Patents

Literature

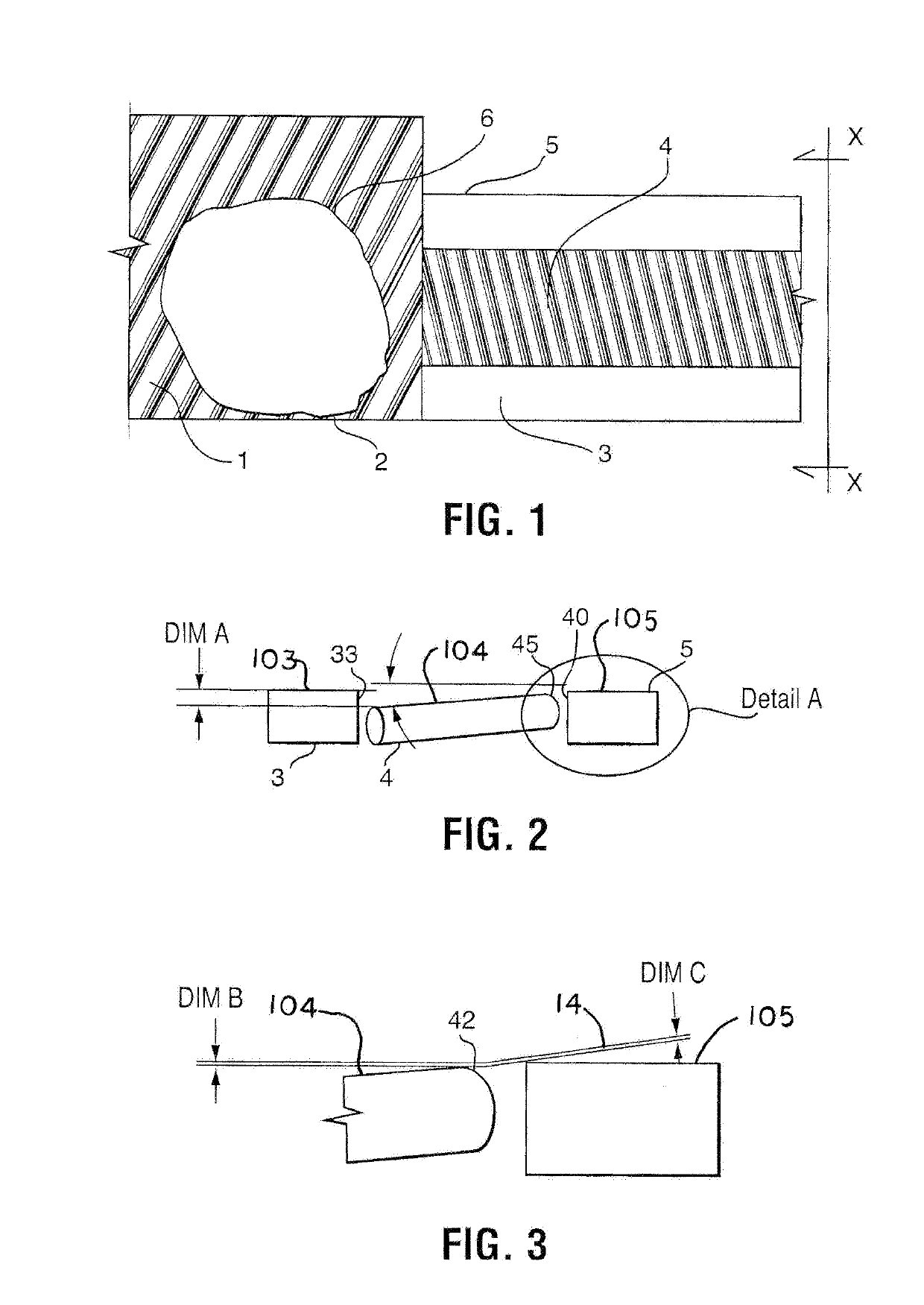

104results about How to "Reduce friction surface" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

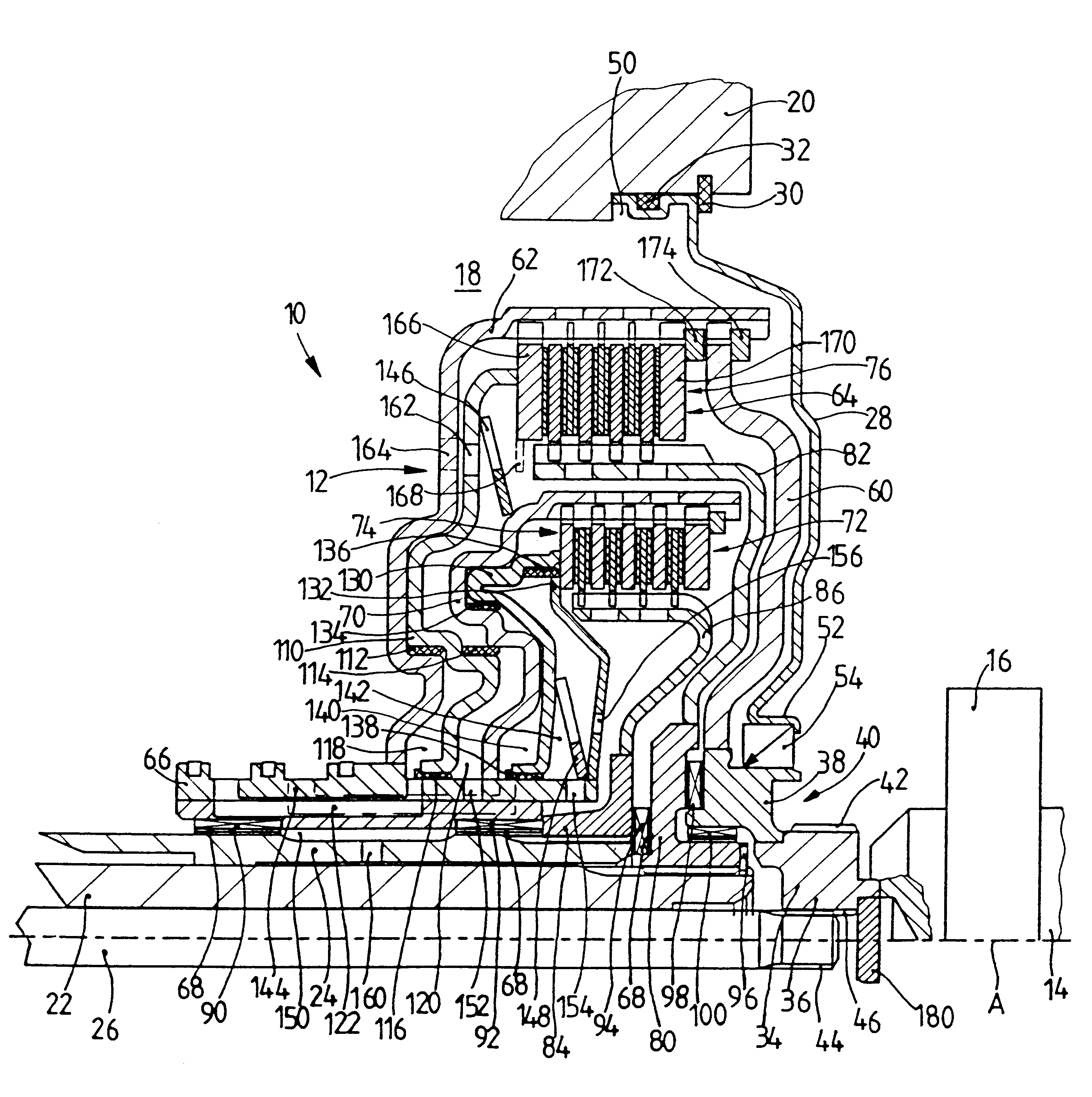

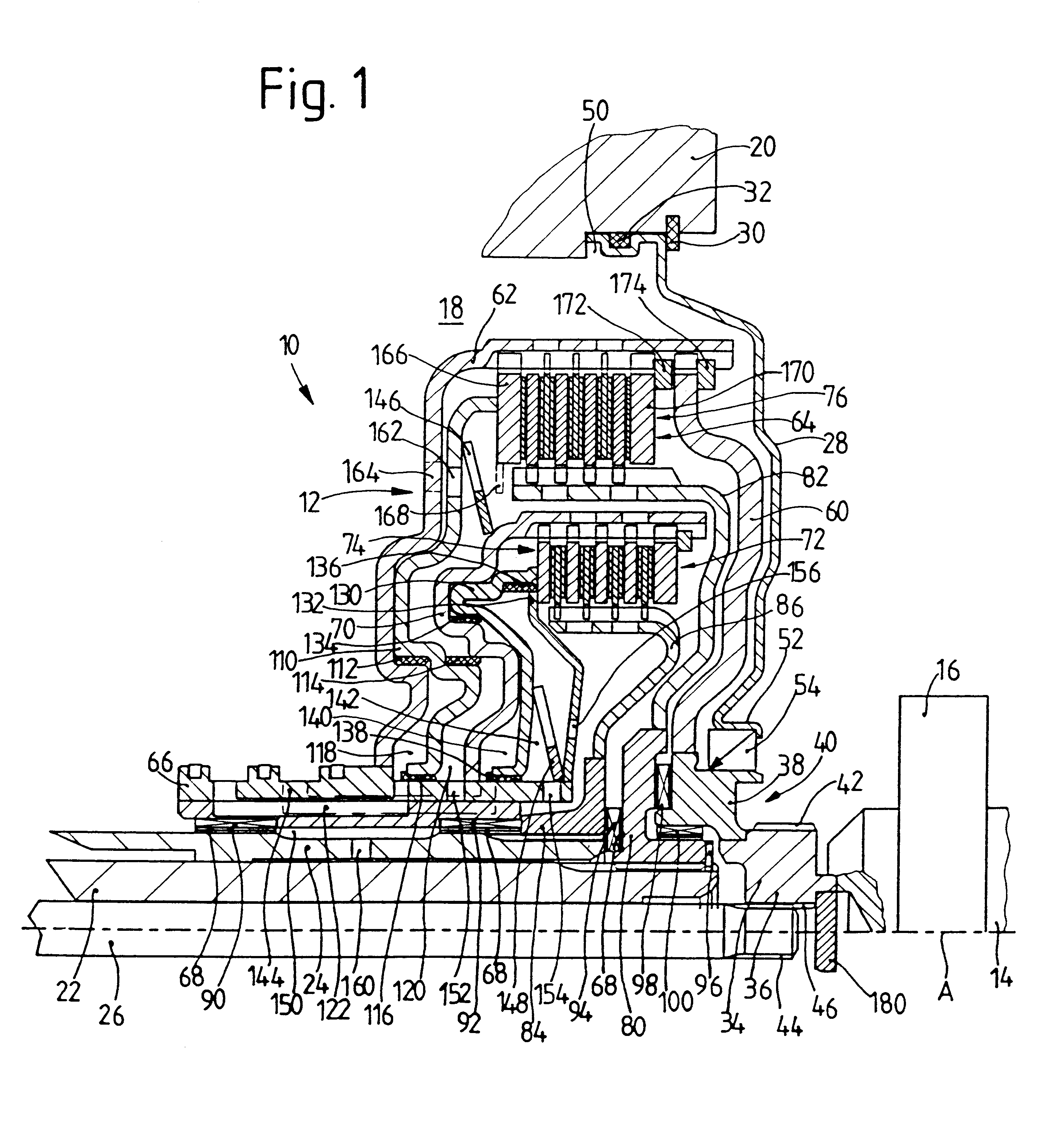

Multiple-clutch device

InactiveUS6523657B1Large massLarge heat capacityRoad transportFluid actuated clutchesMobile vehicleDrivetrain

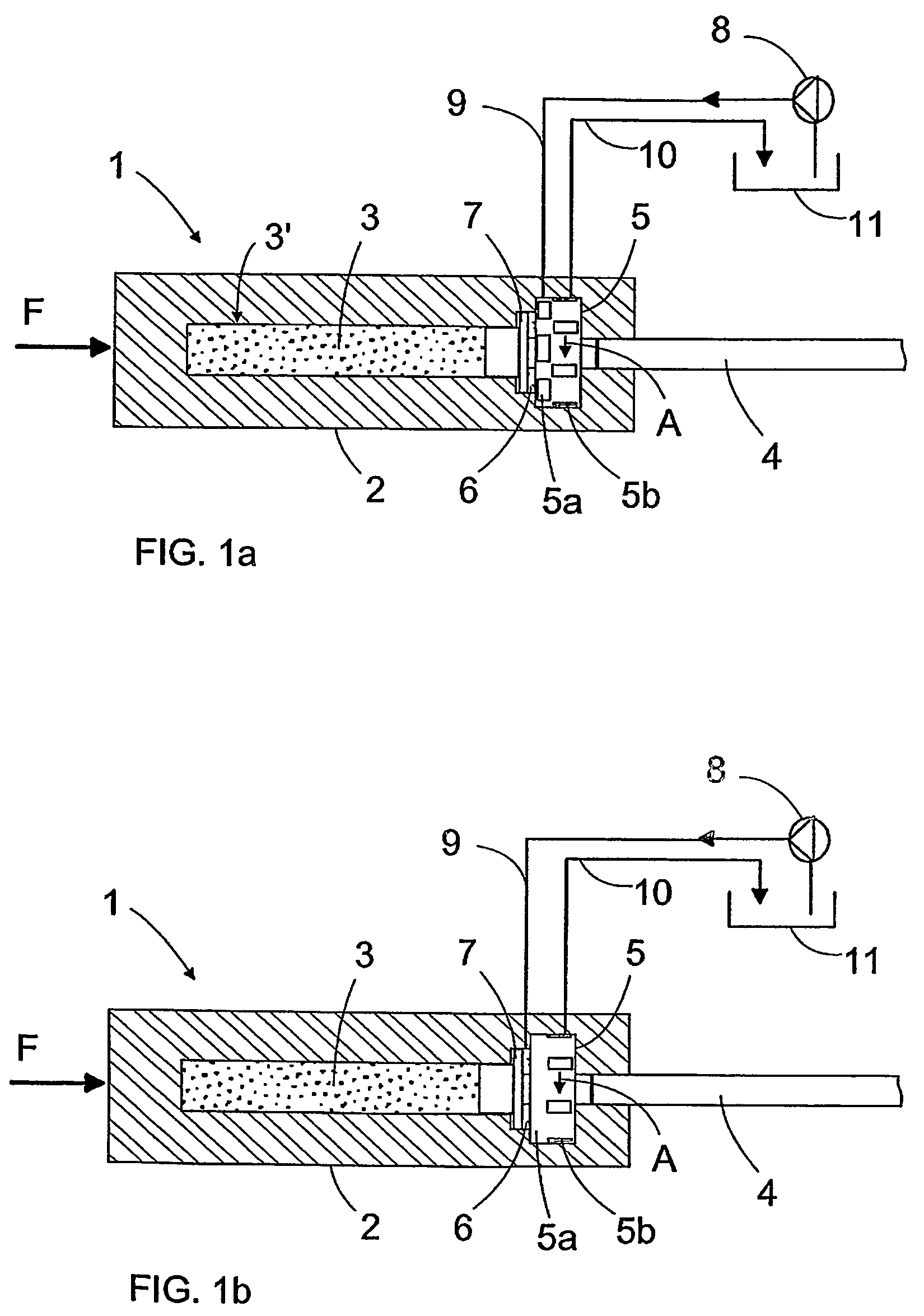

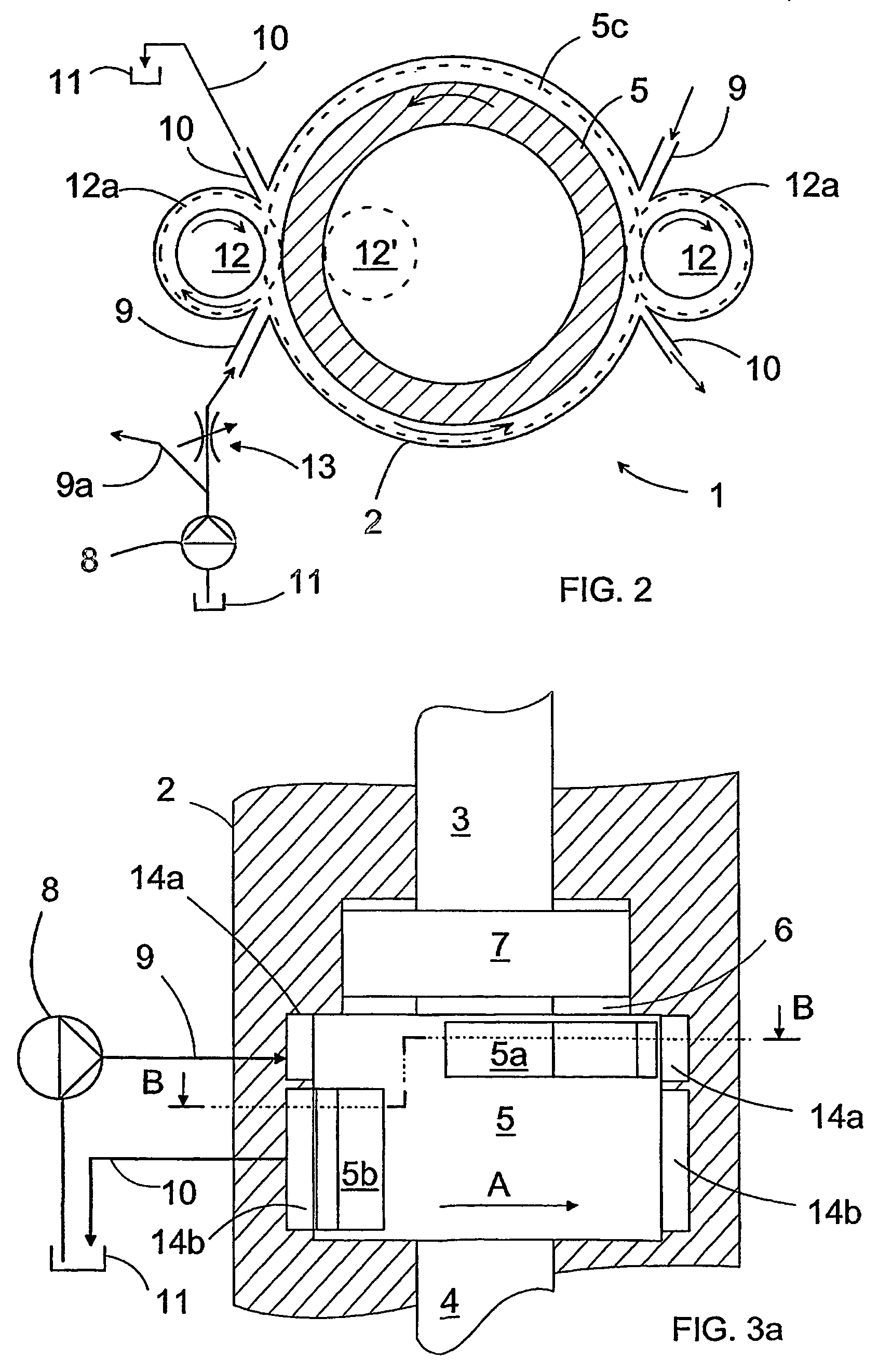

The invention is directed to a multiple-clutch device, such as a double-clutch device, for arranging in a drivetrain of a motor vehicle between a drive unit and a transmission, wherein the clutch device has a first clutch arrangement associated with a first transmission input shaft of the transmission and a second clutch arrangement associated with a second transmission input shaft of the transmission for transmitting torque between the drive unit and the transmission. According to one aspect of the invention, it is suggested that plates in a plate stack of a clutch arrangement constructed as a plate clutch arrangement which have at least one friction facing can be brought into frictional engagement with plates having no friction facing, wherein at least one of the plates not having a friction facing is thicker in axial direction than friction facing carrying elements of adjacent plates having at least one friction facing. Alternatively or in addition, it is suggested that at least one plate which has at least one friction facing of sintered material and at least one plate which has at least one friction facing made of another friction facing material are provided in the plate stack, wherein the other friction facing material has a progressive frictional coefficient curve (dlambd / dDELTAN) in relation to a slip speed (DELTAN).

