Assembling method for three-fulcrum bearing of aircraft engine

An aero-engine and assembly method technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of increasing the number of engine test verifications, increasing engine repair costs, and limiting engine repair efficiency, achieving good results and reducing bearings Failure, effect of reducing radial load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

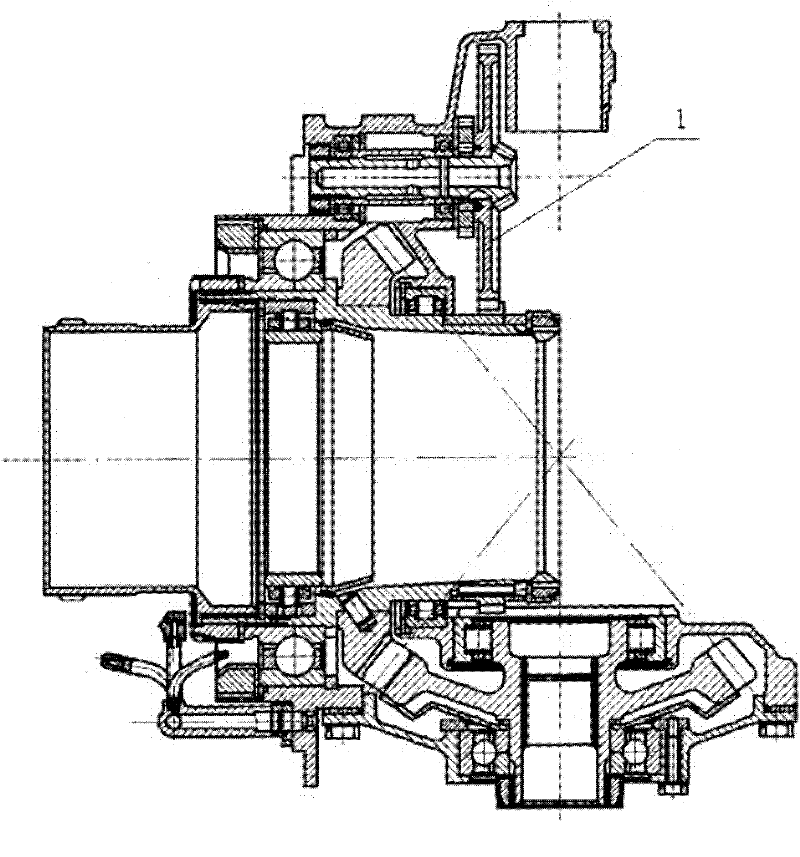

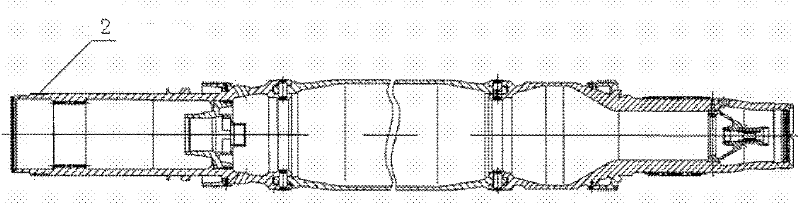

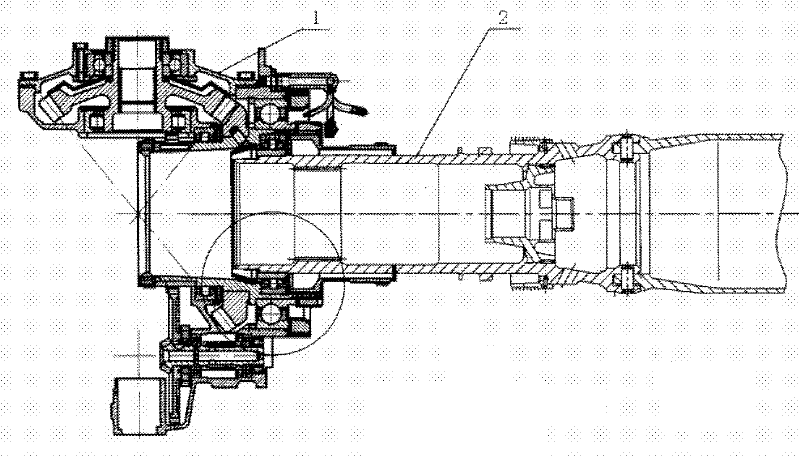

[0033] A method for assembling an aero-engine three-point bearing, comprising the steps of:

[0034] Step 1: Put the central bevel gear into the heating furnace and heat it to 150 degrees;

[0035] Step 2: Use special tooling and presses to assemble the bearing outer ring into the central bevel gear, ensuring that the matching requirements are -0.022mm ~ +0.014mm;

[0036] Step 3: Install the spring ring on the central bevel gear with pliers to fix the bearing, and install the bearing with the marked surface facing the spring ring;

[0037] Step 4: After cooling the bearing to the temperature of the surrounding medium, use a digital universal length measuring instrument to measure the maximum and minimum diameters of the bearing outer ring raceway installed in the central bevel gear, and measure them on 4 planes of the bearing outer ring raceway Diameter, find the average value of 4 diameters;

[0038] Step 5: Install the bearing cage and bearing rolling rod into the inner r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com