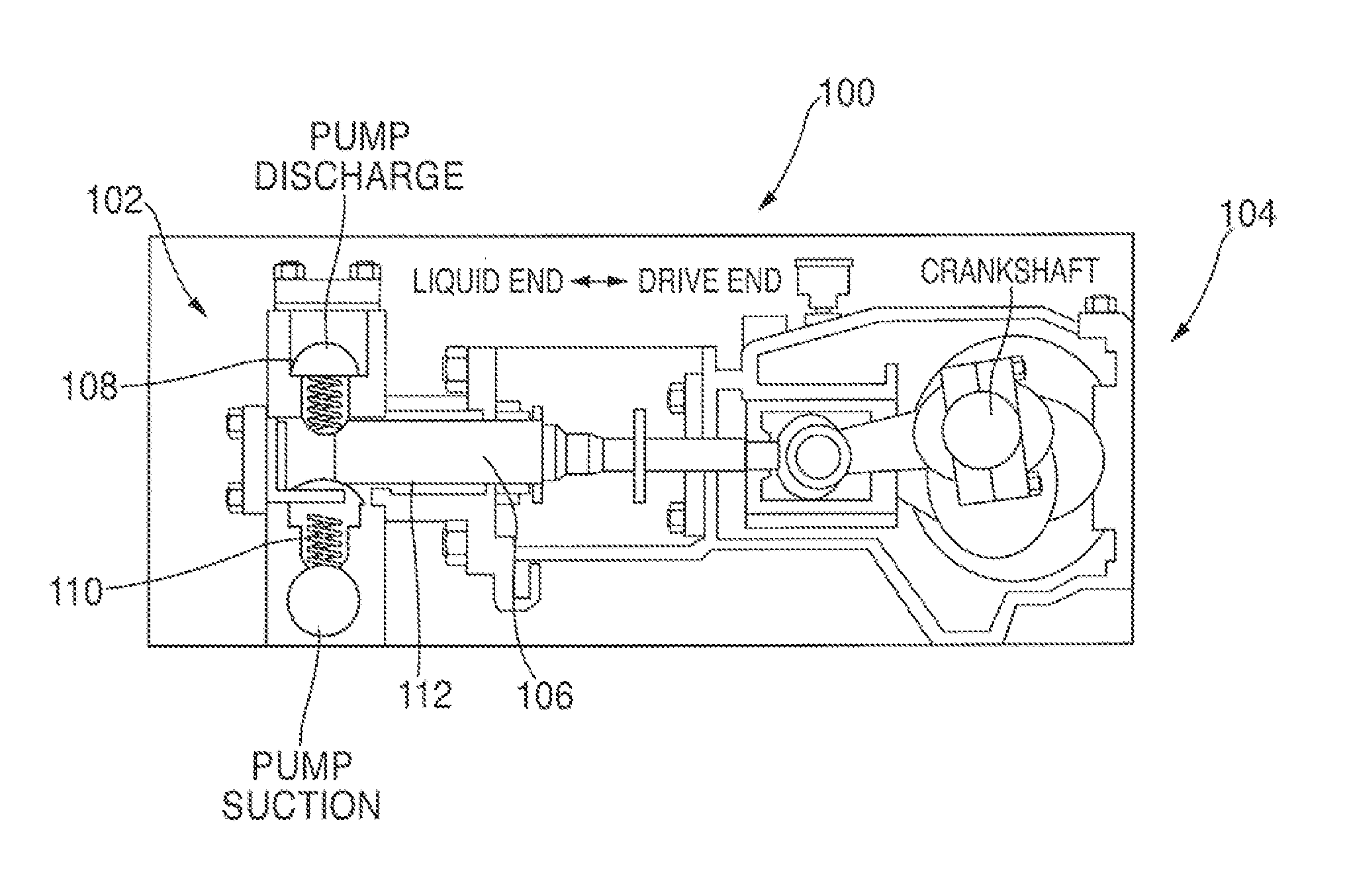

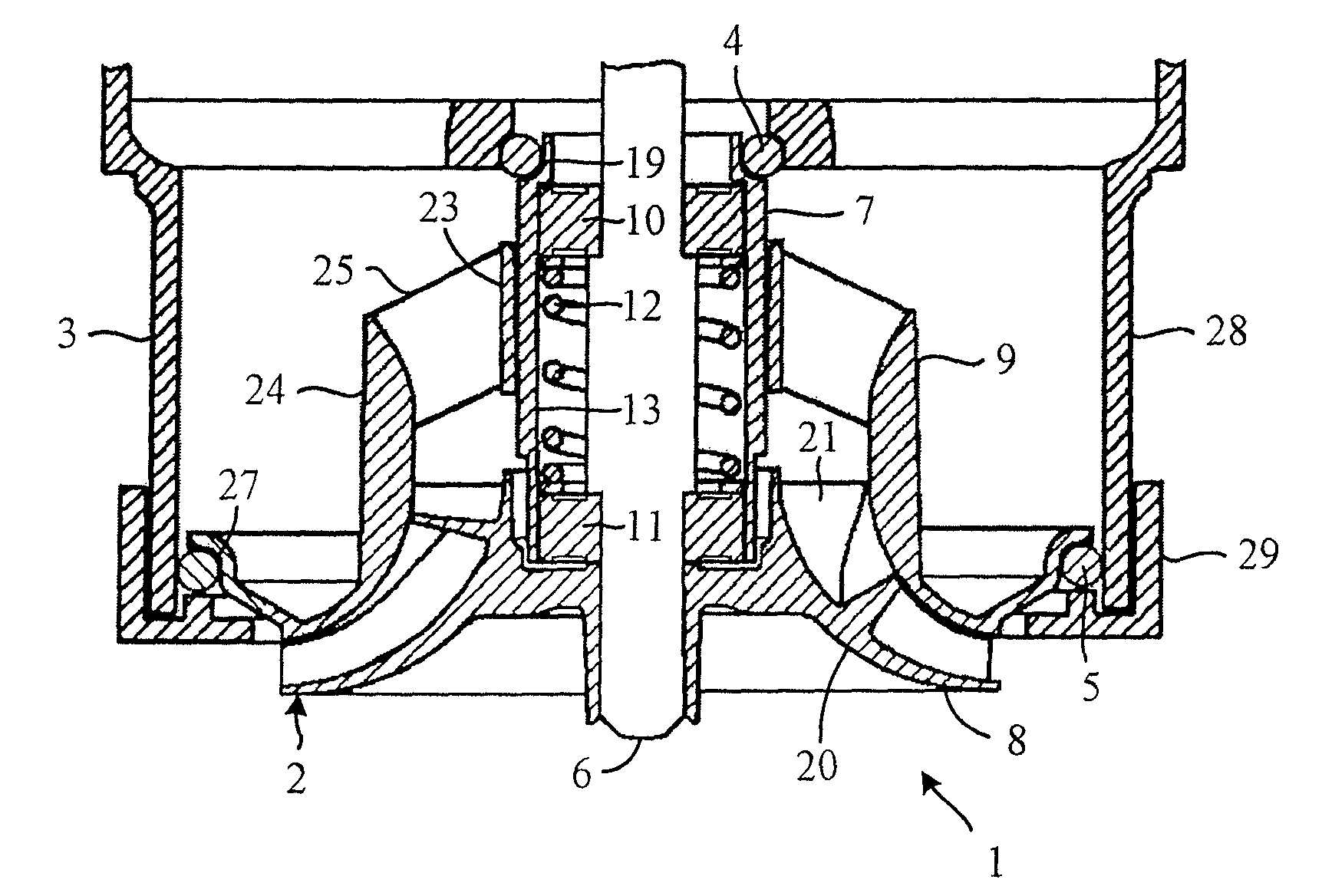

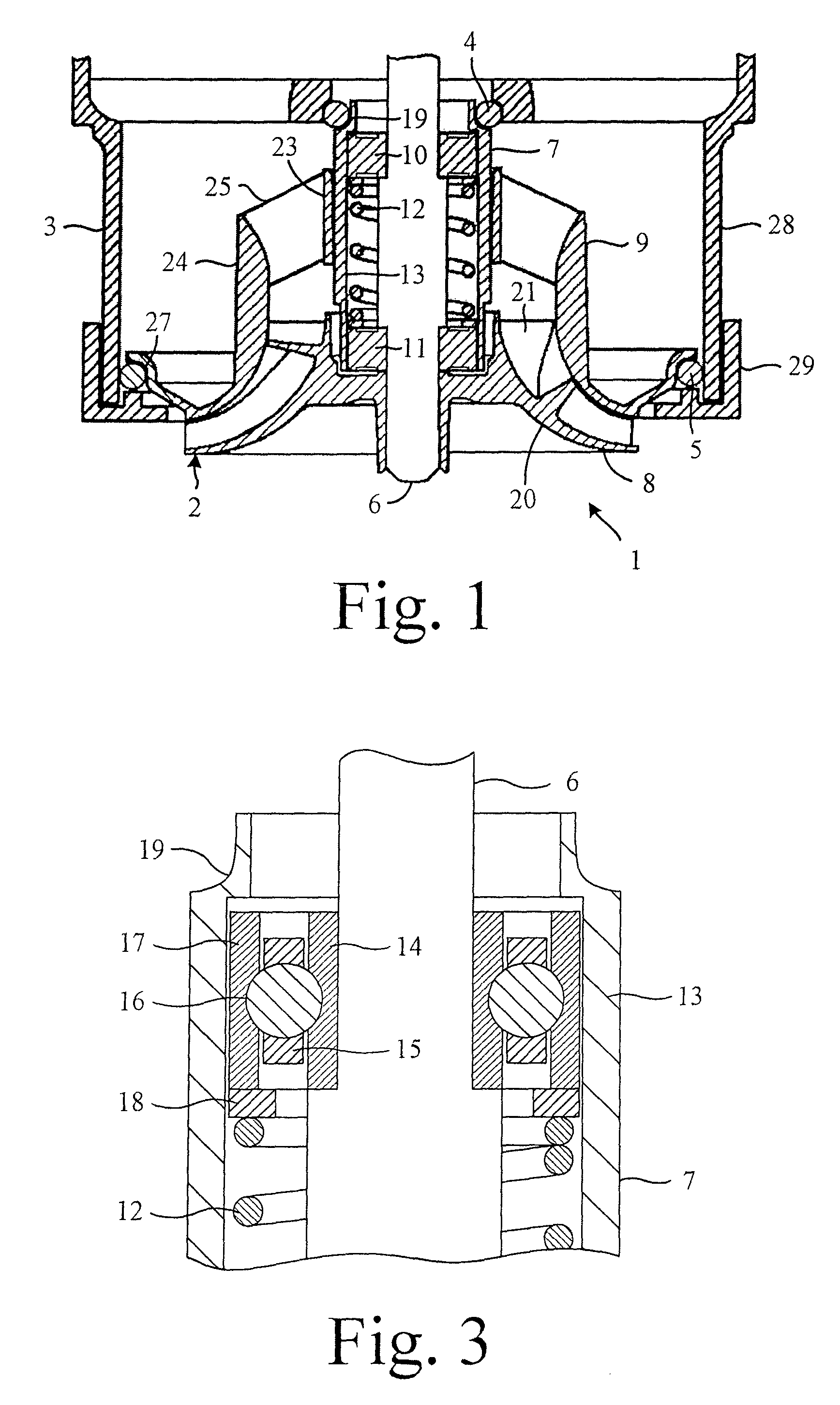

Opposing pump/motors

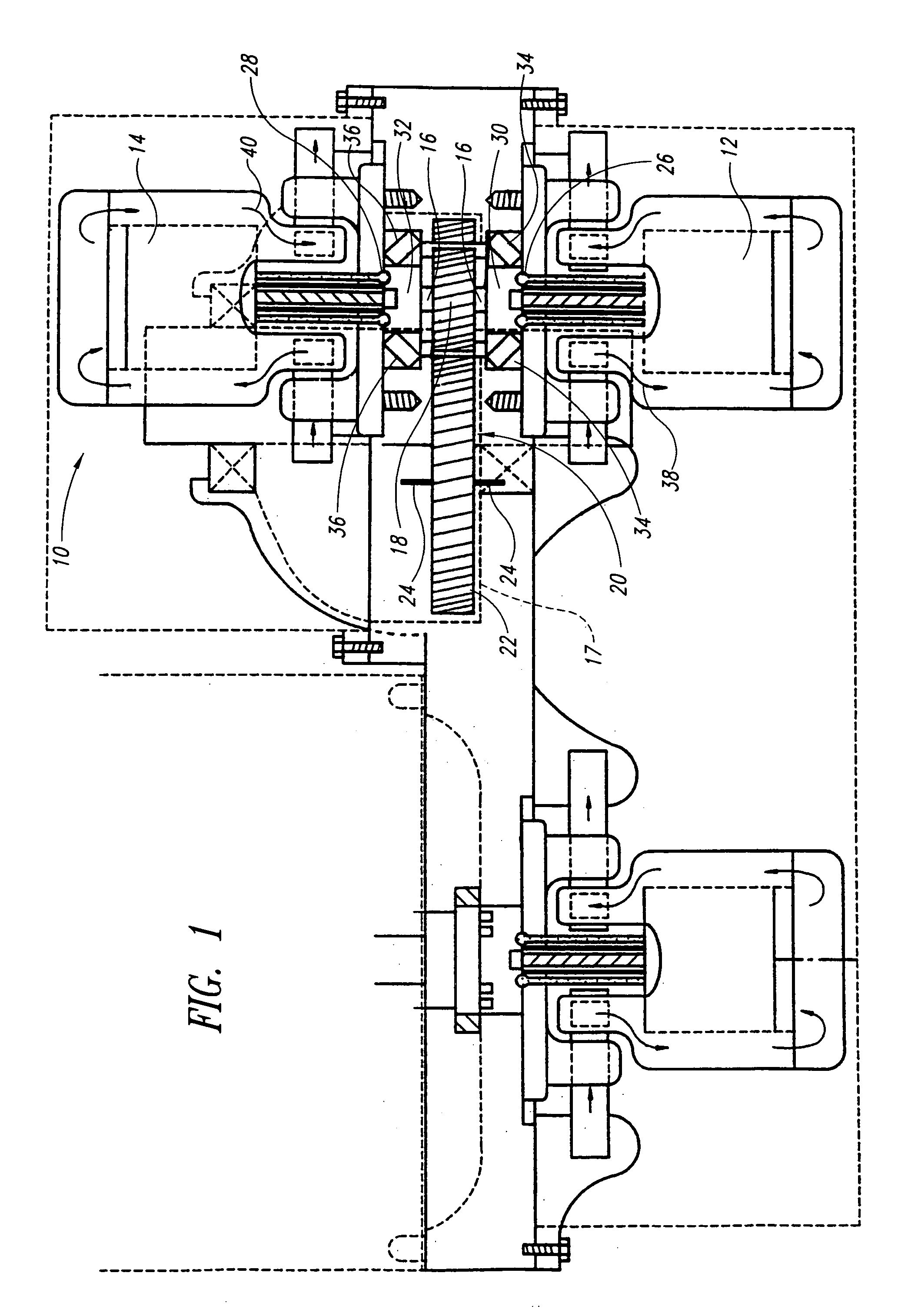

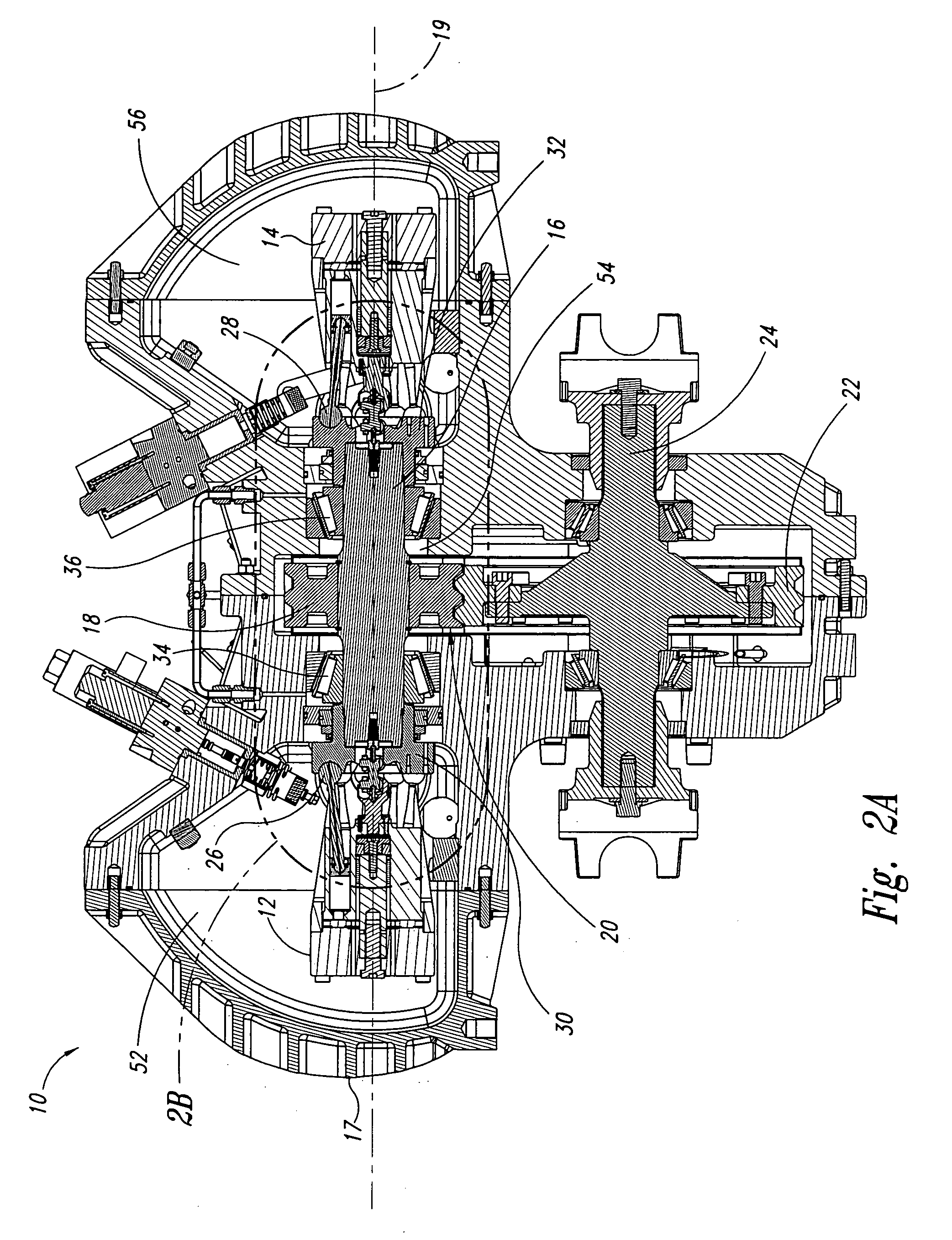

InactiveUS7374005B2Reducing weight and costSmall sizeAuxillary drivesGearing controlMotor driveEngineering

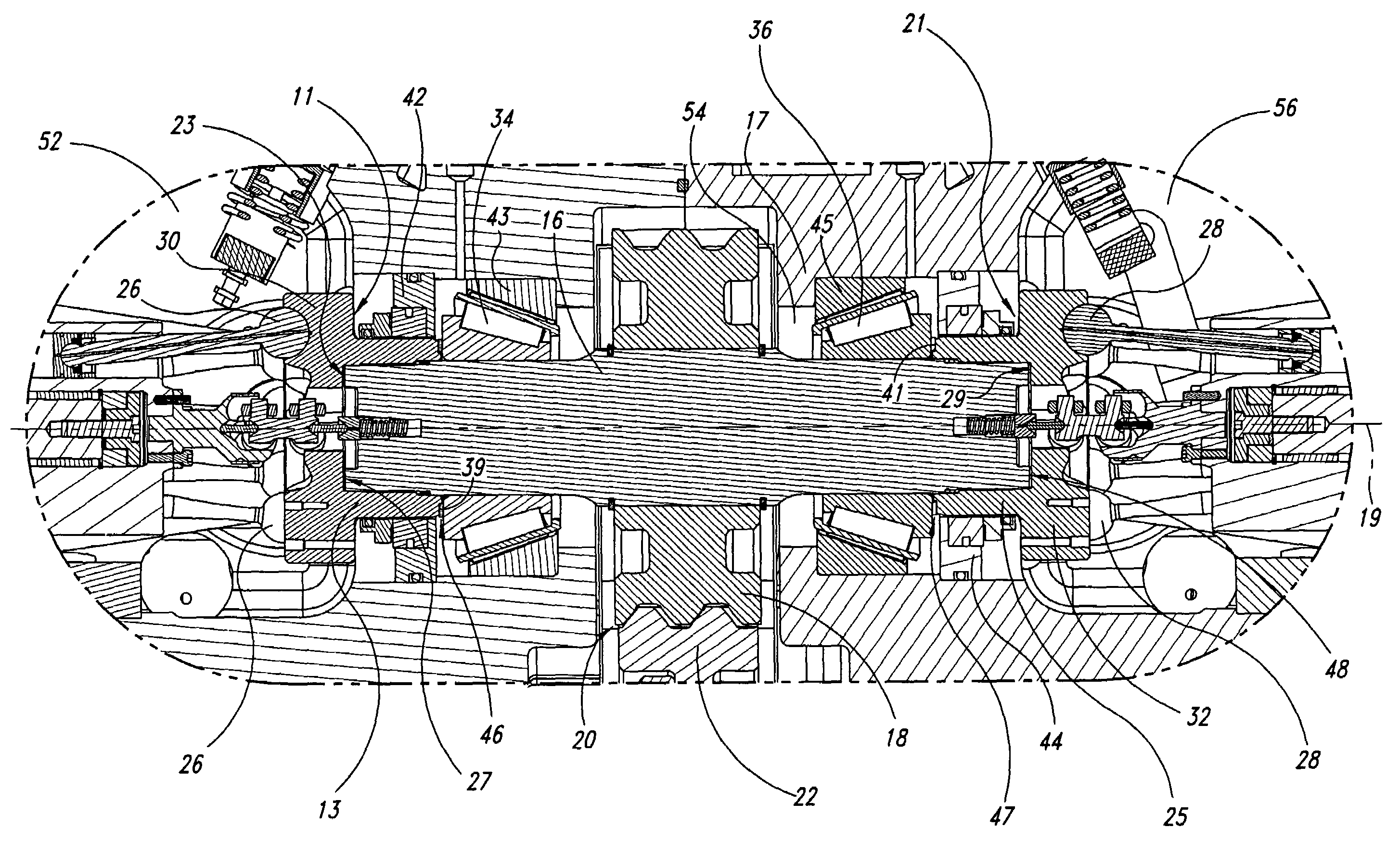

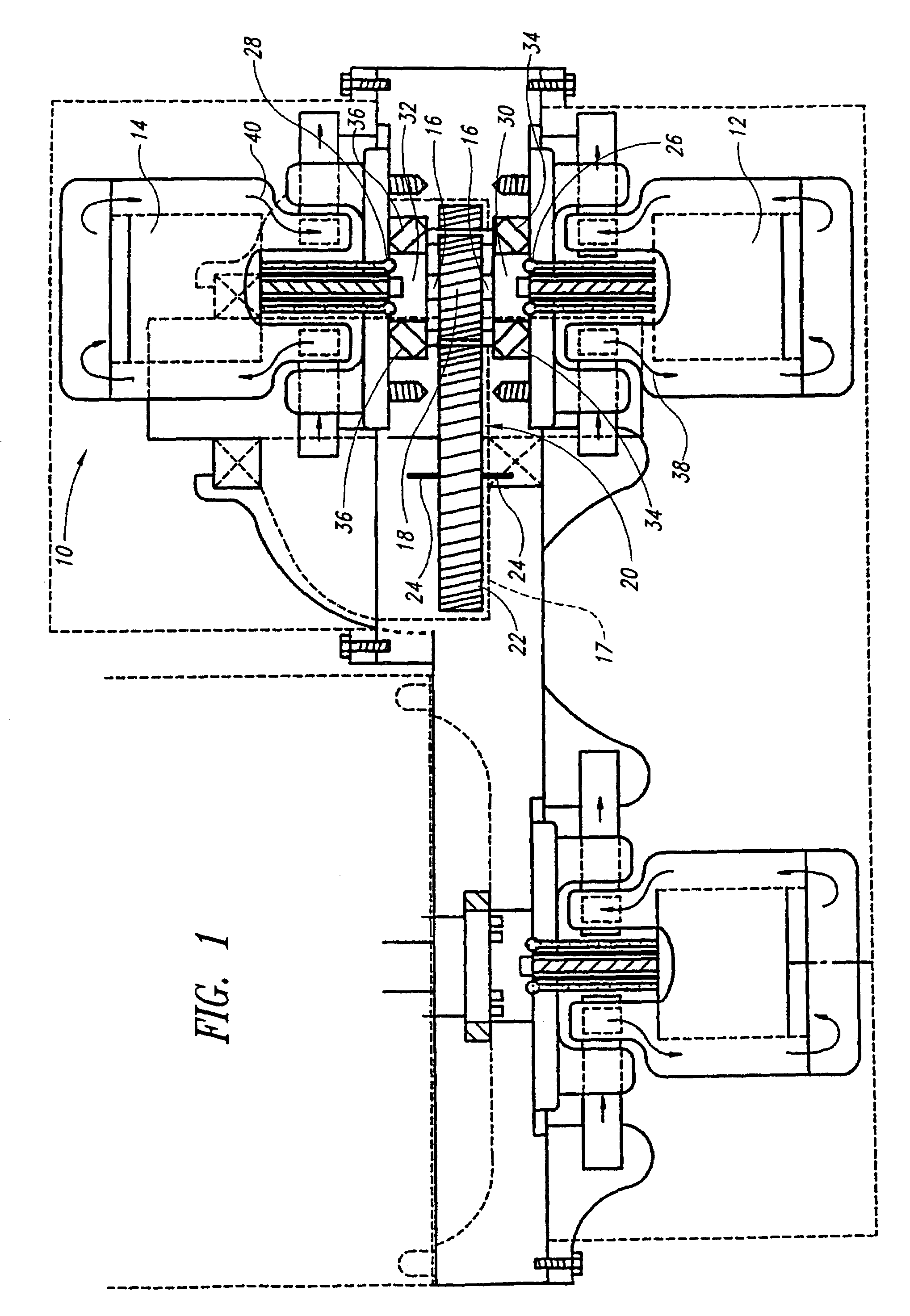

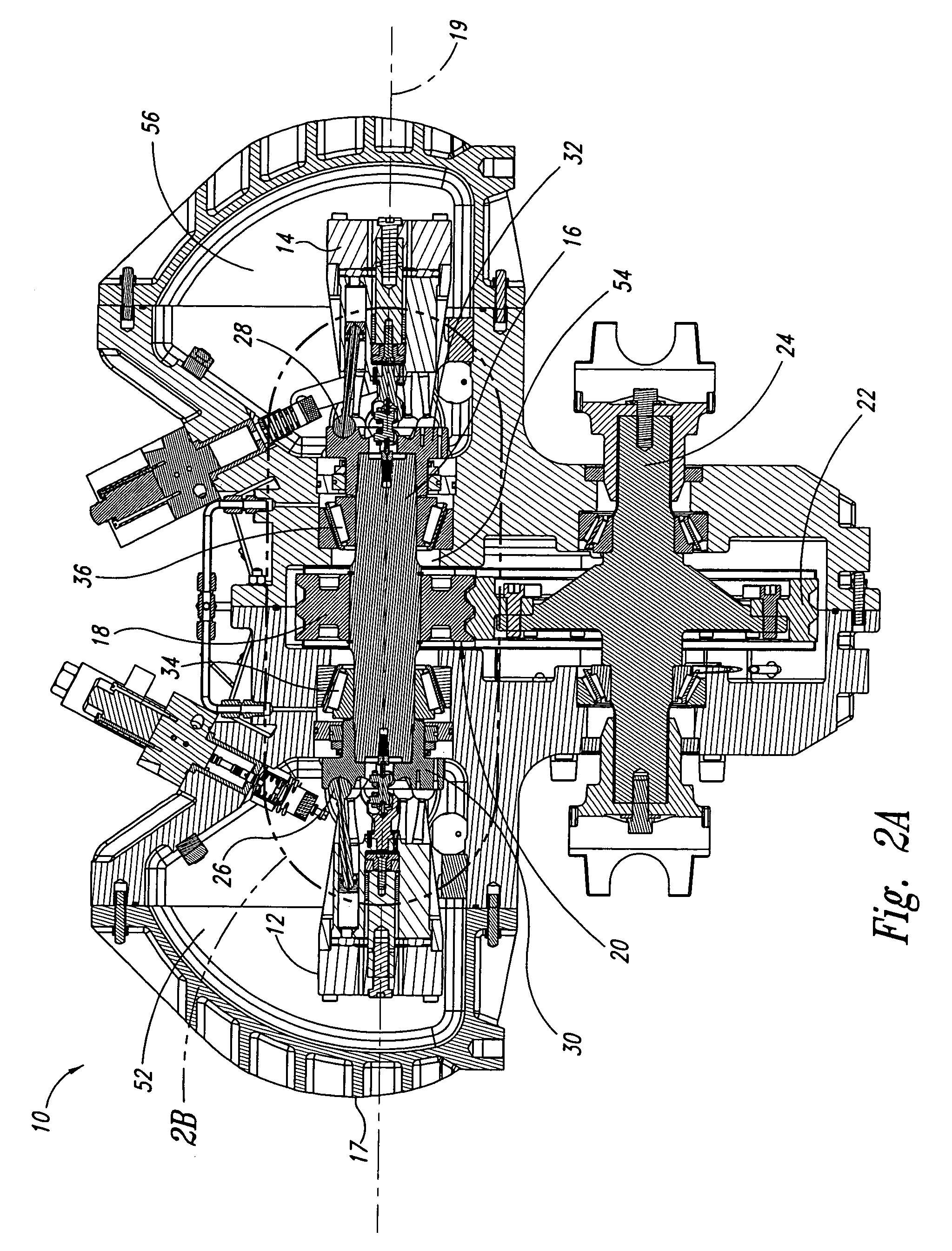

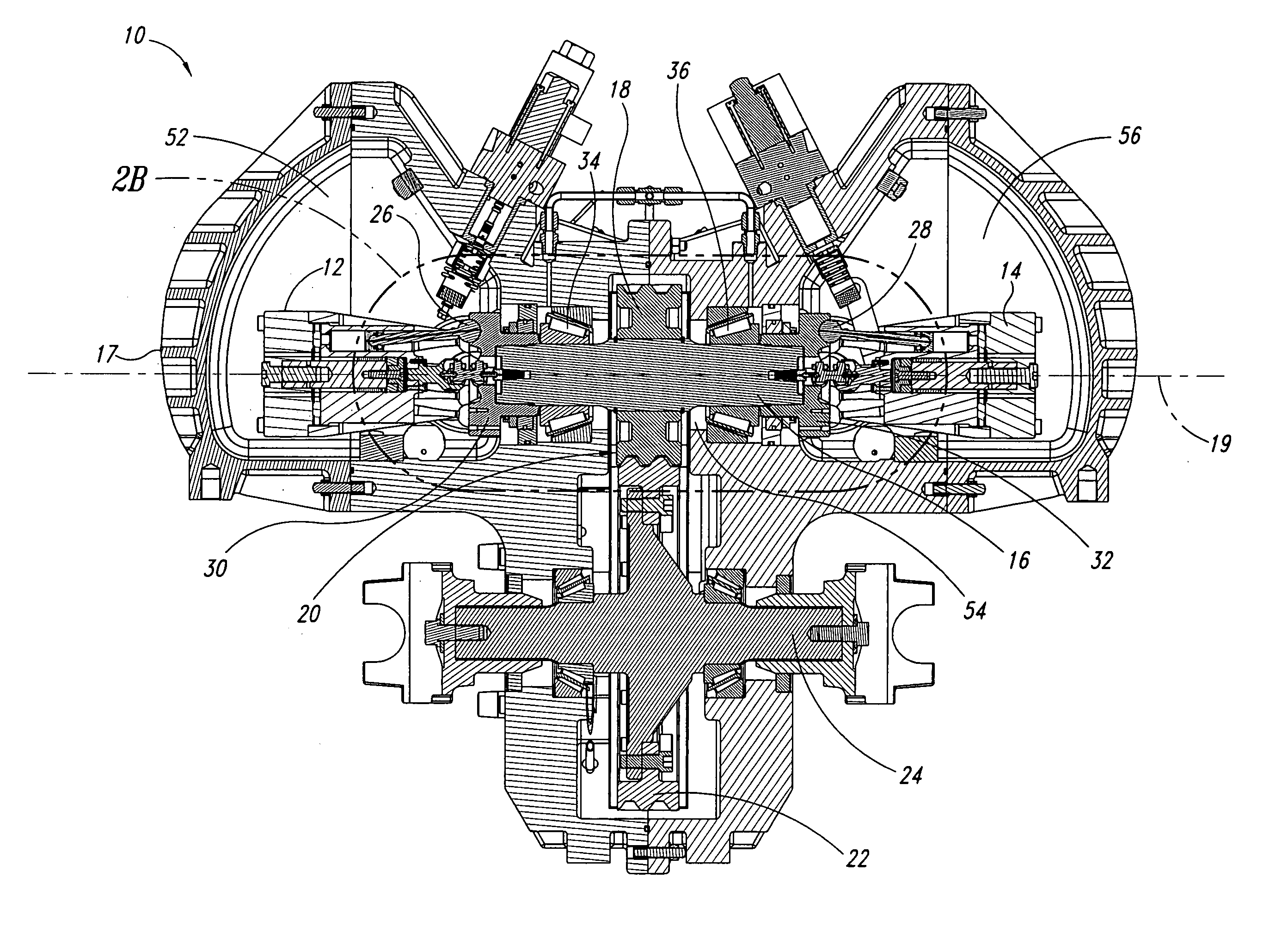

Two motors are arranged on opposing sides of a common shaft, drive plates of the pump / motors being rigidly coupled to each other, for example by being in hard contact with opposing sides of the shaft. By providing hard contact between the pump / motor drive plates and a common shaft, the drive plates and shaft act as a substantially solid element under compression, thereby substantially canceling axial loads generated by the pump / motors directly through the shaft. Residual axial loads are handled via bearings positioned on the shaft adjacent the drive plates in such a manner that the drive plates are in light contact only with the bearings. As a result, friction experienced by the bearings is substantially reduced as compared to conventional systems, thereby improving the efficiency of the system. To further reduce loads on the bearings, the pump / motors are arranged to ensure that they generate radial forces in a direction that is opposite to that of a separation force generated by a torque transferring device carried on the shaft and transmitted to the bearings. A common housing surrounding the two pump / motors, bearings and torque transferring device is divided into three regions, to segregate the bearings and torque transferring assembly from the pump / motors. In this manner, the regions containing the pump / motors are substantially filled with oil to, for example, fully lubricate the pump / motors, while the central region containing the gears and torque transferring device contains a significantly smaller volume of oil to simply splash lubricate the contents of the region, thereby reducing drag on the bearings. Control means are provided for selectively moving the two pump / motors substantially simultaneously to a selected displacement angle, using mechanical systems alone and in combination with hydraulic systems.