Owner:ZF FRIEDRICHSHAFEN AG +1

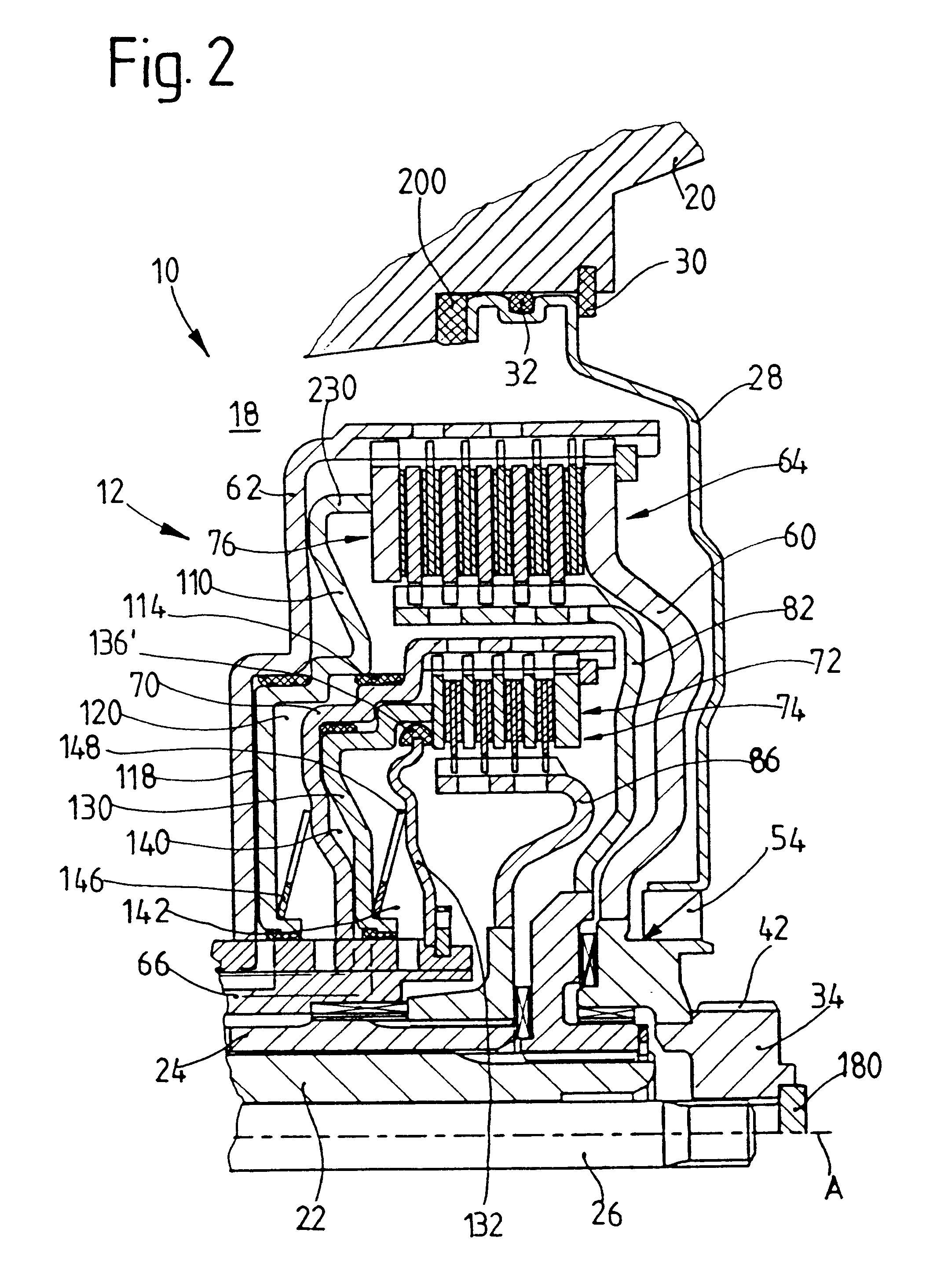

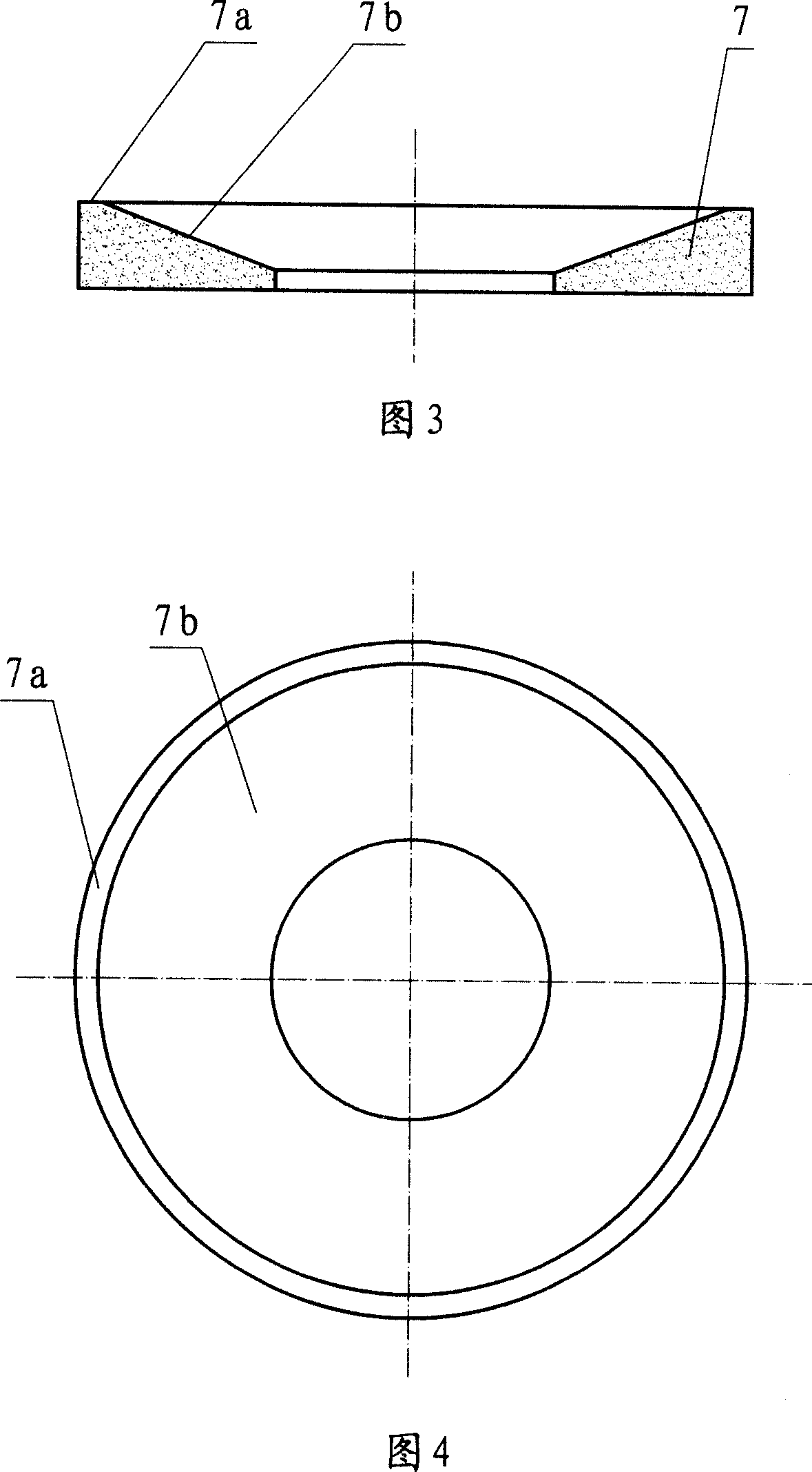

Micro regulating buckwheat sheller

ActiveCN1986062AAchieve fine-tuningHigh precisionGrain huskingGrain polishingPolygonum fagopyrumEngineering

The trimmed buckwheat sheller includes one outer barrel serving as the casing, one inner bushing, one bearing seat with one rotating shaft, one movable wheel on the shaft, one upper cover, one fixed wheel fitting the movable wheel. It features the upper cover comprising one inner ring and one outer ring connected through threads for easy interval regulating and trimming. The present invention has the advantages of high regulating precision, simple and fast regulation, high production efficiency and capacity of processing buckwheat in different plumpness.

Owner:JINZHOU QIAOPAI MACHINERIES

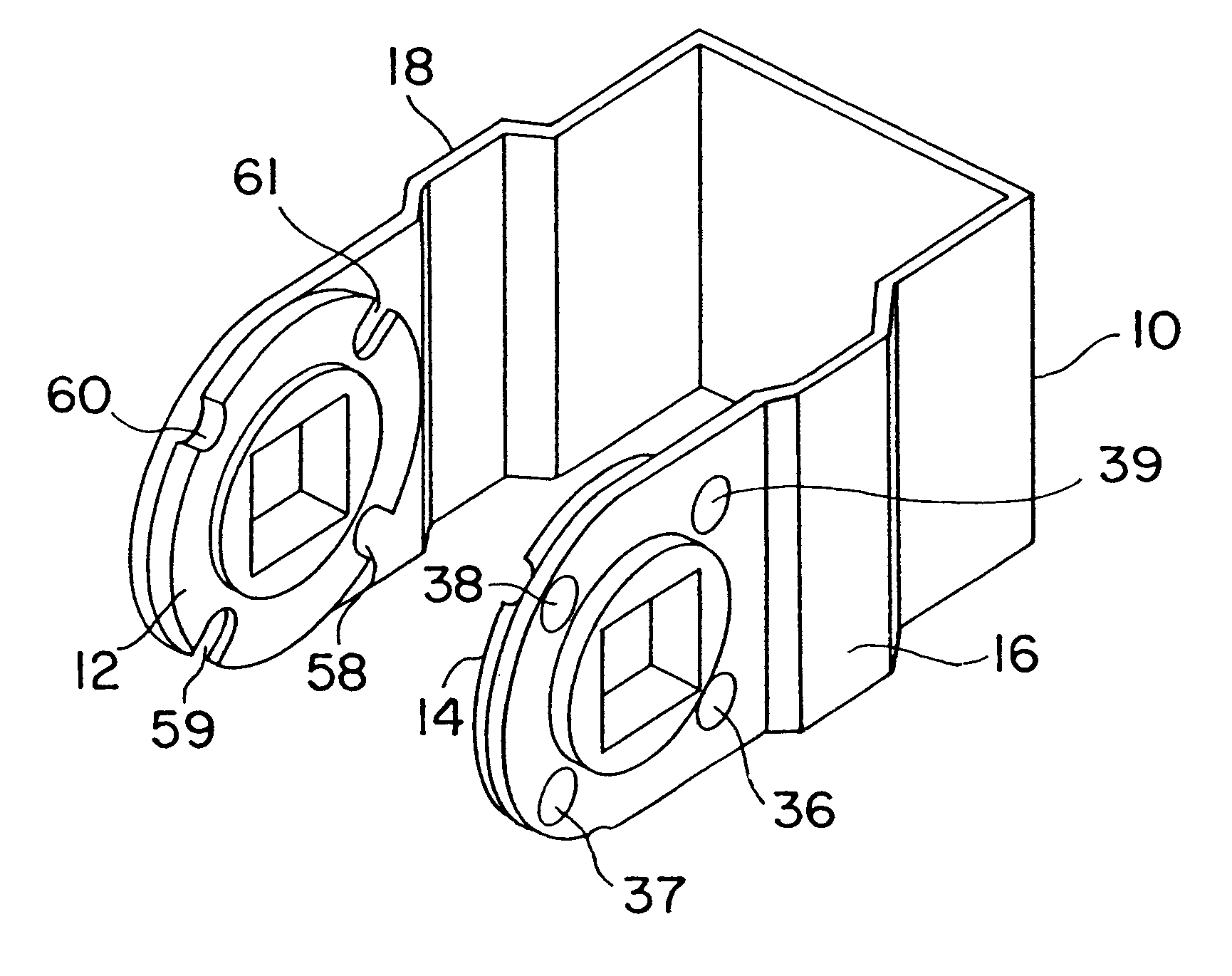

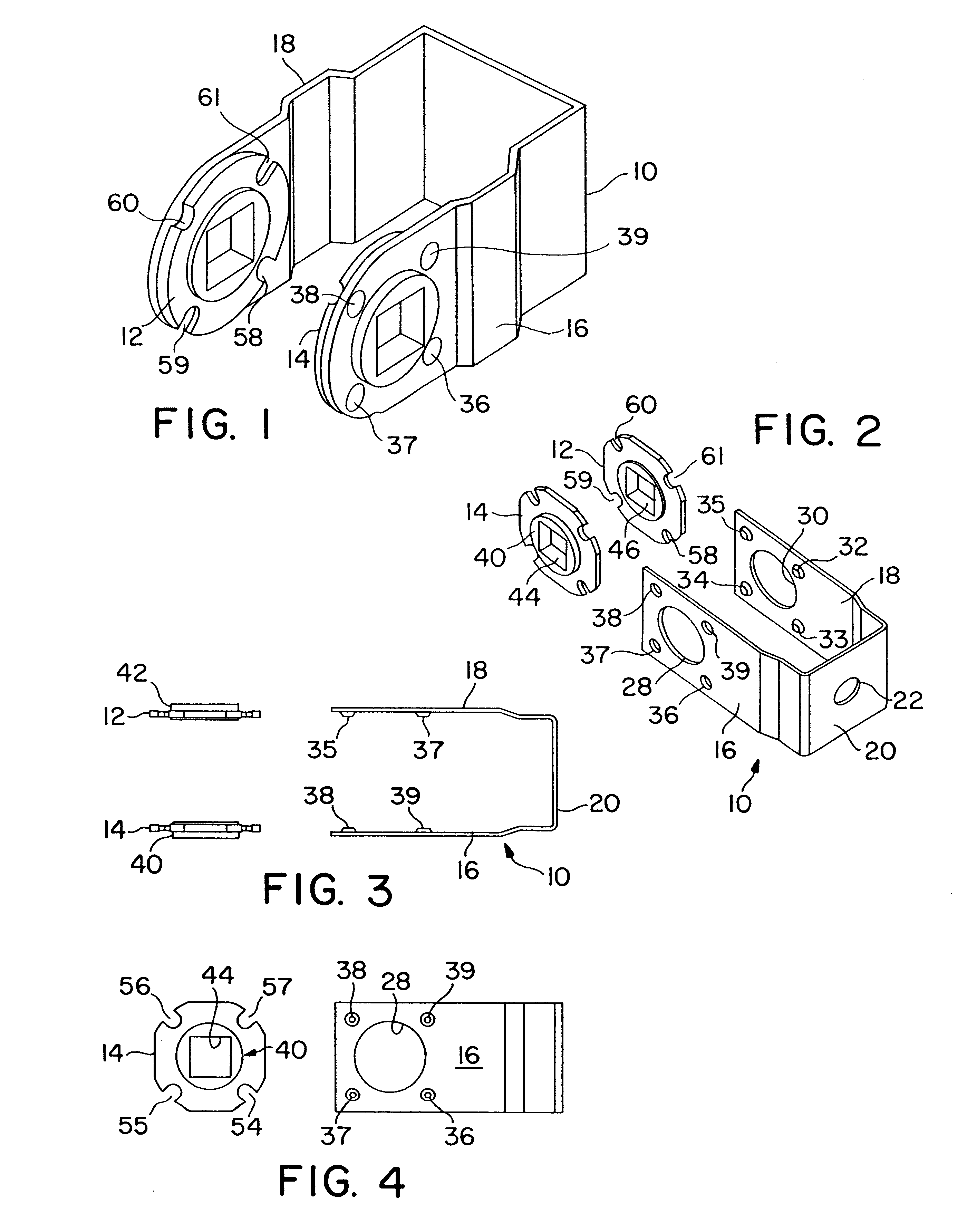

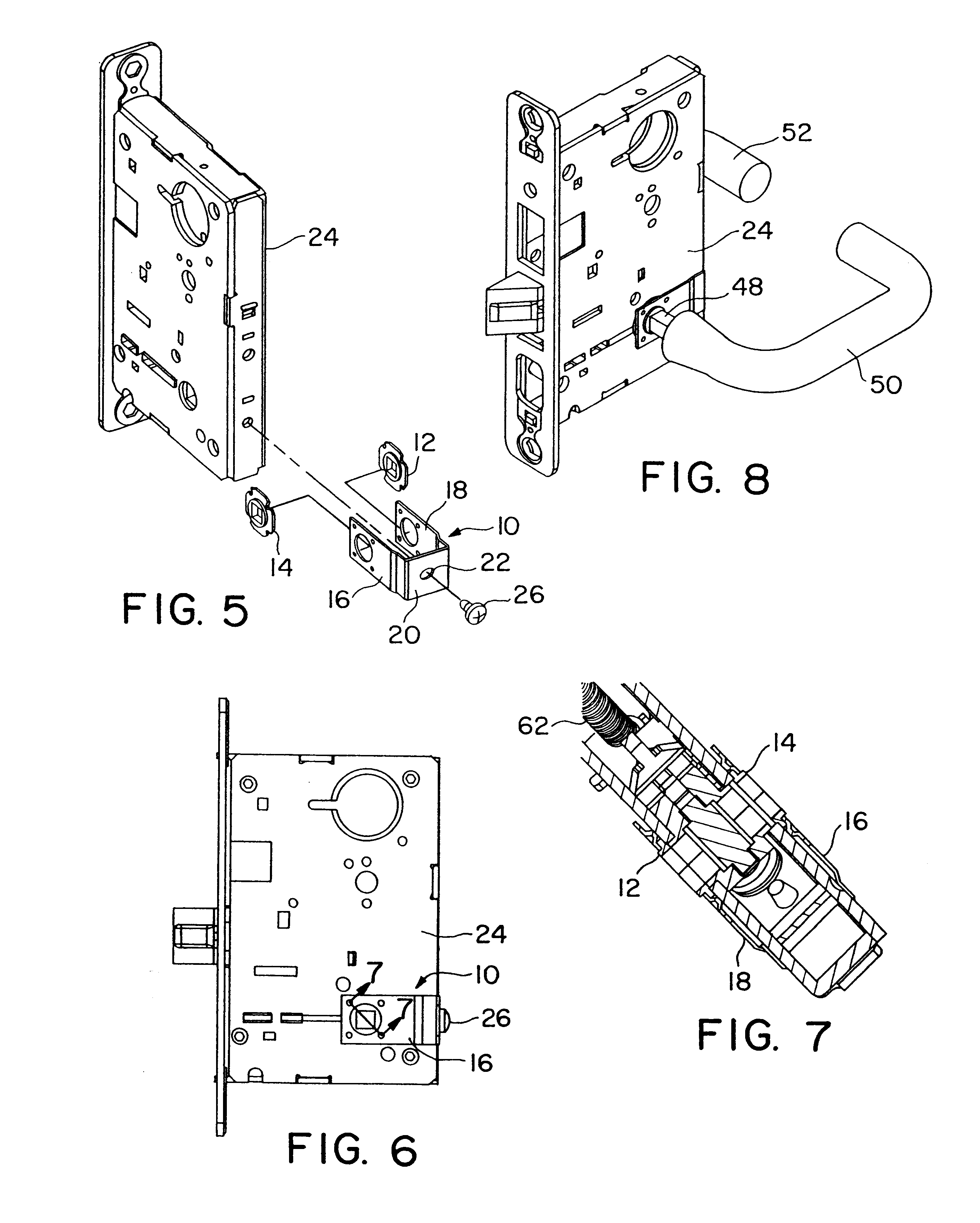

Lever handle support mechanism

InactiveUS6669249B1Reduce manufacturing costHigh densityWing handlesNon-mechanical controlsMonitoring systemEngineering

A handle support mechanism is designed for attachment to a door lock, preferably the exterior of a mortise lock, that has two handles driven back to an initial position with a common return spring after either handle is used. The support mechanism prevents the unused handle from drooping or rotating when the common return spring is compressed as the opposite handle is turned. The support mechanism includes first and second friction discs trapped between the exterior of the mortise lock and the legs of a U-shaped spring bracket. The spring bracket applies an inward spring pressure to prevent a friction disc and its corresponding handle from turning when the other handle is in use. The handle support mechanism improves visual appearance and is particularly suitable for retrofit installations, lever handle designs and mortise locks with independent switch sensors on the two handles that notify a monitoring system as to which handle was turned to open a monitored door.