Owner:GOVERNMENT OF THE US REPRESENTED BY THE ADMINISTRATOR OF THE U S ENVIRONMENTAL PROTECTION AGENCY

Opposing pump/motors

InactiveUS20050207921A1Reduce weightLow costFlexible member pumpsGearing controlMotor driveCombined use

Two motors are arranged on opposing sides of a common shaft, drive plates of the pump / motors being rigidly coupled to each other, for example by being in hard contact with opposing sides of the shaft. By providing hard contact between the pump / motor drive plates and a common shaft, the drive plates and shaft act as a substantially solid element under compression, thereby substantially canceling axial loads generated by the pump / motors directly through the shaft. Residual axial loads are handled via bearings positioned on the shaft adjacent the drive plates in such a manner that the drive plates are in light contact only with the bearings. As a result, friction experienced by the bearings is substantially reduced as compared to conventional systems, thereby improving the efficiency of the system. To further reduce loads on the bearings, the pump / motors are arranged to ensure that they generate radial forces in a direction that is opposite to that of a separation force generated by a torque transferring device carried on the shaft and transmitted to the bearings. A common housing surrounding the two pump / motors, bearings and torque transferring device is divided into three regions, to segregate the bearings and torque transferring assembly from the pump / motors. In this manner, the regions containing the pump / motors are substantially filled with oil to, for example, fully lubricate the pump / motors, while the central region containing the gears and torque transferring device contains a significantly smaller volume of oil to simply splash lubricate the contents of the region, thereby reducing drag on the bearings. Control means are provided for selectively moving the two pump / motors substantially simultaneously to a selected displacement angle, using mechanical systems alone and in combination with hydraulic systems.

Owner:THE UNITED STATES OF AMERICA AS REPRESENTED BY THE ADMINISTATOR OF THE U S ENVIRONMENTAL PROTECTION AGENCY EPA

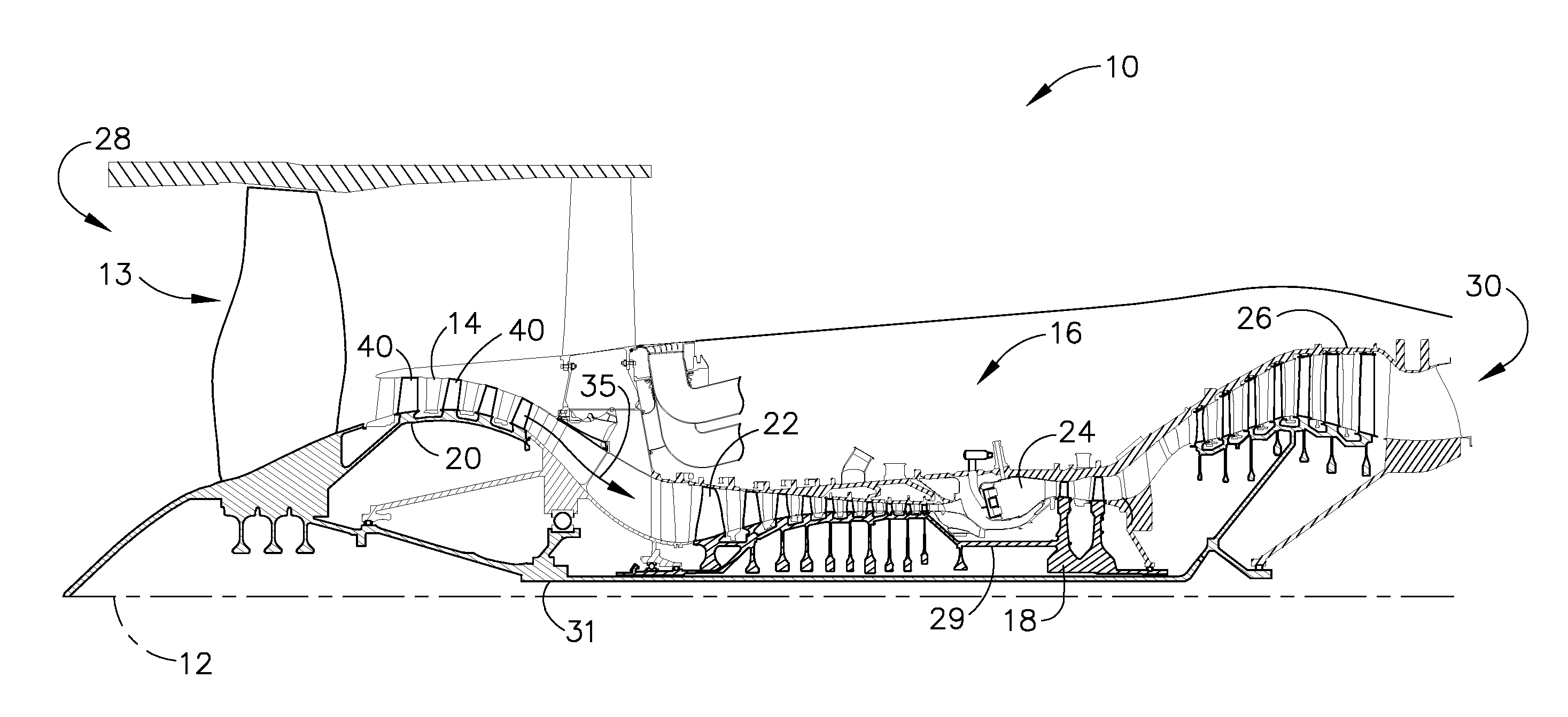

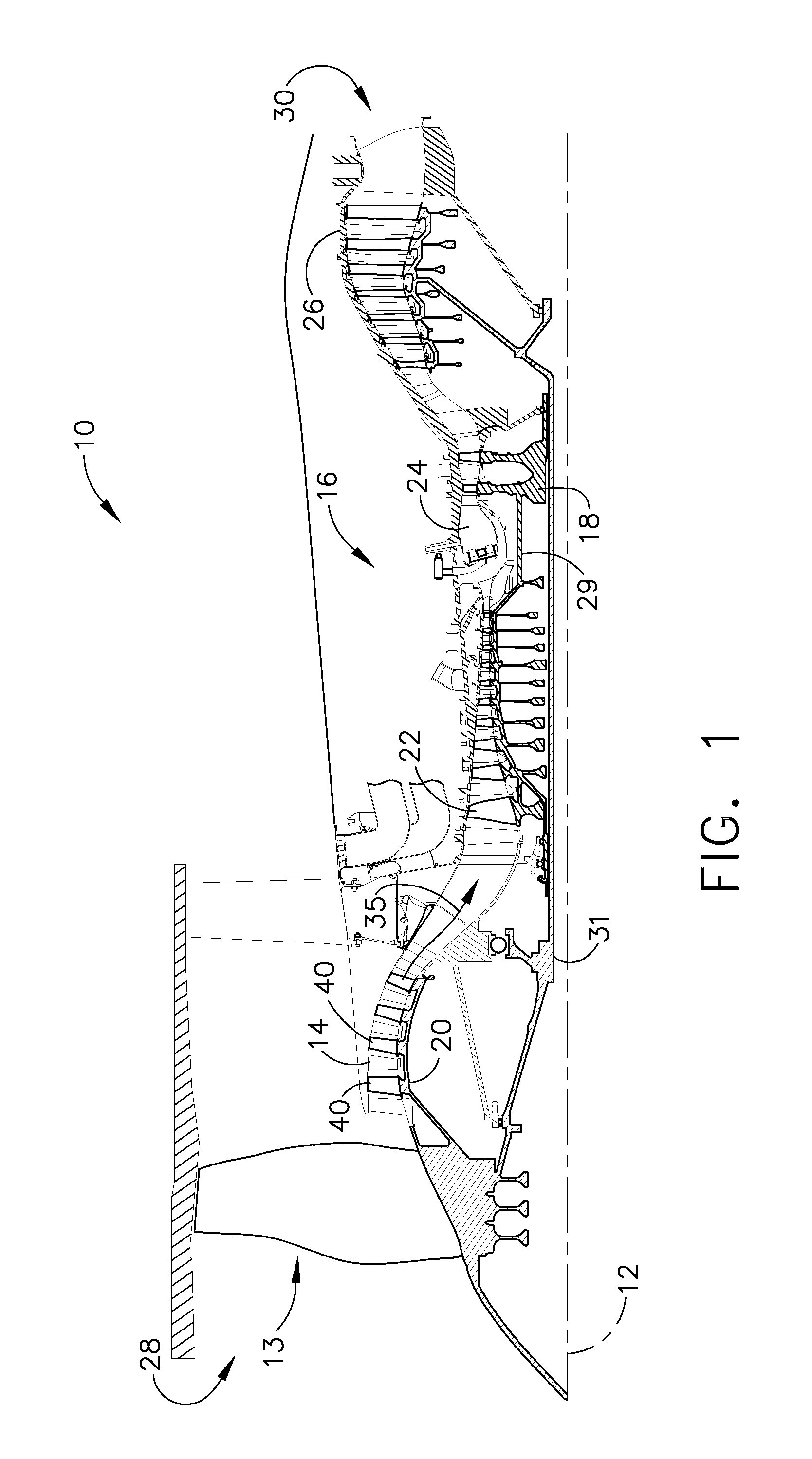

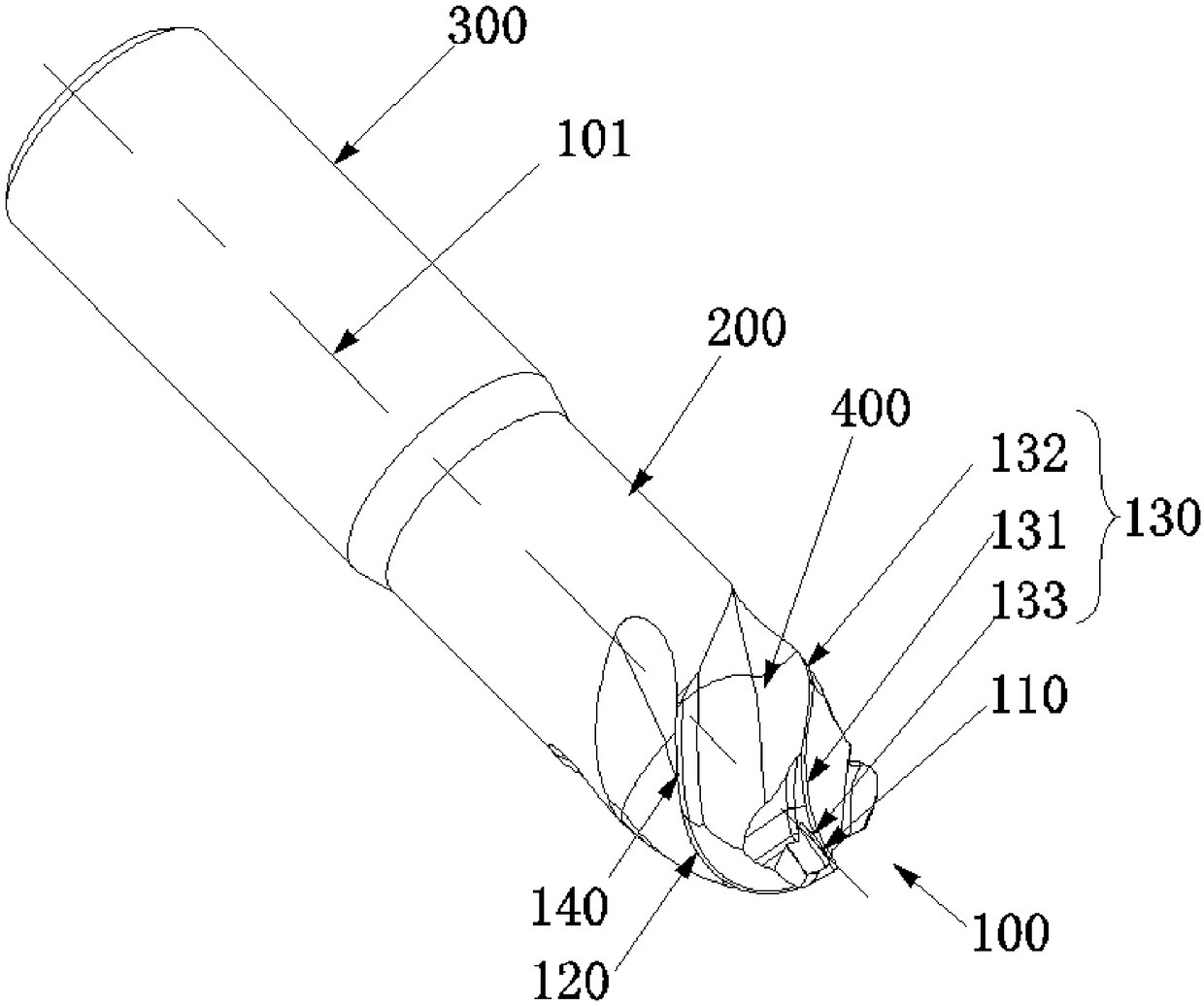

Methods and apparatus for fabricating a rotor assembly

ActiveUS20080159869A1Facilitates reducing radial loadingReduce radial loadPropellersEngine manufactureLeading edgeEngineering

In one aspect, a method for assembling a rotor assembly is provided. The method comprises providing a rotor blade including a first sidewall, a second sidewall, where the first and second sidewalls are connected at a leading edge and a trailing edge and extend in span from a root portion to a tip portion, removing blade material from the tip portion to form a tip portion rake angle that enables the tip portion to extend obliquely between the first and second sidewalls, and coupling the rotor blade to a shaft such that during tip rubs the tip portion rake angle facilitates reducing radial loading induced to the blade during tip rubs.

Owner:GENERAL ELECTRIC CO

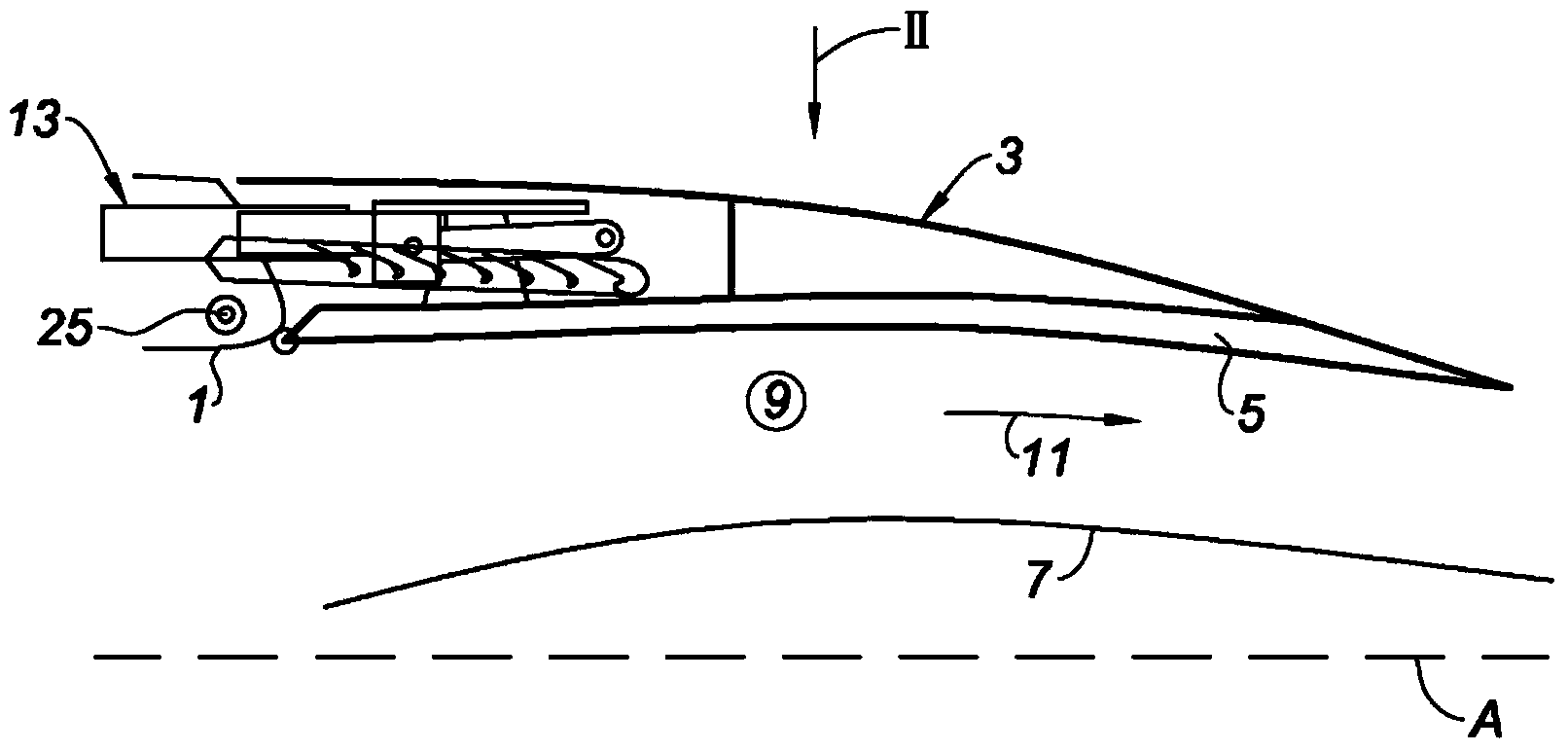

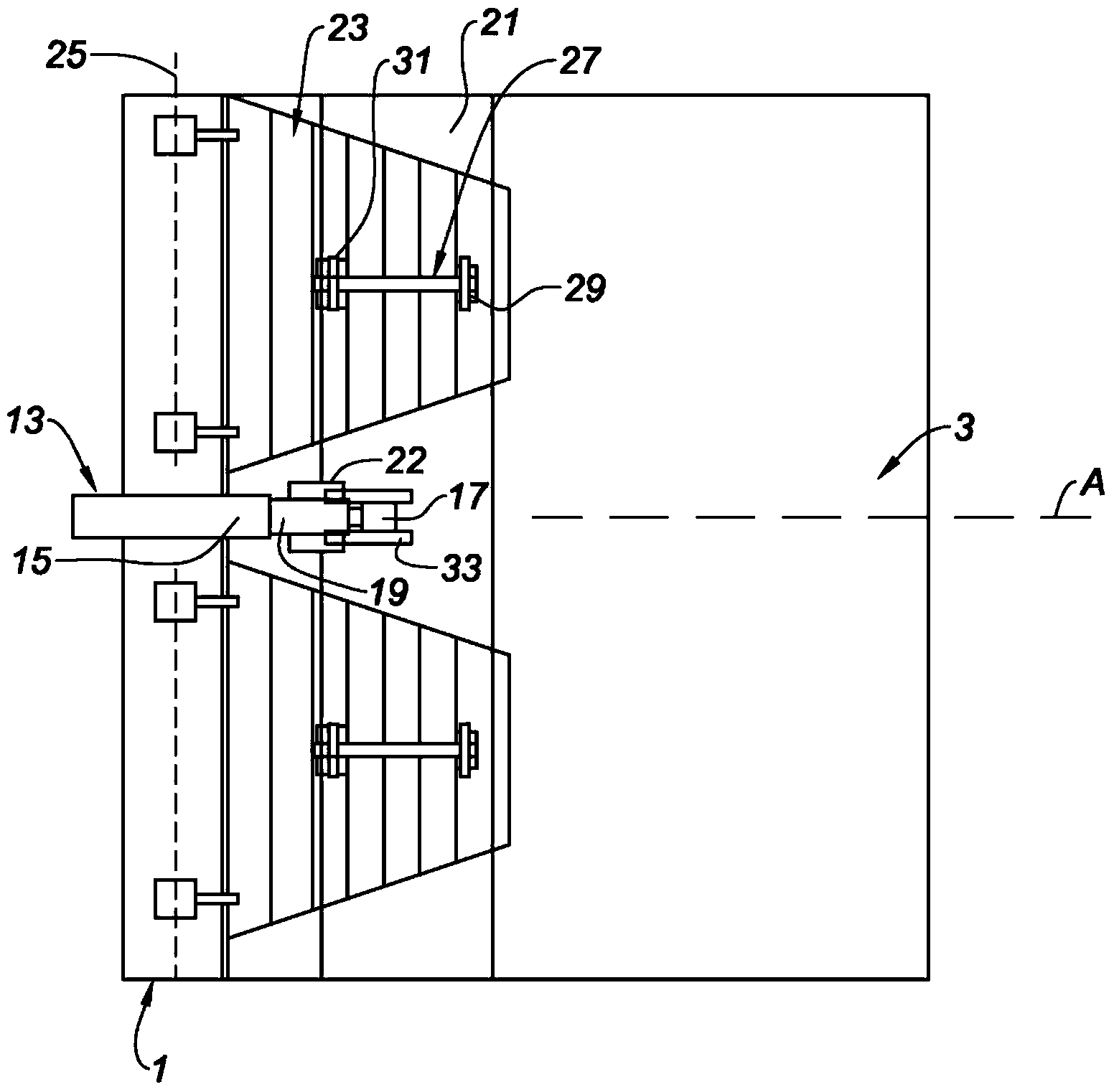

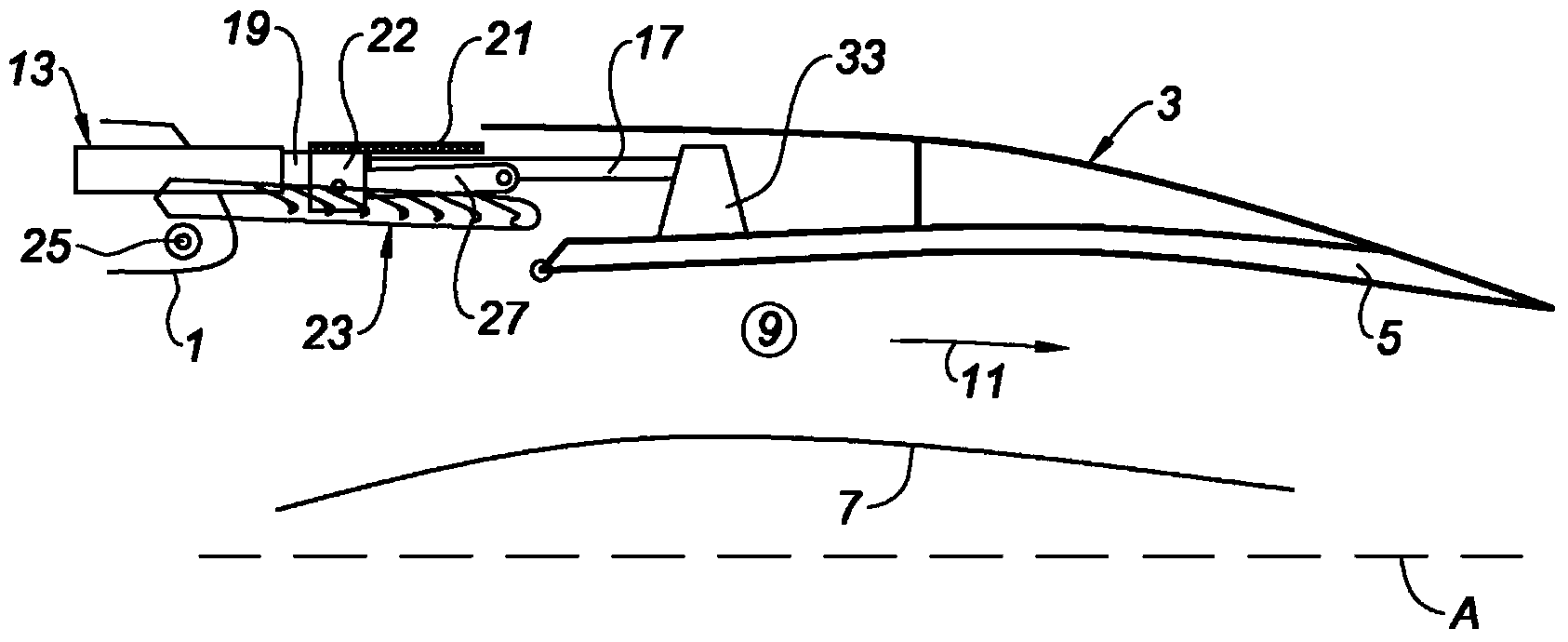

Thrust reverser with pivoting grilles

InactiveCN104114842AAchieve axial elongationGain weightEfficient propulsion technologiesJet propulsion plantsJet engineTurbojet engine

This grid thrust reverser (23) for an aircraft turbojet engine comprises a front frame (1), a sliding cover (3) which slides between a direct jet position and a reverse jet position, a plurality of actuating cylinders (13) interposed between said front frame (1) and said sliding cover (3), and a plurality of grilles (23) mounted pivotably on the front frame (1) between a direct jet position, wherein said grilles (23) are substantially parallel to the axis (A) of the thrust reverser, and a reverse jet position, wherein said grilles are inclined relative to the axis (A) of the thrust reverser, characterised in that it comprises a single radial layer of grilles (23).

Owner:AIRCELLE

Cargo barrier

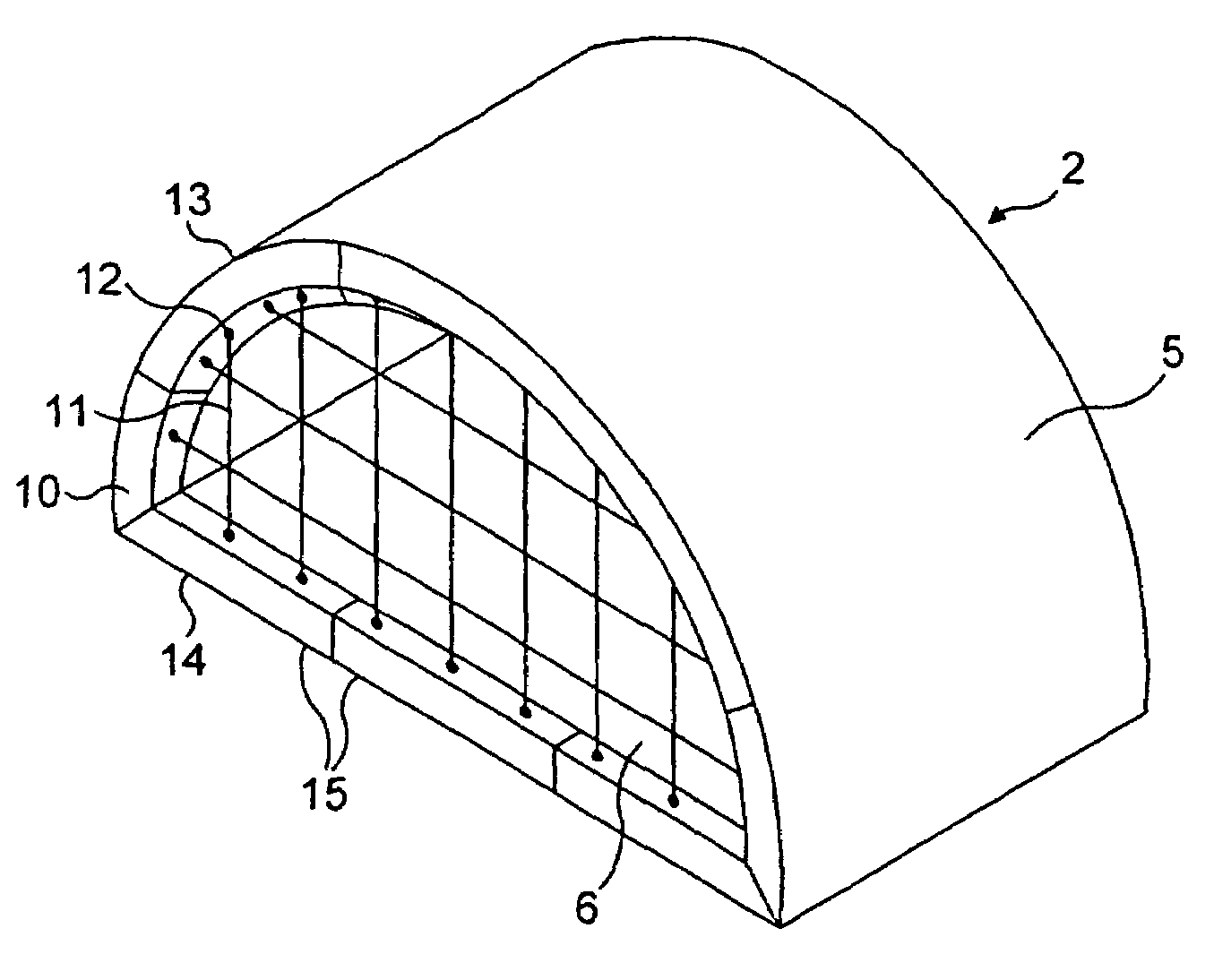

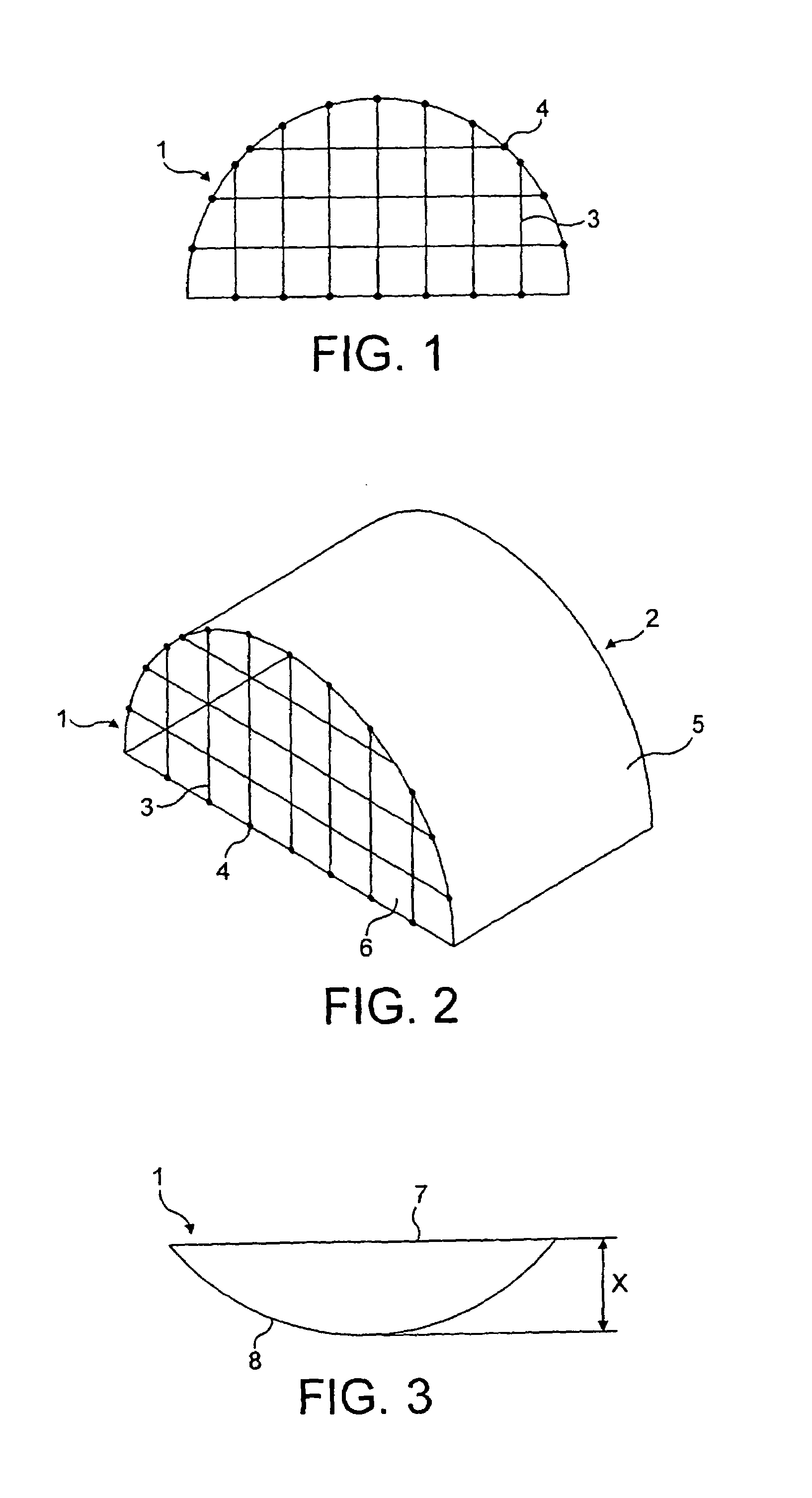

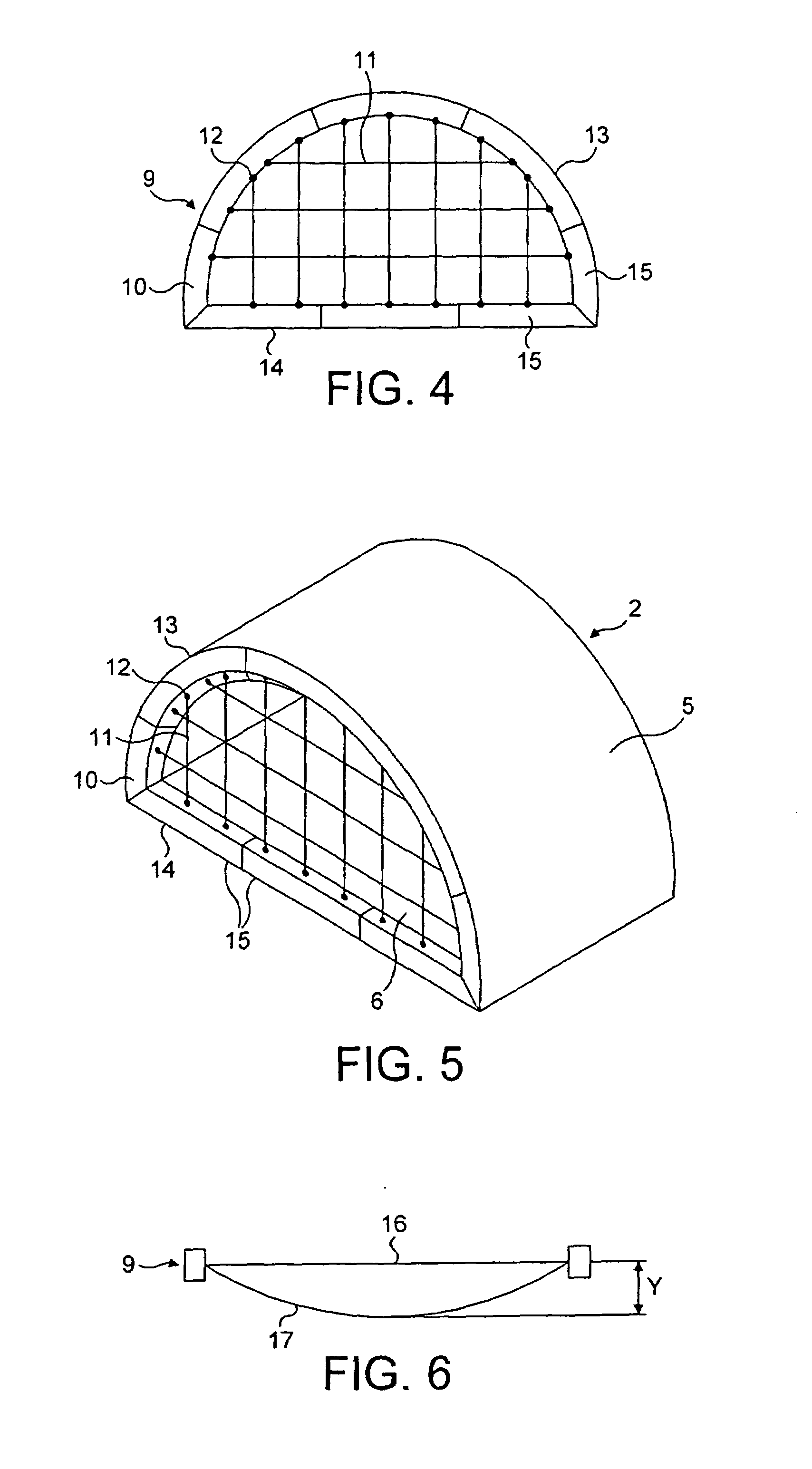

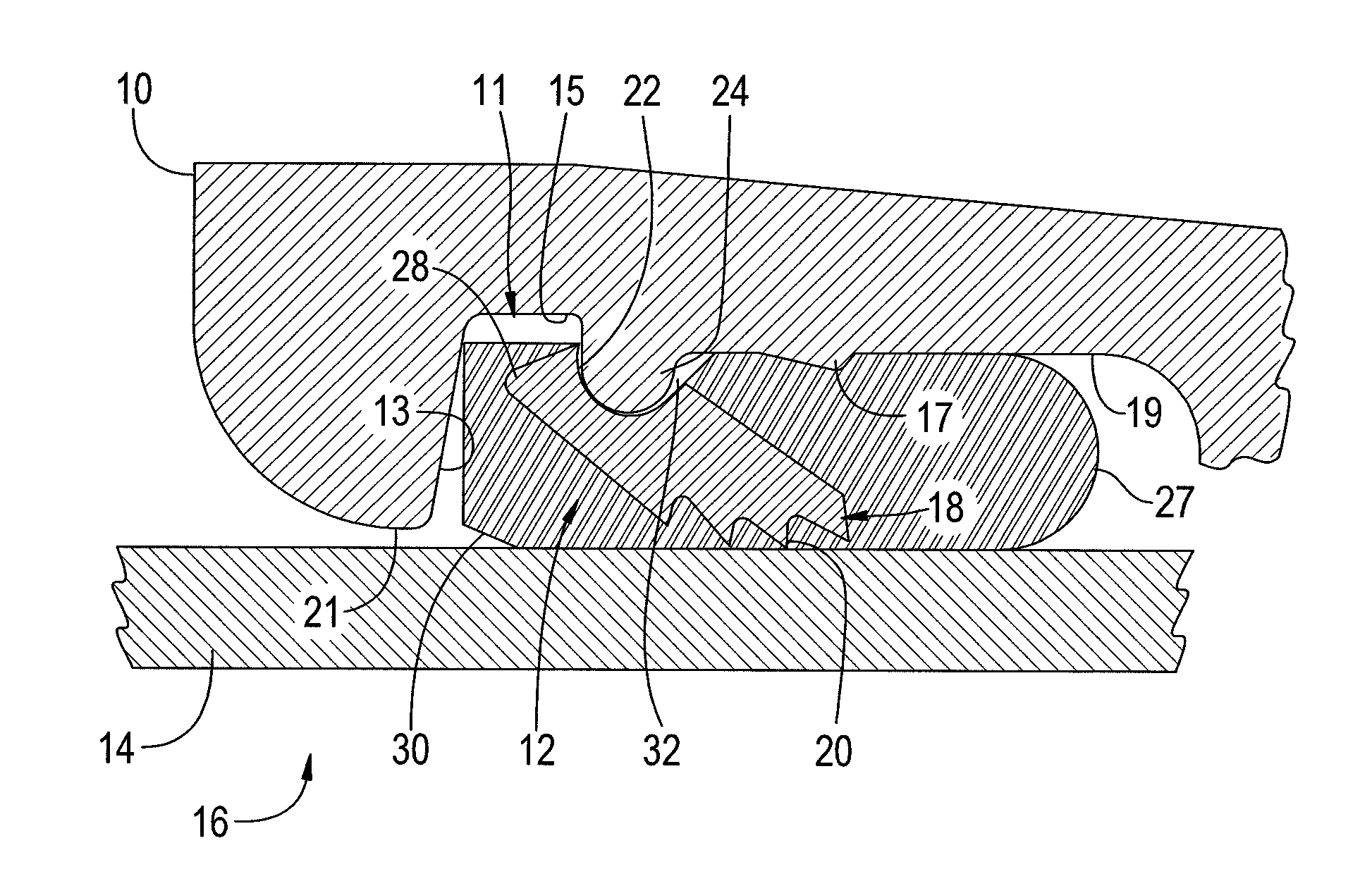

InactiveUS7140823B2Low extensionLift radial loadFreight handlingCargo supporting/securing componentsInterior spaceAirplane

A cargo barrier (9) in or for installation in an aircraft (2), the barrier (9) comprising a peripheral frame structure (10) of rigid material and a cargo restraining net (11), the frame structure (10) being, in the aircraft (2), attached to attachment points on the interior structure of the aircraft and the net being attached to attachment points (12) on the frame structure (10). The frame structure (10) and net (11), in use, form a barrier across an interior space of the aircraft (2) in order to restrain longitudinal movement of cargo within the aircraft (2).

Owner:AMSAFE BRIDPORT LTD

Pipe joint gasket and method of using same

ActiveUS8490273B1Avoid separationAvoid fracturesCouplingsMetal working apparatusEngineeringBiomedical engineering

A gasket for preventing separation of interconnected pipes without damaging the pipes. The gasket includes a compressible body having a plurality of metal segments partially embedded therein. Each of the metal segments includes a row of exposed teeth configured for engaging a spigot end of a pipe and a trough configured for pivotably engaging a bead on a bell. The trough is further configured for shearing or deforming the bead and inhibiting over-pivoting of the segment about the bead when the pipes are partially withdrawn away from one another, for example, during over-pressurization of the pipes.

Owner:MCWANE GLOBAL

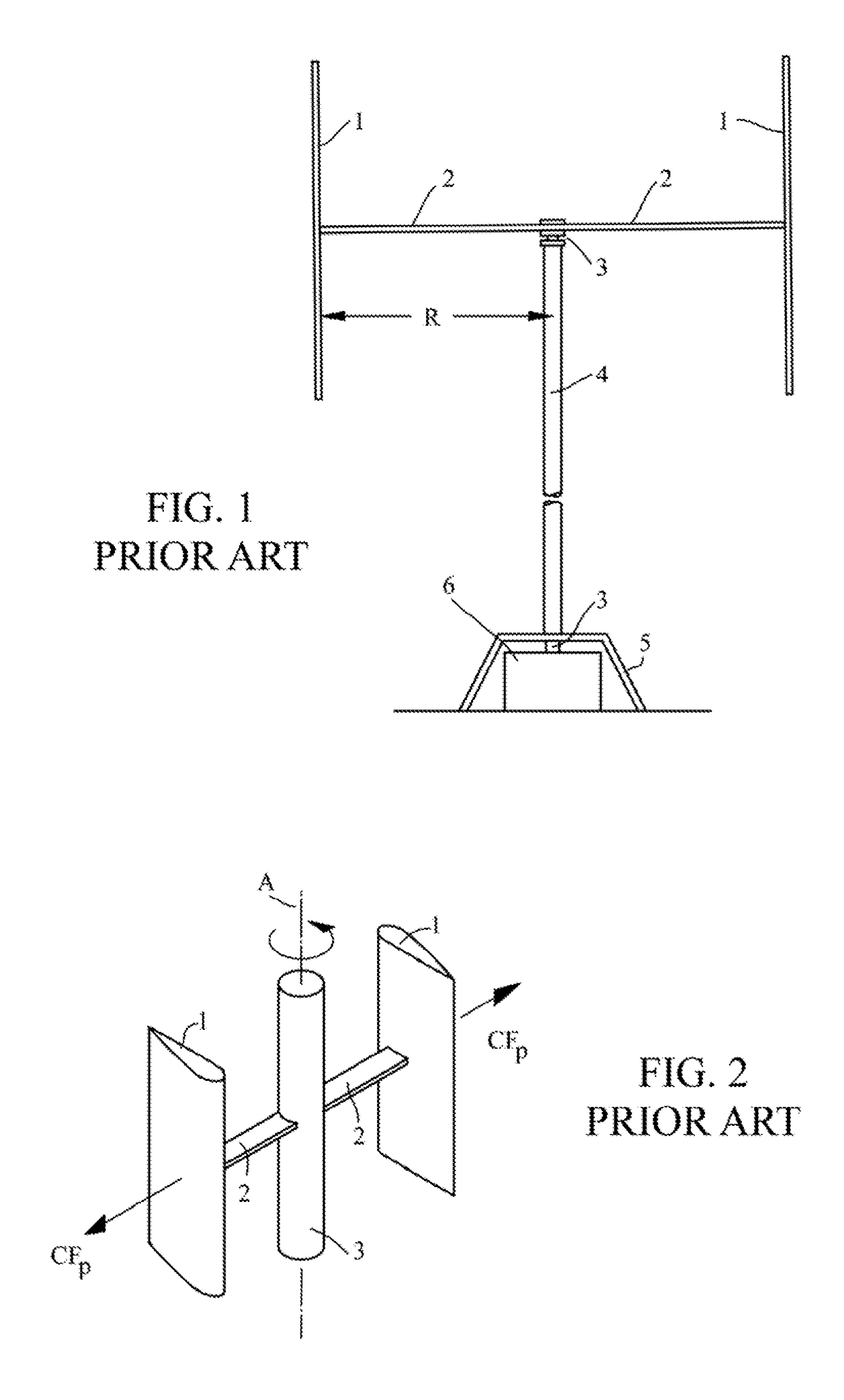

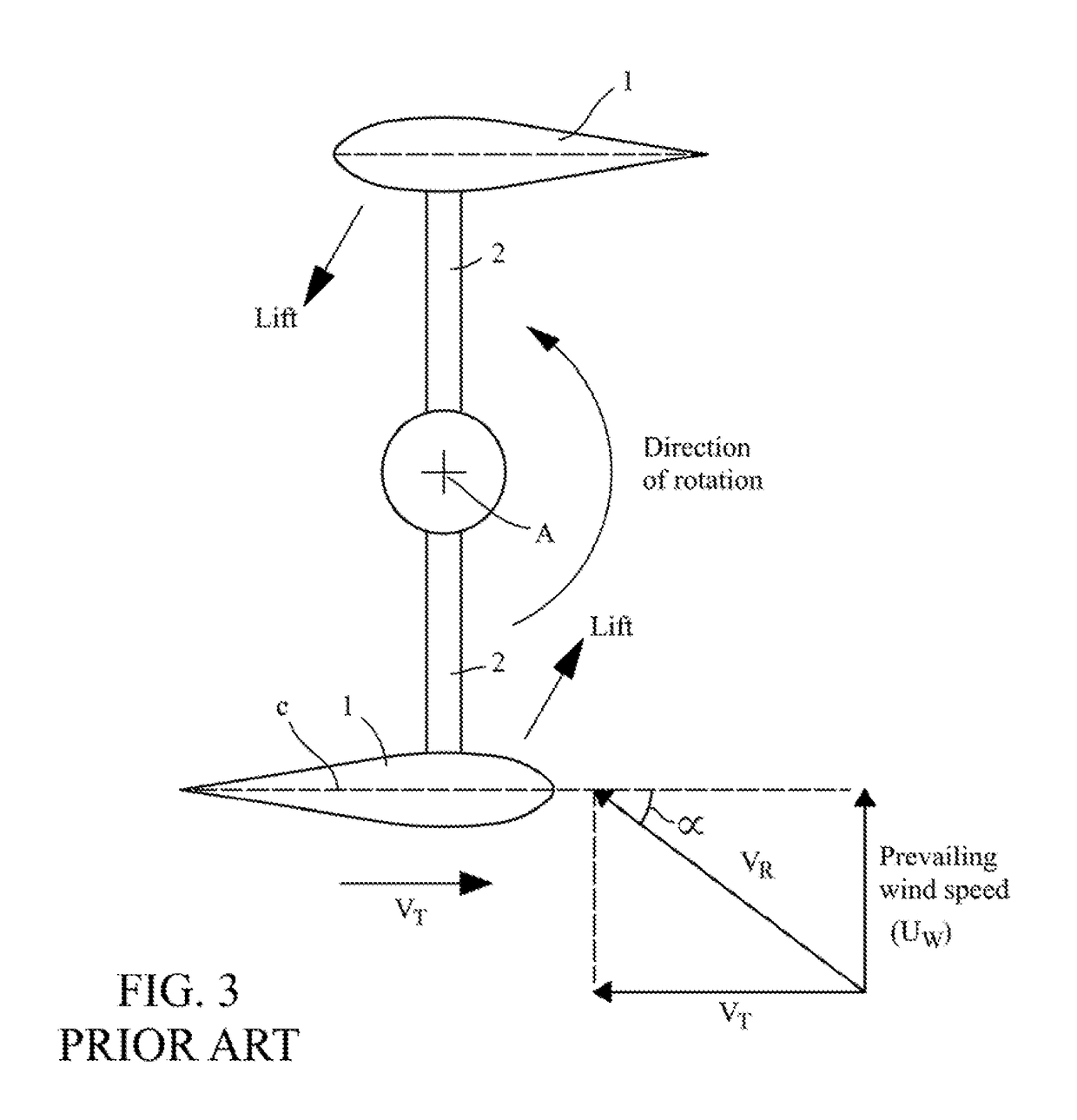

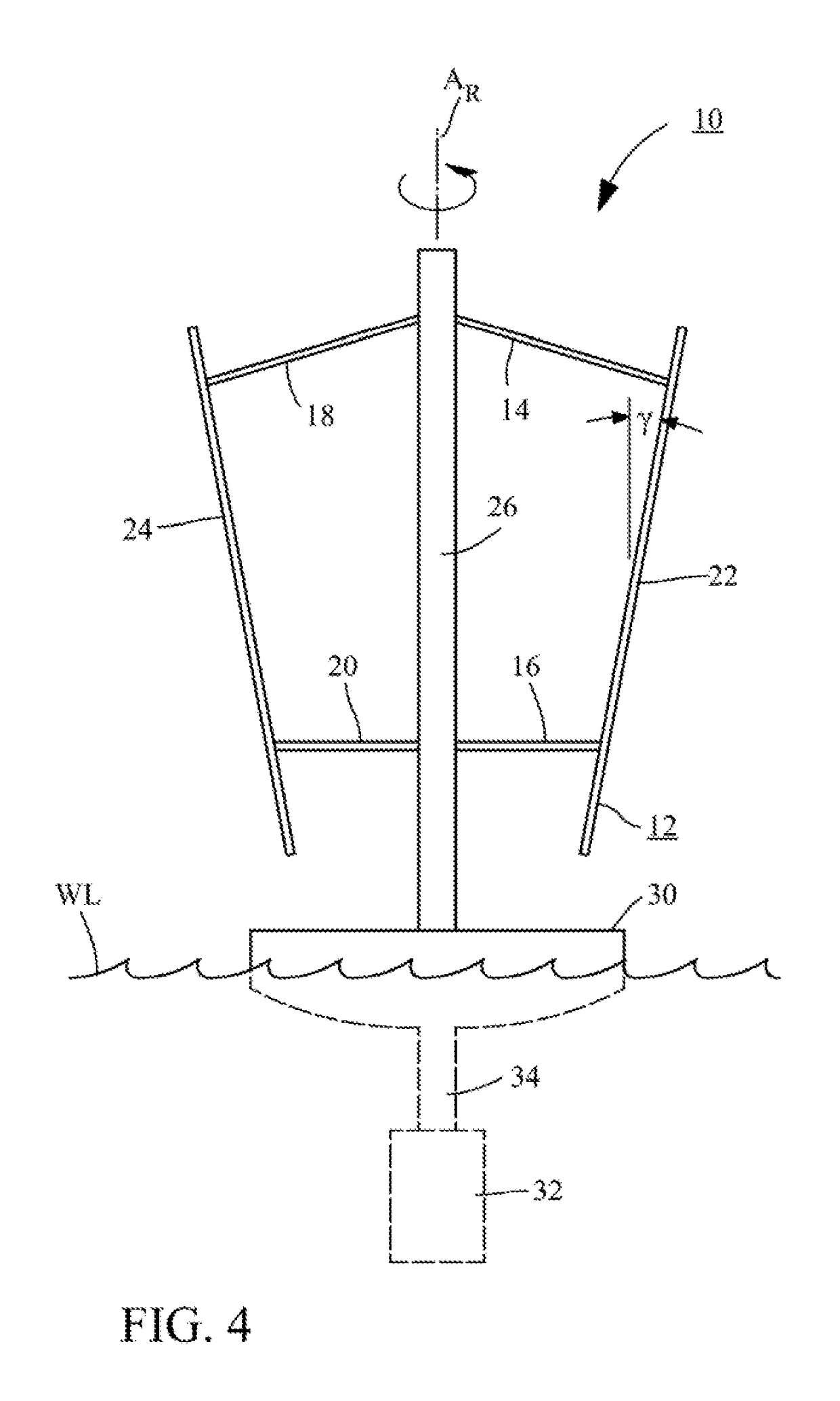

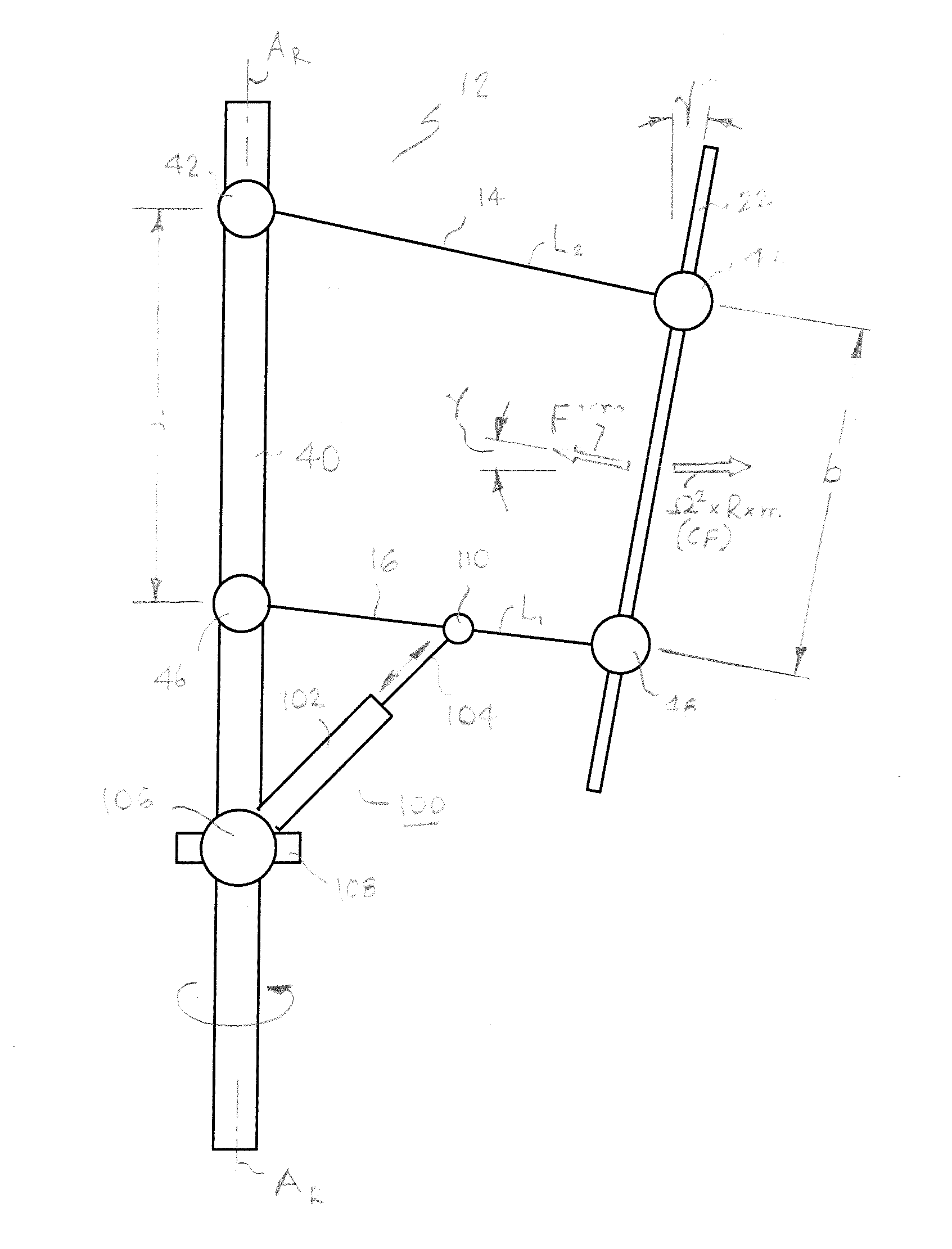

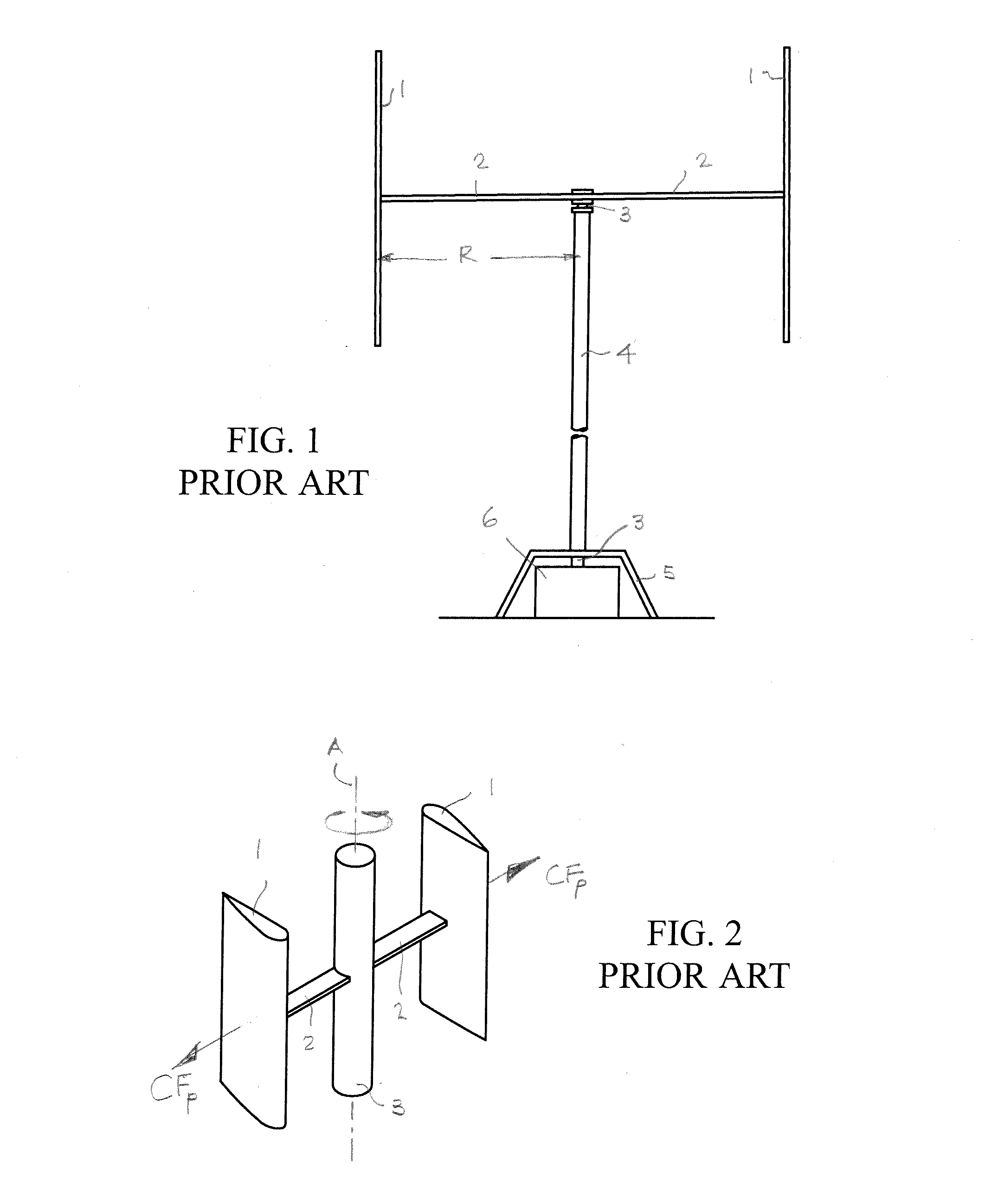

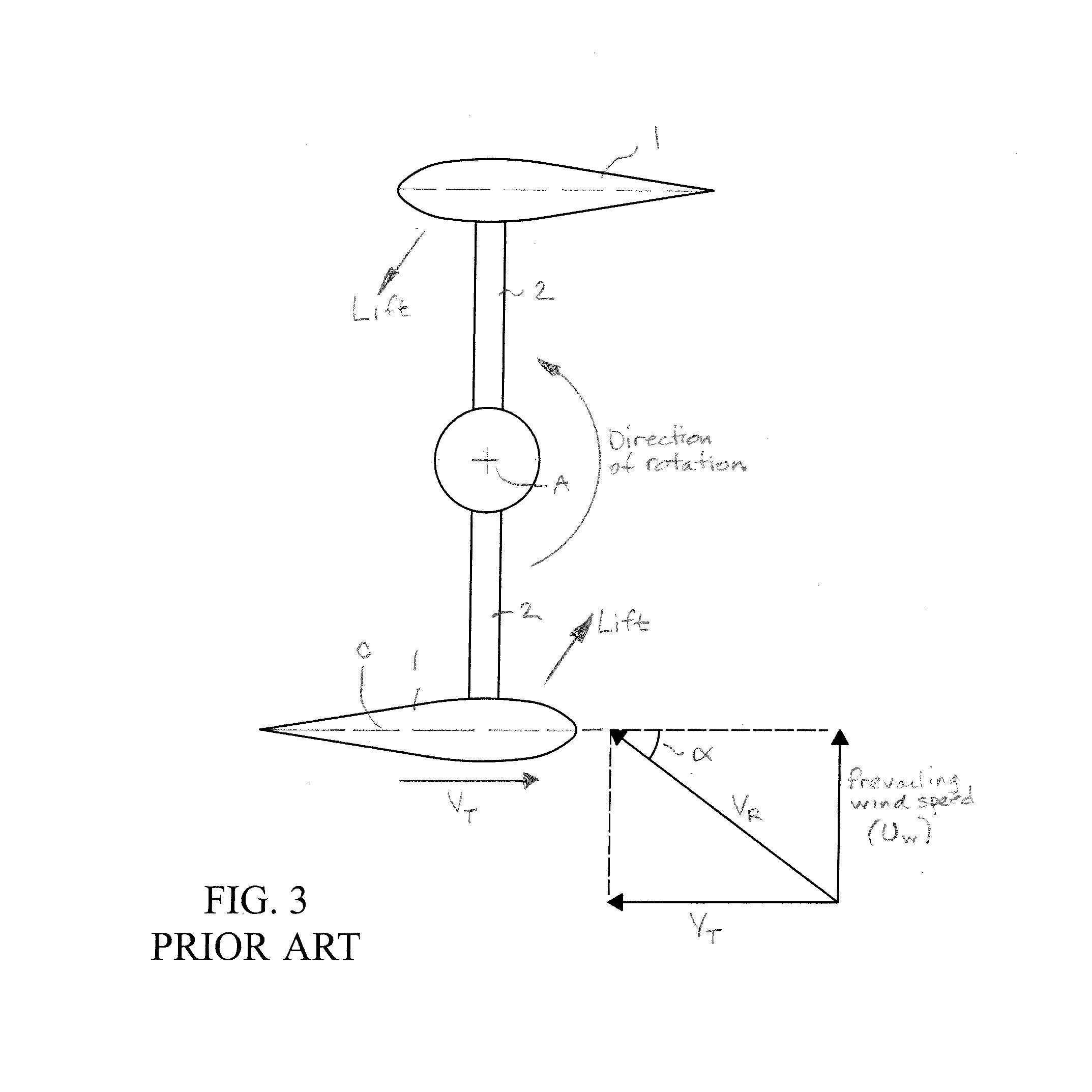

Lift-driven wind turbine with force canceling blade configuration

ActiveUS10208734B2Relieve pressureReduce radial loadWind motor supports/mountsMachines/enginesCentrifugal forceWind force

A lift-driven wind turbine has a turbine rotor with blades mounted to the turbine shaft by two struts hinged to the shaft and each blade to form a four-bar linkage. The blades' airfoil cross section generates lift that rotates the blades around the axis in the presence of a prevailing wind. The airfoil chord forms a geometric angle of attack αG relative to the tangent of the blade path and the struts orient the blades with an outward tilt angle γ. The turbine is designed with values of αG and γ that cause the lift generated by each blade to have an upward component that supports the blade against the force of gravity and a mean radially inward component that substantially balances centrifugal forces on the blade. Wind turbines designed according to the principles disclosed herein facilitate the construction of free-floating utility scale wind turbines for deep water installations.

Owner:CONTINUUM DYNAMICS

Vertical axis lift-driven wind turbine with force canceling blade configuration

ActiveUS20160312765A1Relieve pressureReduce radial loadWind motor supports/mountsWind motor combinationsCentrifugal forceKnife blades

A lift-driven VAWT has a turbine rotor with blades mounted to the turbine shaft by two struts hinged to the shaft and each blade to form a four-bar linkage. The blades' airfoil cross section generates lift that rotates the blades around the axis in the presence of a prevailing wind. The airfoil chord forms a geometric angle of attack αG relative to the tangent of the blade path and the struts orient the blades with an outward tilt angle γ. The turbine is designed with values of αG and γ that cause the lift generated by each blade to have an upward component that supports the blade against the force of gravity and a mean radially inward component that substantially balances centrifugal forces on the blade. VAWTs designed according to the principles disclosed herein facilitate the construction of free-floating utility scale wind turbines for deep water installations.