Owner:SARGENT MANUFACTURING CO INC

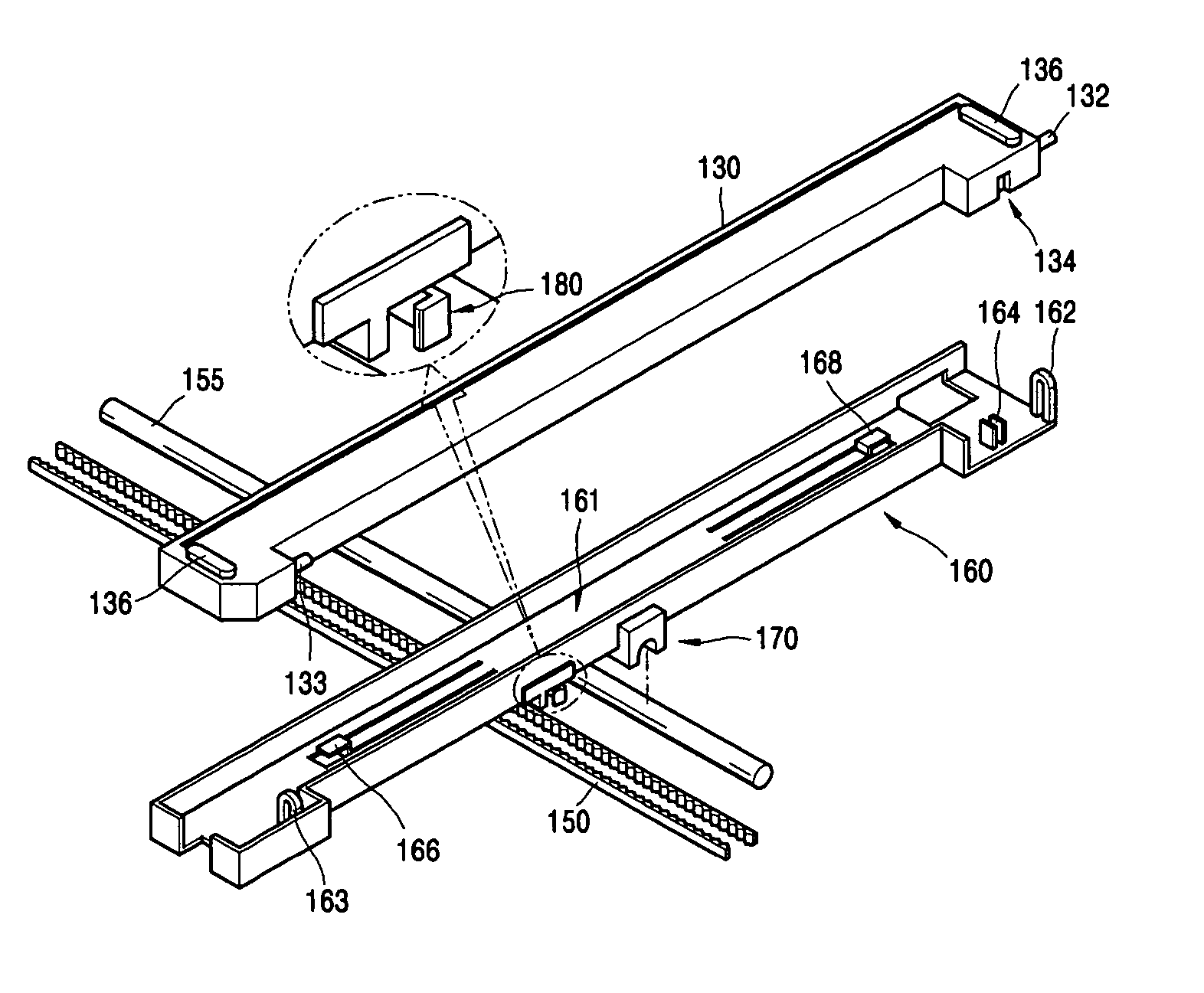

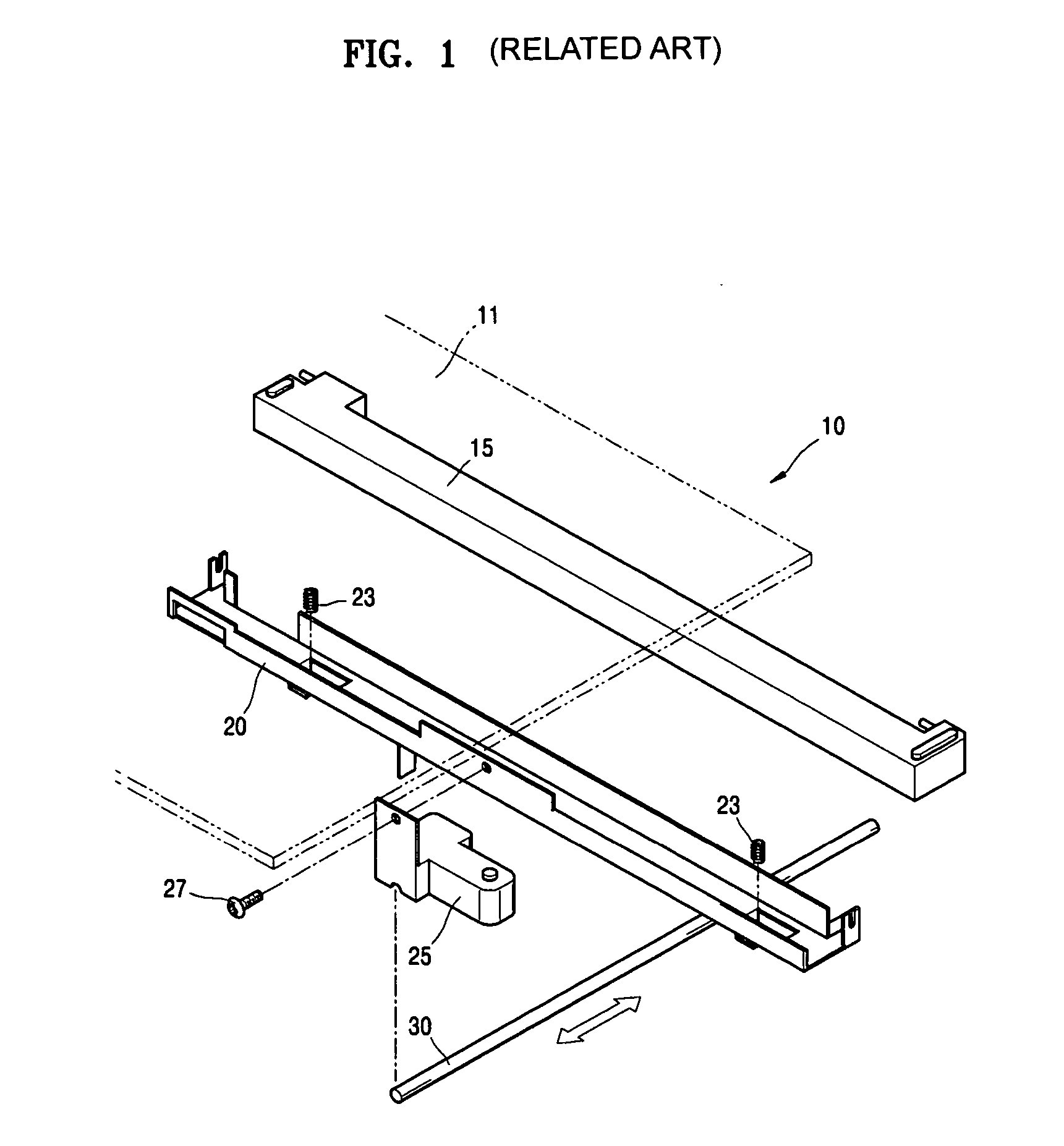

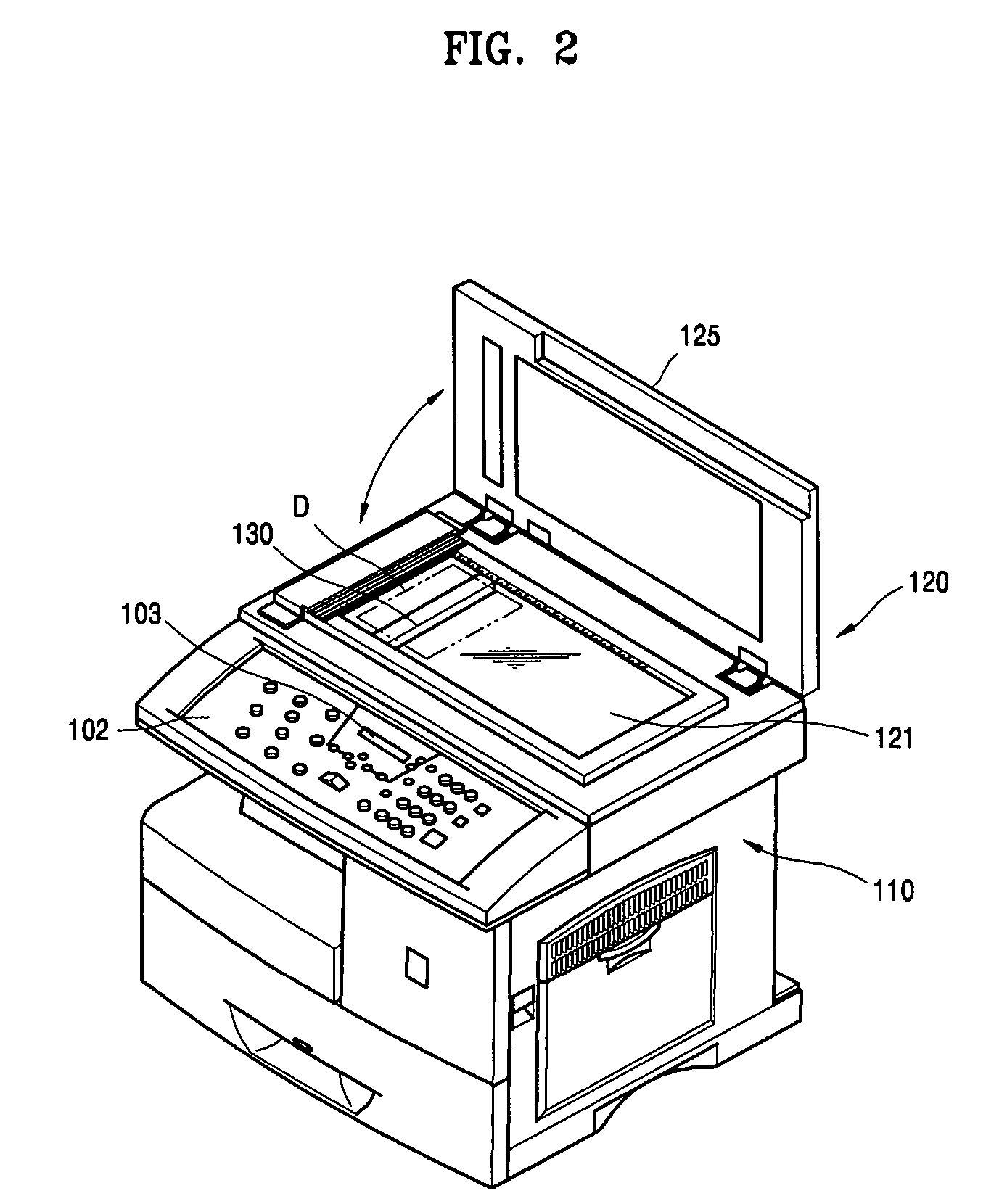

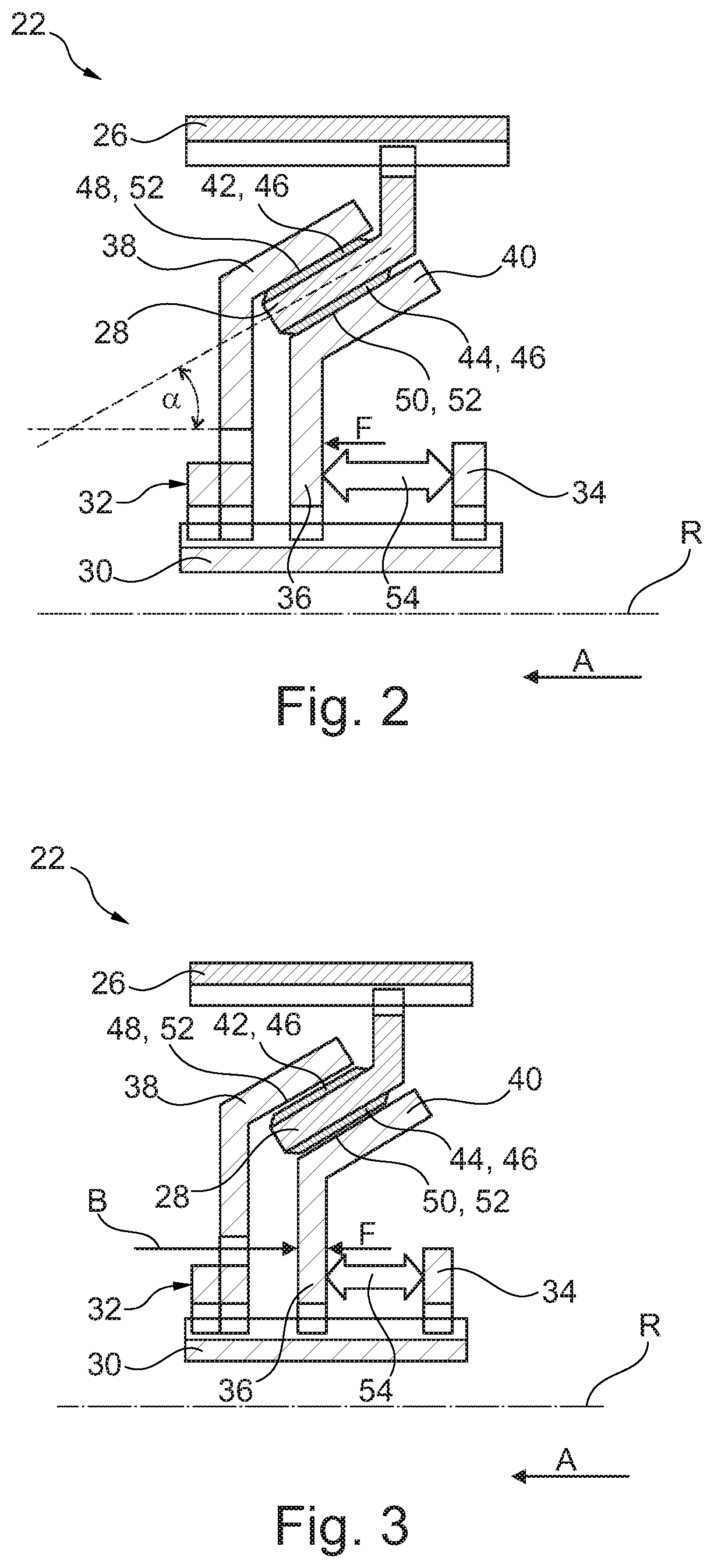

Image scanning unit and image forming apparatus having the same

ActiveUS20060203300A1Reduce decreaseReduce friction surfacePictoral communicationImage formationImage sensor

An image scanning unit an image forming apparatus having the same to scan an image recorded on a document. The image scanning unit includes: a transparent window on which a document to be scanned is laid; an image sensor running straightly under the transparent window for capturing an image recorded on the document, a unit for driving the image sensor; a guide shaft for guiding the straight movement of the image sensor; and an image sensor carrier connected to the driving unit and the guide shaft for straightly moving the image sensor along the guide shaft when the driving unit operates. The image sensor carrier has an image sensor mounting surface on which the image sensor is mounted, and a guide shaft holder integrally formed with the image sensor mounting surface and mounted on the guide shaft.

Owner:HEWLETT PACKARD DEV CO LP

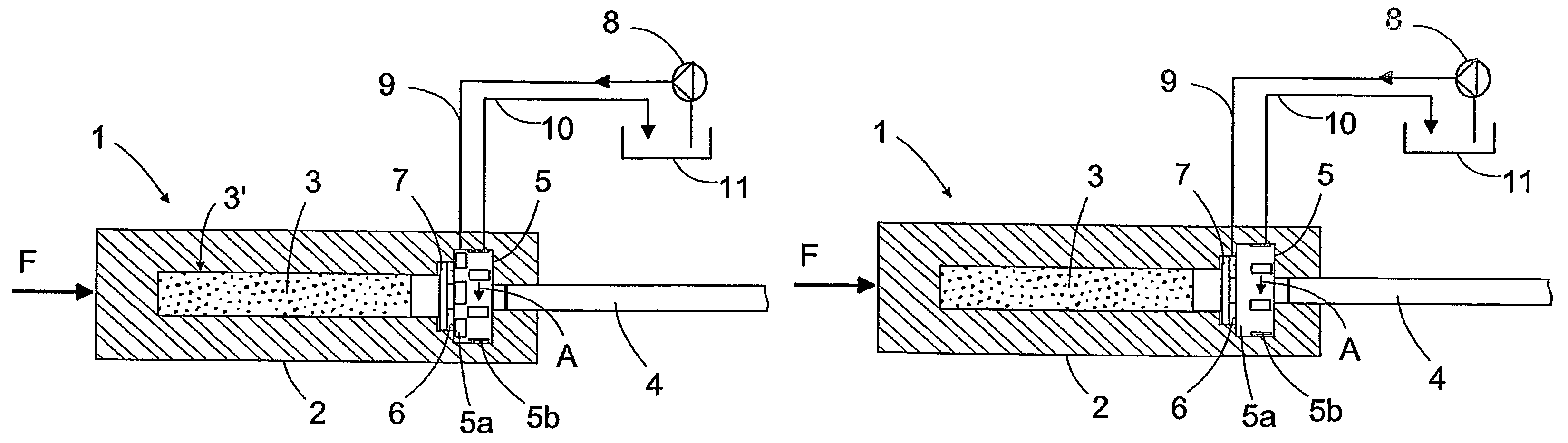

Impact device with a rotable control valve

InactiveUS7290622B2Increase the cross-sectional areaEfficient implementationDrilling rodsConstructionsControl systemControl valves

An impact device includes a frame to which a tool is connectible, and a stress element that is supported on the frame and disposed between the frame and the tool. A hydraulic control system leads pressurized hydraulic fluid into and out of a hydraulic fluid space such that the stress element causes a stress pulse in the tool. The hydraulic control system includes a rotatingly installed control valve that has control openings for intermittently leading the hydraulic fluid out from the hydraulic fluid space.