Owner:CONTINUUM DYNAMICS

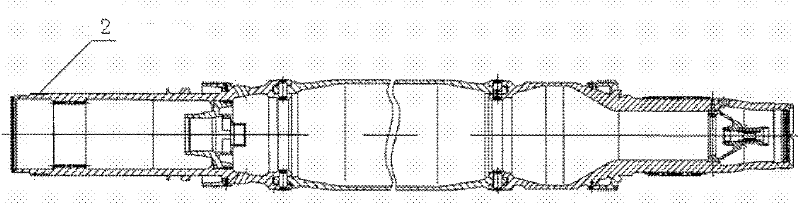

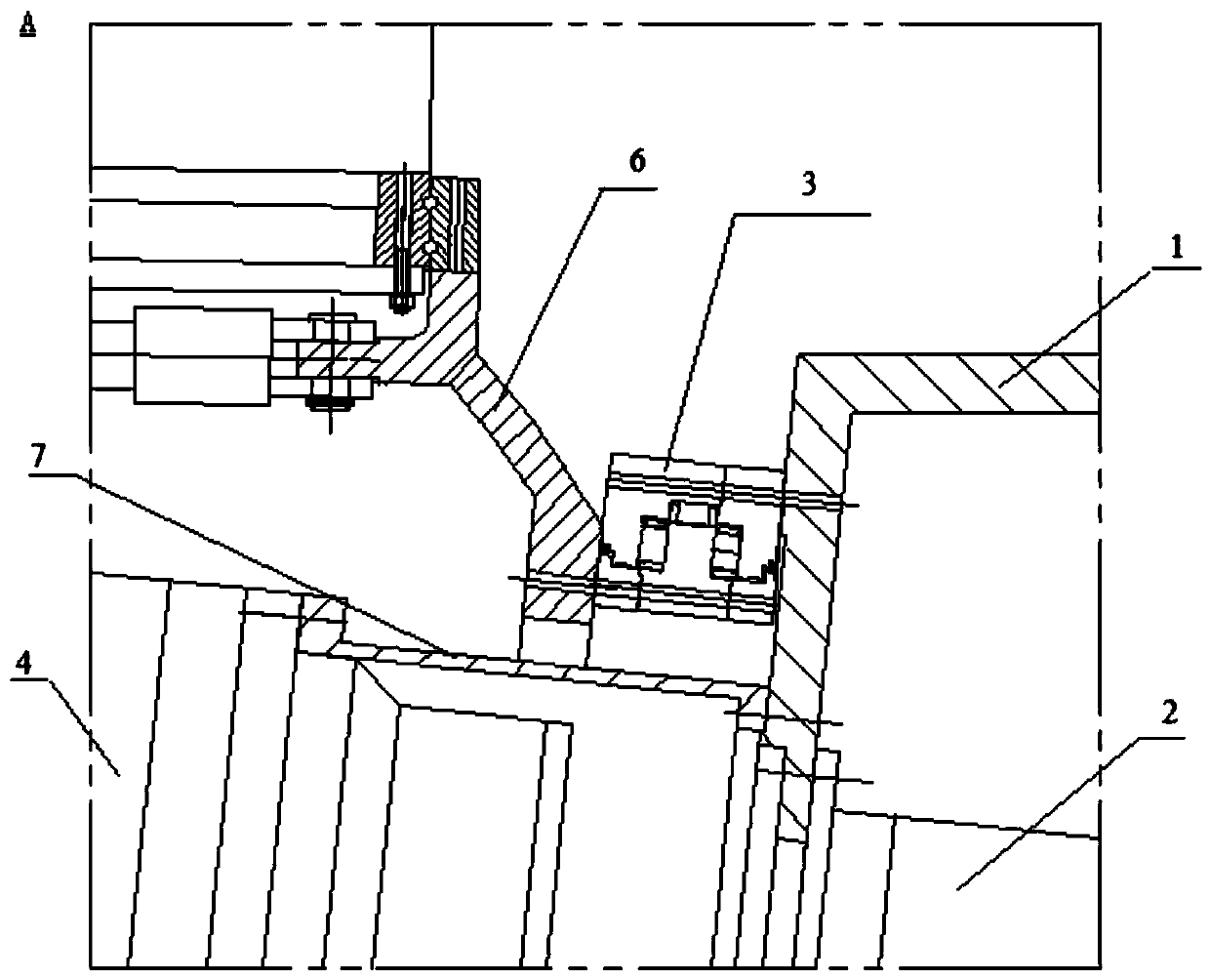

Assembling method for three-fulcrum bearing of aircraft engine

The invention discloses an assembling method for a three-fulcrum bearing of an aircraft engine, belonging to the technical field of engine overhaul. The assembling method comprises the following steps that: a central bevel gear is placed in a heating oven for heating, and a bearing outer ring is assembled in the central bevel gear; a spring ring is mounted on the central bevel bear for fixing the bearing, and the bearing is mounted in a manner that a marking face of the bearing faces to the spring ring; the bearing is cooled to achieve the temperature of an ambient medium, the maximum diameter and the minimum diameter of a runway of the bearing outer ring mounted in the central bevel gear are measured, then diameters on four planes of the runway of the bearing outer ring are measured, and then an average value is obtained; a bearing retainer and a bearing rolling rod are mounted in an inner ring of the bearing outer ring, and the bearing retainer is mounted in an manner that a marking face of the bearing retainer faces to the spring ring; a bearing inner ring is mounted on a low-pressure turbine shaft, and numbers in sets face to the front end face of the low-pressure turbine shaft; the bearing inner ring is cooled, and the low-pressure turbine shaft is cooled to obtain the temperature of ambient environment; and the maximum diameter and the minimum diameter are determined by measuring the diameters on six planes of a runway of the bearing inner ring, and then the bearing assembling play is calculated.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

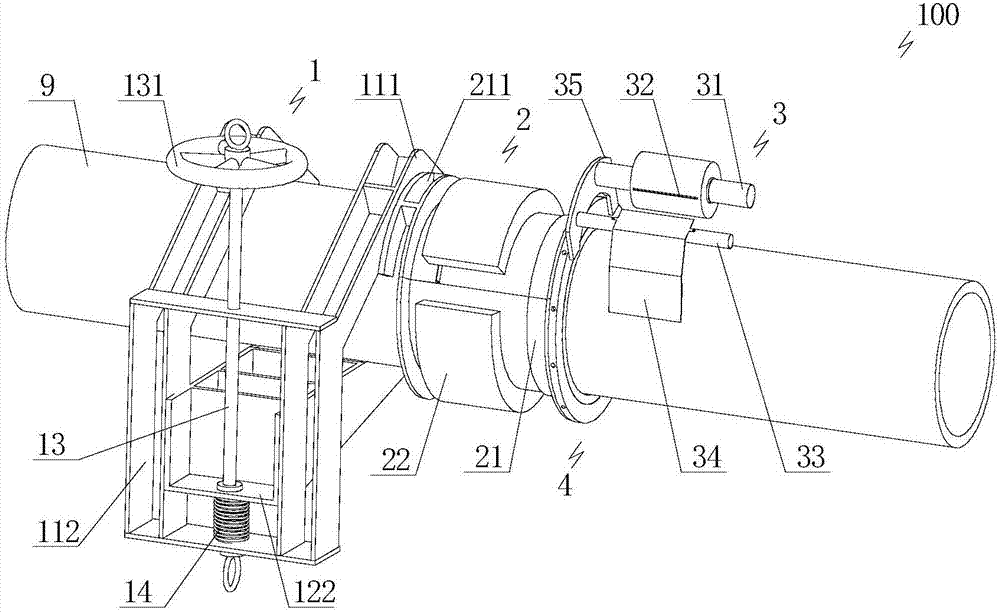

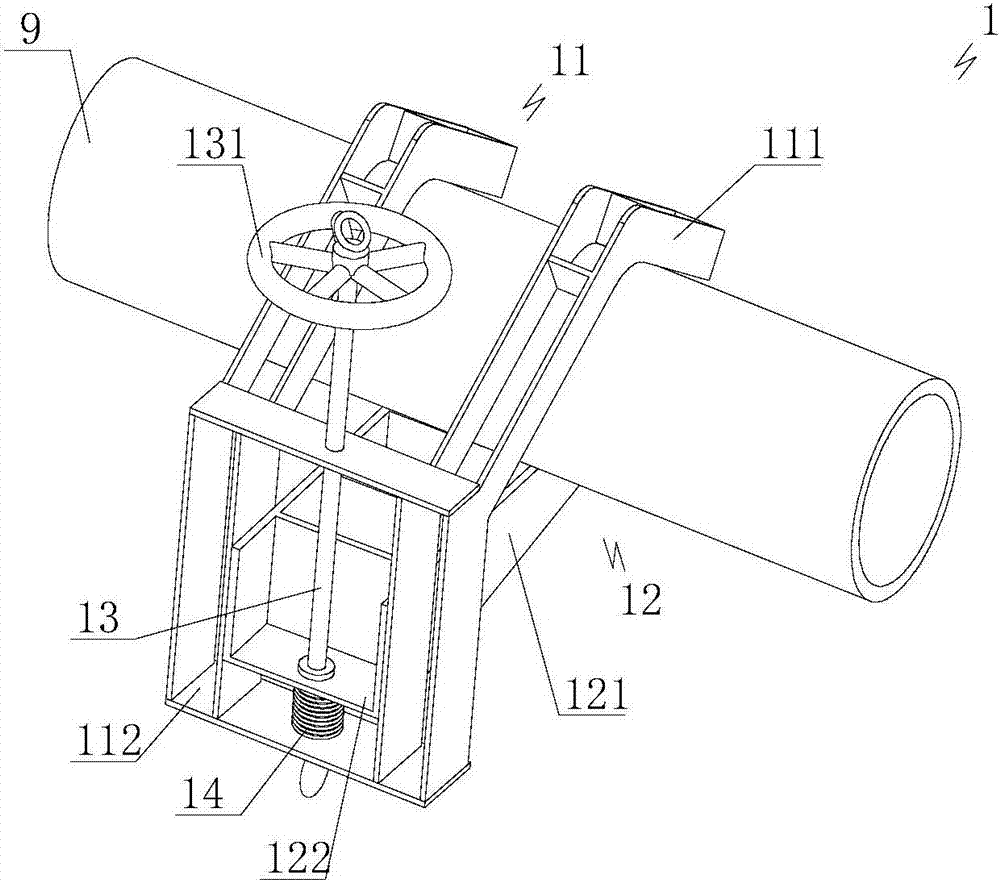

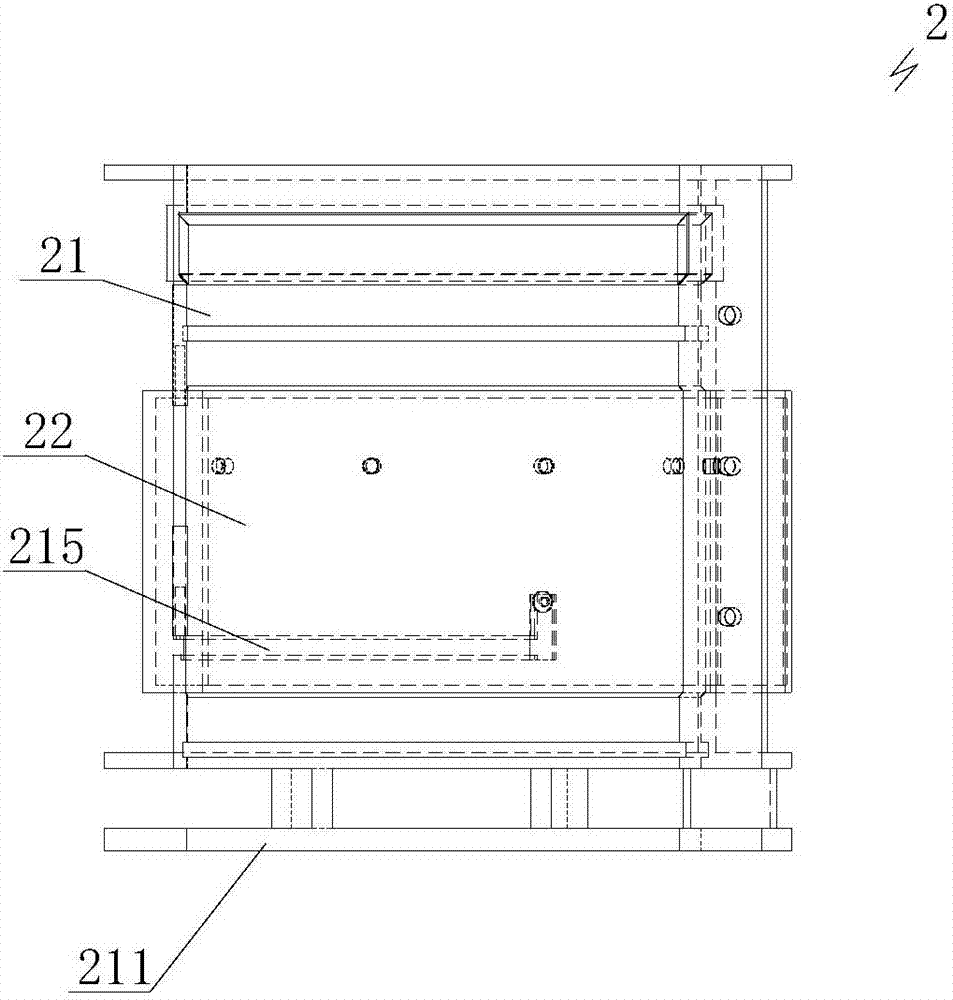

Defect repairing tool for submarine pipeline

ActiveCN106979383ASimple structureReduce radial loadPipe laying and repairOcean bottomMarine engineering

The invention provides a defect repairing tool for a submarine pipeline. The defect repairing tool for the submarine pipeline comprises a clamping module structure, a coating module structure and a coiling module structure, wherein the coating module structure capable of forming a coating layer on a defect area of the submarine pipeline to be repaired is connected to one side of the clamping module structure which is controlled through a remote operated vehicle (ROV) and capable of clamping the submarine pipeline to be repaired; the coating module structure sleeves the outer wall of the submarine pipeline to be repaired in a circumferential opening-closing manner and can axially move along the submarine pipeline to be repaired; the coiling module structure capable of forming a coiling layer on the coating layer is connected to one side, far away from the clamping module structure, of the coating module structure; the coiling module structure can axially move along the submarine pipeline to be repaired and can be rotated around the submarine pipeline to be repaired. The repairing tool is operated through the ROV, so that the maximum diving depth of workers can be overcome; the repairing process is continuous, complete and high in efficiency; and the problem of defect repairing of the submarine pipeline in a deep water environment can be solved.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

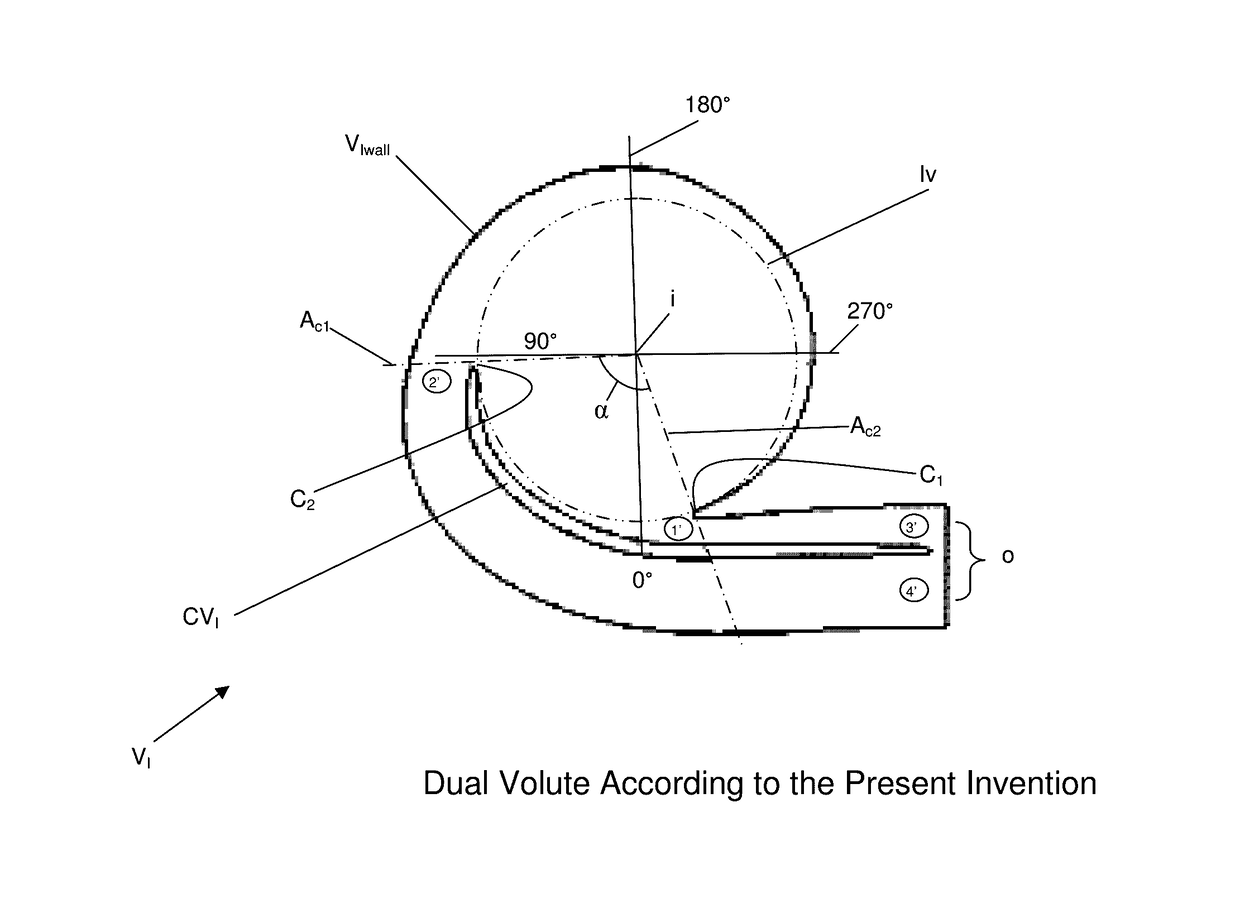

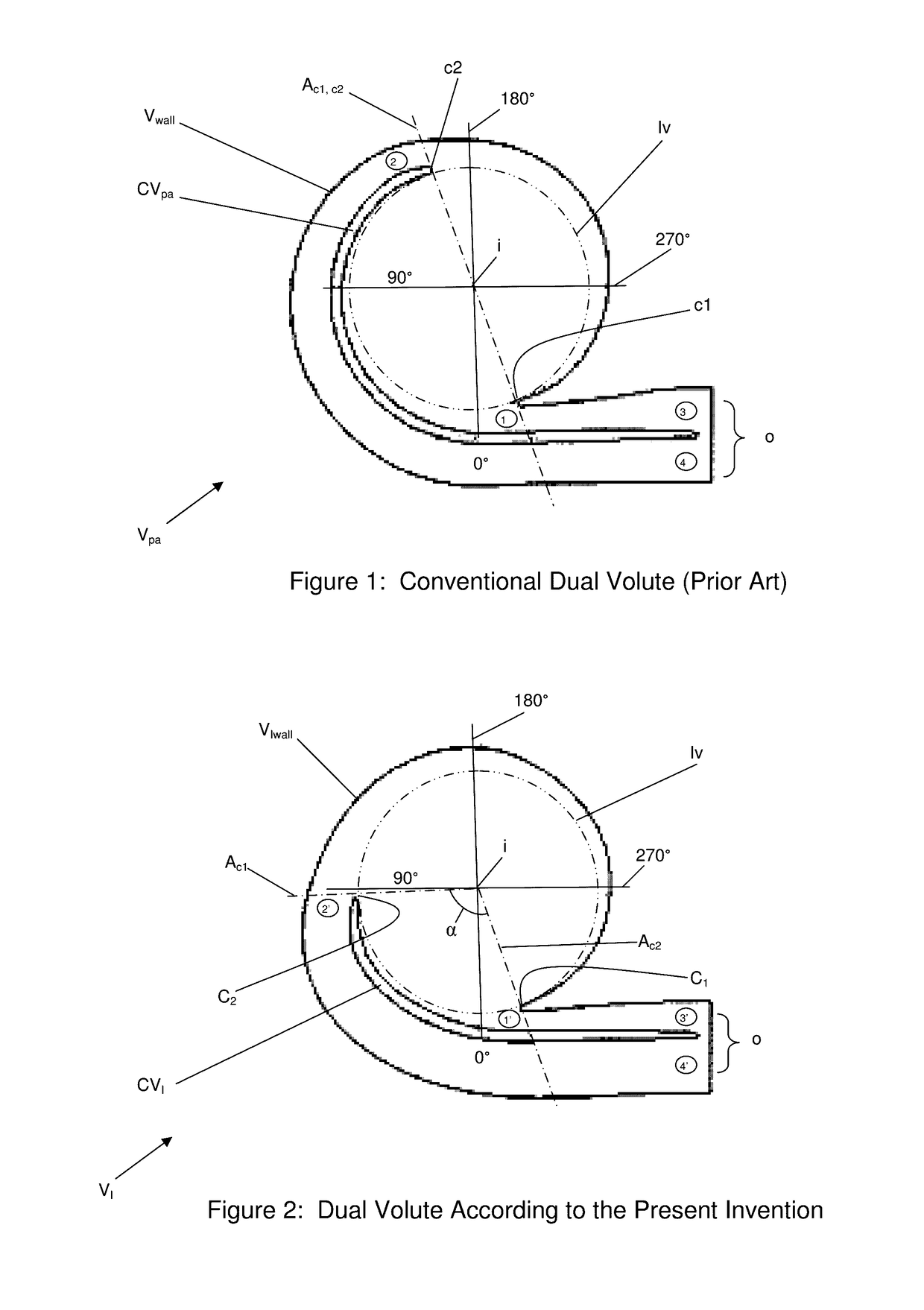

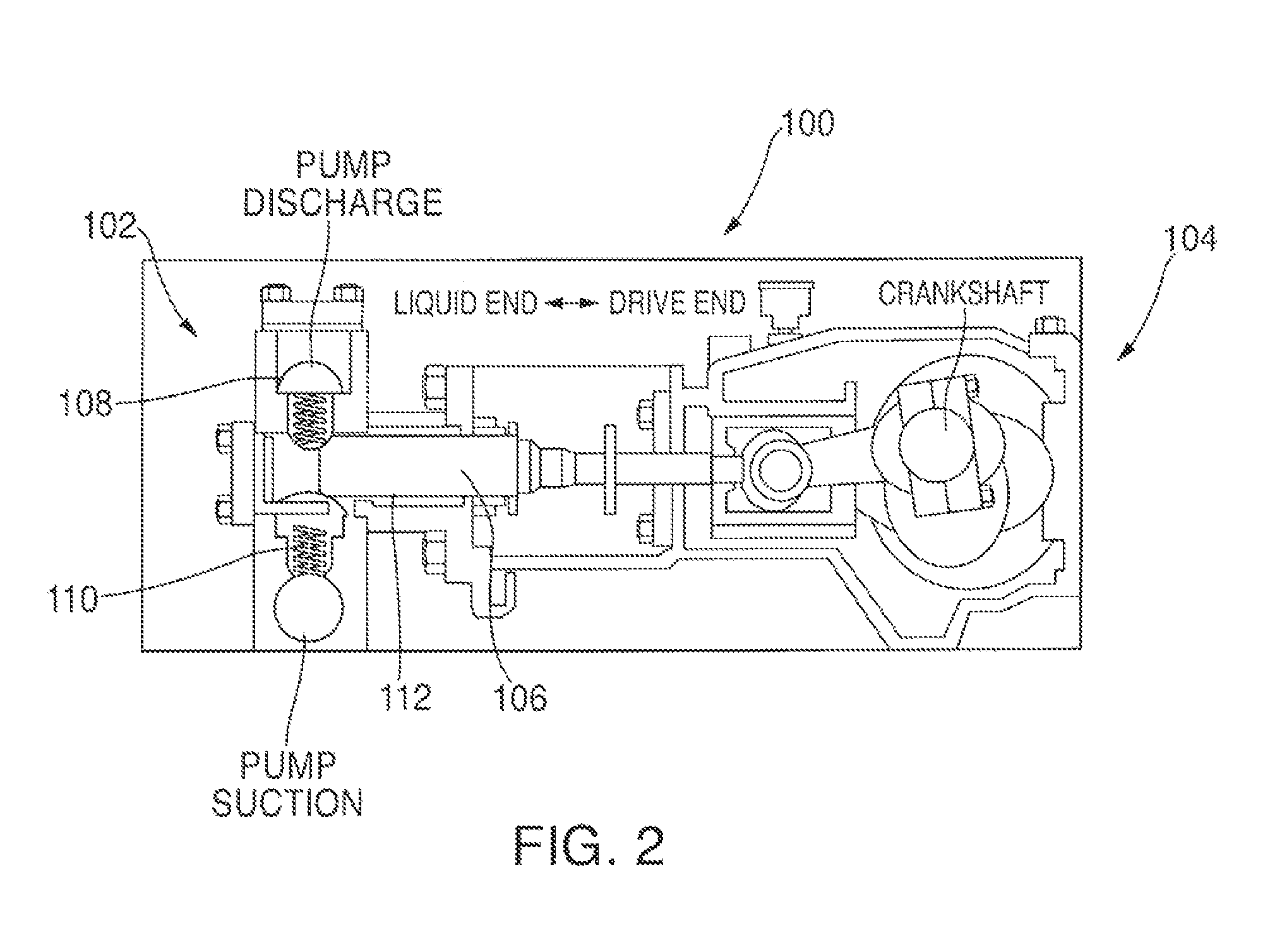

Volute Design For Lower Manufacturing Cost and Radial Load Reduction

InactiveUS20170067481A1Reduce radial loadPromotes stress balancePump componentsPumpsManufacturing cost reduction

A volute for a pump featuring a volute or casing having a pump inlet for receiving a fluid being pumped, a pump discharge for providing the fluid, and a volute or casing vane forming double volutes therein. The volute has an upper cutwater farthest from the pump discharge defining an upper cutwater throat area and an end of passage for the upper cutwater, and also has a lower cutwater closest to the pump discharge defining a lower cutwater throat and a corresponding end of passage for the lower cutwater. The upper cutwater throat area is dimensioned to be greater than and not equal to the lower cutwater throat area so the upper cutwater throat area and the lower cutwater throat area provide substantially equal flow velocity at both the upper cutwater and the lower cutwater in response to an angular sweep of the fluid being pumped. The end of passage for the upper cutwater is dimensioned with an upper cutwater passage area that is greater than and not equal to a corresponding lower cutwater passage area of the corresponding end of passage for the lower cutwater so that upper and lower cutwater passage areas at the pump discharge are balanced as a function of differing rates of flow of the fluid being pumped therein and so that the fluid being pumped from associated ends of the upper and lower cutwater passage areas meets at the pump discharge with a substantially equal velocity.