Owner:SANDVIK MINING & CONSTR OY

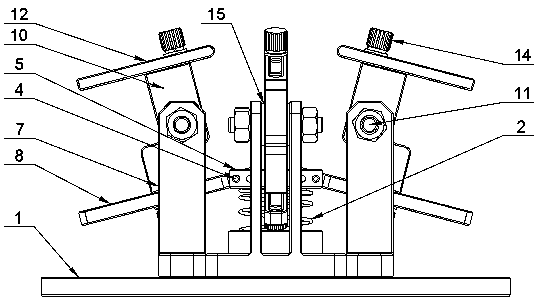

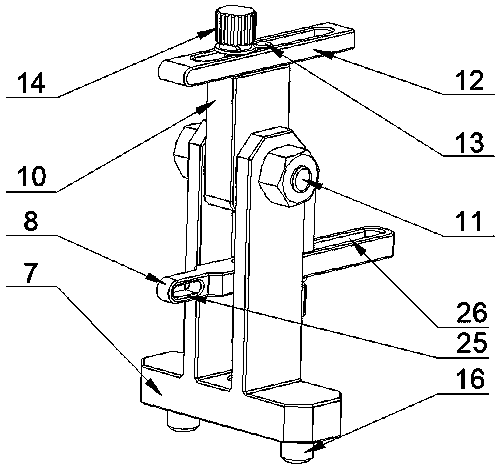

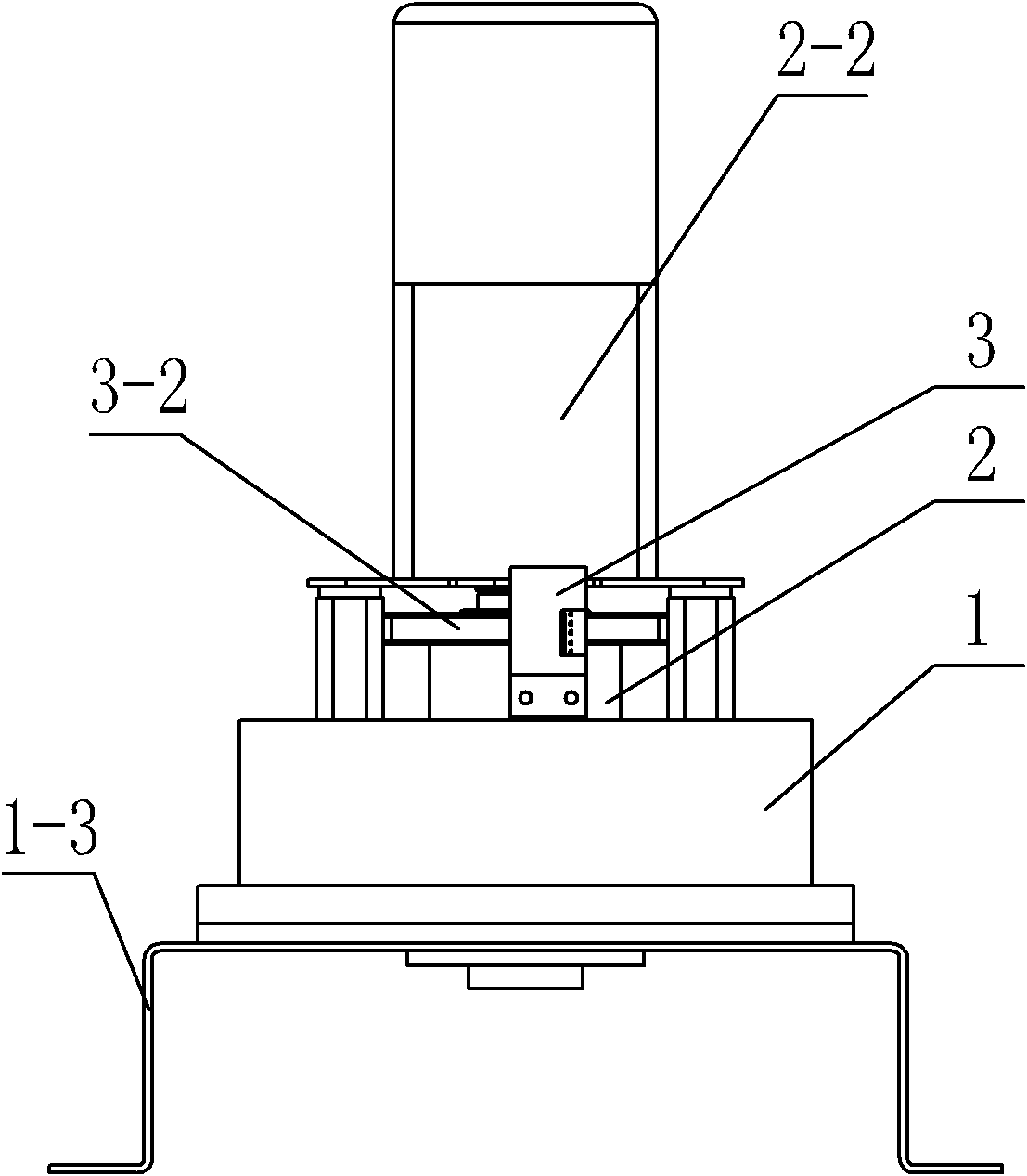

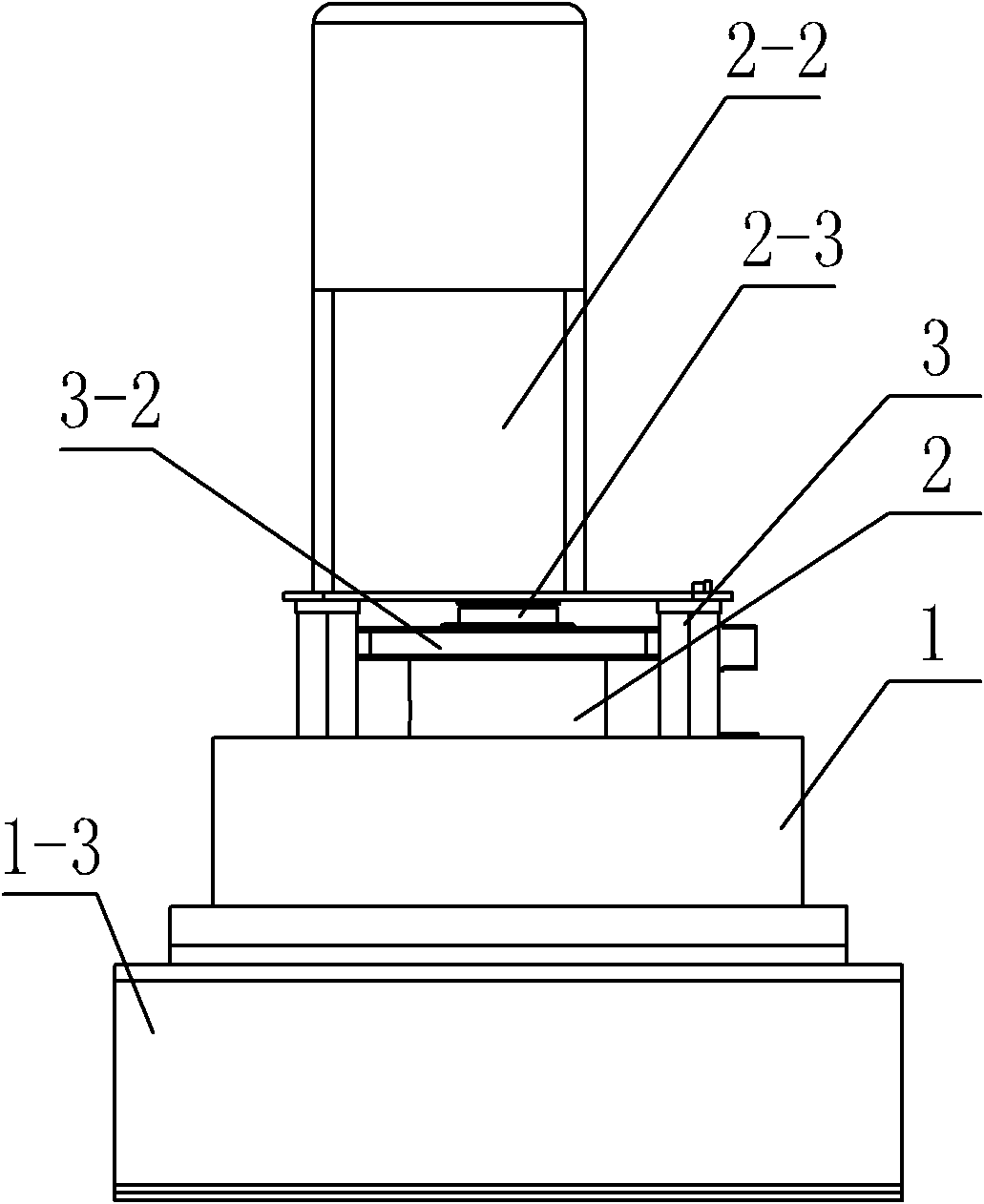

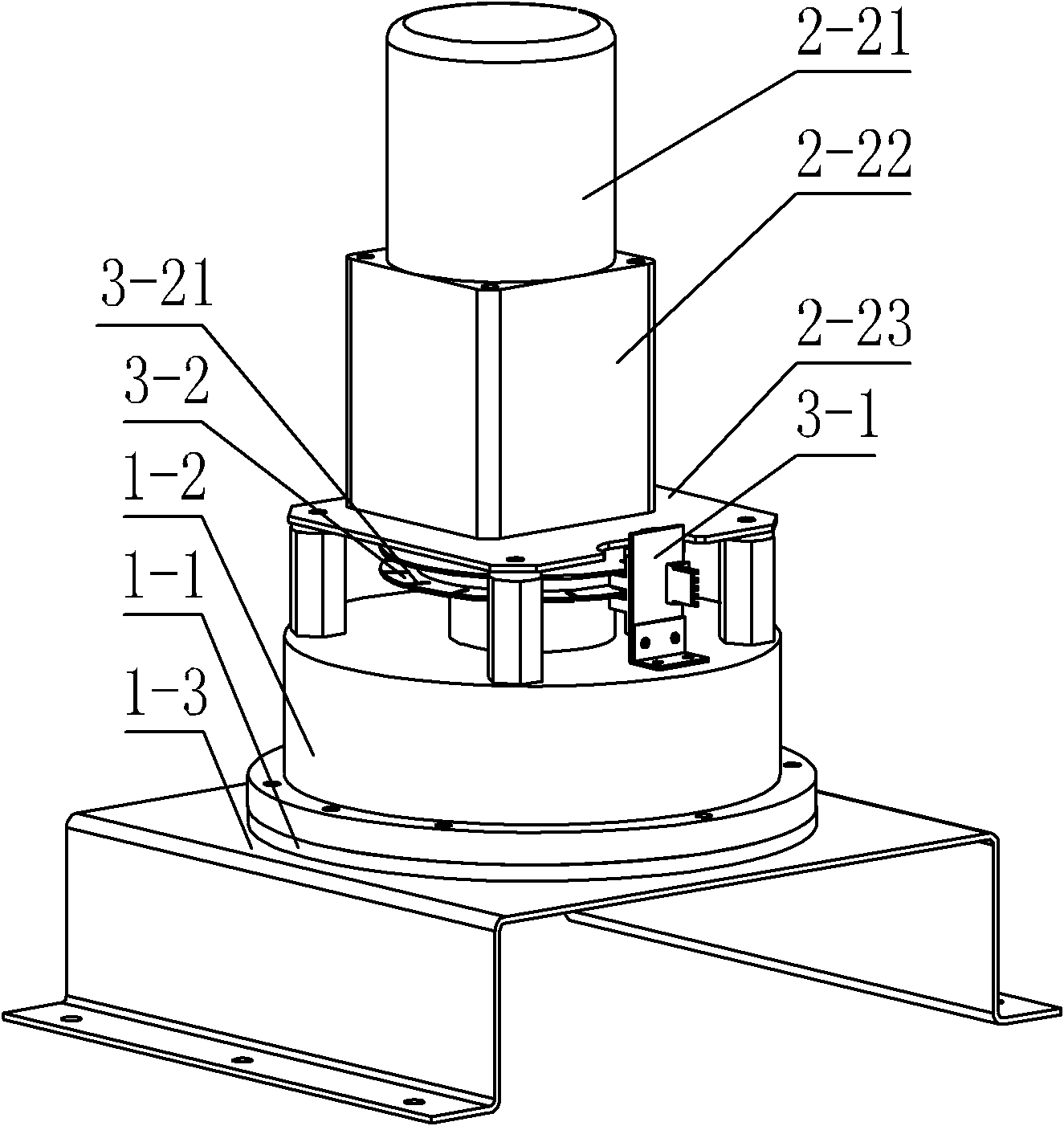

Gravity self-centering self-locking clamp

PendingCN110014315AImplementation intoEasy to grabPositioning apparatusMetal-working holdersModular designSelf locking

The invention discloses a gravity self-centering self-locking clamp. The gravity self-centering self-locking clamp is composed of a chassis, a bearing structure and two or more clamping units. Each clamping unit is composed of a clamping rod, a lifting rod, a clamping arm and a stand column. The stand columns and chassis are fixed. The clamping arms are fixed on the stand columns and can rotate along the stand columns. The clamping rods are fixed at the top ends of the clamping arms. The lifting rods are fixed at the bottom ends of the clamping arms. The bearing structure is composed of a spring and a carrier plate. The spring makes contact with the chassis. The carrier plate is fixedly connected with the lifting rod. The modular design is adopted, gravity and elastic force are combined through the lever principle, products are automatically clamped when being placed in the clamp and automatically loosened when being taken out from the clamp, and the clamp has the automatic centering effect and the self-locking effect.

Owner:徐旭东

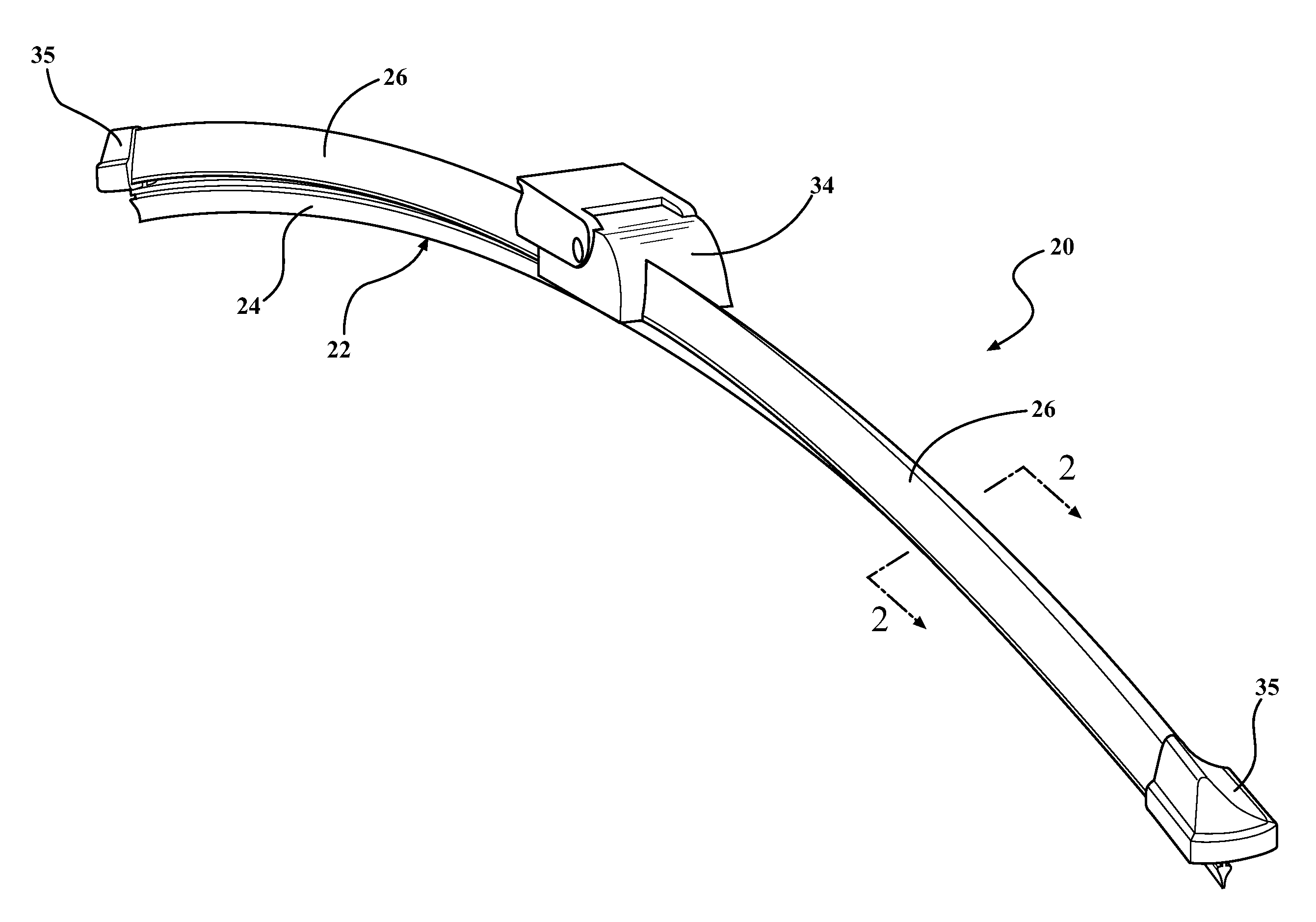

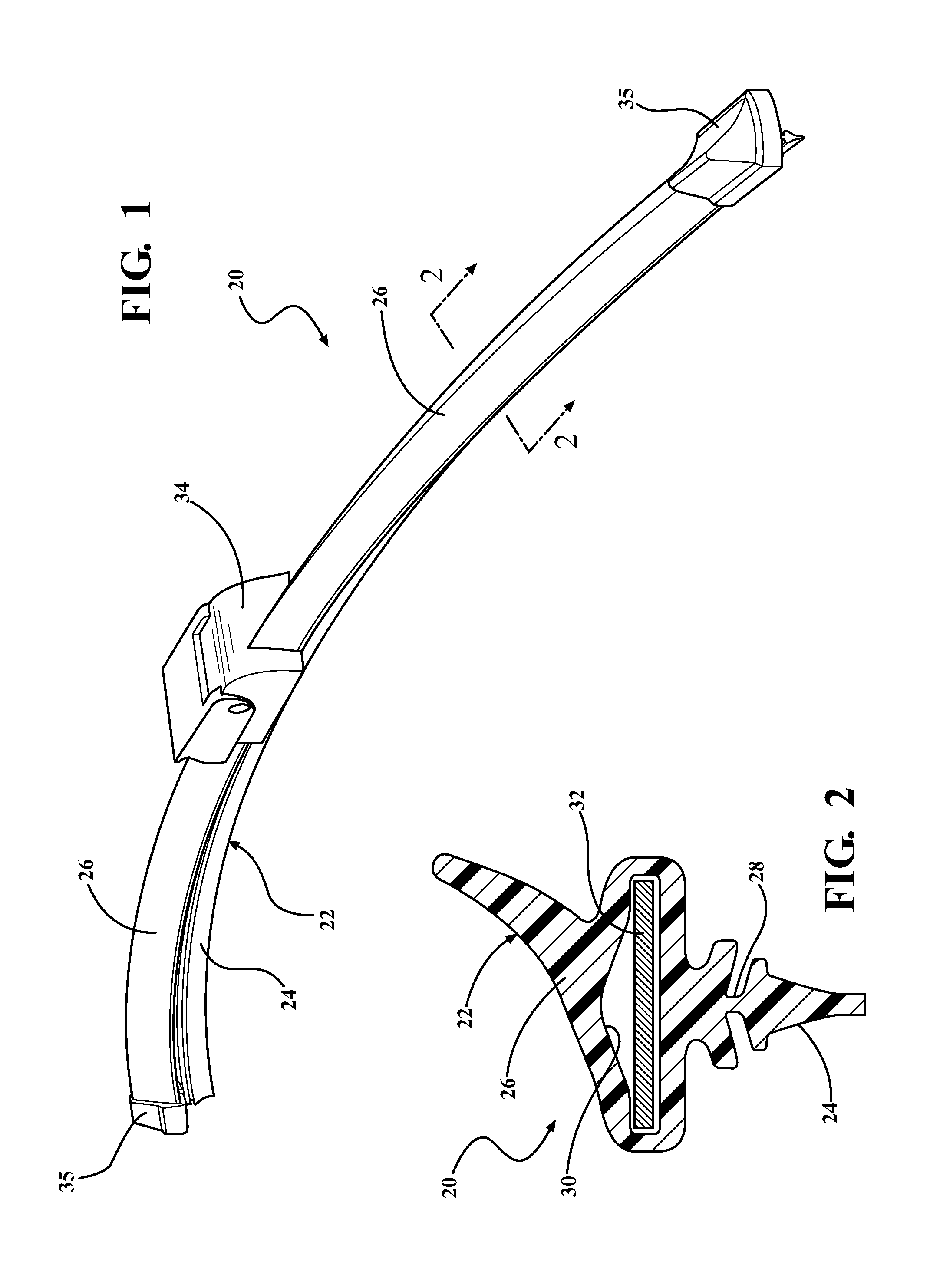

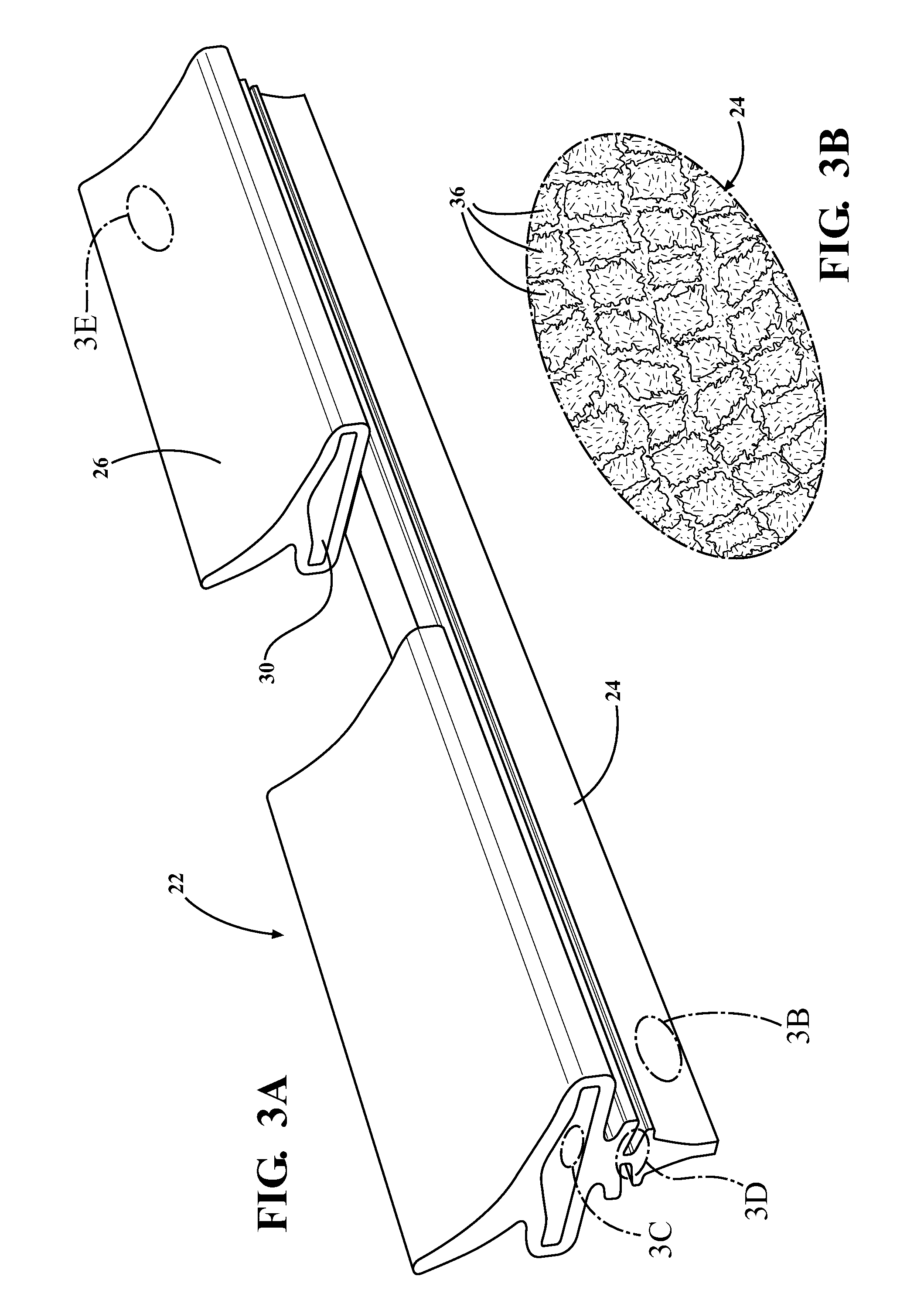

Windscreen wiper device

ActiveUS20130125332A1Improve performanceImprove the immunityCeramic shaping apparatusWindow cleanersWindshieldWindscreen wiper

A windscreen wiper device is provided including a longitudinally extending wiper strip of a flexible material. At least one carrier of a spring-like material operatively supports and biases the wiper strip into a predetermined configuration. The windscreen wiper device further includes a connecting device for connection with a wiper arm. At least a portion of the wiper strip has a microtextured surface formed directly into the flexible material. The microtextured surface may be on, for example, any one of or any combination of a wiping portion, a channel, a hinge portion and a spoiler portion of the wiper strip.

Owner:TRICO PROD CORP

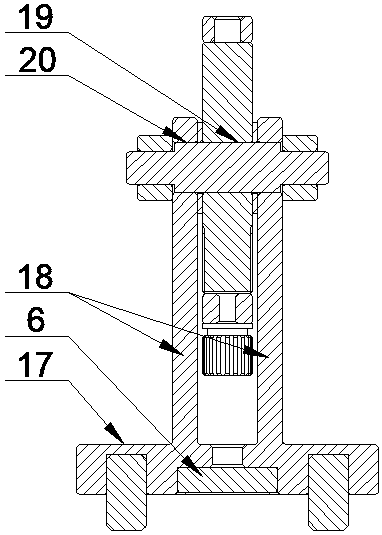

Liquid distribution valve for tissue dehydrator

InactiveCN102135192AReduce volumeLow driving powerOperating means/releasing devices for valvesMultiple way valvesMechanical engineeringEngineering

The invention relates to a liquid distribution valve for a tissue dehydrator. The liquid distribution valve comprises a valve shell, and a distribution valve plug which can be rotated in the valve shell; a plurality of liquid inlet holes are uniformly distributed on the valve shell along the circumferential direction; the distribution valve plug is provided with a liquid communication hole which can be communicated with the liquid inlet holes through rotation and an optoelectronic switch control device for controlling the distribution valve plug to rotate; the optoelectronic switch control device comprises an optoelectronic signal receiving unit, a dividing plate and a control device; the diving plate is coaxially arranged on a rotation shaft of the distribution valve plug; open slots of which the number is the same as that of the liquid inlet holes on the valve shell are uniformly distributed on the dividing plate along the circumstantial direction; and the optoelectronic signal receiving unit is arranged at the corresponding position of the open slots of the dividing plate. Accurate control is realized by adopting an optoelectronic switch, the structure of the distribution valve plug is improved, the volume is reduced, the friction surface is reduced, driving power is lower, the liquid distribution valve is rotated more flexibly, and can act in place more reliably, the sealing effect is improved, and the phenomenon of liquid leakage is avoided.

Owner:ZHONGWEI ELECTRONICS INSTR FACTORY ZHANGZHOU CITY

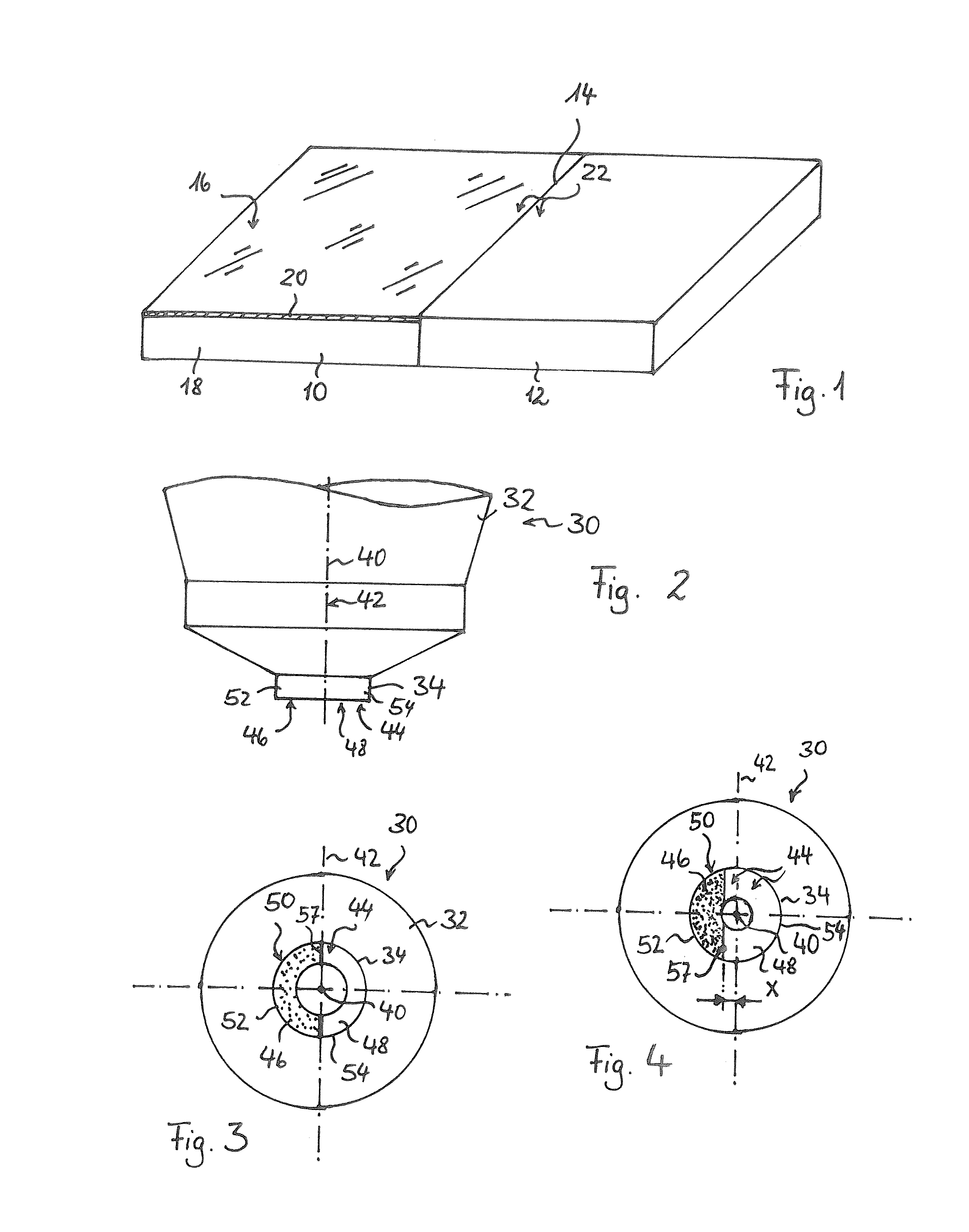

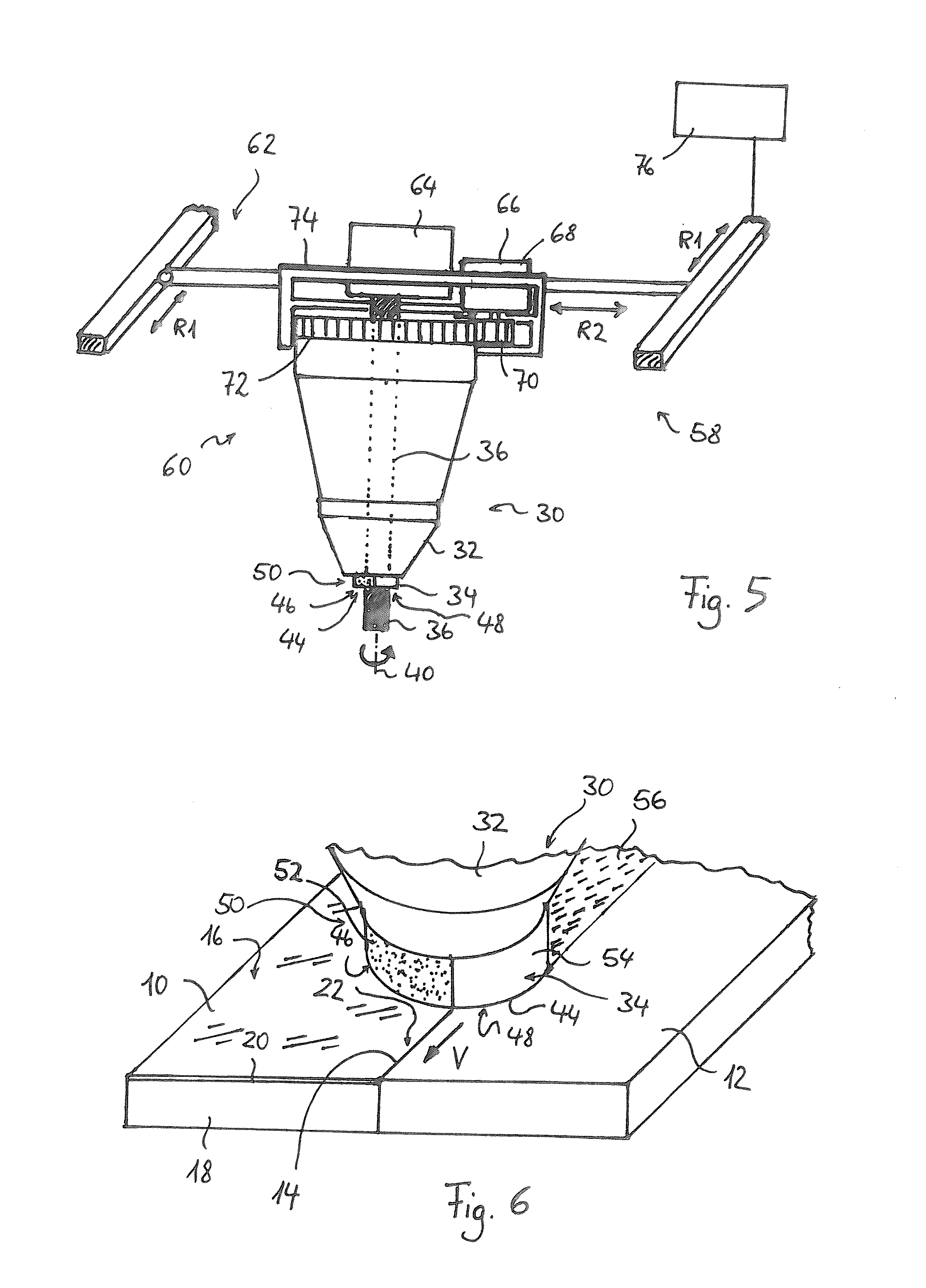

Friction Stir Processing Tool and Friction Stir Processing Method For a Workpiece Having Surface Coating

ActiveUS20140361069A1Reduce frictional resistanceReduce friction surfaceWelding/cutting auxillary devicesAuxillary welding devicesFriction stir processingFriction force

A friction stir processing tool having a shoulder, which is implemented on a body, and which has a friction surface for pressing against at least one workpiece at least partially provided with a surface coating, and a friction reducing unit for reducing the friction resistance between the surface coating and the friction surface.

Owner:EADS DEUT GMBH

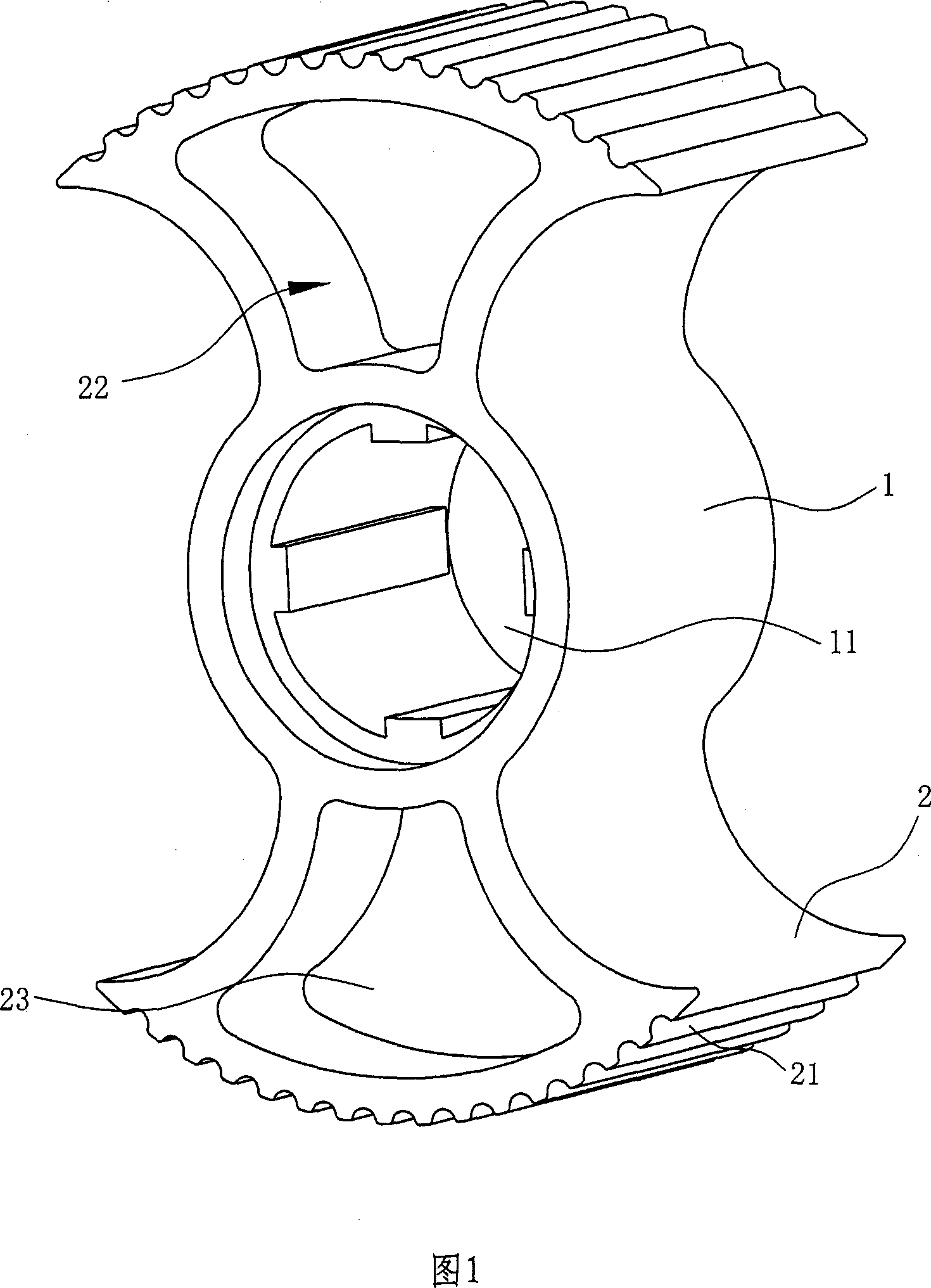

Rotor for rotation type displacement pump

ActiveCN101000052AExtended service lifeSimple structureRotary piston pumpsRotary piston liquid enginesPositive displacement pumpEngineering

The rotor for rotary displacement pump includes one main body with central shaft hole and blades set symmetrically around the shaft hole. The blade has groove parallel to the rotor axis in the end and cavities in the two-side tangent to the rotor axis. In case that t some granular or hard impurity passes through the end of the blade, the impurity can crush into the groove to avoid jamming of and friction to the blade, and this can ensure the fluent conveyance of medium and increase the service life of the rotor pump.