Owner:FLUID HANDLING

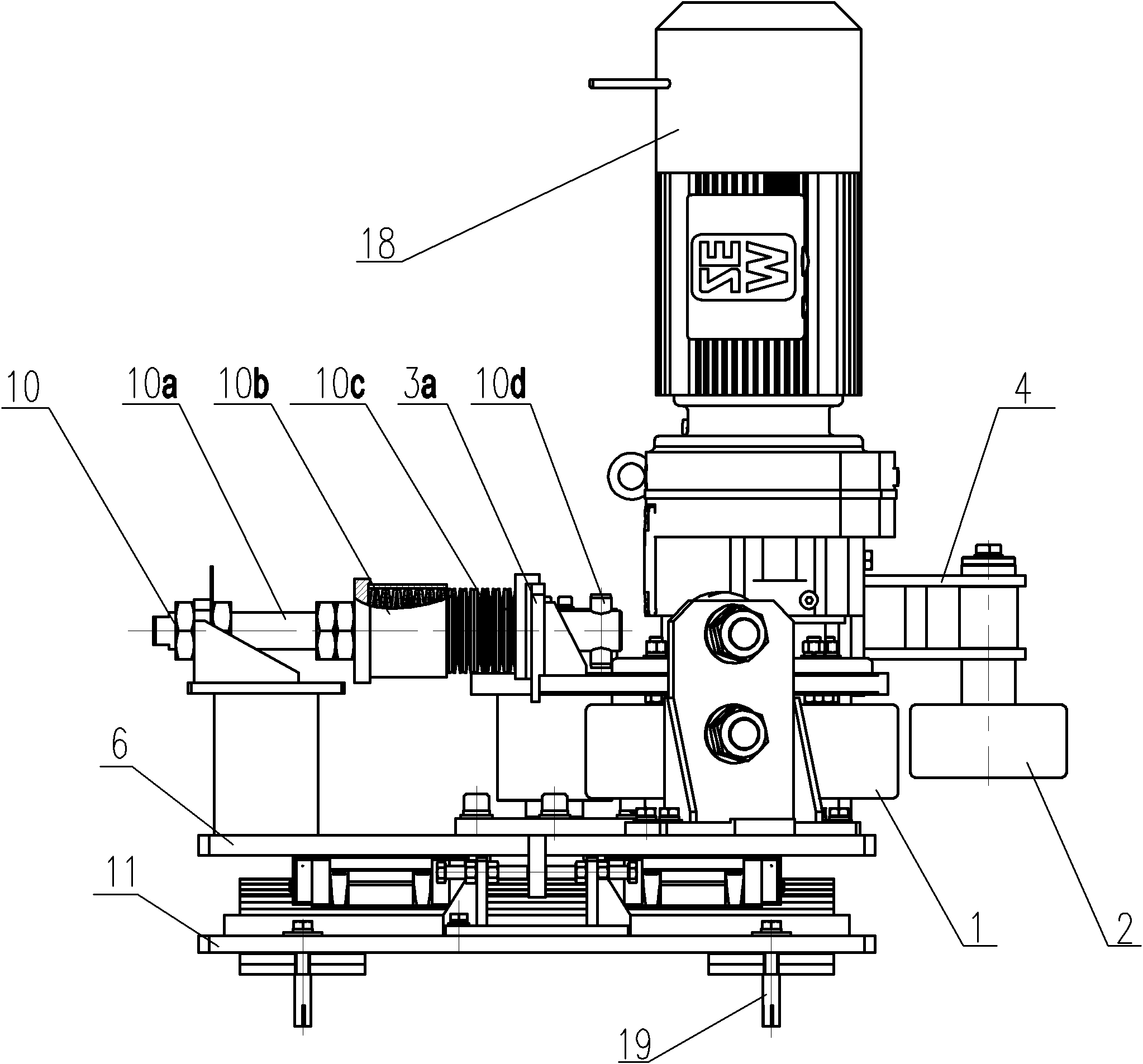

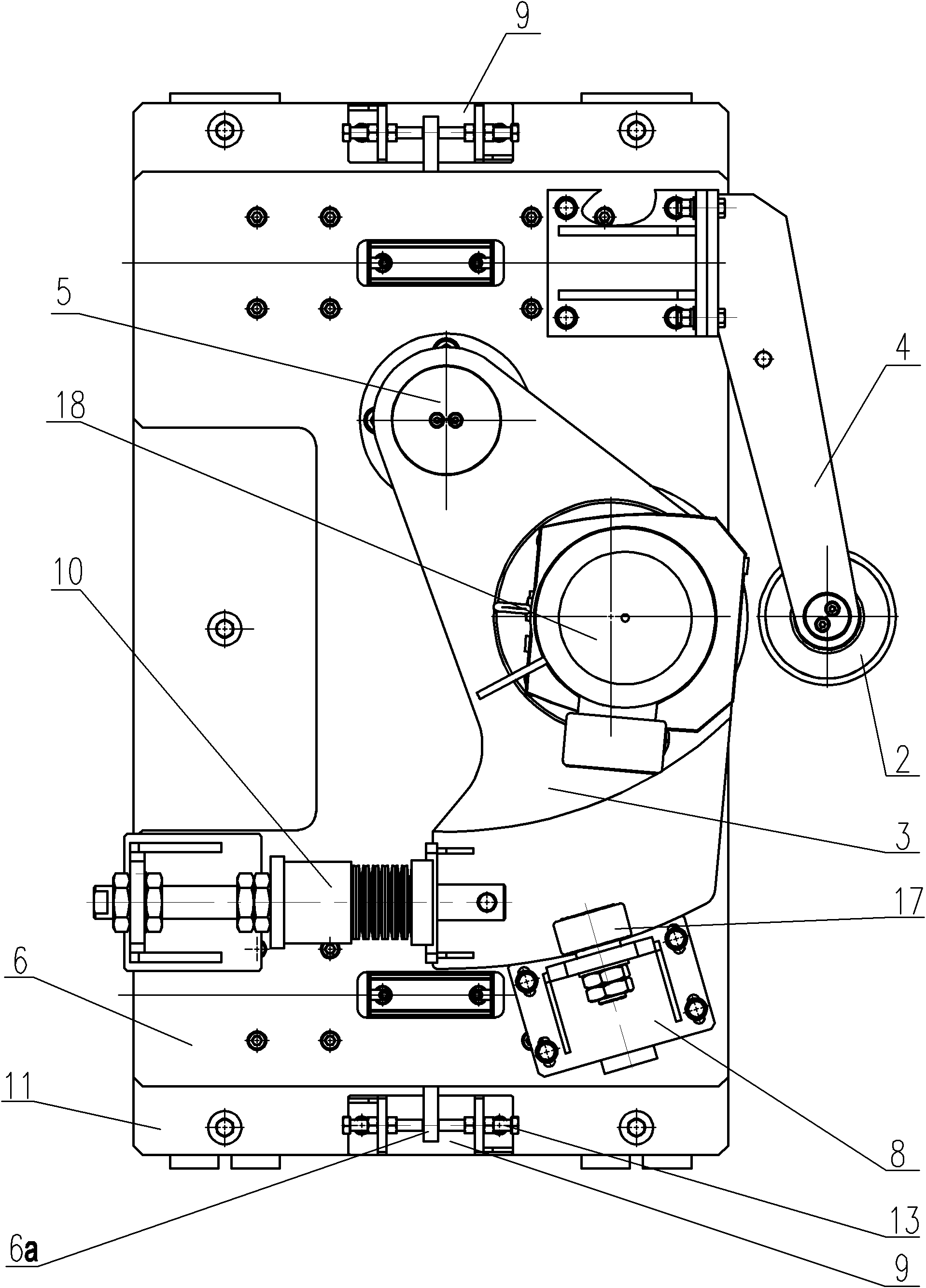

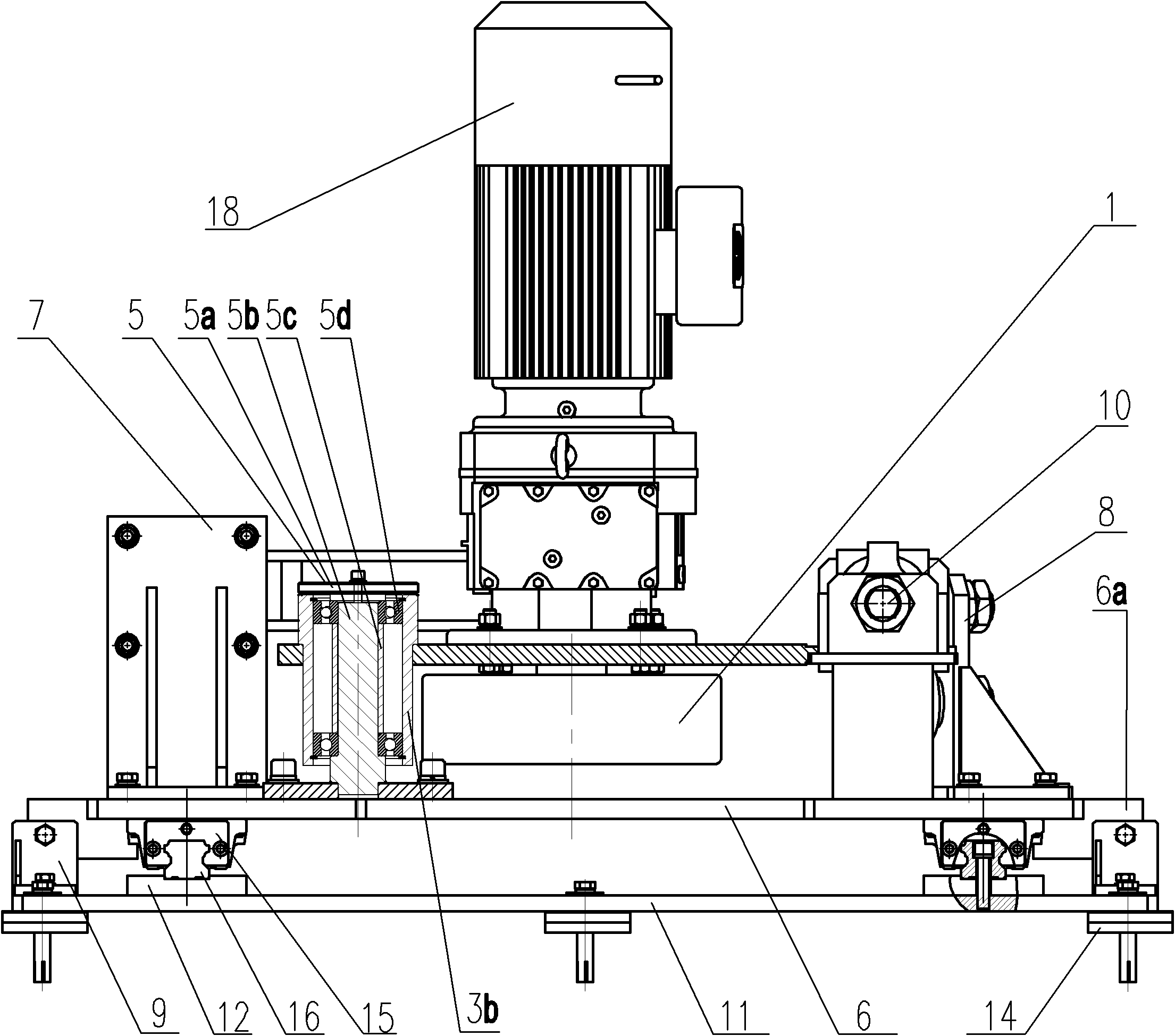

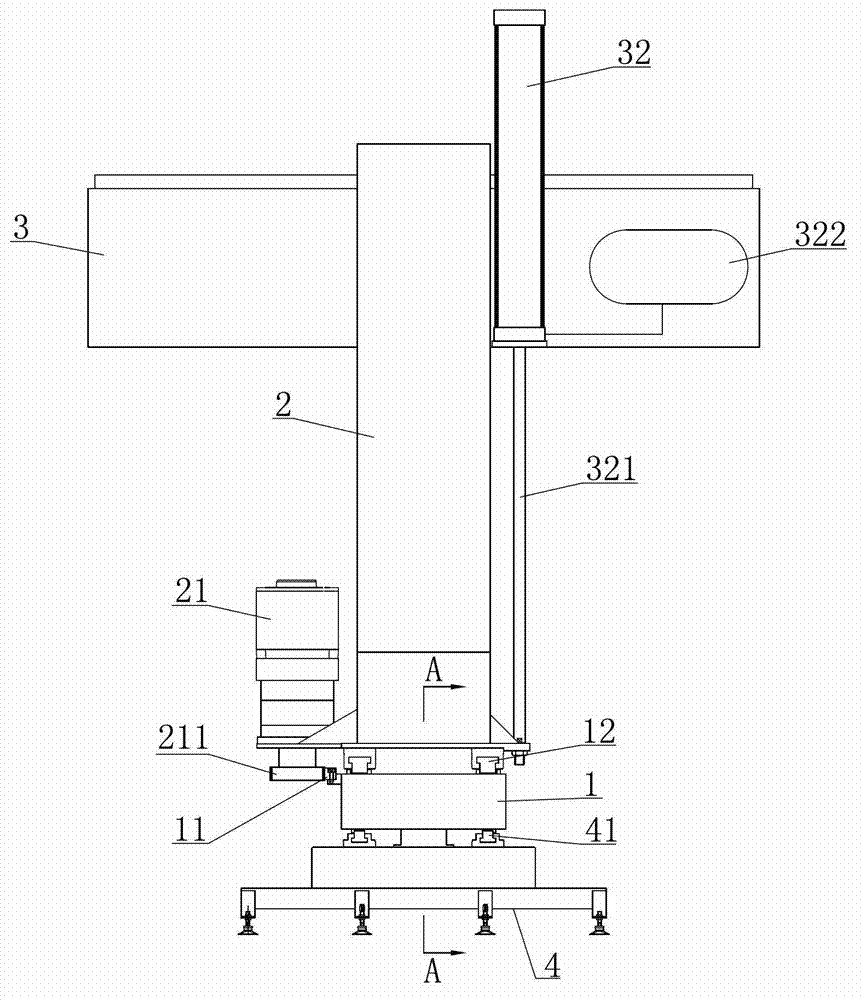

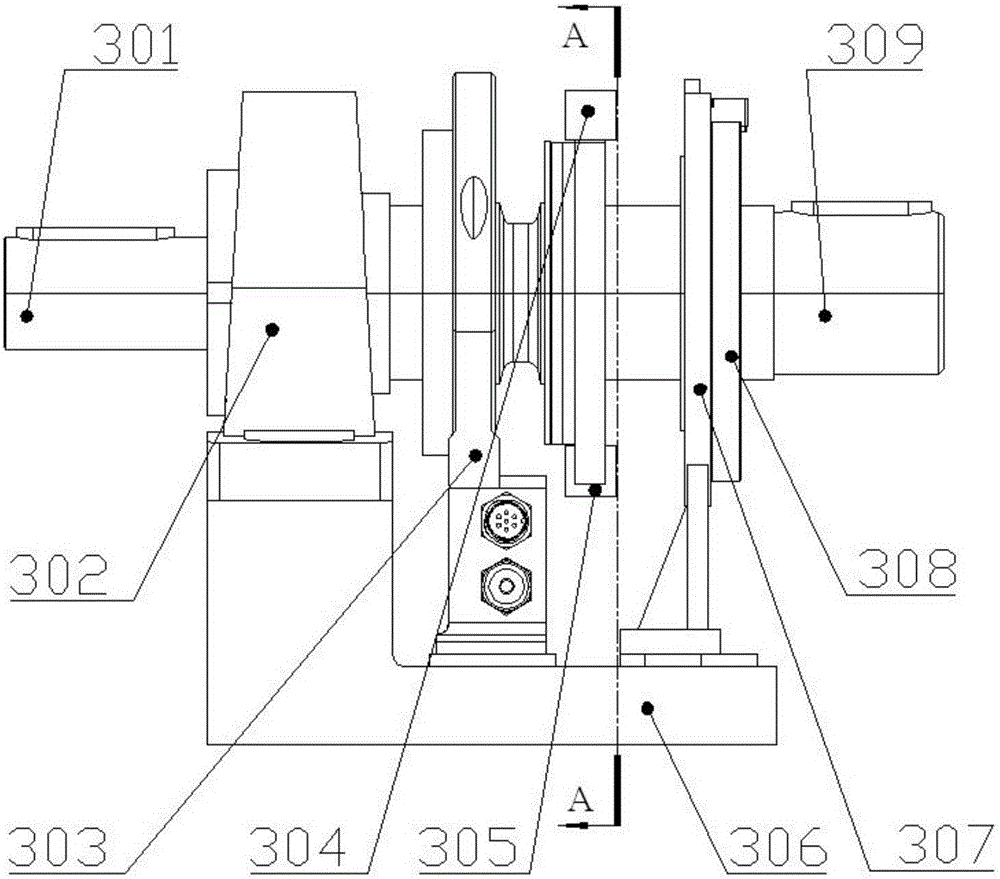

Drive device of adjustable rotating platform

InactiveCN102079445AReduce radial loadEasy to adjust the positionConveyor partsRotary stageProduction line

The invention relates to a drive device of an adjustable rotating platform for carrying out carrier reversing of production line products. The drive device comprises an expansion bolt, wherein the expansion bolt is arranged on a bottom plate; a linear guide rail is fixedly arranged on the upper surface of the bottom plate through a base plate; a sliding block is connected to the linear guide rail in a sliding way; a seat plate is fixedly arranged on the sliding block through a fixed base; a driven arm support and a cam driven bearing support are arranged at intervals on the seat plate; a rotary assembly is fixedly arranged on the seat plate; a driven arm is fixedly arranged on the driven arm support; a friction driven wheel is arranged on the driven arm; two cam driven bearings screwed up and down through a gasket are arranged on the cam driven bearing support; a swinging arm is rotatably arranged on the rotary assembly; a deceleration motor is fixedly arranged on the swinging arm; a friction drive wheel is arranged on an output shaft of the deceleration motor; and a rotatable elastic pushing device with the swinging arm is arranged on the seat plate. Because the gravity direction of the declaration motor is superposed with an axle centre of the drive shaft, the radial load of the drive shaft is reduced and the service life is prolonged.

Owner:MIRACLE AUTOMATION ENG CO LTD

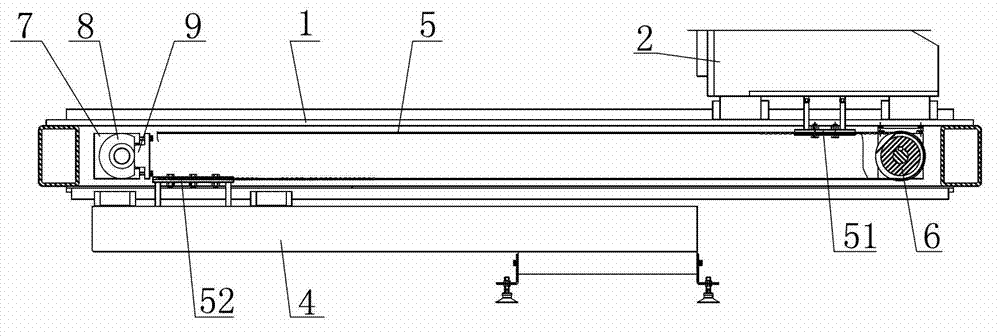

Double-speed feeding machine

The invention discloses a double-speed feeding machine which mainly solves the technical problem of higher motor radial loads due to longer motor output shafts of existing double-speed feeding machines. The double-speed feeding machine comprises a feeding shaft, a lifting shaft, a fixed crossbeam and an end picker. The lifting shaft is mounted on the crossbeam, the feeding shaft is slidably connected onto the lifting shaft, the end picker is slidably connected onto the feeding shaft, and a synchronous feeding device is arranged in the feeding shaft and comprises a synchronous belt and a synchronous wheel. The synchronous belt is fixedly connected with the end picker and the lifting shaft, a feeding motor is arranged on the lifting shaft, and the feeding motor and the feeding shaft are in transmission through a gear rack pair. The double-speed feeding machine is mainly applied to conveying machinery needing to move quickly at the X-axial direction.

Owner:HUZHOU MACHINE TOOL WORKS

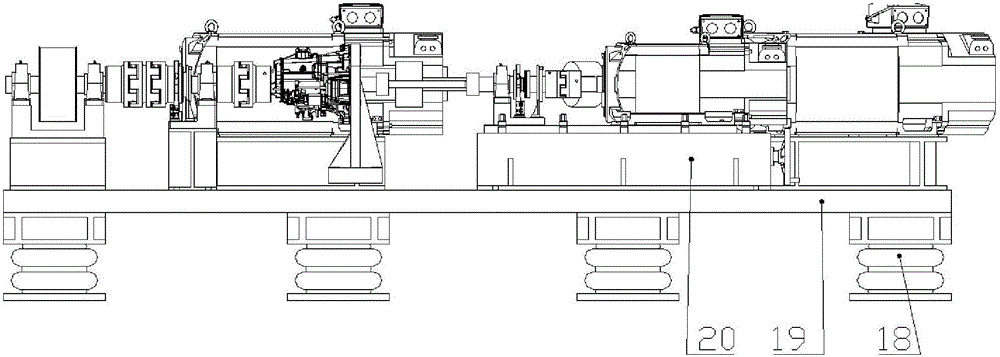

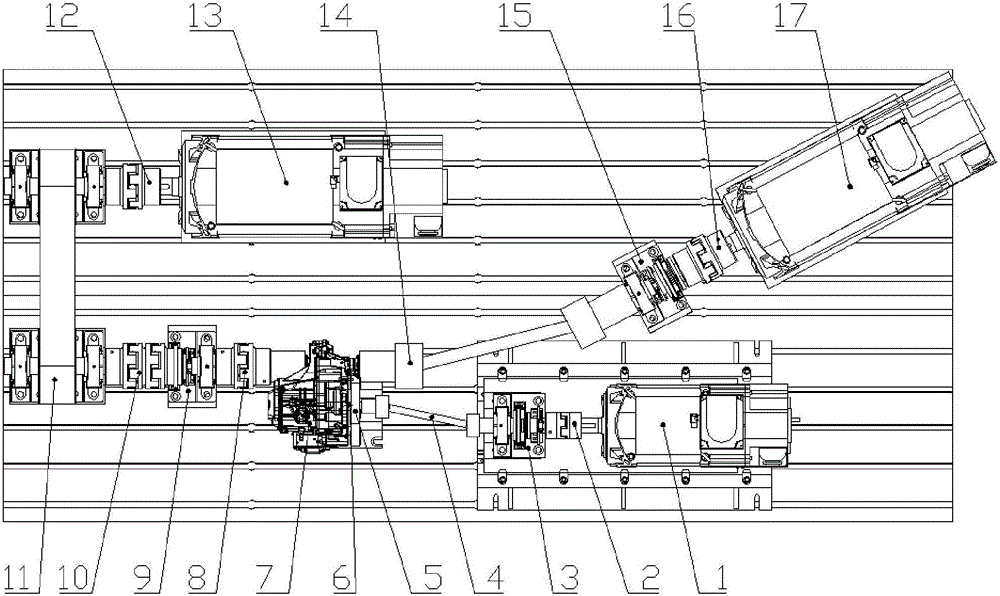

Testing stand for testing transmission error of mechanical gearbox of front drive automobile and comprehensive testing method

InactiveCN105699077AShorten the lengthTake advantage ofMachine gearing/transmission testingCombined testElectric machine

The invention relates to a testing stand for testing the transmission error of a mechanical gearbox of a front drive automobile and a comprehensive testing method, and belongs to the technical field of automobile gearbox test. The testing stand comprises a driving motor, an input shaft resilient coupler, a comprehensive input shaft transmission error detection device, an input shaft cage-type synchronous universal shaft coupler, a gearbox input spline shaft, a certain type gearbox, a first output shaft resilient coupler, a comprehensive first output shaft transmission error detection device, an arc tooth synchronous belt drive input shaft resilient coupler, an arc tooth synchronous belt transmission device, an arc tooth synchronous belt transmission output shaft resilient coupler, a first loading motor, a second output shaft cage type synchronous universal shaft coupler, a comprehensive second output shaft transmission error detection device, a second output shaft resilient coupler and a second loading motor. The testing stand is novel in structure, the first loading motor is arranged in a bias manner, the occupied space is small, and static and dynamic transmission errors of a gearbox can be measured. The testing stand has high universality.

Owner:JILIN UNIV

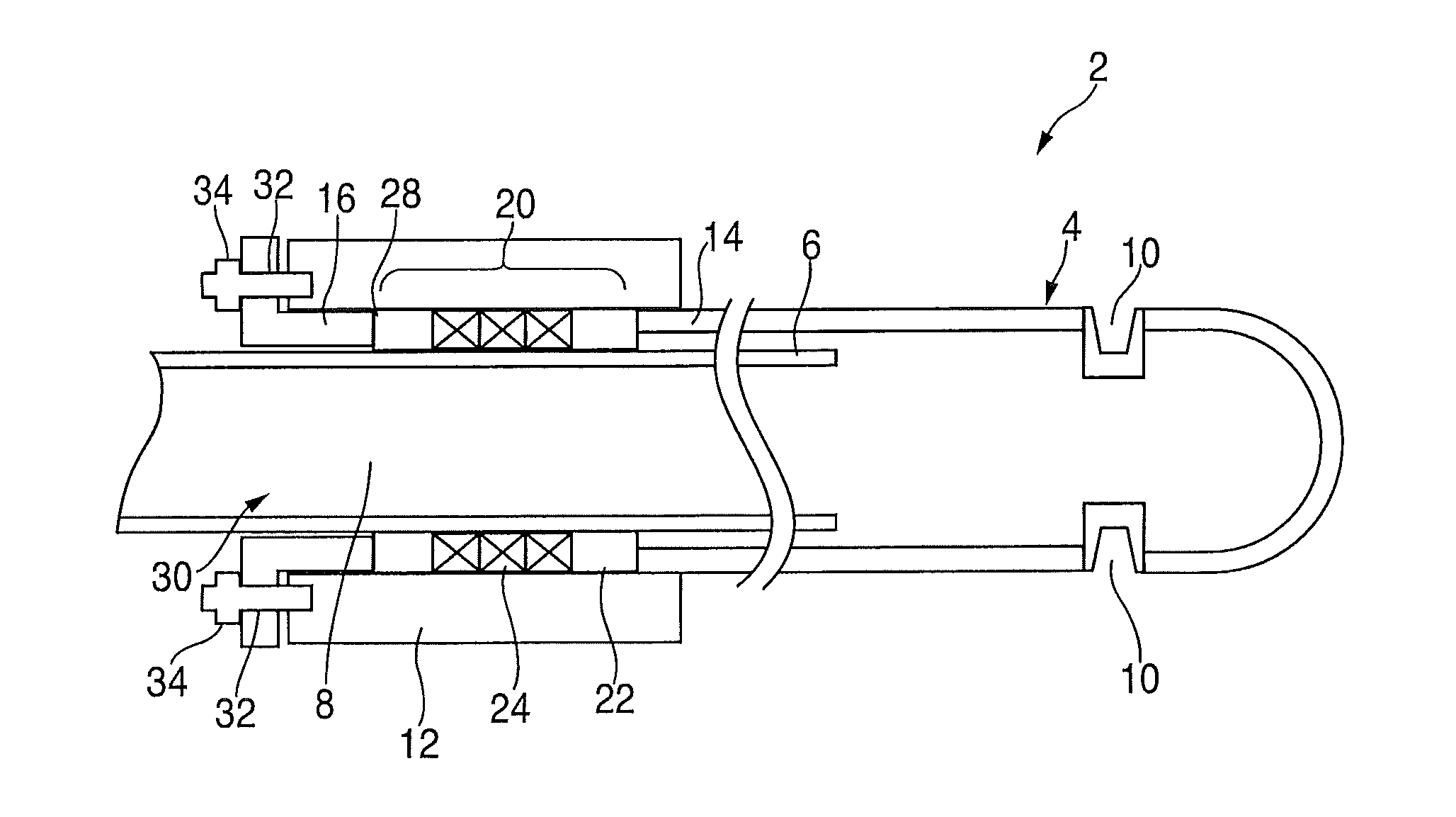

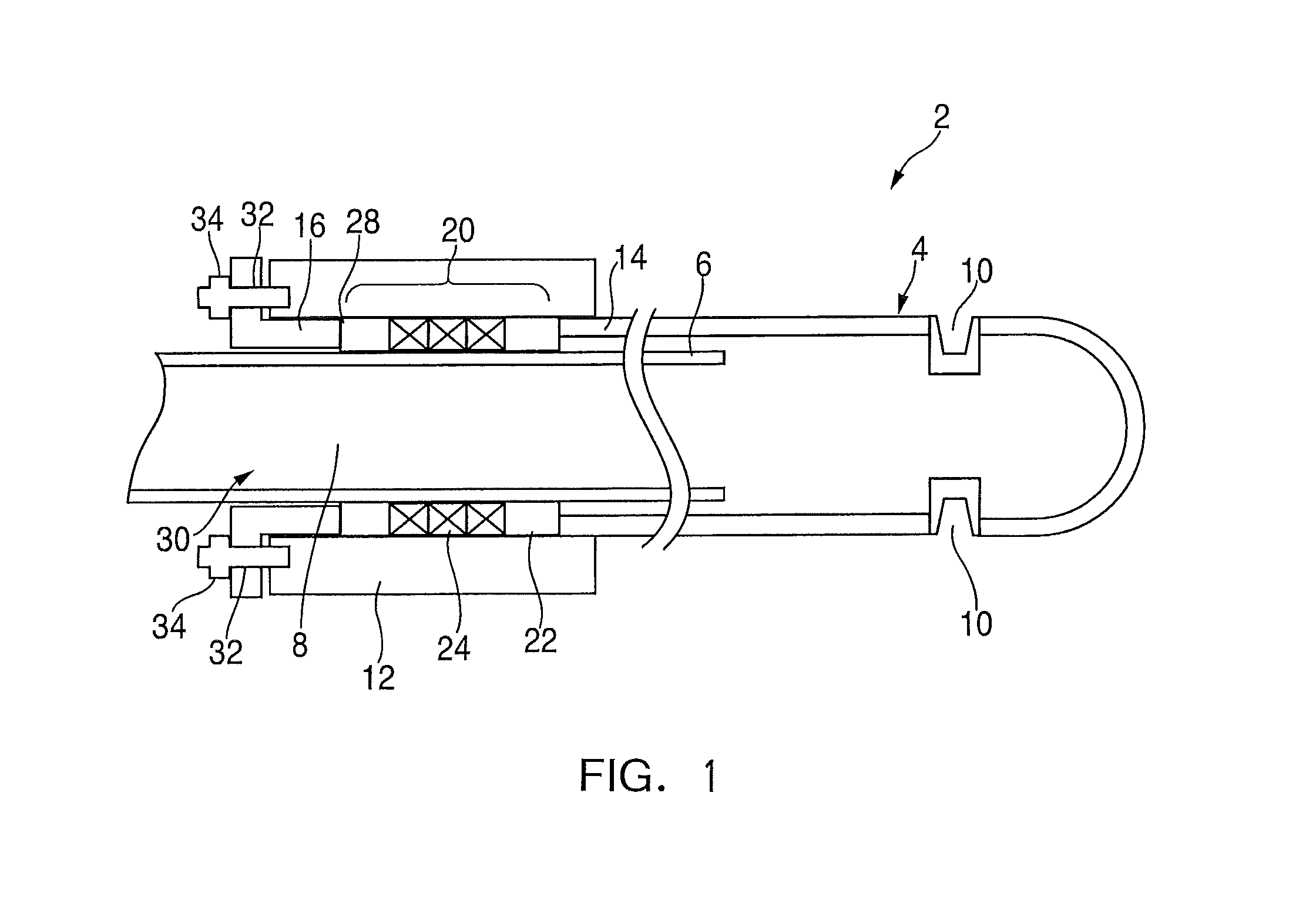

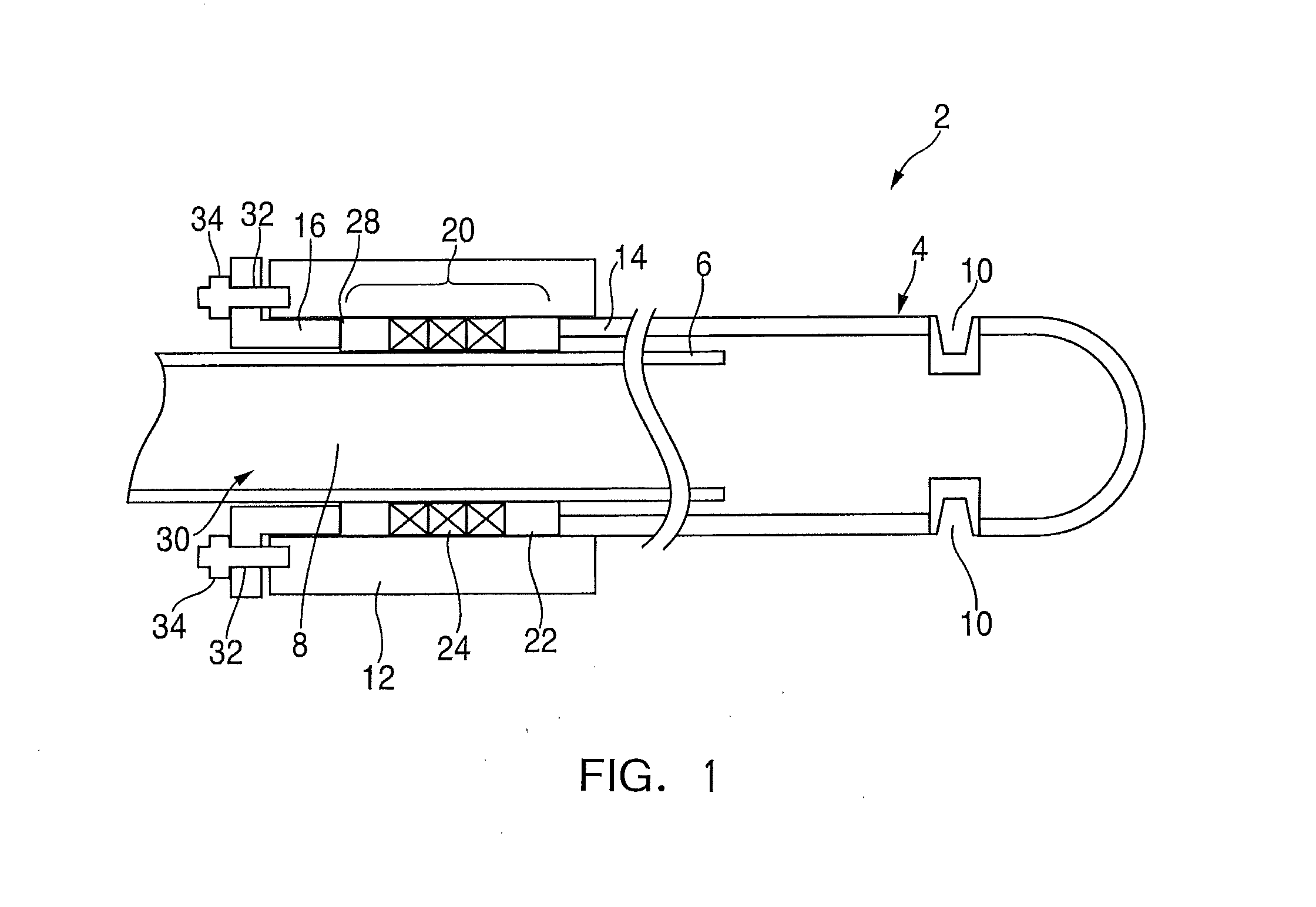

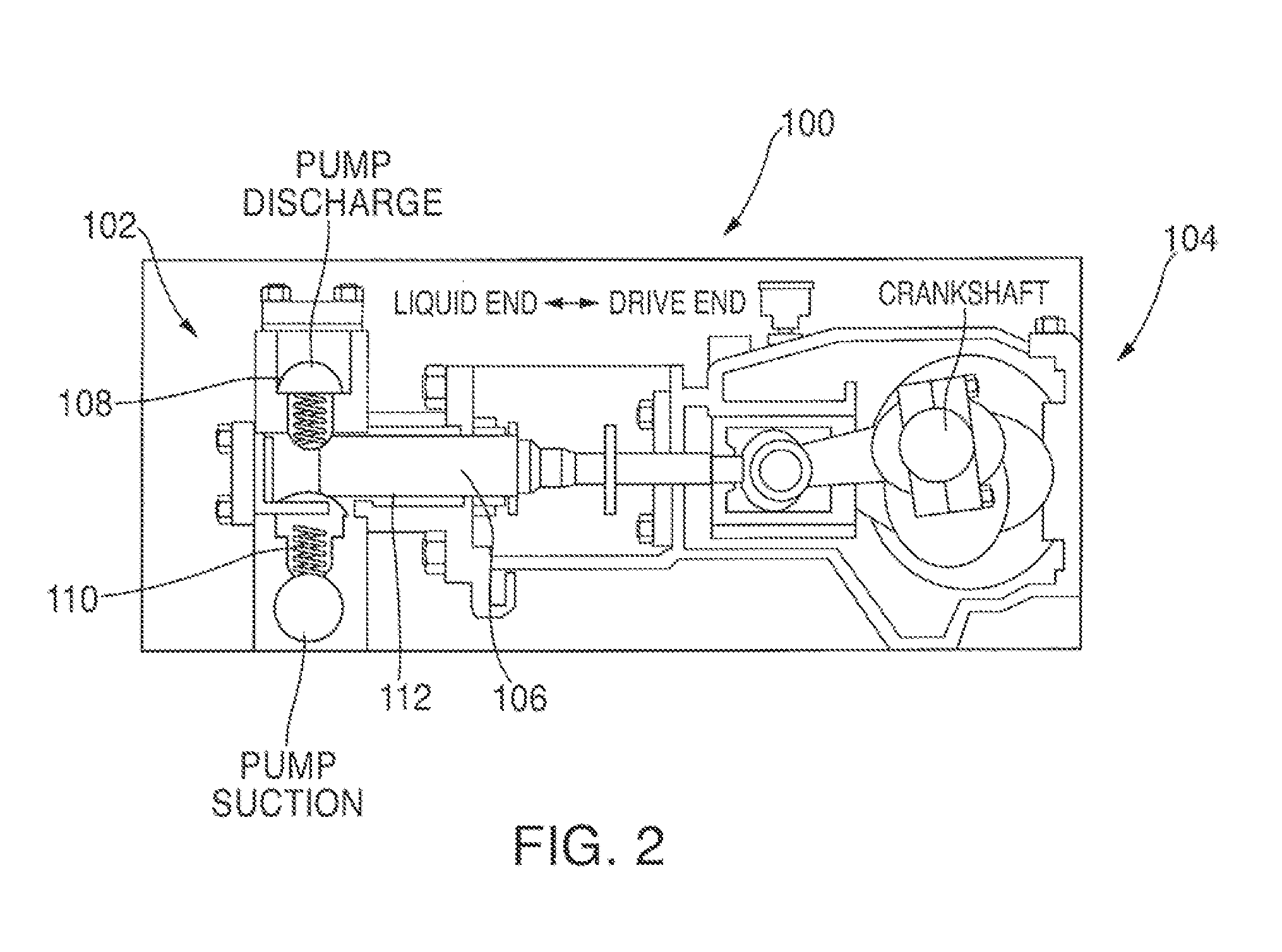

Seal-bearing assembly

ActiveUS8814432B2Lift radial loadReduce radial loadPumpsSliding contact bearingsBearing surfaceMechanical engineering

A seal-bearing assembly to be inserted into the seal cavity of a mechanical device to provide a seal and a bearing surface to eliminate whip in a rotating and / or reciprocal cylindrical member. The seal-bearing assembly is particularly well suited for use in a reciprocal pump and between the steam lance and fixed steam tube in a sootblower. The assembly includes at least a pair of outer substantially rigid cylindrical bearings having an inner bore to be positioned over the cylindrical member and at least one complimentary flexible textile packing ring disposed between the two outer bearing members. In assemblies including an additional bearing, it is surrounded by at least one flexible packing on each side. The inner bore of the bearing members provide a bearing surface for eliminating whip of the moving elements in the device.

Owner:SEAL RYT CORP

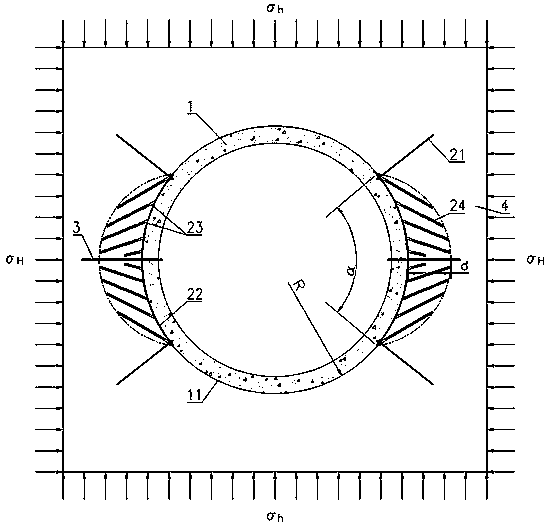

Deep vertical well supporting structure and construction method thereof

ActiveCN109854285AReduce radial loadFully mobilize self-supporting abilityShaft sinkingAnchoring boltsHorizontal stressStructural engineering

The invention provides a deep vertical well supporting structure. The deep vertical well supporting structure comprises anchor net fixing areas, drilled hole groups and static crushing agents, whereinthe anchor net fixing areas are symmetrically arranged on the wellbore tunneling section in the maximum horizontal stress direction, the drilled hole groups are formed in the mode of extending from the anchor net fixing areas into surrounding rock, and the drilled hole groups are filled with the static crushing agents; the anchor net fixing areas comprise anchor nets and anchor rods for fixing the anchor nets; and the anchor rods, the anchor nets, the drilled hole groups and the static crushing agents are combined to form a crescent in-situ yielding arch structure which is closely attached tothe position between the well wall and the surrounding rock. Compared with the relevant technology, the deep vertical well supporting structure utilizes the characteristics of being prone to extrusion and deformation during bearing force of the in-situ yielding arch structure to sufficiently mobilize the self-bearing ability of the deep part of the surrounding rock in the maximum horizontal stress direction, thus the radial load of the well wall in the maximum main stress direction is reduced, and bending stress generated in the well wall due to non-uniform horizontal confining pressure is reduced. The invention further provides a construction method of the deep well supporting structure.