Owner:宁波得利时泵业有限公司

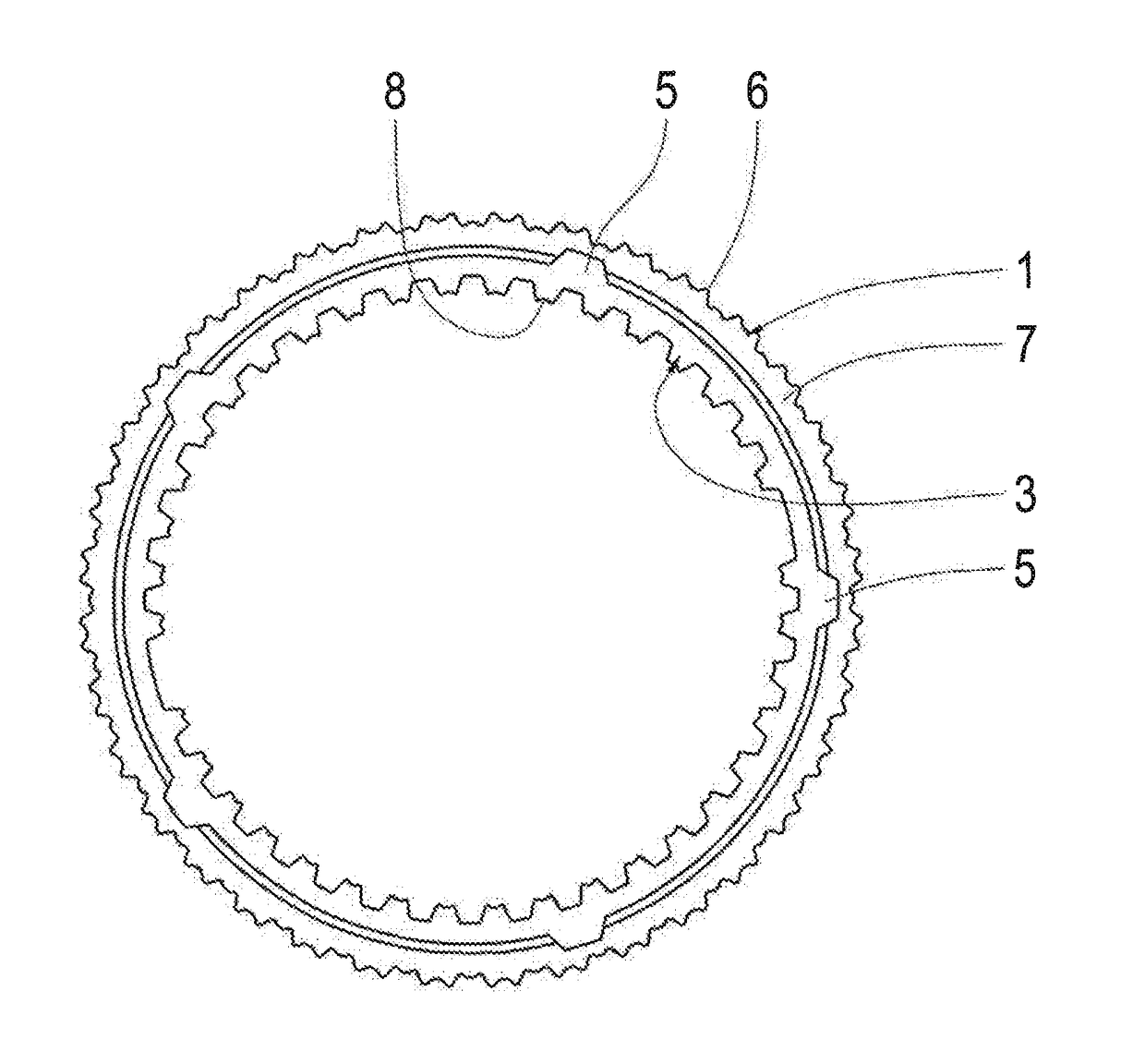

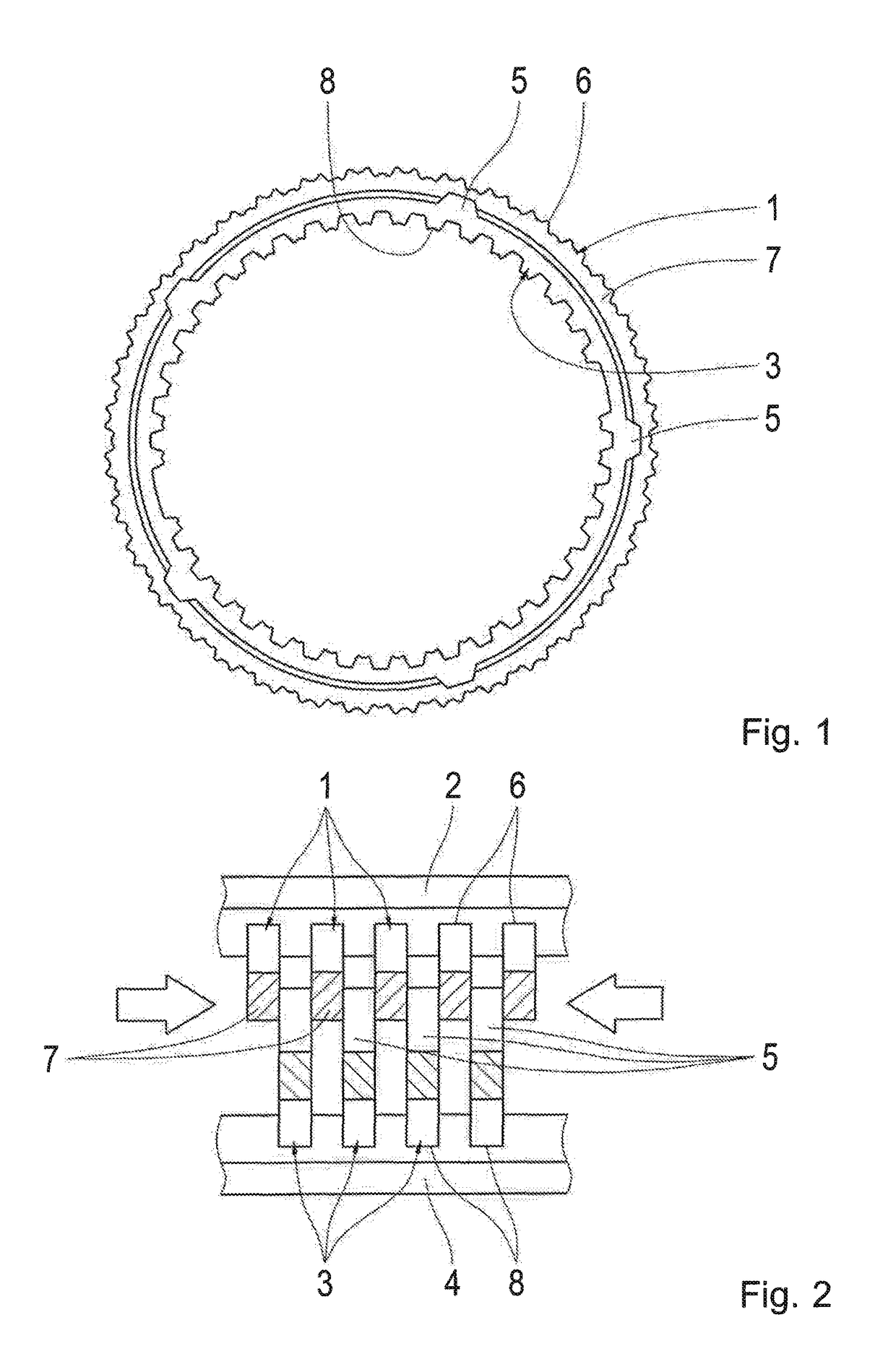

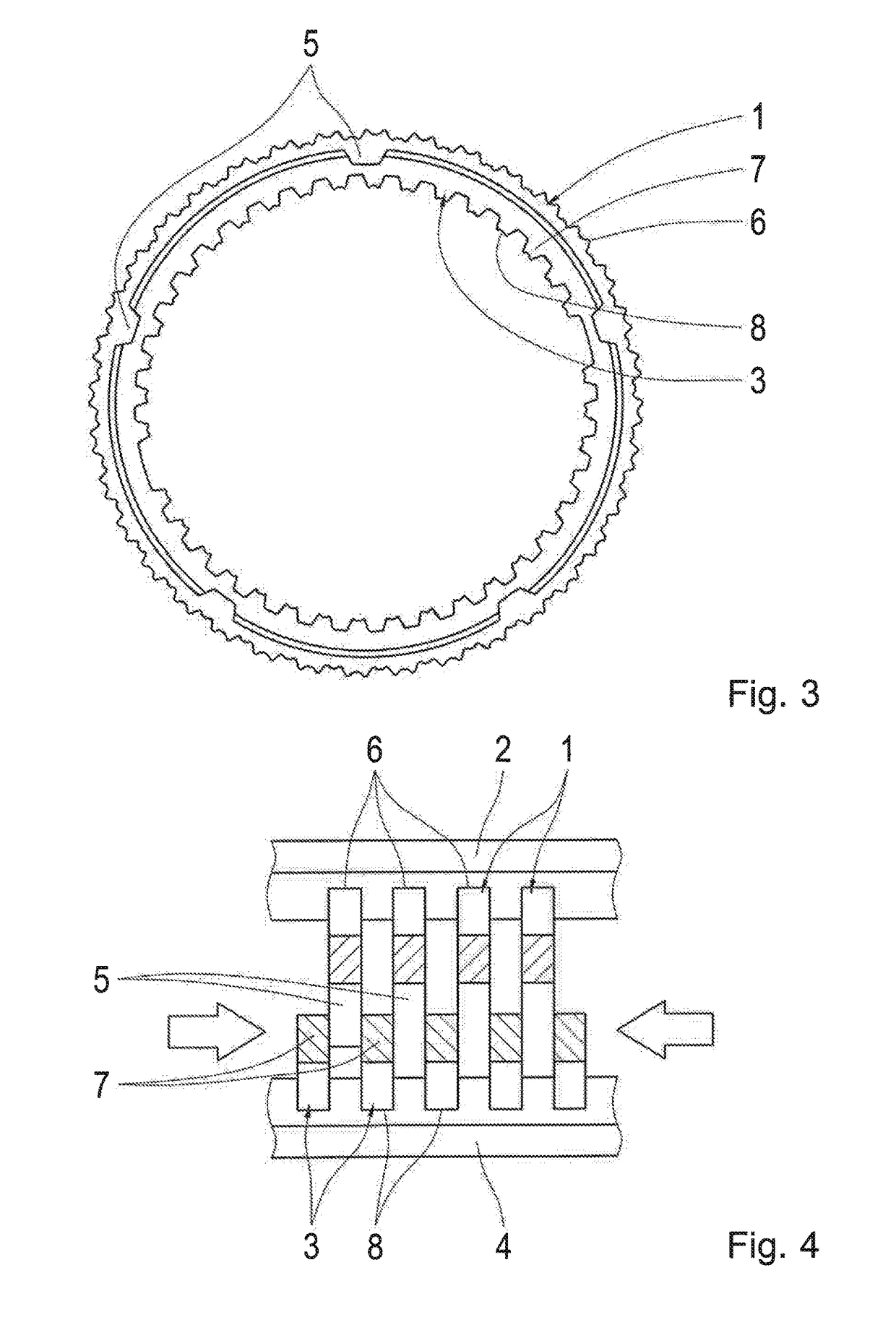

Frictional shifting element for a vehicle transmission

ActiveUS9856922B2Cost-effective manufacturingDrag torques that are as lowFriction clutchesEngineeringMechanical engineering

Owner:ZF FRIEDRICHSHAFEN AG

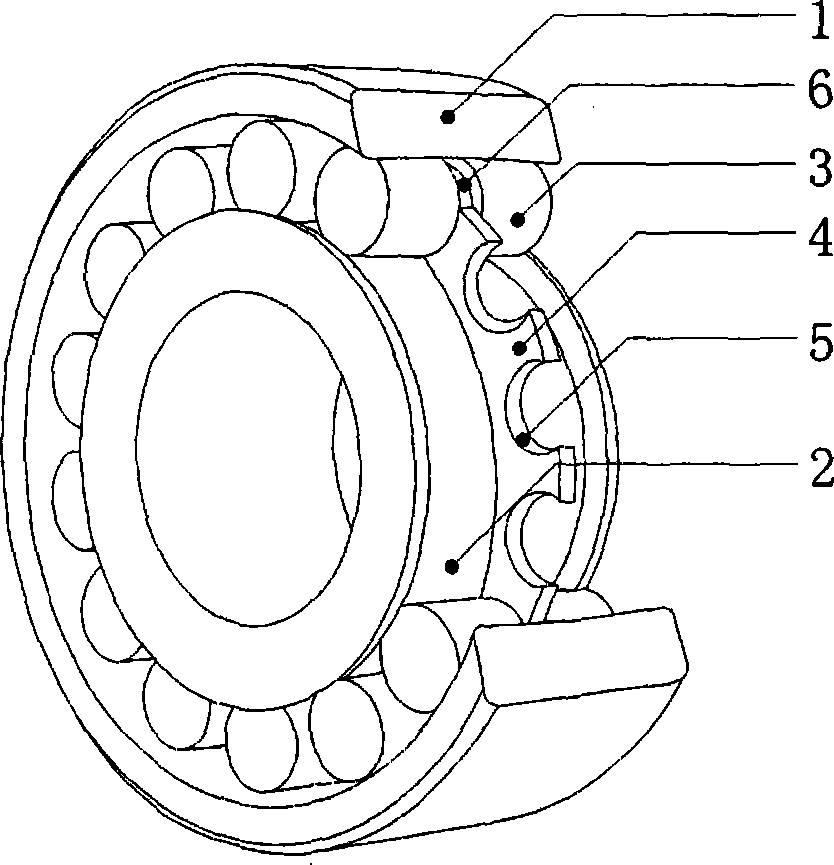

Center-shaft-type cylindrical roller bearing

InactiveCN103807303AIncrease the number ofImprove carrying capacityBearing componentsEngineeringBearing surface

The invention discloses a center-shaft-type cylindrical roller bearing. The center-shaft-type cylindrical roller bearing comprises an inner sleeve ring, an outer sleeve ring, a row of cylindrical waist-diameter sunken center shaft rollers and a rolling circular ring retainer; an excircle roller way of the inner sleeve ring or a roller way of the outer sleeve ring is internally sleeved with a rolling circular ring C-shaped retainer; the center-shaft-type cylindrical roller is embedded in a C opening of the rolling circular ring C-shaped retainer; the center-shaft-type cylindrical roller is fully filled with the C-shaped retainer while the outer sleeve ring is arranged. A bearing surface is increased by increasing the number of the rollers so as to improve the load capacity of the bearing; the noise is reduced by reducing the frictional surfaces of the retainer and the rollers, and the service life of the bearing is prolonged.

Owner:李岚

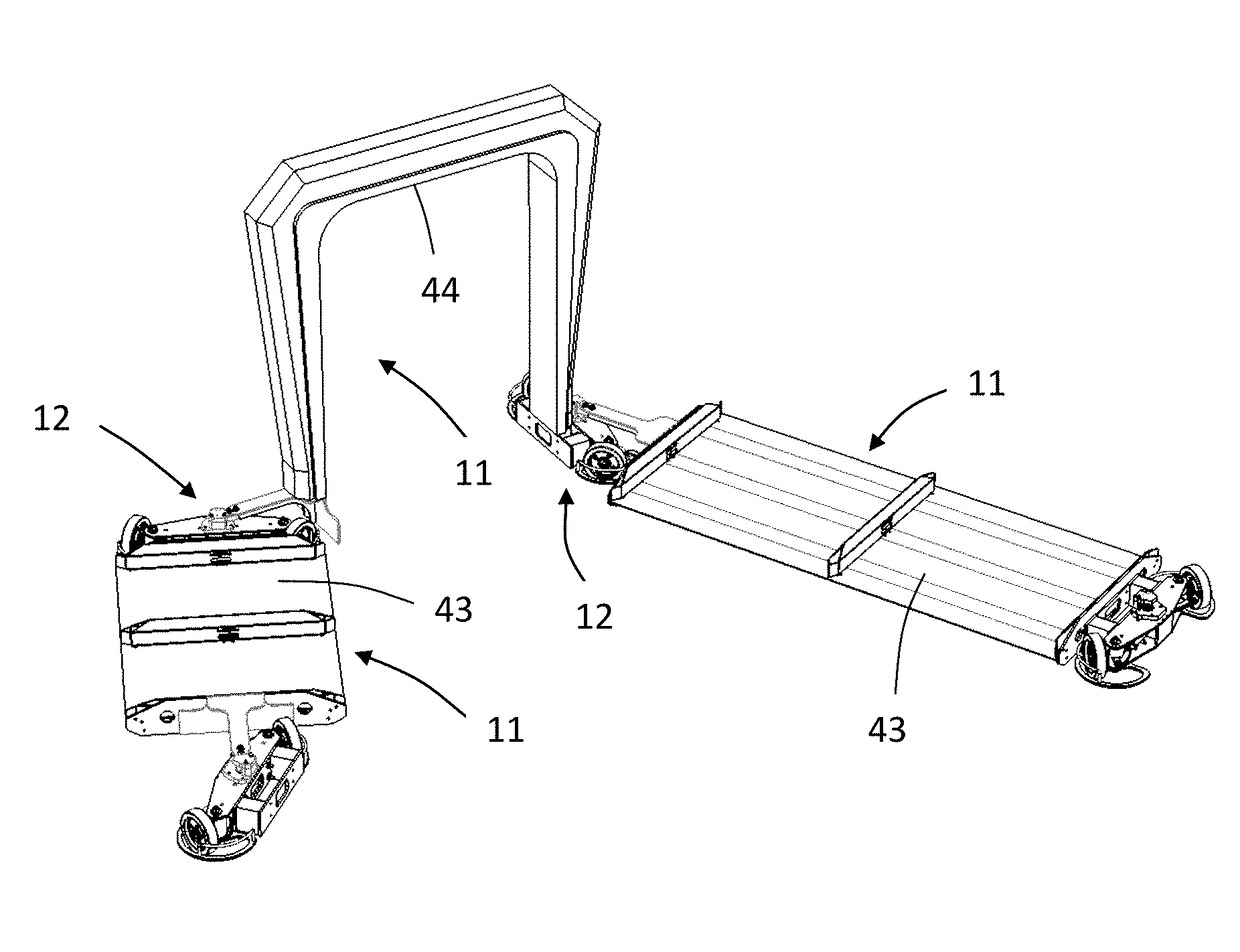

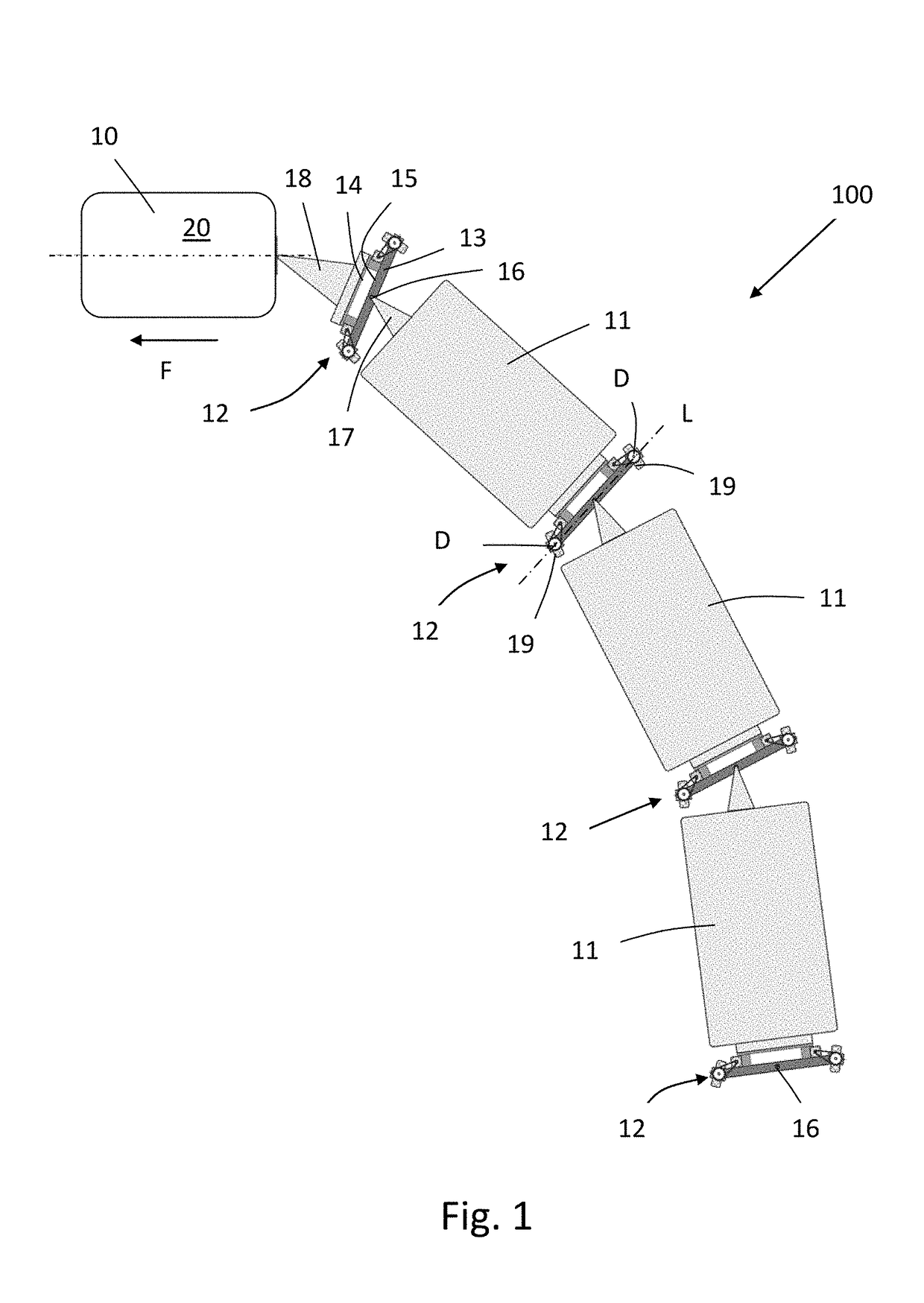

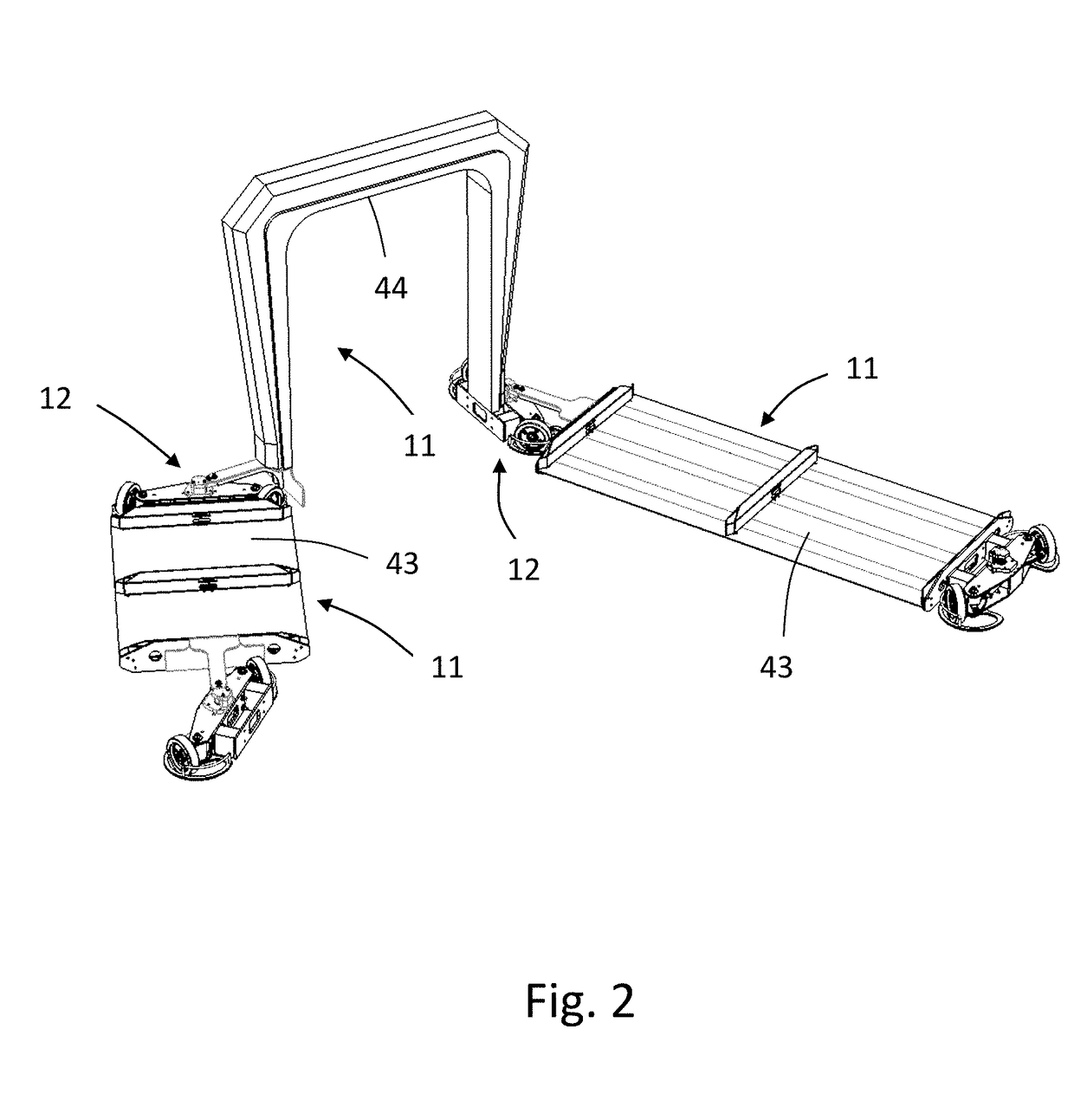

Railless tugger train

InactiveUS20180001947A1Simple configurationSimplified design layoutSteering linkagesVehicle cleaning apparatusEngineeringMechanical engineering

A railless tugger train (100) includes a train module (10), at least one transportation module and at least two axis modules, wherein each axis module has a stiffly configured axis beam, at which a first mounting device is configured in the form of a stiff mounting of the train module or a transportation module and at which a second mounting device is configured for an articulated connection of a transportation module. At least two wheels (19) are mounted at the axis beam in such a way that the wheels are each rotatable around a rotation axis (D) which is configured vertical to the longitudinal axis (L) of the axis beam.

Owner:HELMUT SCHMIDT UNIV UNIV DER BUNDESWEHR HAMBURG

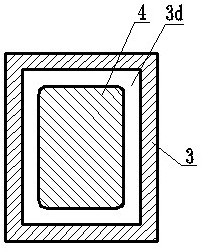

The Machining Method of the Wear-resistant Layer on the Bottom Arc of the Connecting Rod in the Hydraulic Motor

InactiveCN102274971AGood wear resistanceImprove working reliability and lifePowder metallurgyLubrication

The invention relates to a method for machining an abrasion resistance layer of a bottom curved surface of a connecting rod of a hydraulic motor. The method comprises the following steps of: 1) preparing a powder metallurgy material; 2) pressing the abrasion resistance layer; 3) removing an oxidized surface layer from the connecting rod; 4) forming a copper-plated layer on the bottom curved surface of the connecting rod; 5) welding the abrasion resistance layer to a position corresponding to the bottom curved surface of the connecting rod; and 6) sintering the abrasion resistance layer onto the bottom curved surface of the connecting rod. The method has the advantages that: the formed abrasion resistance layer has high abrasion resistance, heat resistance, friction reduction and wearing resistance performance, so that the hydraulic motor can keep long-term high lubrication performance and abrasion resistance performance during high speed running and has higher working reliability and service life; meanwhile, working resistance is reduced, the mechanical transmission efficiency is high and the bearing capacity of the motor is high; furthermore, material consumption of the abrasion resistance layer is reduced and the production cost is saved; and pollution to the environment caused by adopting babbitt metals is avoided.

Owner:KUNSHAN JINFA HYDRAULIC MACHINERY

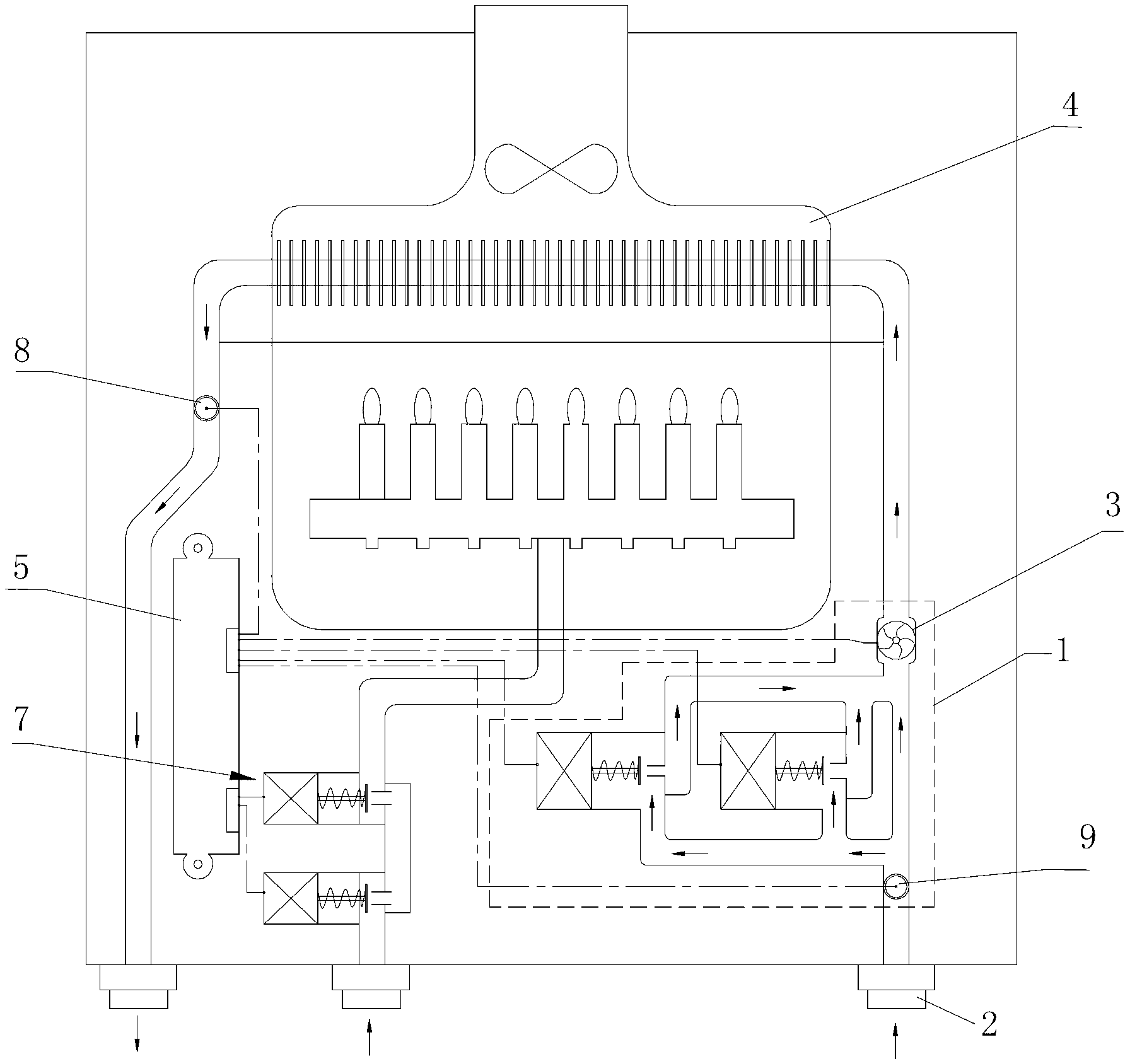

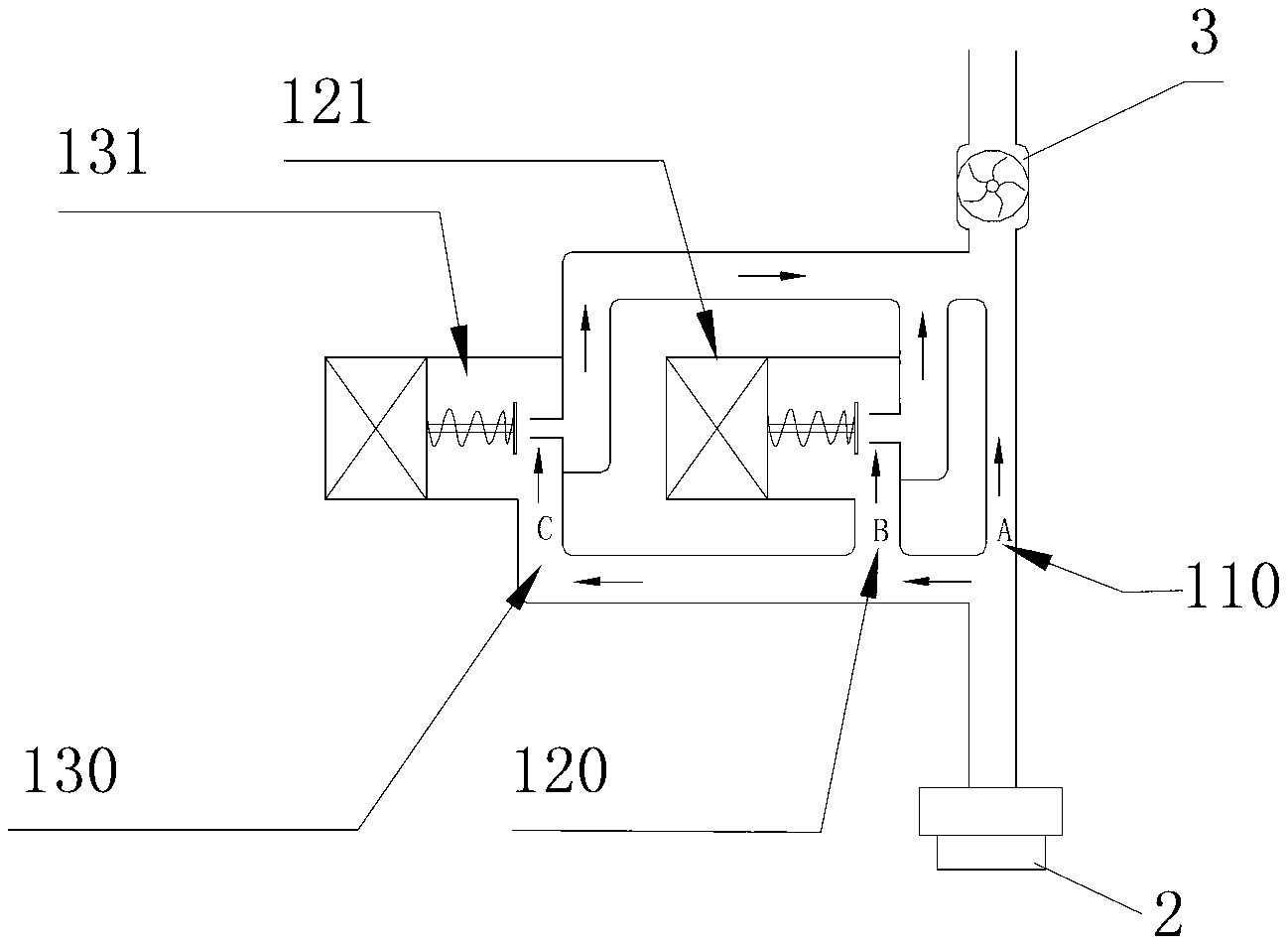

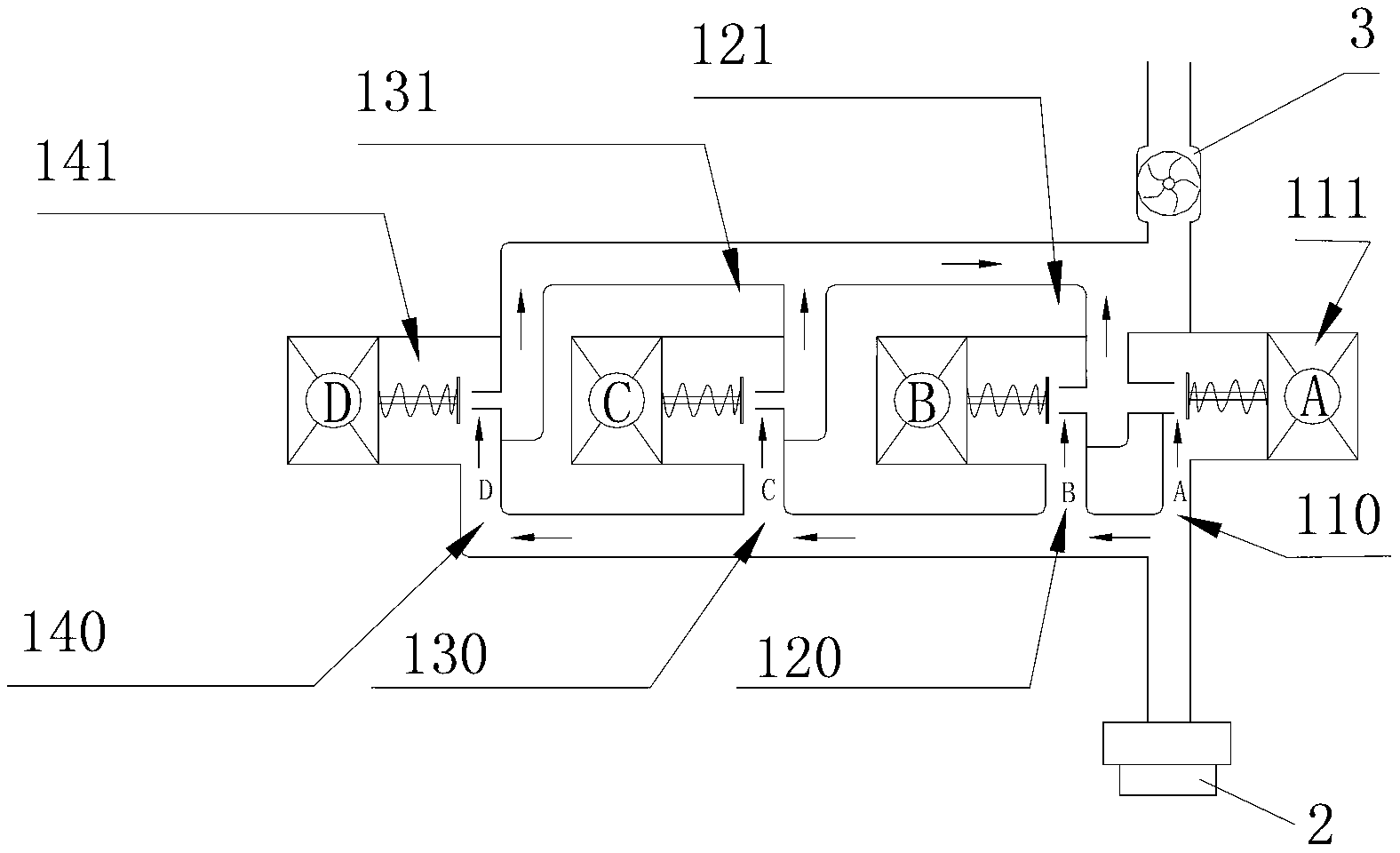

Gas water heater water channel distribution control device system and water channel distribution device

ActiveCN103277899ADoes not affect normal useReduced mechanical propertiesFluid heatersFailure rateDistribution control

The invention relates to a special water channel distribution device for a gas water heater, and aims to provide a gas water heater water channel distribution control device system and a water channel distribution device which are lower in failure rate, longer in service life and more stable in constant-temperature effect. The water channel distribution device comprises a water channel distributor, a central controller and a water flow sensor, the water flow sensor is used for detecting water inlet flow or water outlet total flow, a plurality of water channel branches are arranged on the water channel distributor and used for proportionally dividing a water channel of the water heater into a plurality of channels for distribution control, an electromagnetic valve is mounted on each water channel branch, and the water flow sensor and the electromagnetic valves are respectively and electrically connected with the central controller. The water channel distribution device is matched with a gas proportioning valve, a water inlet temperature probe and a water outlet temperature probe to form the gas water heater water channel distribution control device system, and the water inlet temperature probe and the water outlet temperature probe are used for detecting water temperatures.