Owner:CINF ENG CO LTD

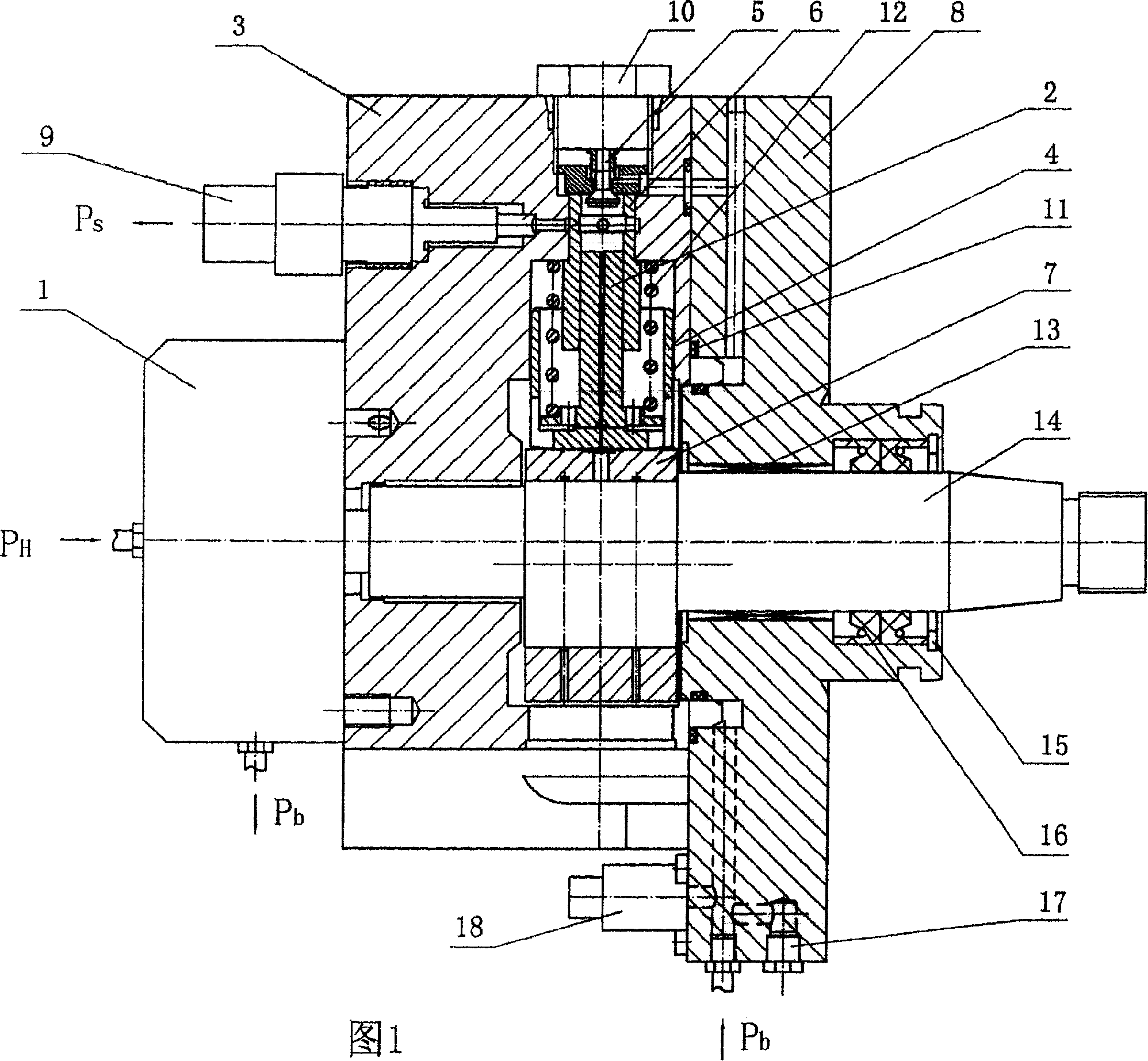

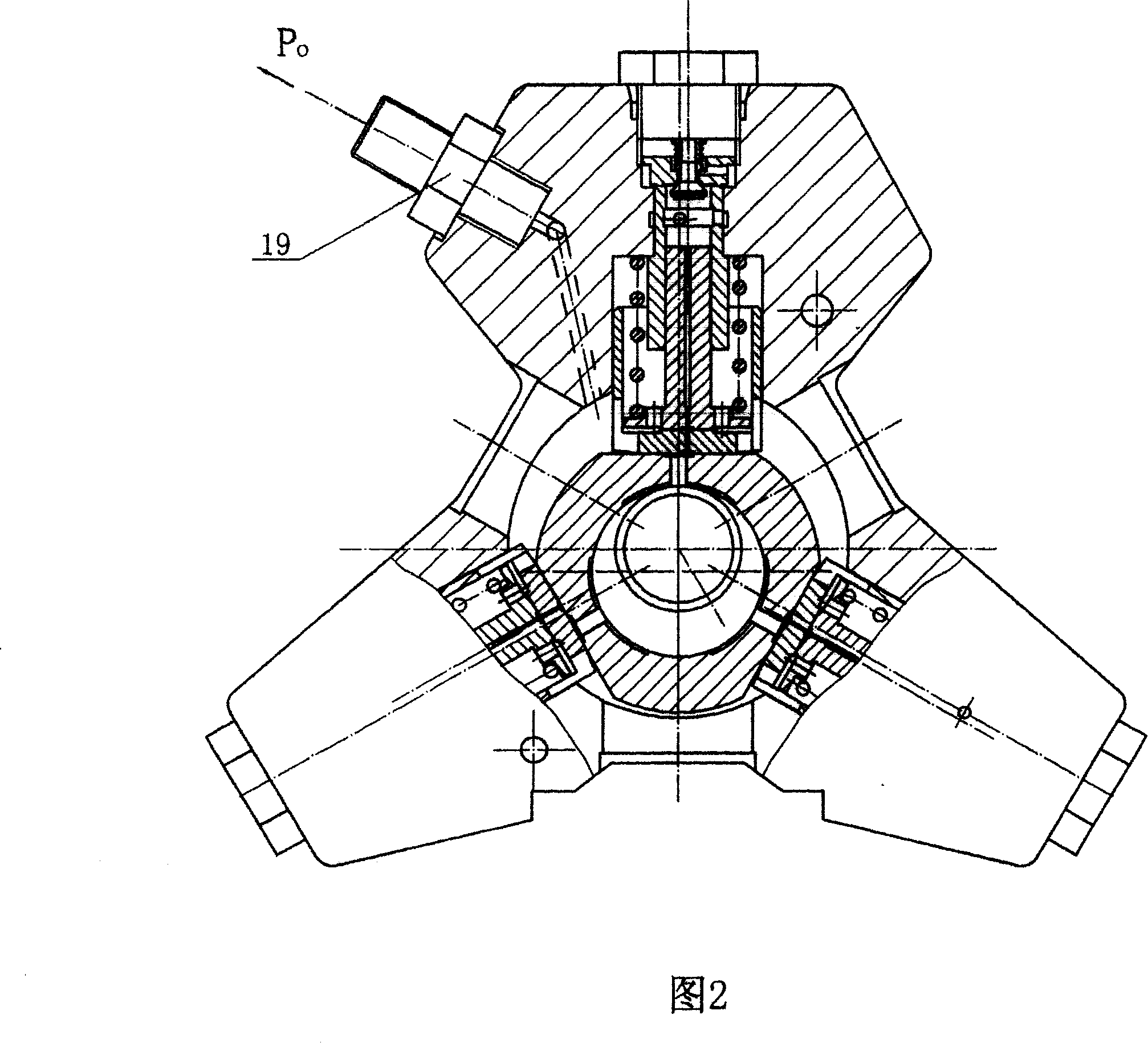

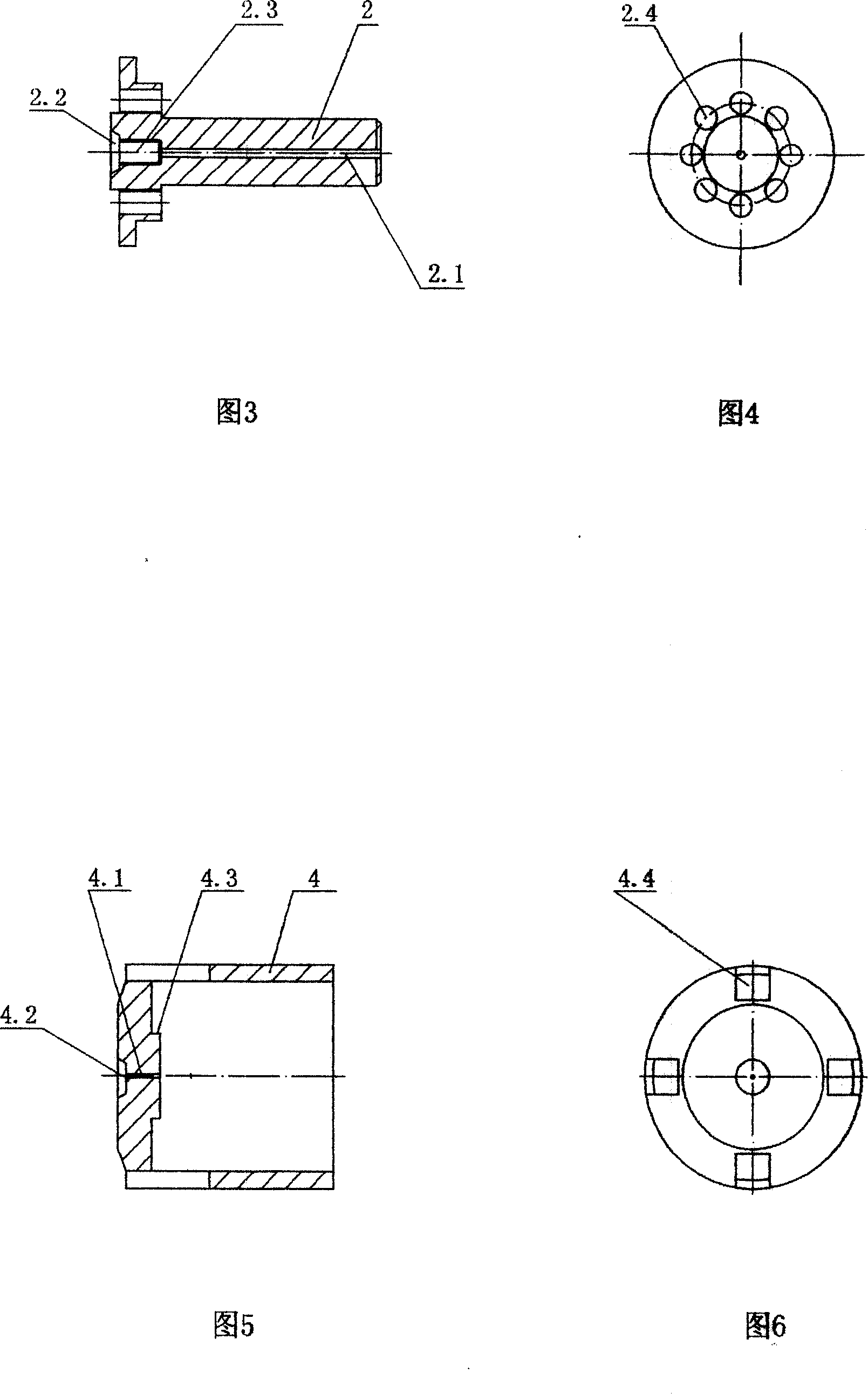

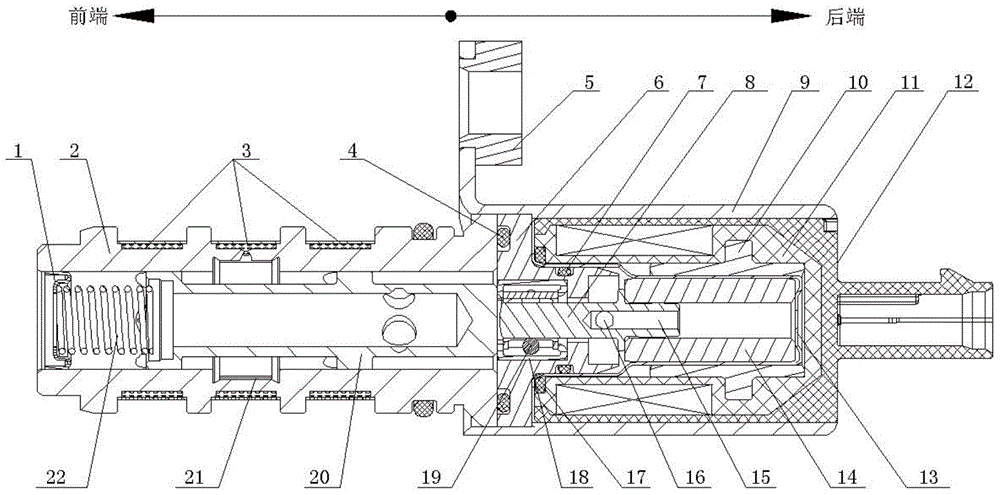

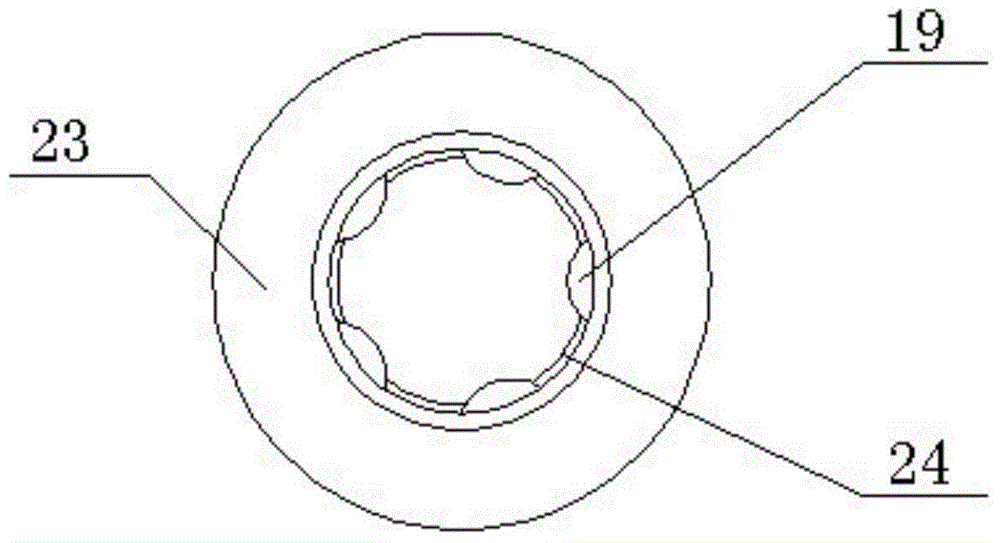

160Mpa electro-hydraulic proportional control radial piston pump

InactiveCN101126381AExtend working lifeReduce radial loadPositive displacement pump componentsPositive-displacement liquid enginesProportional controlRadial piston pump

The invention discloses a 160Mpa electrohydraulic proportional control radial plunger pump, comprising a slippage pump, a plunger, a case, an inlet valve, a stator, a pump bonnet, a vent valve, a transmission shaft, a bearing and so on. The invention is characterized in that the stator is arranged on the transmission shaft which is in the middle of a main oil pump; a large plunger is arranged on the upper end of the stator and a plunger is arranged in the large plunger; the outer side of the plunger is sleeved with a plunger bushing, the upper end of which is connected with the inlet valve, a row of oil valves are arranged on the case; an electrohydraulic proportional speed-regulating valve and an overflow valve are arranged on the pump bonnet; the slippage pump is arranged at the left end of the main pump. The invention causes the rotator always to have an film lubrication with the internal surface of the stator during the rotation, at the same time the radial load of the stator and the rotator and the lateral force of the plunger are reduced, the service life is prolonged and the work efficiency is improved and the application fields are wider; furthermore, the invention can gradually occupy the international market and has bright prospect.

Owner:卢堃 +1

Turbo compressor

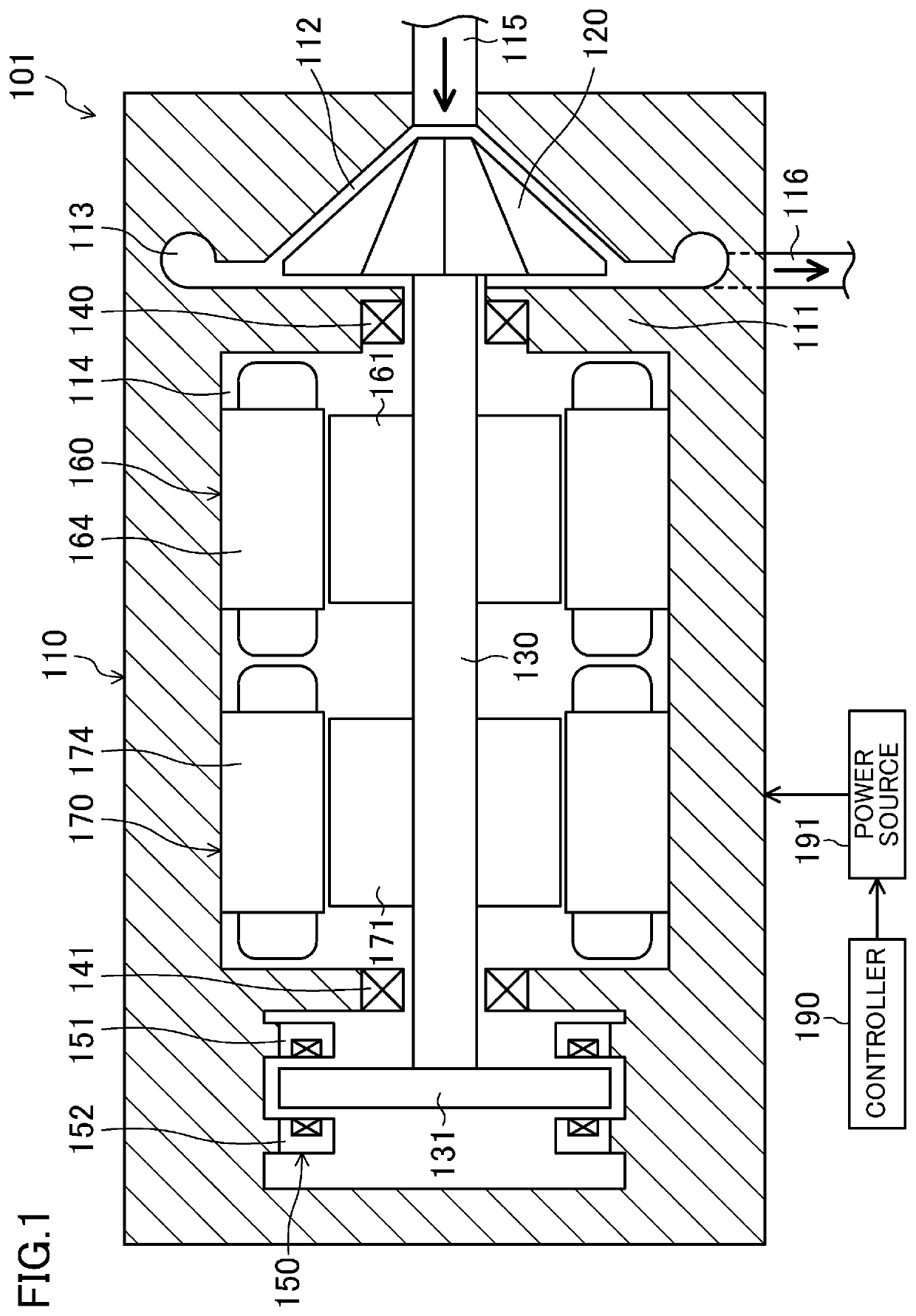

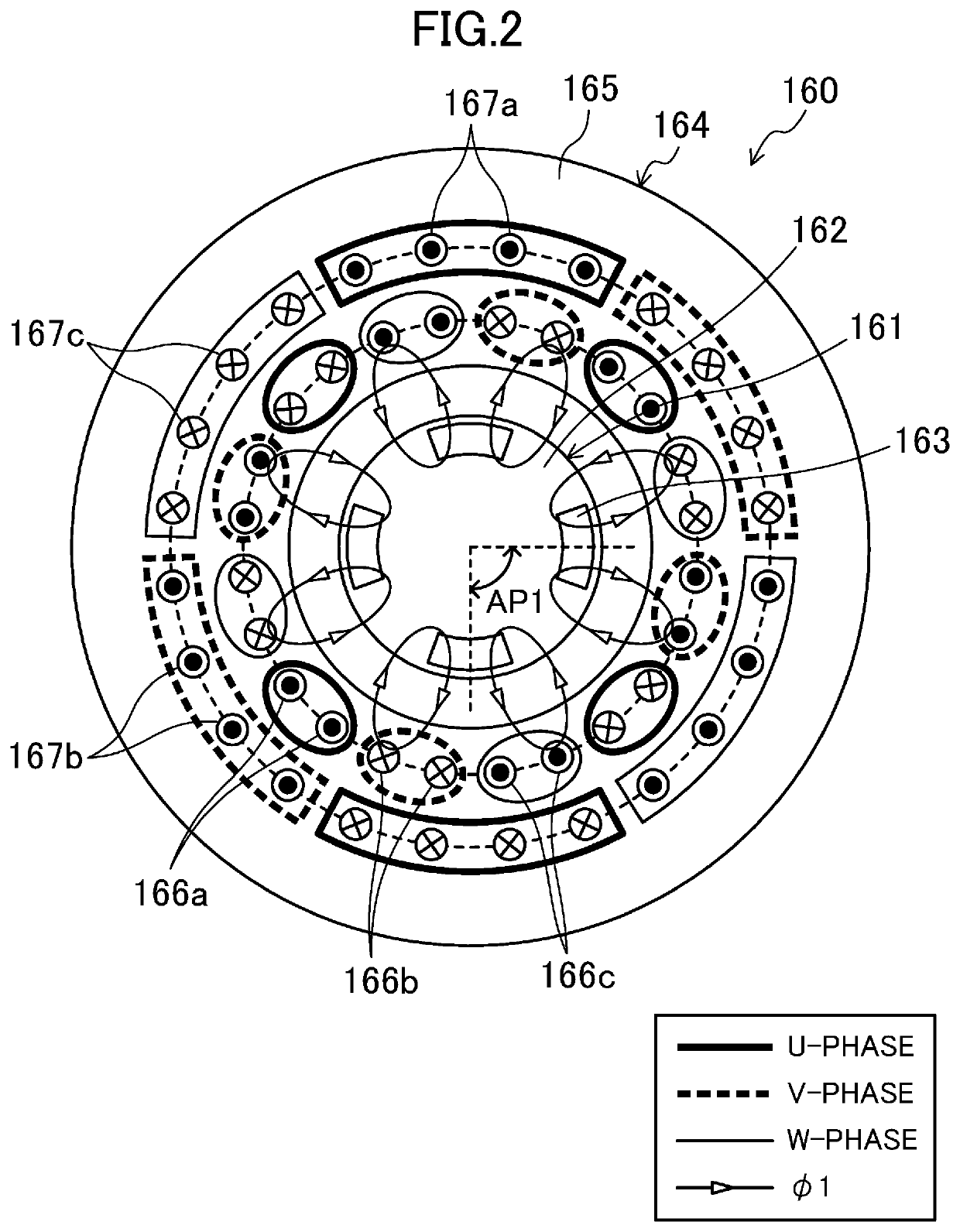

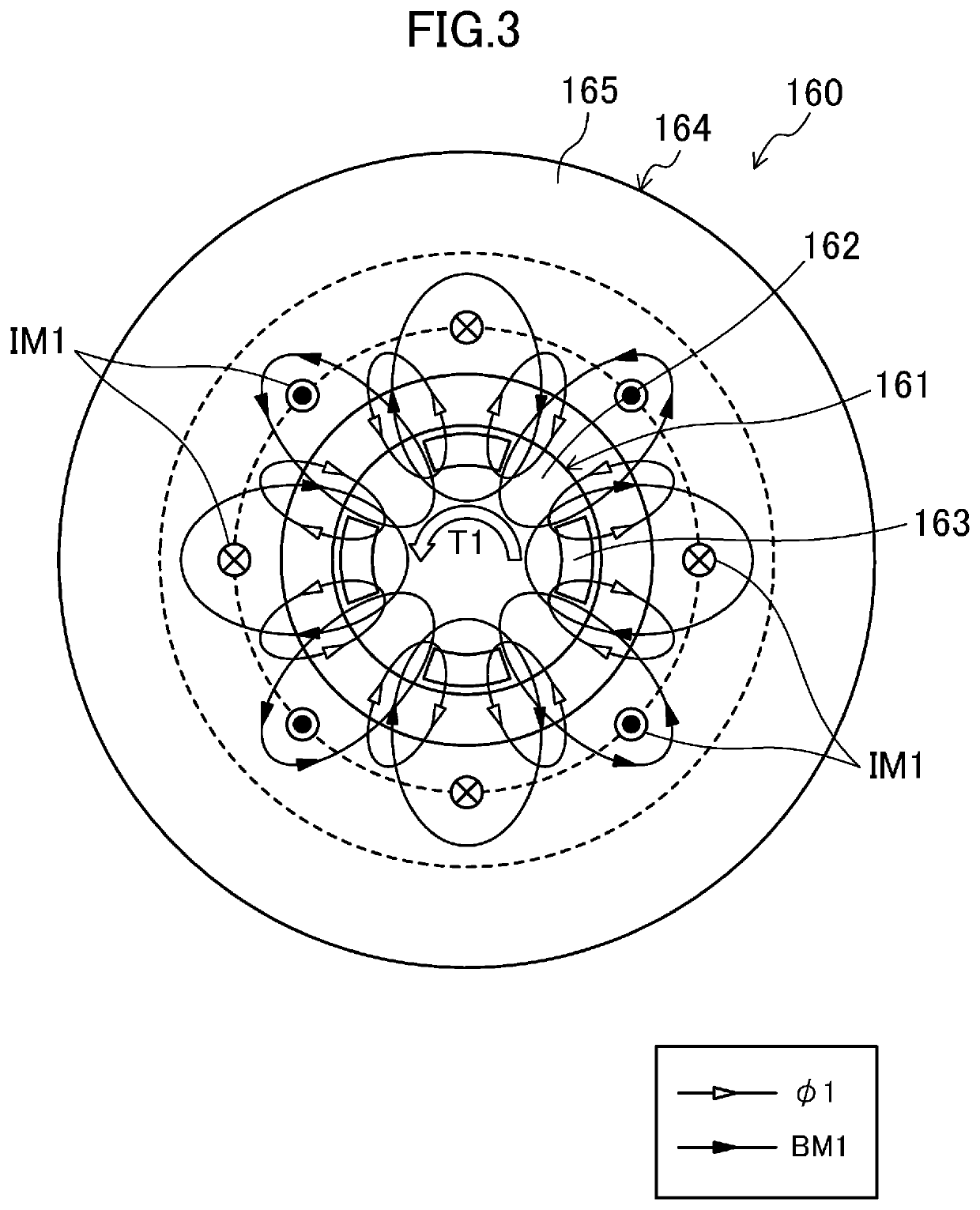

PendingUS20210115929A1Easy to controlAchieving Reliability RequirementsCompressorAC motor controlDrive shaftElectric machinery

A drive support unit of a turbo compressor includes at least one bearingless motor. The at least one bearingless motor includes a rotor-stator pair constituted by a rotor and a stator, and is configured to rotationally drive a drive shaft and to support a radial load of the drive shaft in a contactless manner. Accordingly, it is possible to provide a turbo compressor to which a bearingless motor is applied.

Owner:DAIKIN IND LTD

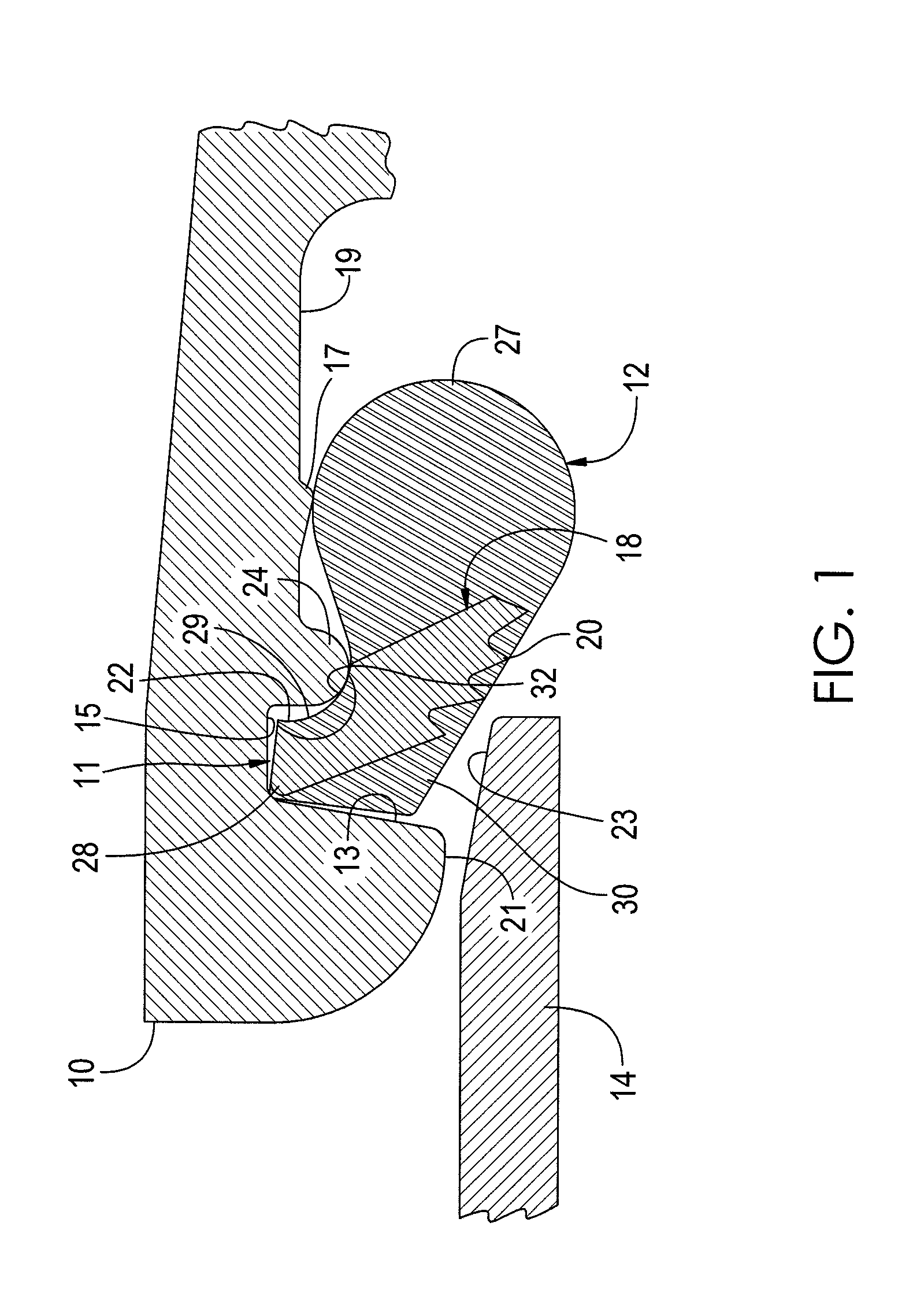

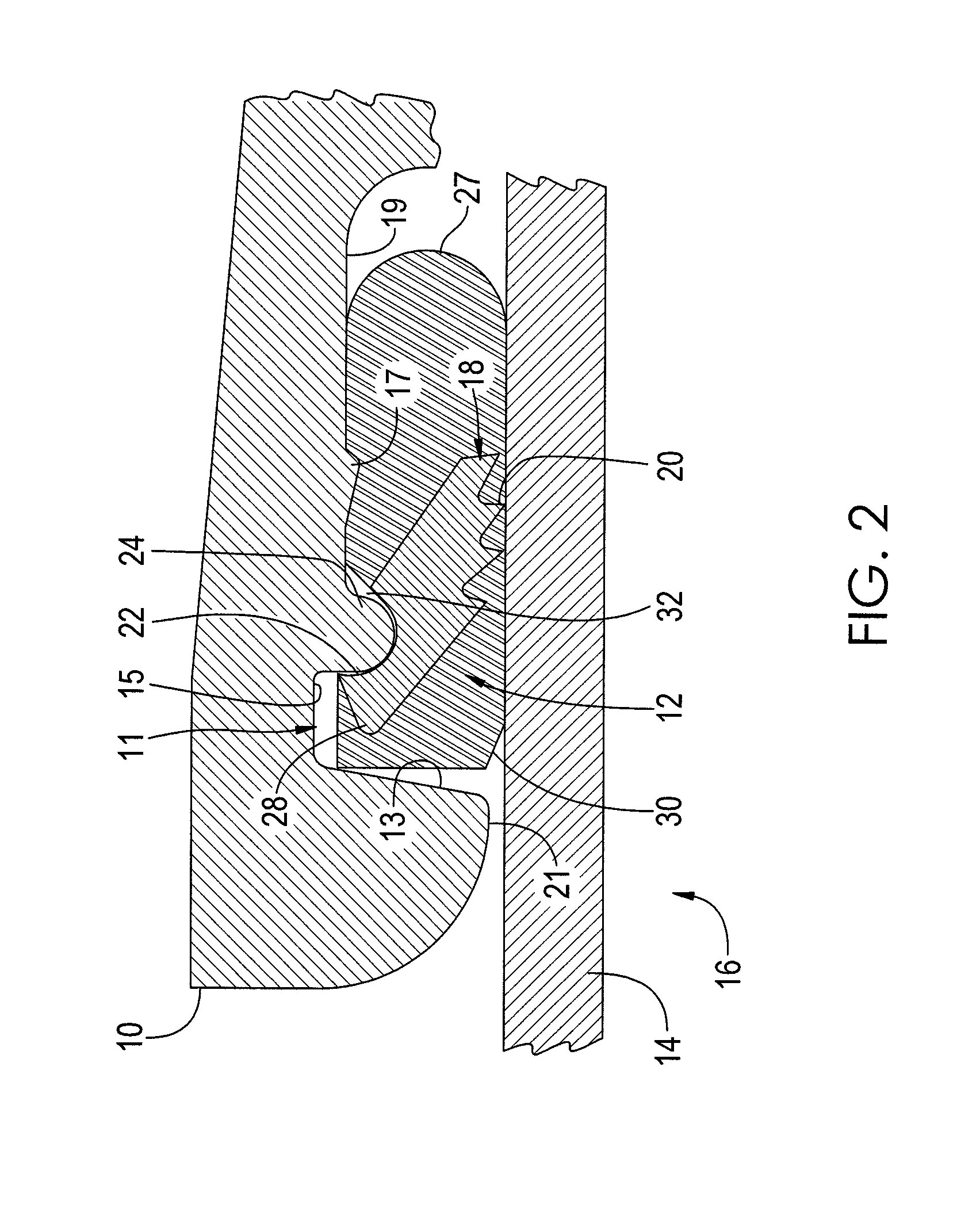

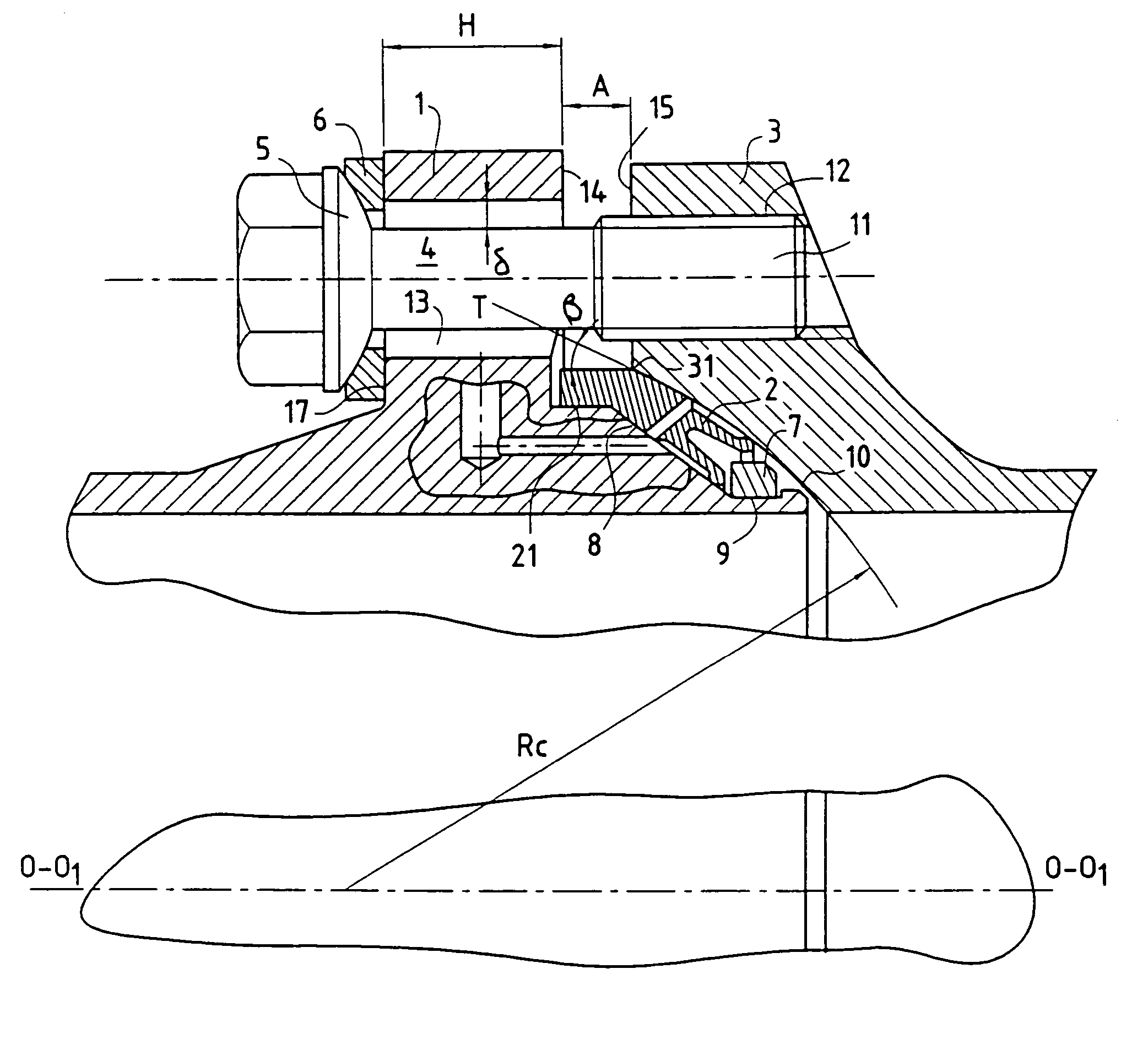

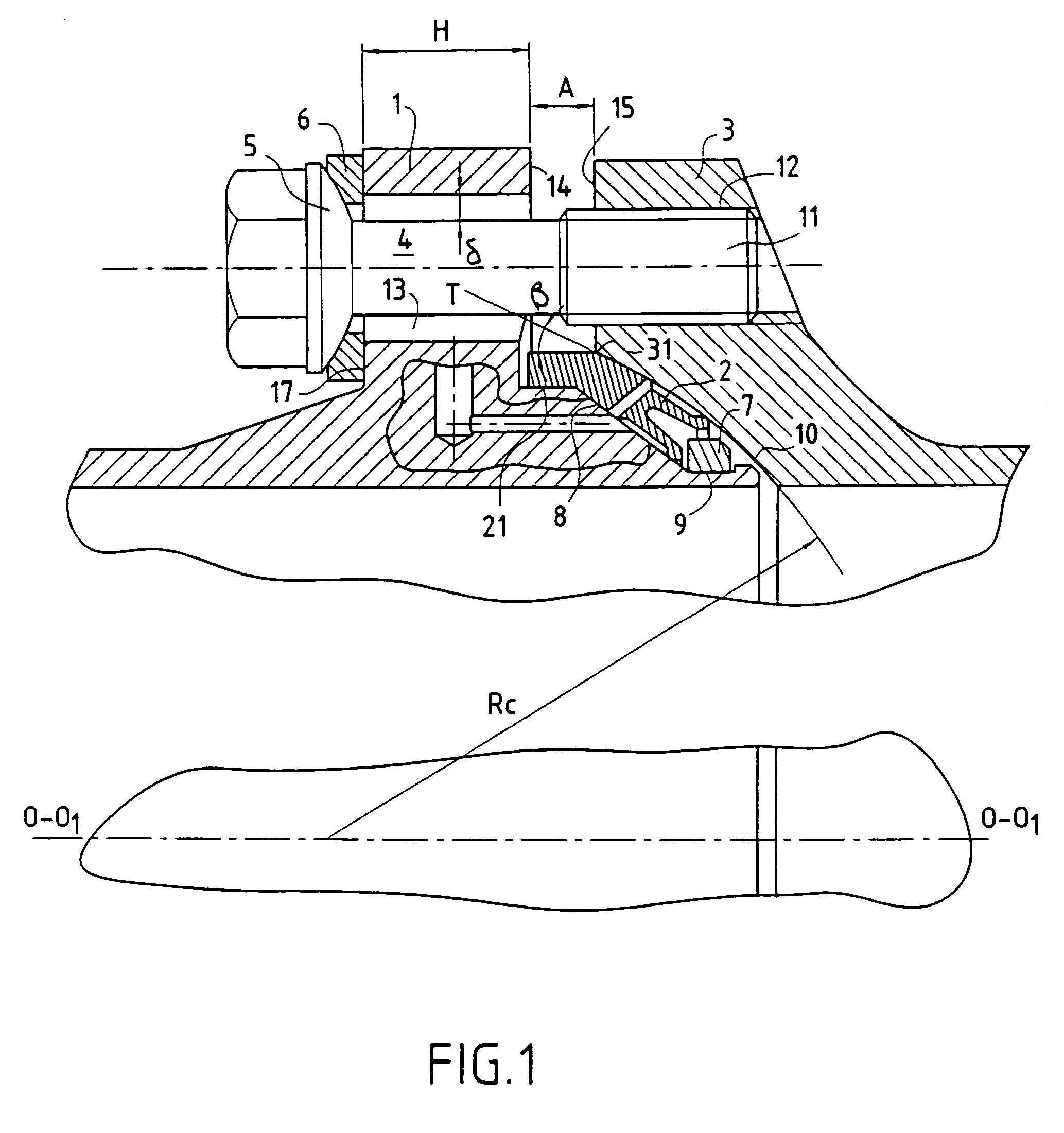

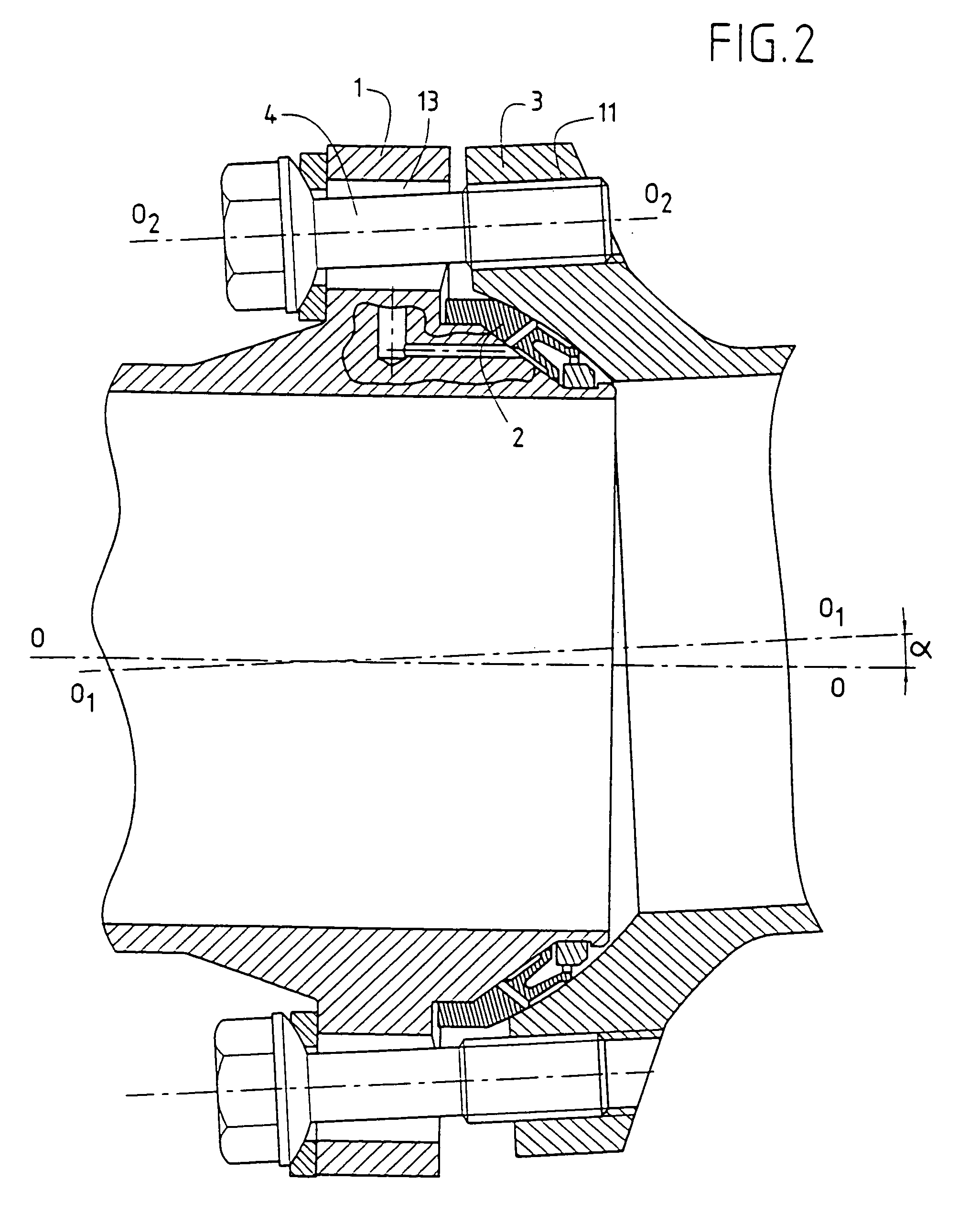

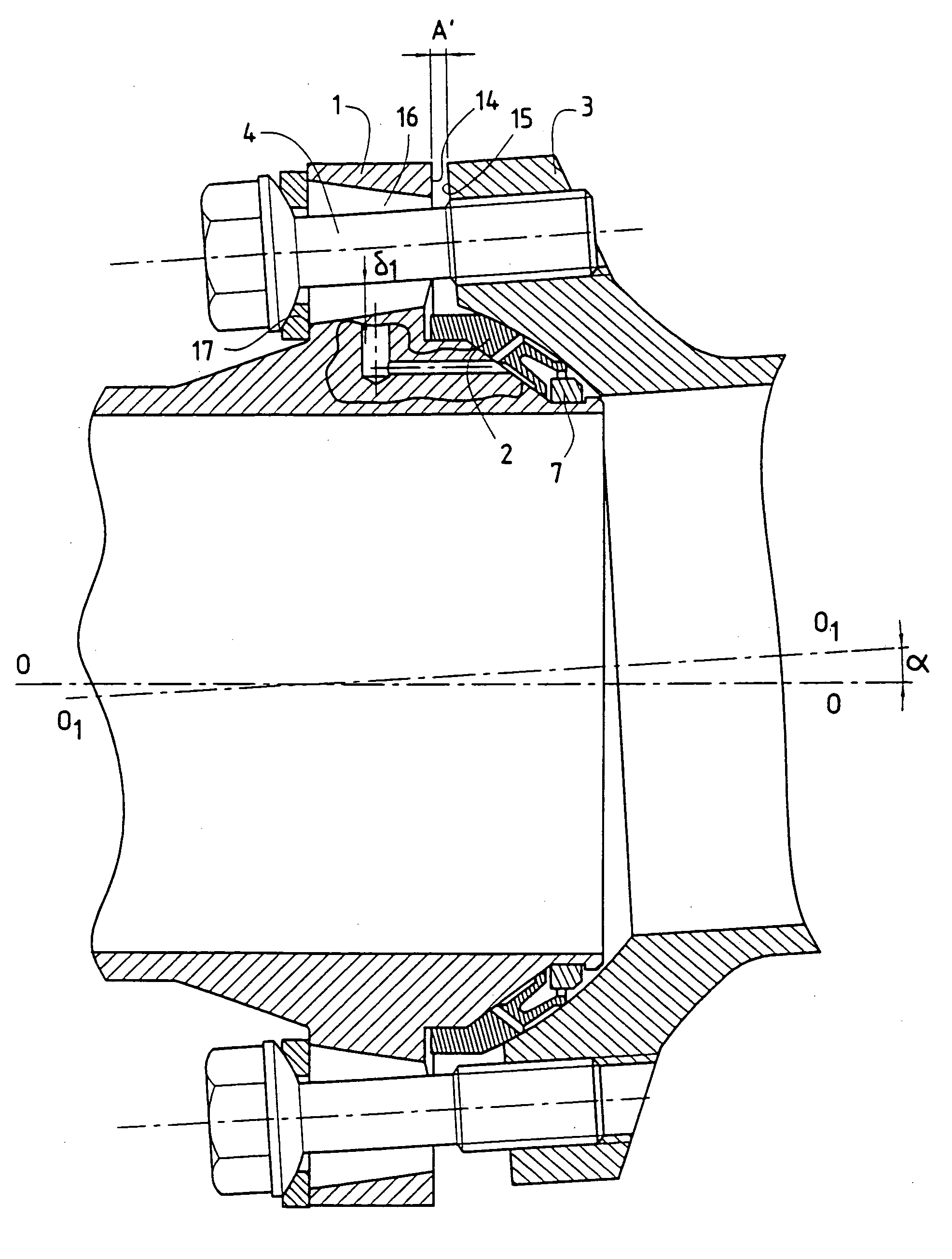

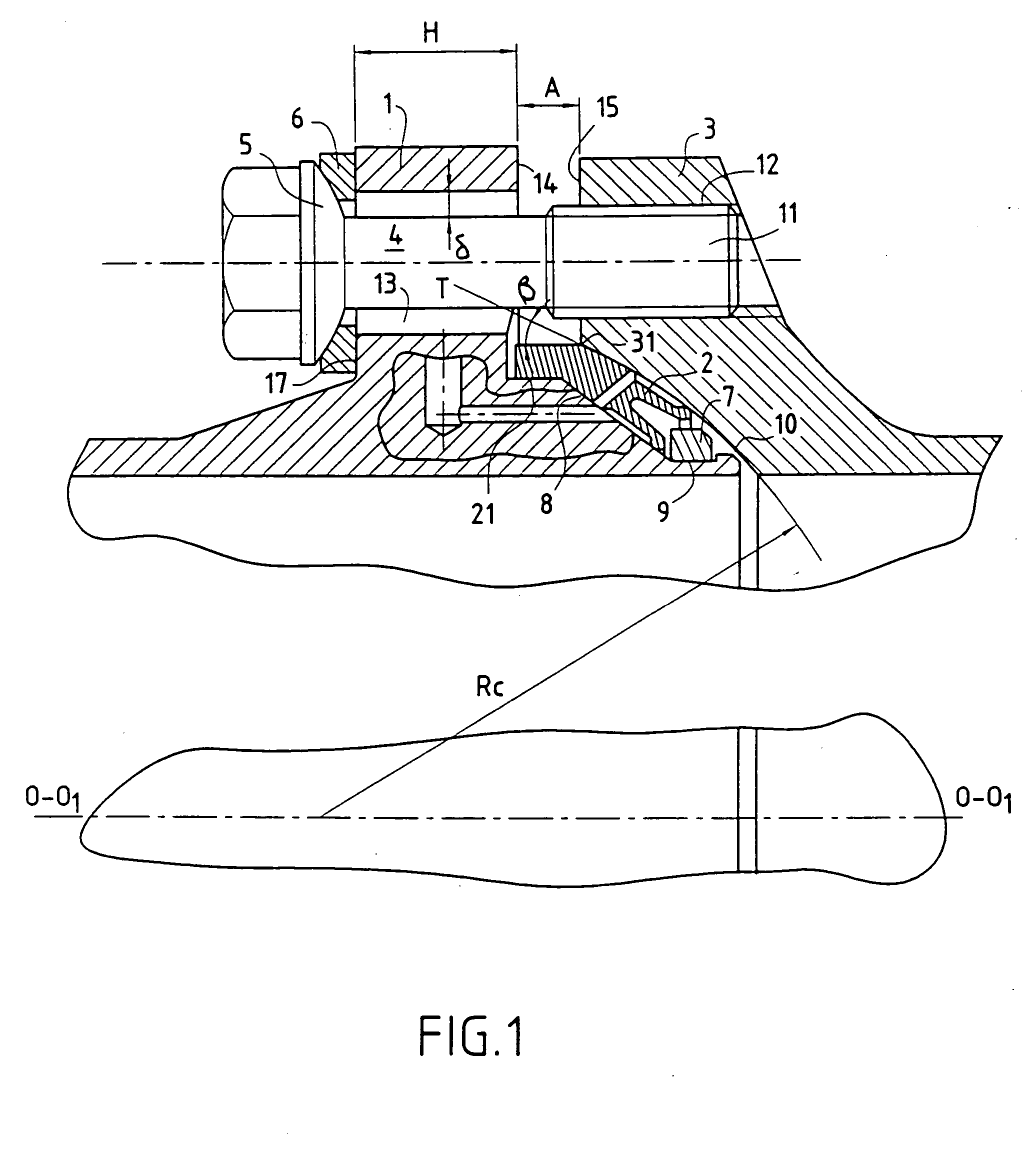

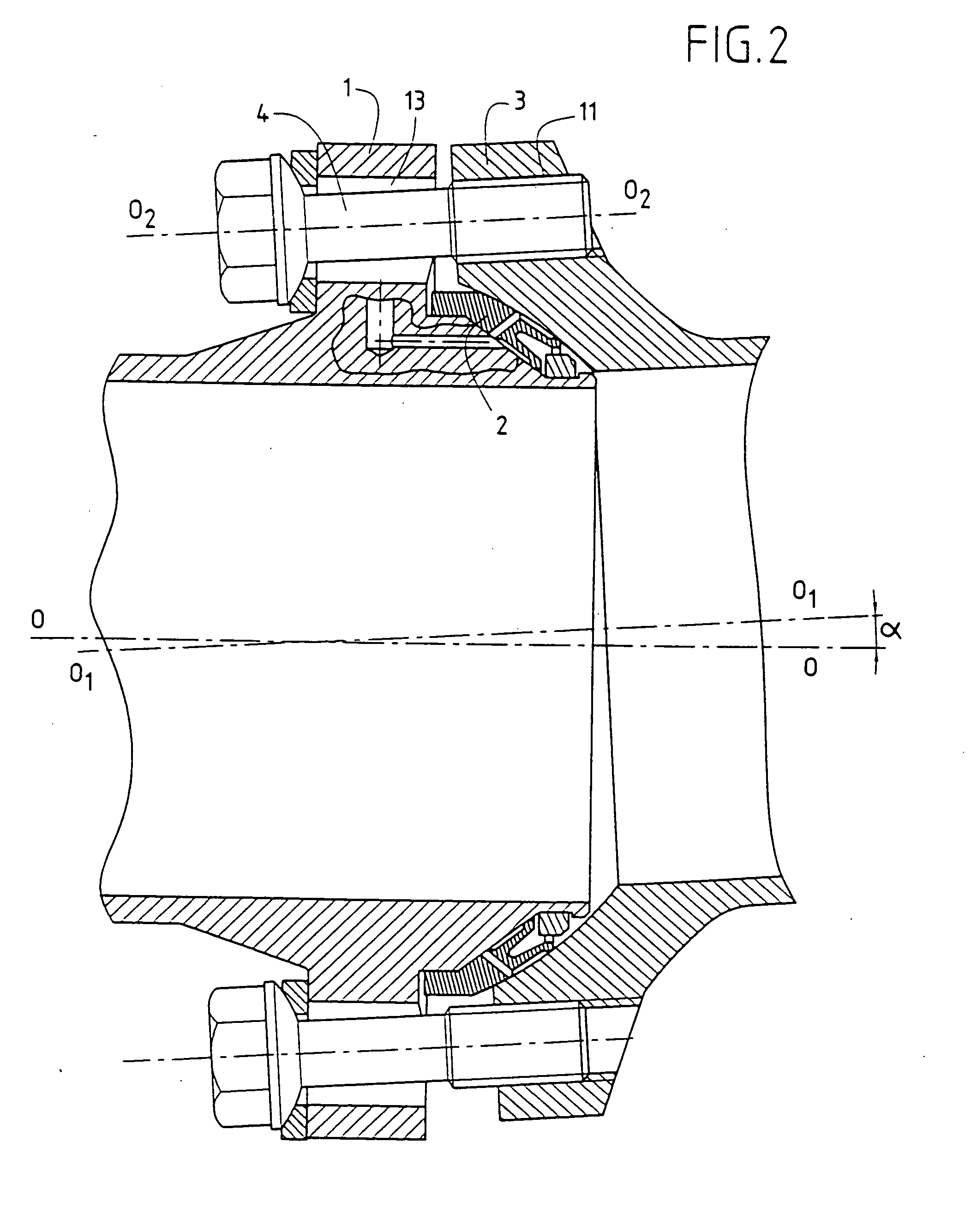

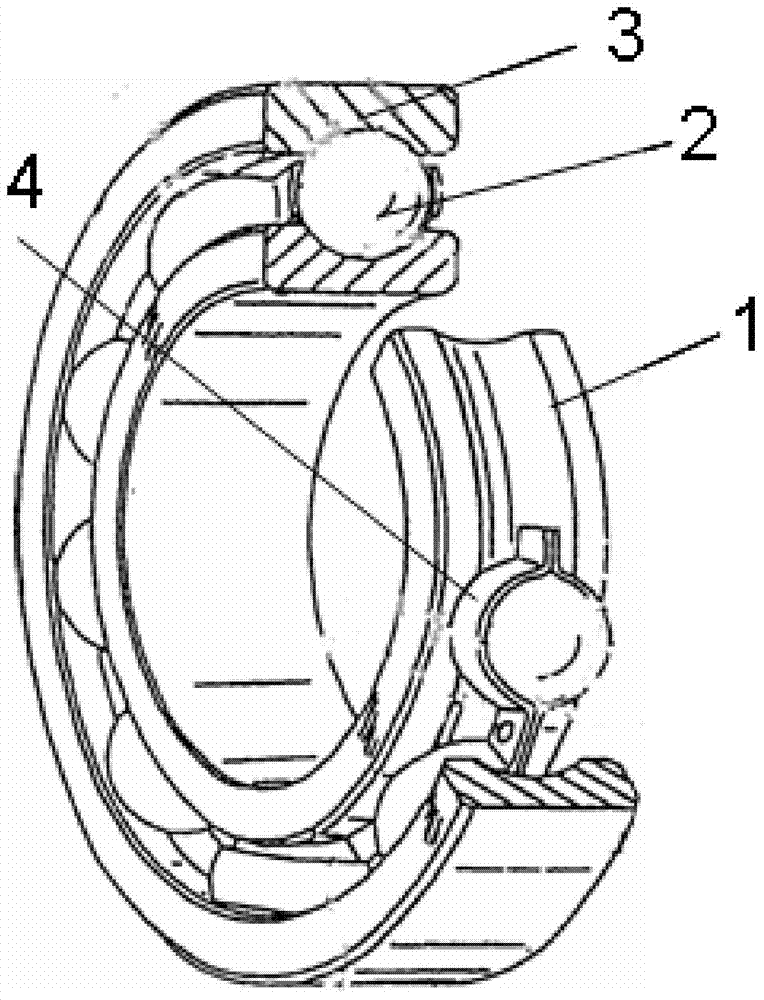

Flanged coupling device with a static ball-and-socket joint

InactiveUS7118139B2Increase the differenceReduce radial loadSleeve/socket jointsFlanged jointsHydrogenCoupling

The invention relates to couplings for fluid flowlines and more particularly to couplings that can be dismantled comprising flanges and a static ball-and-socket joint for use with flowlines having a diameter lying in the range 40 mm to 200 mm and transporting fluids (gases or liquids) of high penetrability, at high temperature of up to 800° C., and at high pressure of up to 450×105 Pa. Teh device comprises a flanged coupling device with a static ball-and socket joint comprising a first coupling member (1) having a conical sealing surface (8), a second coupling member (3) having concave sealing surface (10) of spherical shape, a two-barrier metal gasket (2) disposed between the sealing surface (8, 10) of the first and second coupling members (1, 3), and assembly means (4) for assembling the first and second coupling members (1, 3) together so as to hold the gasket (2) between their respective sealing surfaces (8, 10). The metal gasket (2) is made of a refractory granular nickel alloy that withstands hydrogen, having uniform fine grain structure with isotropic properties and coated in three sealing layers, the first layer (27) being of nickel, the second layers (28) being of silver, and the third layer (29) being an antifriction lubricant of an inorganic material that is compatible with the fluid used.

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A +1

Seal-bearing assembly

ActiveUS20140105527A1Lift radial loadReduce radial loadEngine sealsPiston ringsEngineeringBearing surface

A seal-bearing assembly to be inserted into the seal cavity of a mechanical device to provide a seal and a bearing surface to eliminate whip in a rotating and / or reciprocal cylindrical member. The seal-bearing assembly is particularly well suited for use in a reciprocal pump and between the steam lance and fixed steam tube in a sootblower. The assembly includes at least a pair of outer substantially rigid cylindrical bearings having an inner bore to be positioned over the cylindrical member and at least one complimentary flexible textile packing ring disposed between the two outer bearing members. In assemblies including an additional bearing, it is surrounded by at least one flexible packing on each side. The inner bore of the bearing members provide a bearing surface for eliminating whip of the moving elements in the device.

Owner:SEAL RYT CORP

Flanged coupling device with a static ball-and-socket joint

InactiveUS20040175226A1Increase the differenceReduce radial loadAdjustable jointsCouplings for rigid shaftsLine tubingCoupling

The invention relates to couplings for fluid flowlines and more particularly to couplings that can be dismantled comprising flanges and a static ball-and-socket joint for use with flowlines having a diameter lying in the range 40 mm to 200 mm and transporting fluids (gases or liquids) of high penetrability, at high temperature of up to 800° C., and at high pressure of up to 450x10<5 >Pa. Teh device comprises a flanged coupling device with a static ball-and socket joint comprising a first coupling member (1) having a conical sealing surface (8), a second coupling member (3) having concave sealing surface (10) of spherical shape, a two-barrier metal gasket (2) disposed between the sealing surface (8, 10) of the first and second coupling members (1, 3), and assembly means (4) for assembling the first and second coupling members (1, 3) together so as to hold the gasket (2) between their respective sealing surfaces (8, 10). The metal gasket (2) is made of a refractory granular nickel alloy that withstands hydrogen, having uniform fine grain structure with isotropic properties and coated in three sealing layers, the first layer (27) being of nickel, the second layers (28) being of silver, and the third layer (29) being an antifriction lubricant of an inorganic material that is compatible with the fluid used.

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A +1

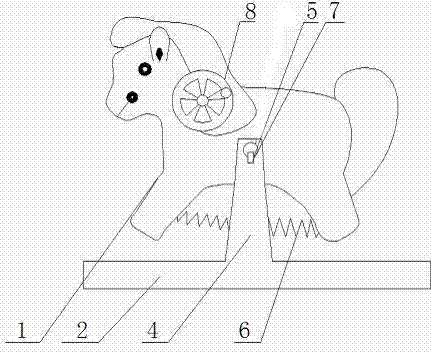

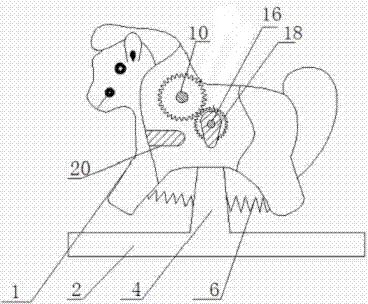

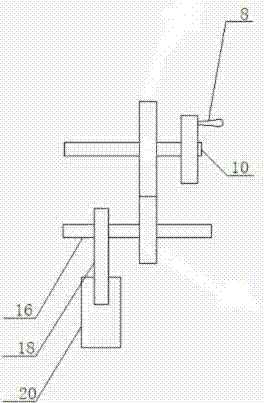

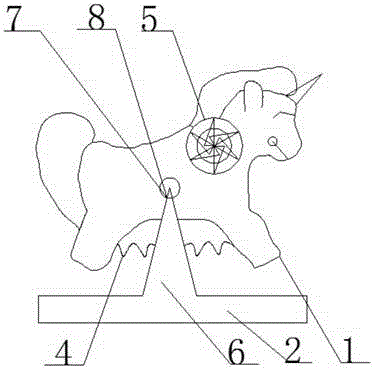

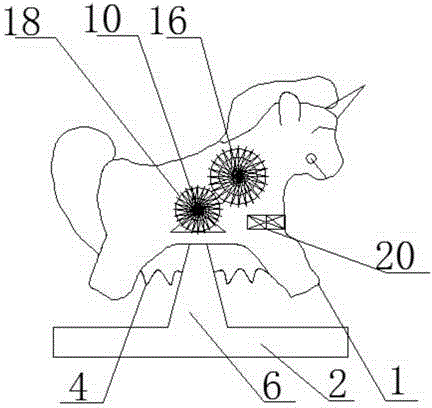

Wooden horse toy

Owner:苏州益童游乐设备有限公司

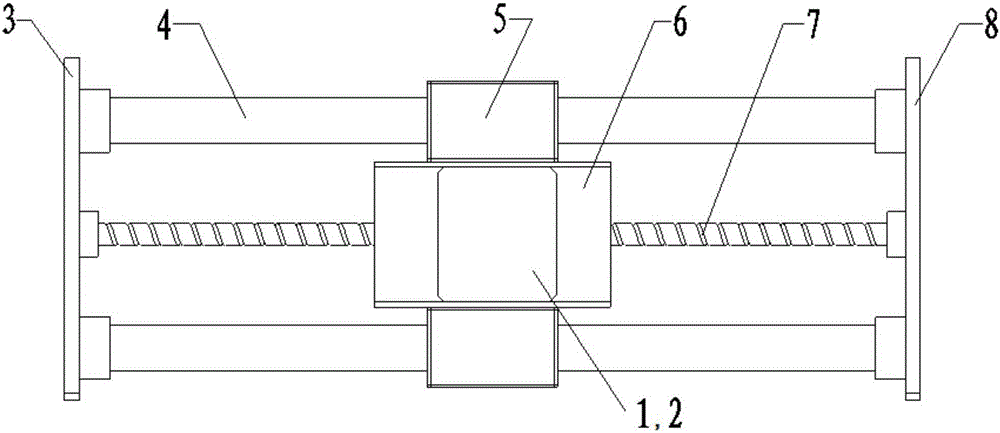

Moving mass center adjusting electromechanical actuator

ActiveCN106655609AReduce volumeReduce weightMechanical energy handlingElectromechanical actuatorMass center

The invention belongs to the field of actuators and specifically discloses a moving mass center adjusting electromechanical actuator which comprises a servo battery, a control driver, a front baffle plate, guide rails, a guiding support structure, a servo motor, a ball screw pair and a rear baffle plate, wherein the front baffle plate and the rear baffle plate are respectively fixed on two ends of two guide rails and the ball screw pair; the ball screw pair is positioned between the two guide rails, and a bottom part of the servo motor can slide on the guiding support structure in a reciprocating manner along the guide rails; two sides of the servo motor are respectively provided with the control driver and the servo battery; the servo motor, the control driver, the servo battery and the guiding support structure form a mass block which can move along the guide rails in a reciprocating manner. According to the electromechanical actuator, the mass center of the whole electromechanical actuator can be changed via control of reciprocating movement of the mass block.

Owner:BEIJING RES INST OF PRECISE MECHATRONICS CONTROLS

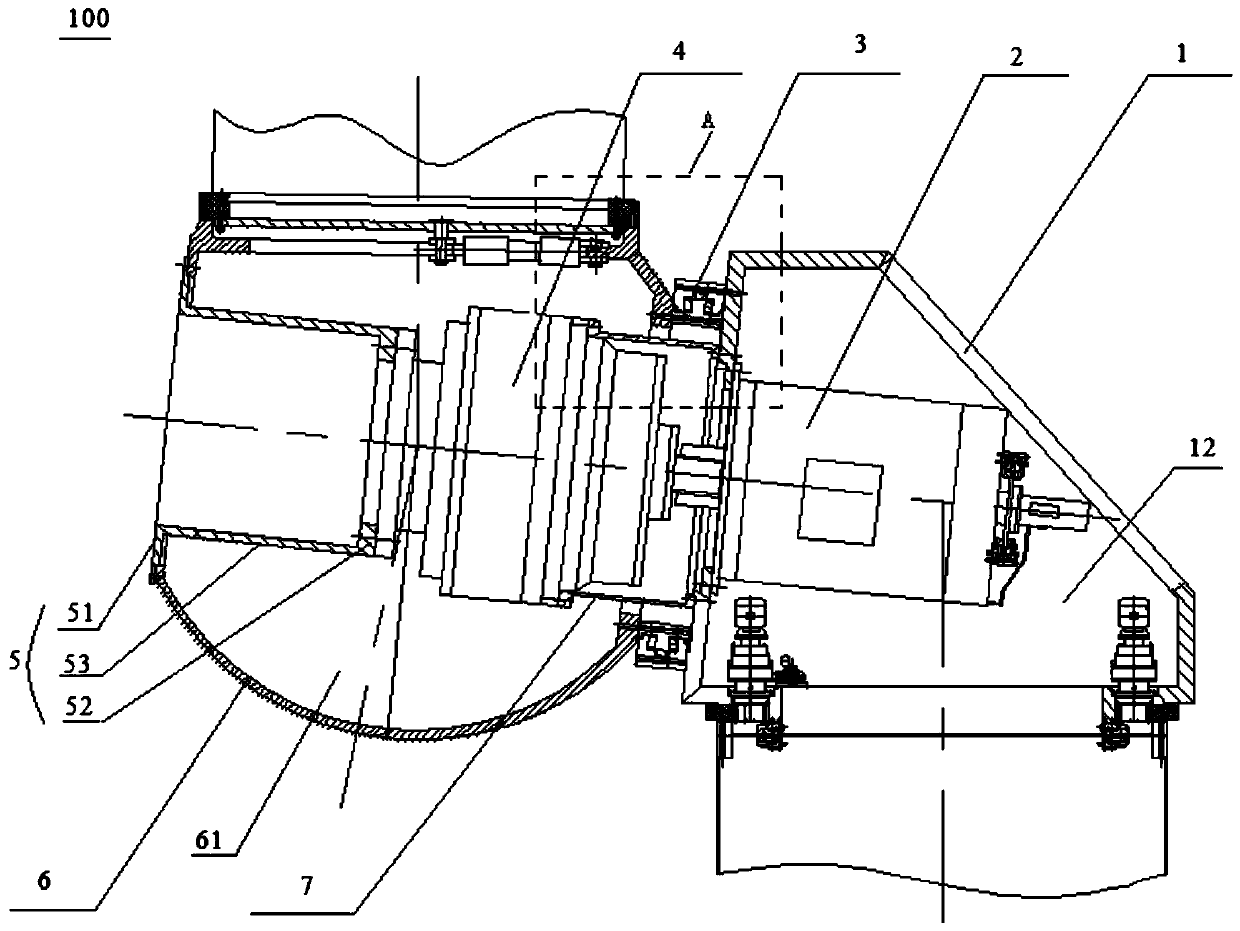

Wind power generation equipment

ActiveCN110080953AShorten the axial lengthReduce radial loadMachines/enginesWind motor combinationsRe engineeringElectric generator

The application discloses wind power generation equipment. The wind power generation equipment comprises a wind wheel, a speed increasing box and a power generator; a wheel hub of the wind wheel is provided with a first accommodating cavity; the speed increasing box is mounted in the first accommodating cavity; an input shaft of the speed increasing box is in power coupling connection with the wheel hub; one of an input shaft of the power generator and an output shaft of the speed increasing box is arranged out of the other of the input shaft of the power generator and the output shaft of thespeed increasing box in a sleeving manner, and the input shaft of the power generator and the output shaft of the speed increasing box are in power coupling connection with each other. According to the wind power generation equipment disclosed by the invention, the axial length of the overall wind power generation equipment can be greatly reduced and the radial load between the wind wheel and thepower generator can be reduced by redesigning the structural positions and the connecting structures of the wheel hub, the speed increasing box and the power generator, so that the size and the weightof the overall wind power generation equipment can be reduced; and the installation cost can be reduced.

Owner:STATE POWER INVESTMENT CORP RES INST

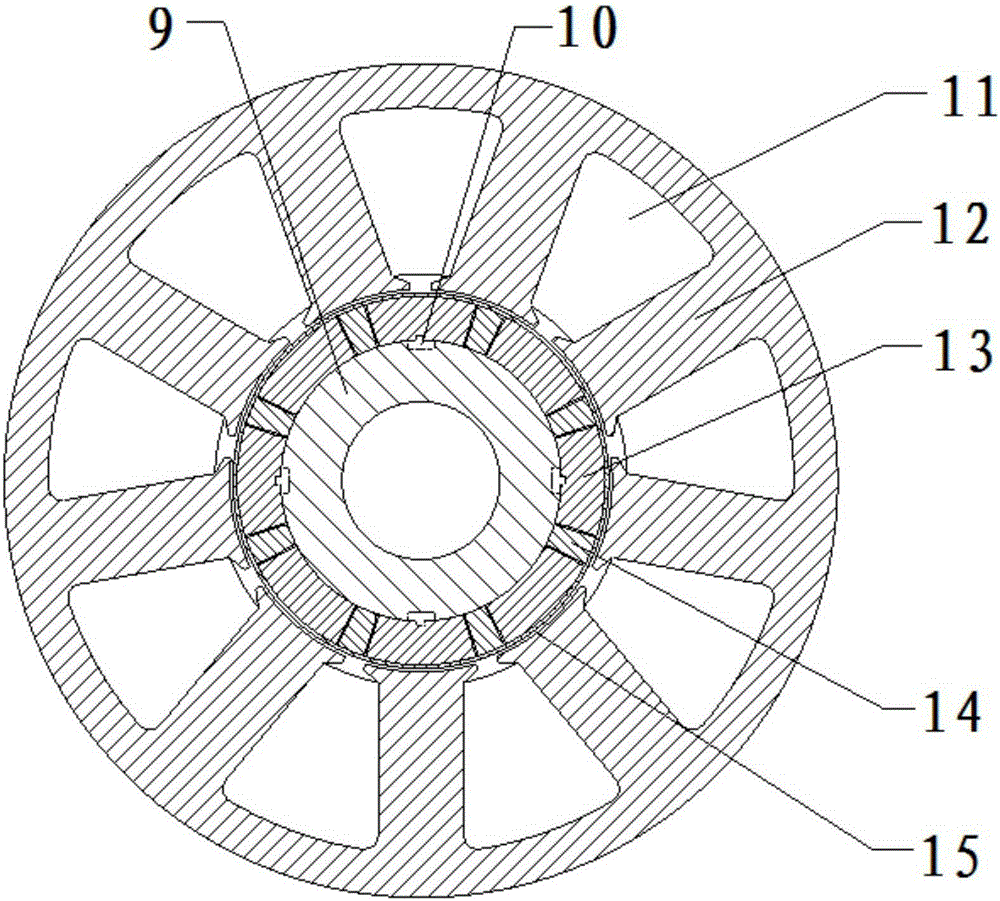

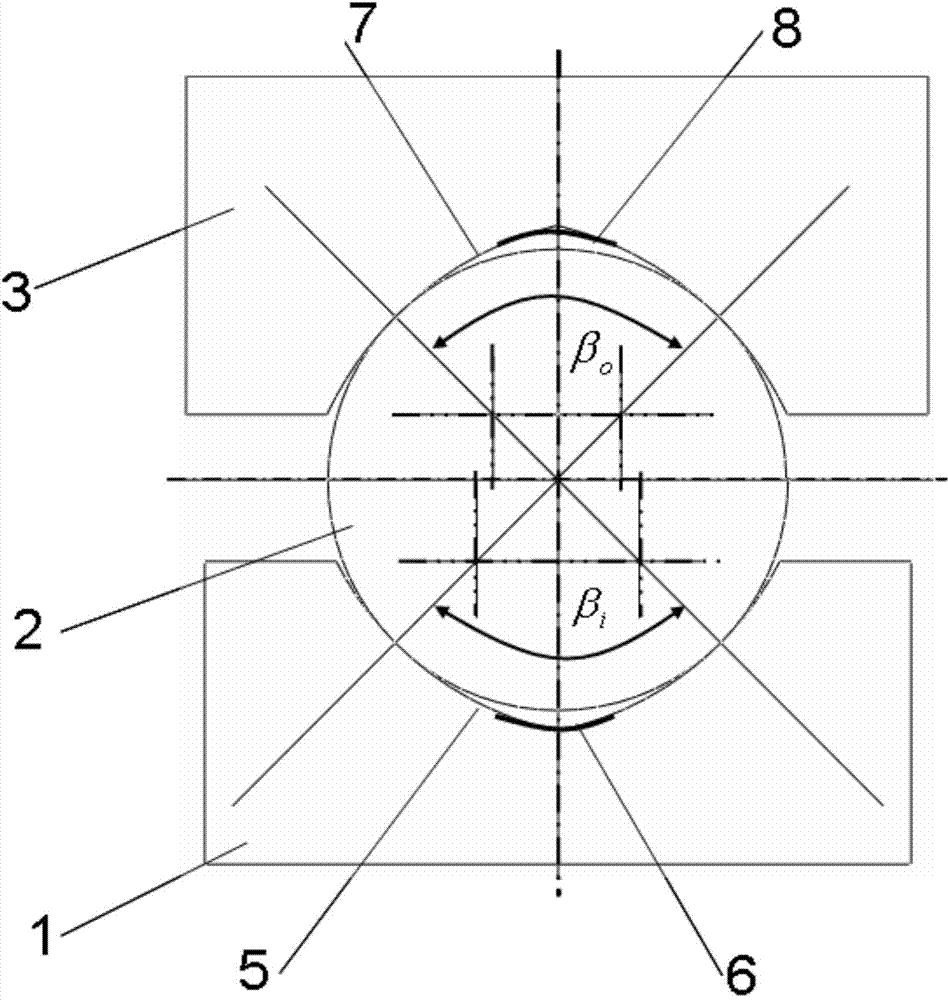

Integrated ferrule four-point contact ball bearing

InactiveCN103527625AReduce radial loadImprove fatigue lifeRoller bearingsBearing componentsBall bearingEngineering

The invention discloses an integrated ferrule four-point contact ball bearing. The integrated ferrule four-point contact ball bearing comprises a bearing inner ring, balls, an outer ring and a retainer, wherein the bearing inner ring and the bearing outer ring are respectively provided with an annular roll way, each annular roll way is in two-point contact with one ball, and the included angle beta i between two contact points and a ball center connecting line and the included angle beta o between the other two contact points and the ball center connecting line both range from 20 degrees to 150 degrees; the balls are internally tangent with a curve of the roll way of the inner ring and a curve of the roll way of the outer ring respectively, a radial clearance is formed between the outer ring and the corresponding ball, another radial clearance is formed between the inner ring and the corresponding ball, the curvature radius ri of a section profile curve of the annular roll way of the inner ring is 1.01-1.16 times of the radius r of each ball, and the curvature radius ro of a section profile curve of the annular roll way of the outer ring is also 1.01-1.16 times of the radius r of each ball. Due to the fact that the clearances are formed between the balls and the annular roll ways, the lubrication conditions of the bearing can be improved, and the fatigue life of the bearing can be prolonged; the balls and the annular roll ways are well matched, so that the service life of the bearing is long.

Owner:DALIAN JIAOTONG UNIVERSITY

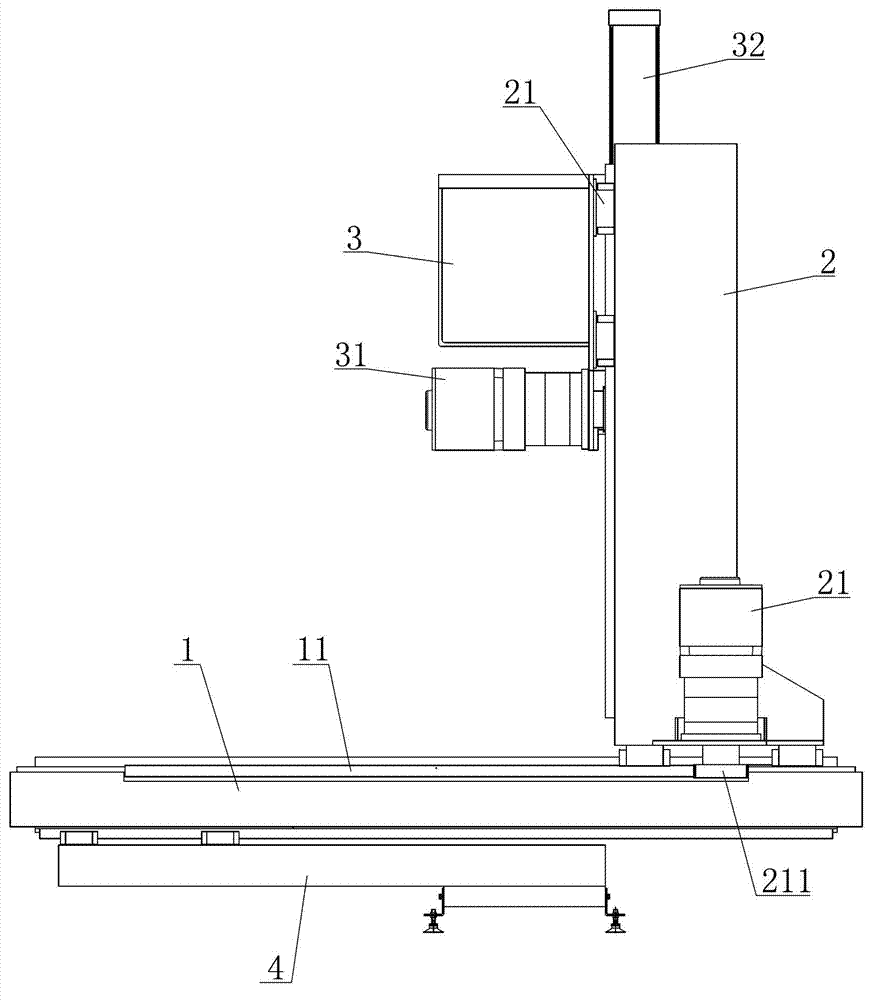

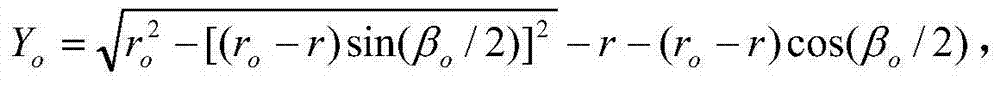

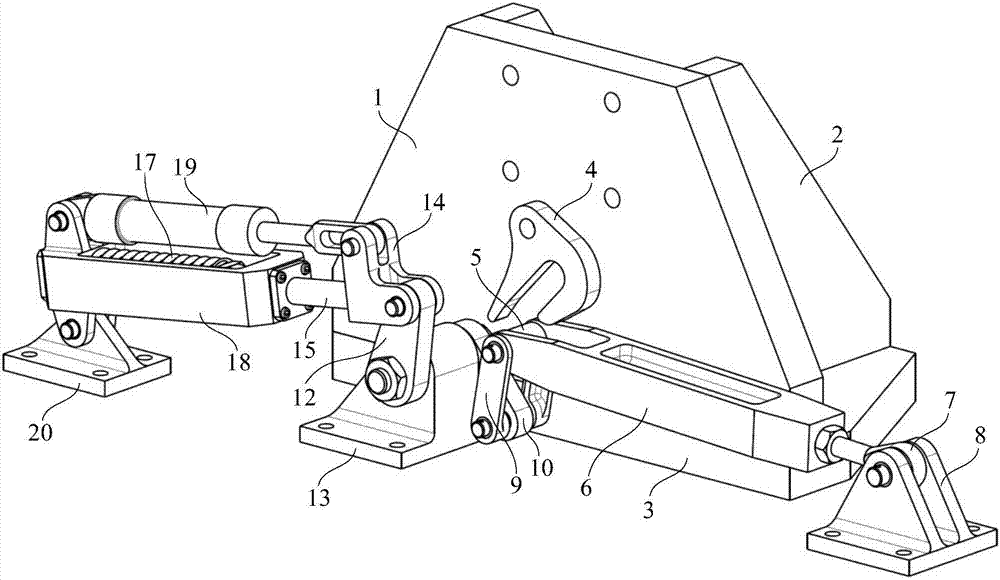

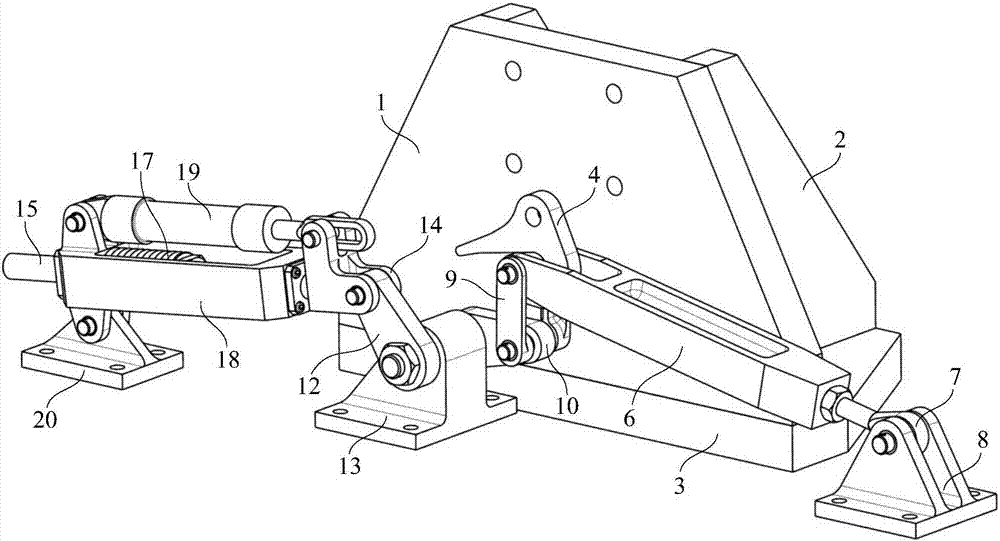

Up-lock reliability test device capable of realizing lock ring horizontal position adjustment

The invention provides an up-lock reliability test device capable of realizing lock ring horizontal position adjustment, belongs to the technical field of aviation equipment up-lock reliability test, and aims at solving the problems that the present aircraft up-lock test device has low integral rigidity and cannot realize manual adjustment of the lock ring horizontal position. The up-lock is a test piece and is installed on a supporting rack. A lock ring module, a crank module and a loading driving module are arranged below the up-lock and fixed on the surface of a vibration table through a support respectively. The lock ring module is used for simulating upward and downward movement of the lock ring under the real situation and can realize adjustment of the lock ring horizontal position. The loading driving module is used for driving the lock ring to upward and downward move and loading working load on the up-lock through the lock ring module. The crank module is arranged between the lock ring module and the loading driving module and used for transmitting the movement and the load of the loading driving module to the lock ring module. The up-lock reliability test device is used for reliability testing of the up-lock.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Toy

Owner:ANHUI BOLANGDAO AMUSEMENT EQUIP

Engine oil control valve with guiding structure

ActiveCN104454061AReduce friction surfaceReduce friction and wearMachines/enginesNon-mechanical valveMagnetic coreEngine valve

The invention provides an engine oil control valve with a guiding structure. The engine valve control valve comprises a valve element (20), a pole shoe (6), a magnetic core shaft (8), a magnetic core (14) and an electromagnetic solenoid assembly (12). A guiding sleeve (13) is arranged between the magnetic core (14) and a rear yoke sleeve (10) on the electromagnetic solenoid assembly (12), the magnetic core shaft (8) is fixedly connected with the magnetic core (14), the guiding structure with balls (19) is arranged between the magnetic core shaft (8) and the pole shoe (6), sliding friction is adopted between one end of the magnetic core (14) and the guiding sleeve (13), and rolling friction is adopted between the other end of the magnetic core (14) and the balls (19) through the magnetic core shaft (8). A stressed supporting point of the magnetic core can be transferred to the balls, the length of the arm of force of the acting force of the valve element to the magnetic core shaft is reduced, radial loads borne by the magnetic core and the guiding sleeve on the right side of the balls are reduced, abrasion of the magnetic core and the guiding sleeve is effectively lowered, and the service life of the engine oil control valve is effectively prolonged.

Owner:MIANYANG FULIN PRECISION MACHINING

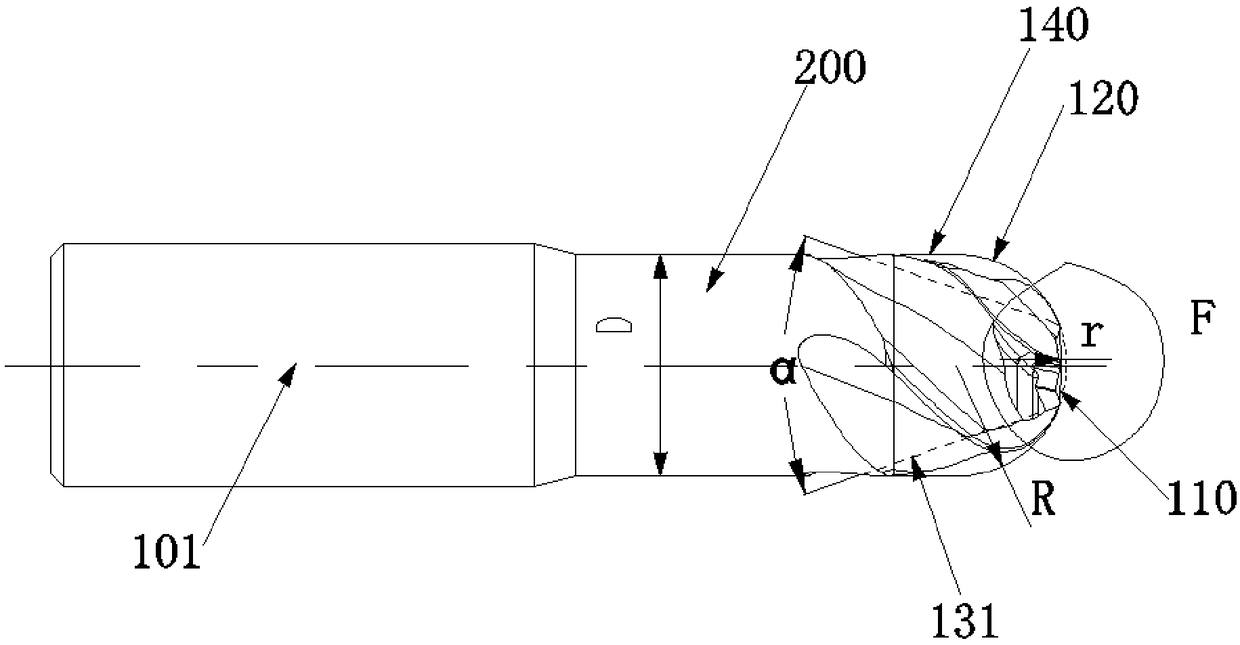

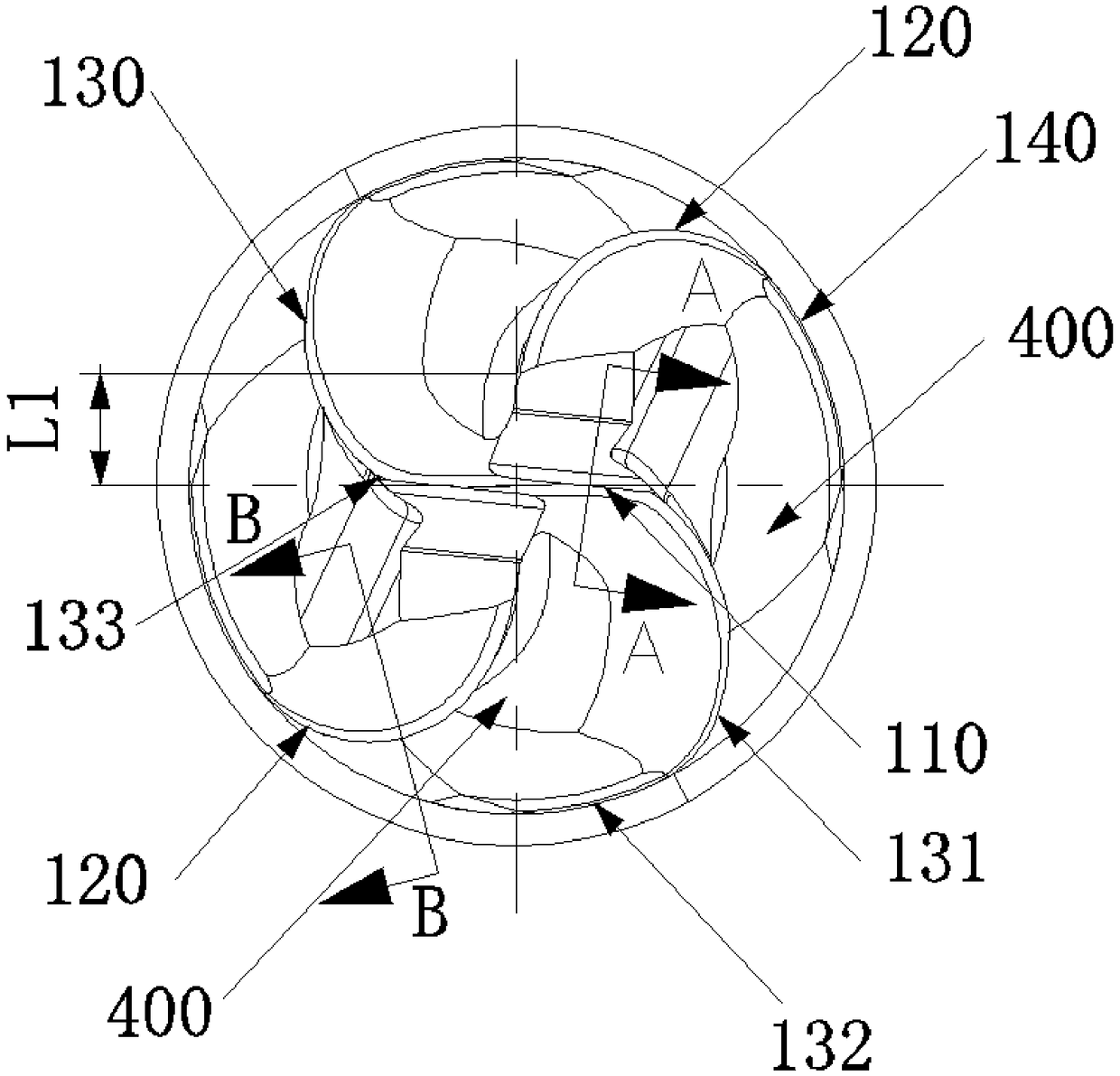

Multifunctional ball endmill

ActiveCN109262038ALow radial loadImprove cutting efficiencyMilling cuttersMilling cutting insertsEngineeringMilling cutter

The invention discloses a multifunctional ball endmill which includes a cutting portion, an assembly and disassembly portion and a connecting portion for the cutting portion, the assembly and disassembly portion. The cutting portion includes an inner ball cutting edge and at least one pair of outer ball cutting edges. The inner ball cutting edge and a central shaft are cross and are rotatably symmetric with respect to the central shaft, two outer ball cutting edges in each pair of outer ball cutting edges are rotatably symmetric with respect to the central shaft, a radial spacing is reserved between the outer ball cutting edges and the central shaft, a spherical surface formed by the inner ball cutting edge rotating with respect to the central shaft and a spherical surface formed by the outer ball cutting edge rotating with respect to the central shaft are cross, the spherical surface radius of the inner ball cutting edge is r, and the spherical surface radius of the outer ball cuttingedge is R, meeting: 5R<=r<=15R. The spherical surface radius of the inner ball cutting edge is far greater than that of the outer ball cutting edge, and when performing cavity large feeding cutting or flat surface copy milling, the endmill has a low radial load and high cutting efficiency.

Owner:ZHUZHOU CEMENTED CARBIDE CUTTING TOOLS CO LTD

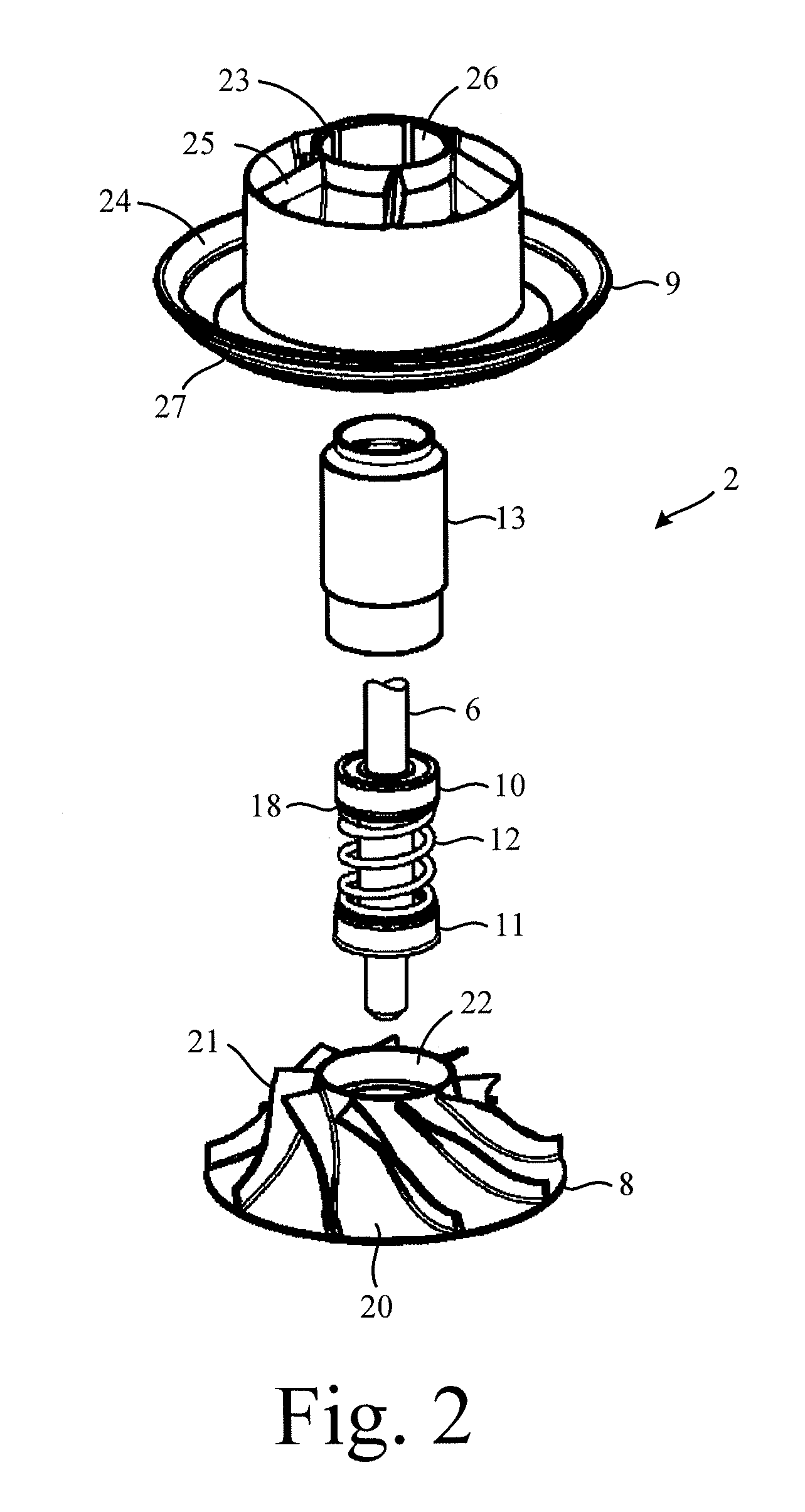

Bearing assembly

ActiveUS8864460B2Easy to installSolving the Insufficiency of ElasticityPump componentsBall bearingsEngineeringMechanical engineering

A bearing assembly that includes a first bearing, a second bearing, a spring and a sleeve. The spring applies a preload to each of the bearings, and the sleeve surrounds the spring and the bearings. The sleeve includes an end portion that extends axially beyond the first bearing. The end portion includes a step down in the outer diameter that defines a seat for an o-ring.

Owner:DYSON TECH LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com