Owner:陈雄

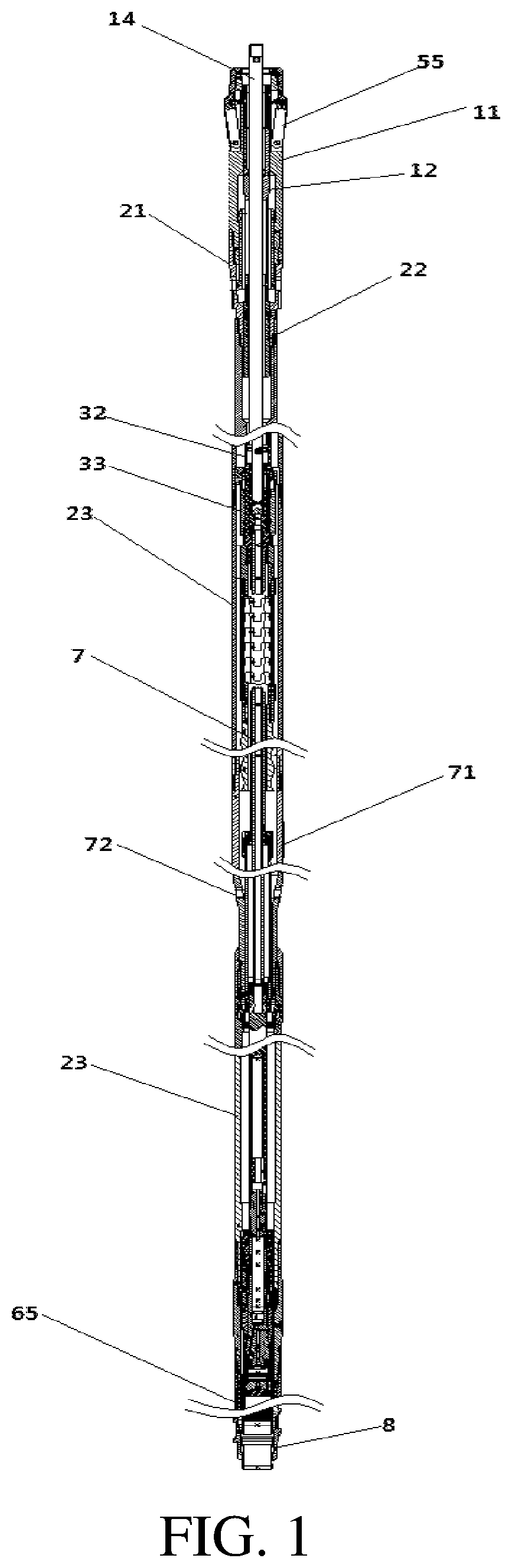

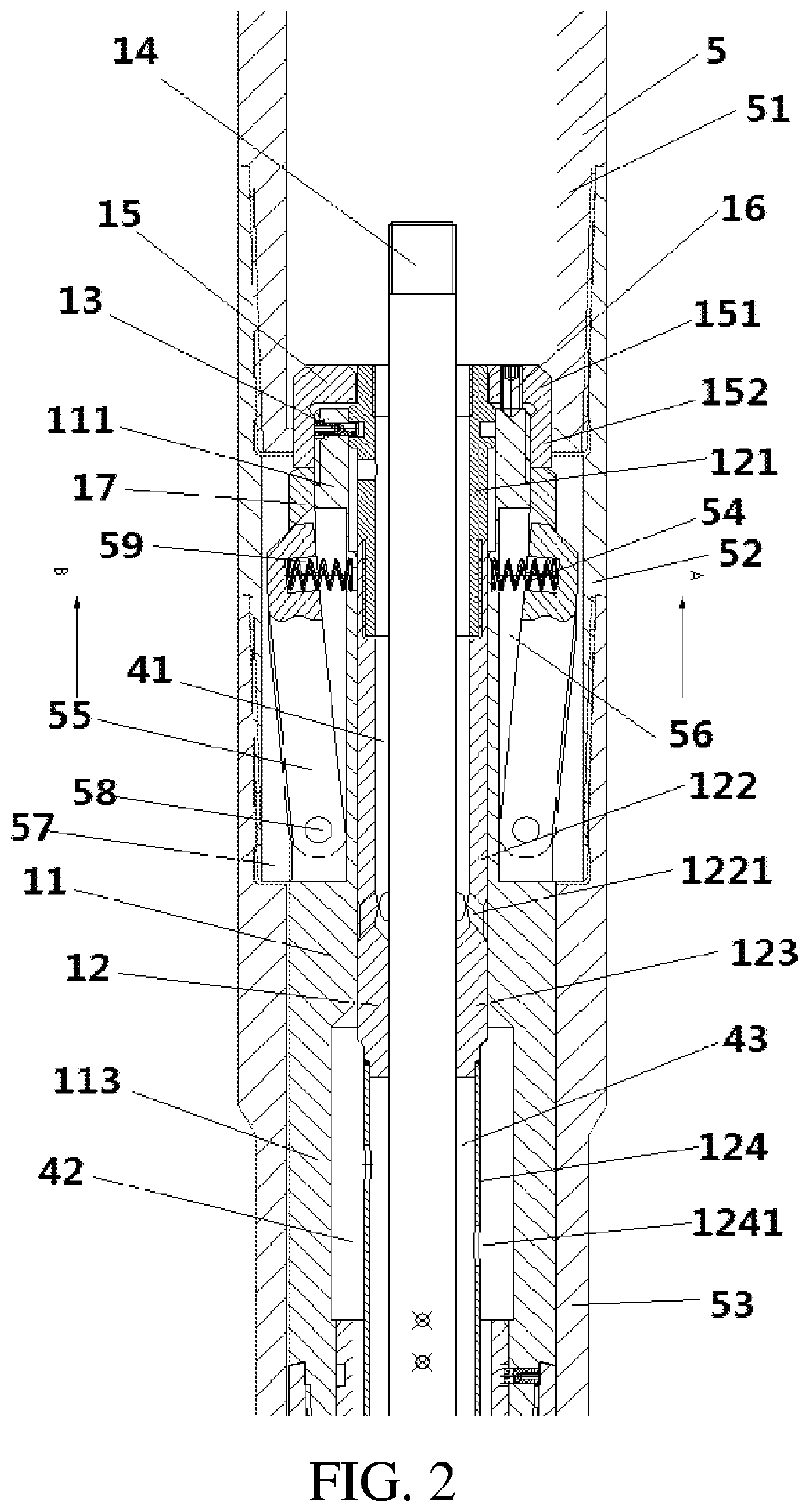

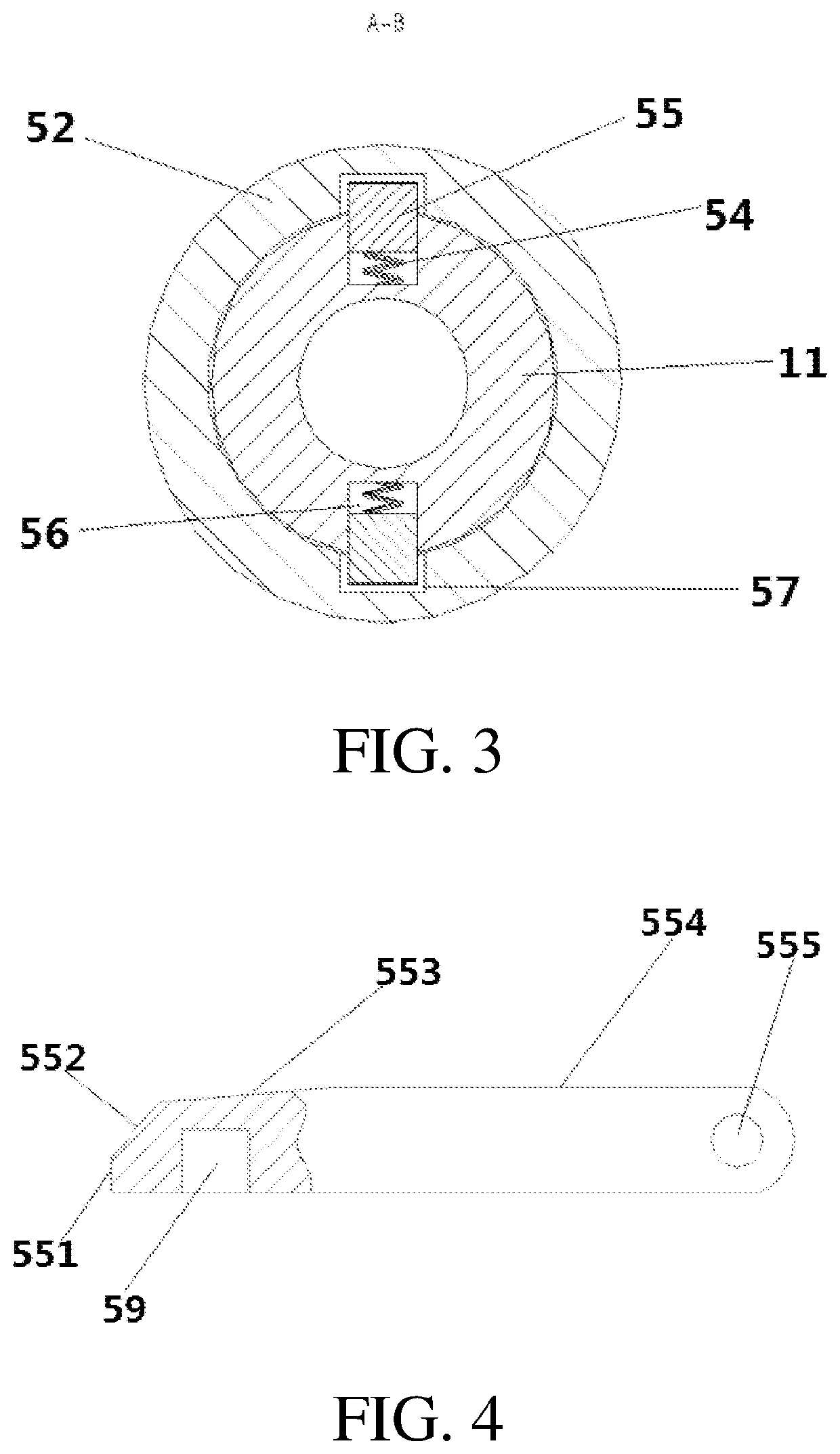

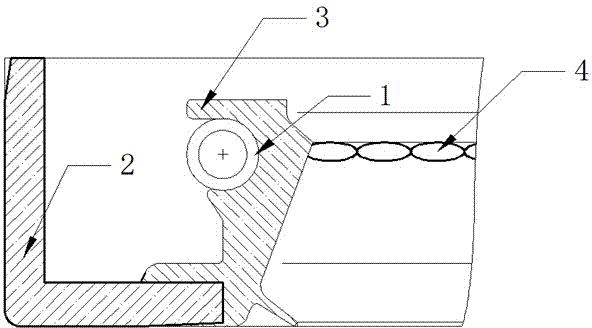

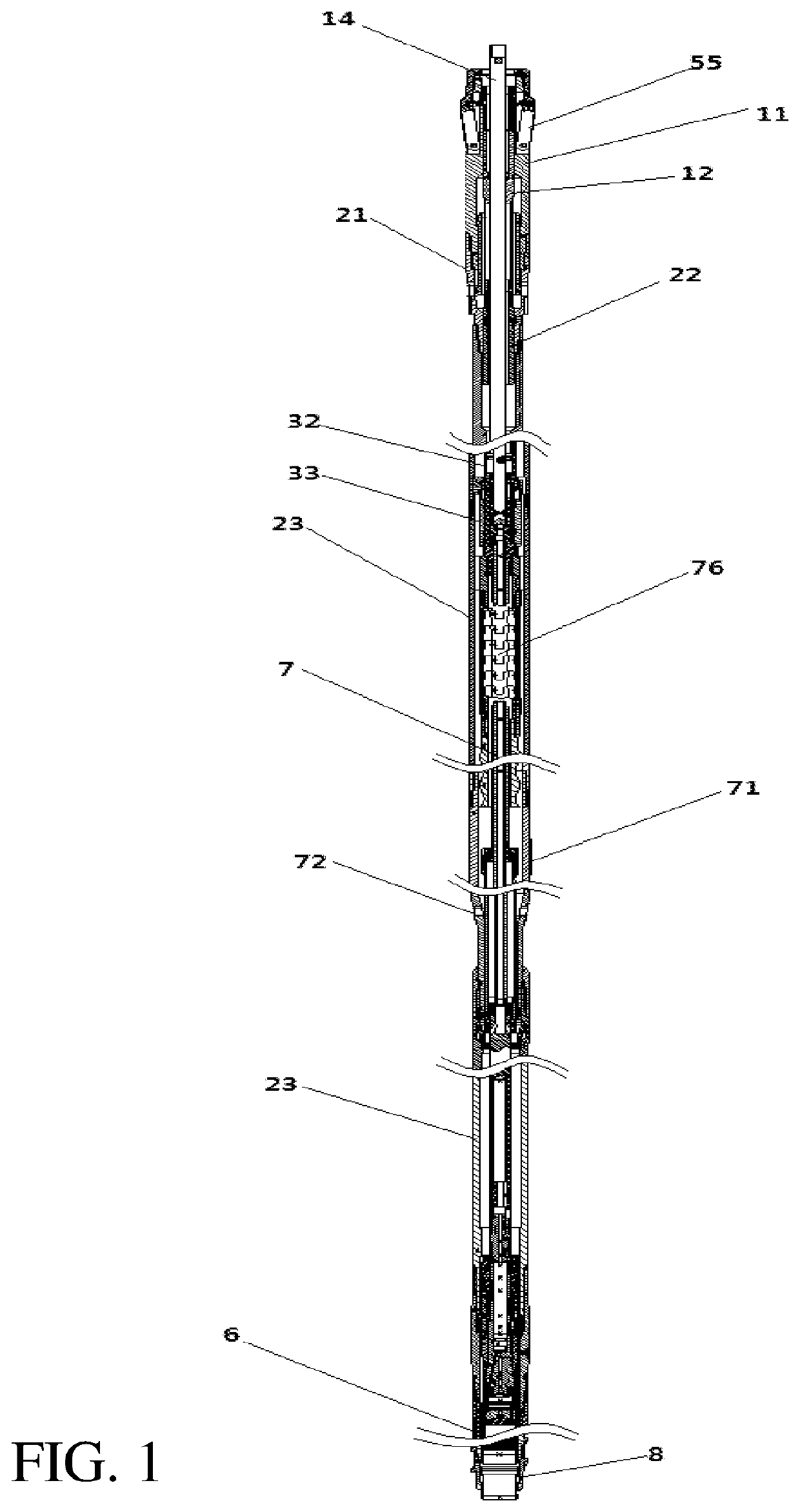

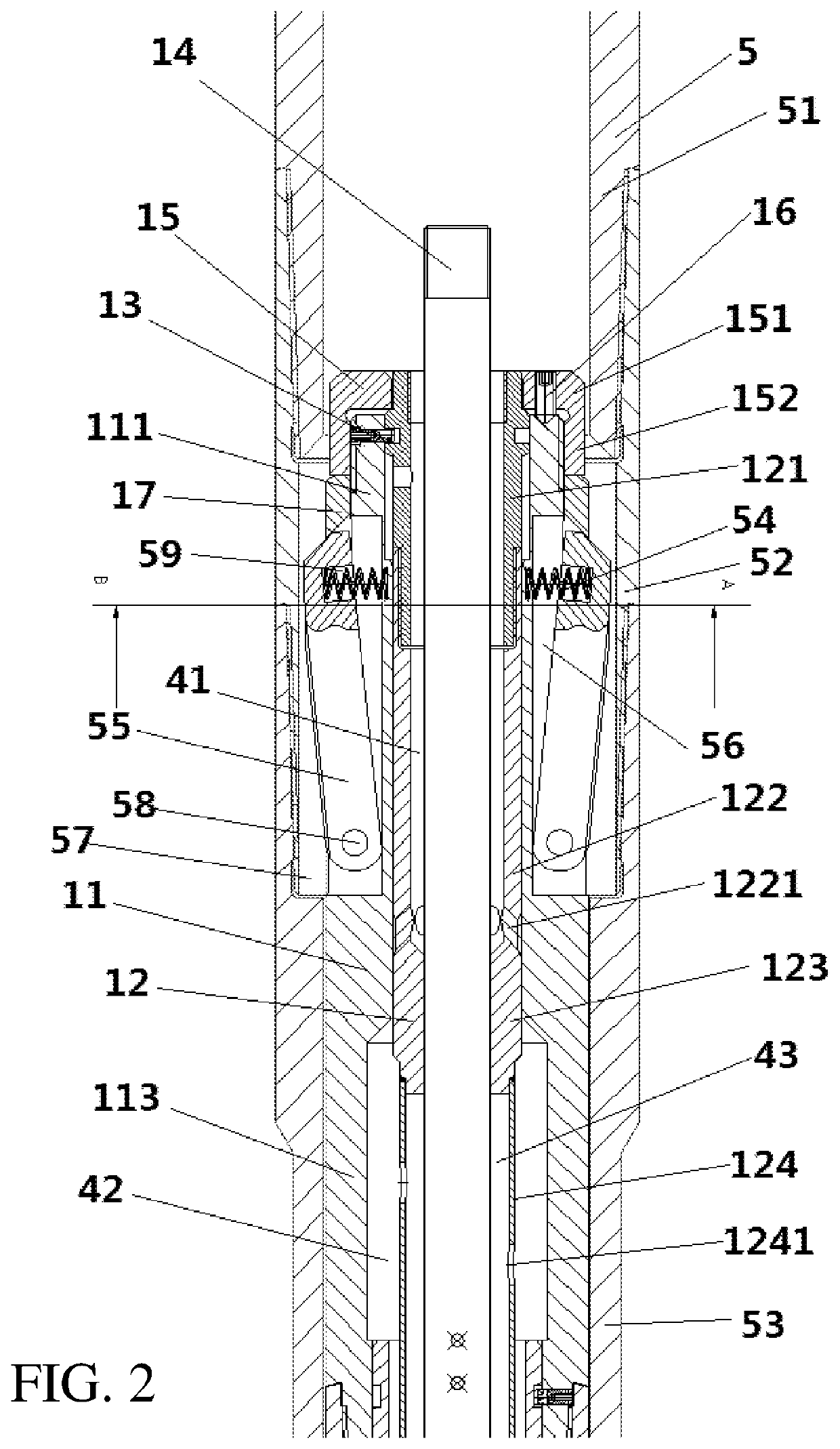

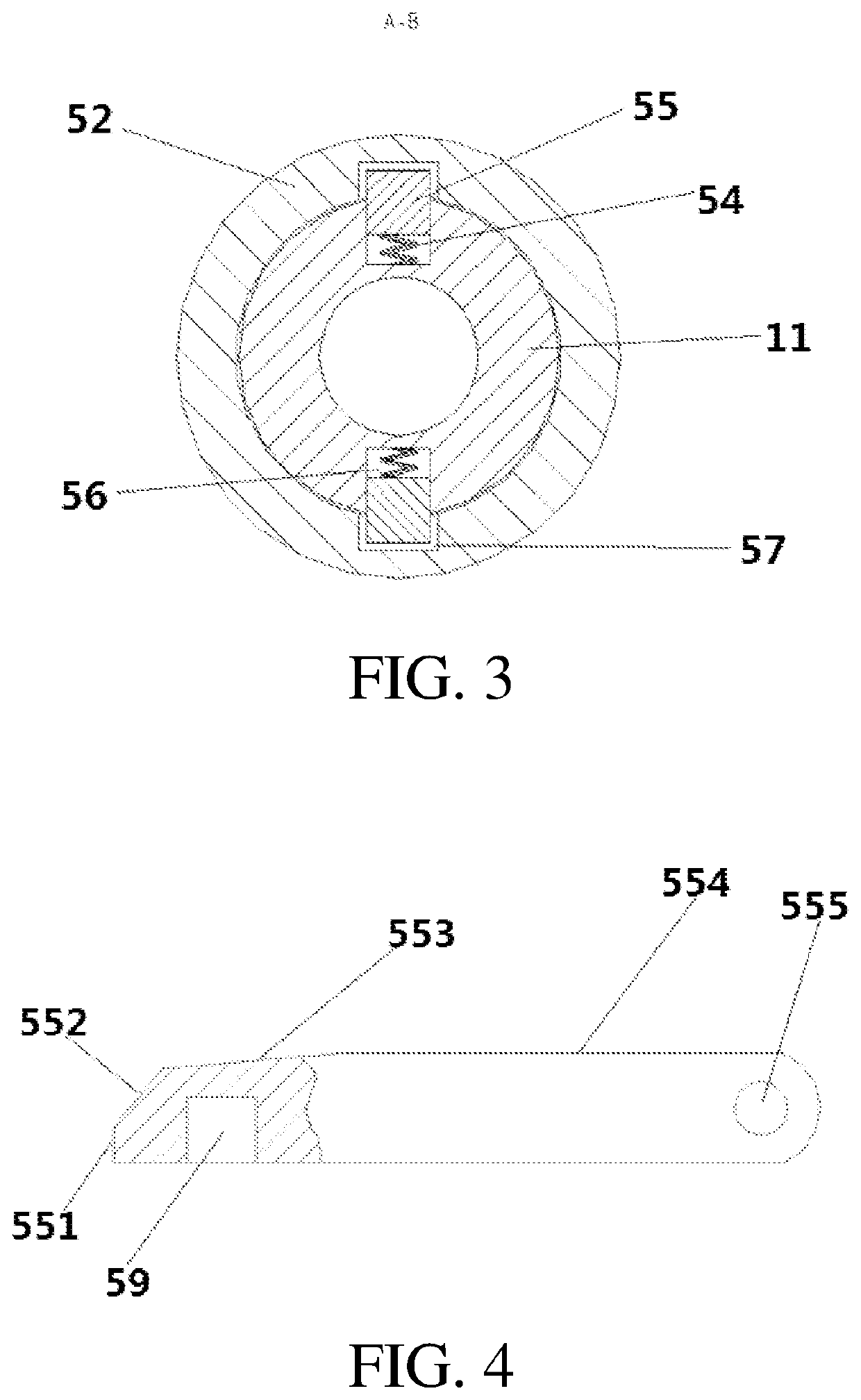

Drilling mechanism of coring drilling rig

PendingUS20220213739A1Avoid scratchesExtended service lifeDrilling rodsBorehole drivesHydraulic motorClassical mechanics

A drilling mechanism of a coring drilling rig has a central rod, a fluid channel starting module, an outer barrel, an outer barrel unlocking module, a shunting module and a drill bit. The central rod penetrates the fluid channel starting module. The outer barrel unlocking module and an inner cavity of the shunting module from back to front. The fluid channel starting module is behind the outer barrel and is connected to the outer barrel unlocking module. The shunting module is in front of the outer barrel unlocking module, and a hydraulic motor is connected in front of the shunting module. The outer barrel has a driving section that is a rotor of the hydraulic motor. The outer wall of the outer barrel is fixedly connected to a centralizer, and the front end of the outer barrel is connected to the drill bit.

Owner:SHENZHEN UNIV +1

Chinese-doughnut-shaped oil-back line oil seal

Owner:RIZHAO DONGDU RUBBER & PLASTIC PROD

Driving system for core drilling rig

PendingUS20220213745A1Increase powerAvoid scratchesDrilling rodsBorehole drivesCouplingClassical mechanics

A driving system for a core drilling rig has a driving motor. The driving motor has an outer rotor and an inner stator, and mutually-matched convex ribs are provided on the inner wall of the outer rotor and the outer wall of the inner stator. The outer rotor and the inner stator are in clearance fit. A clearance between the outer rotor and the inner stator is a driving liquid channel. The length of the outer rotor is less than that of the inner stator. The outer rotor is provided between the front and rear ends of the inner stator. The outer rotor is connected to an outer cylinder. The rear end of the inner stator is connected to a coupling.

Owner:SHENZHEN UNIV +1

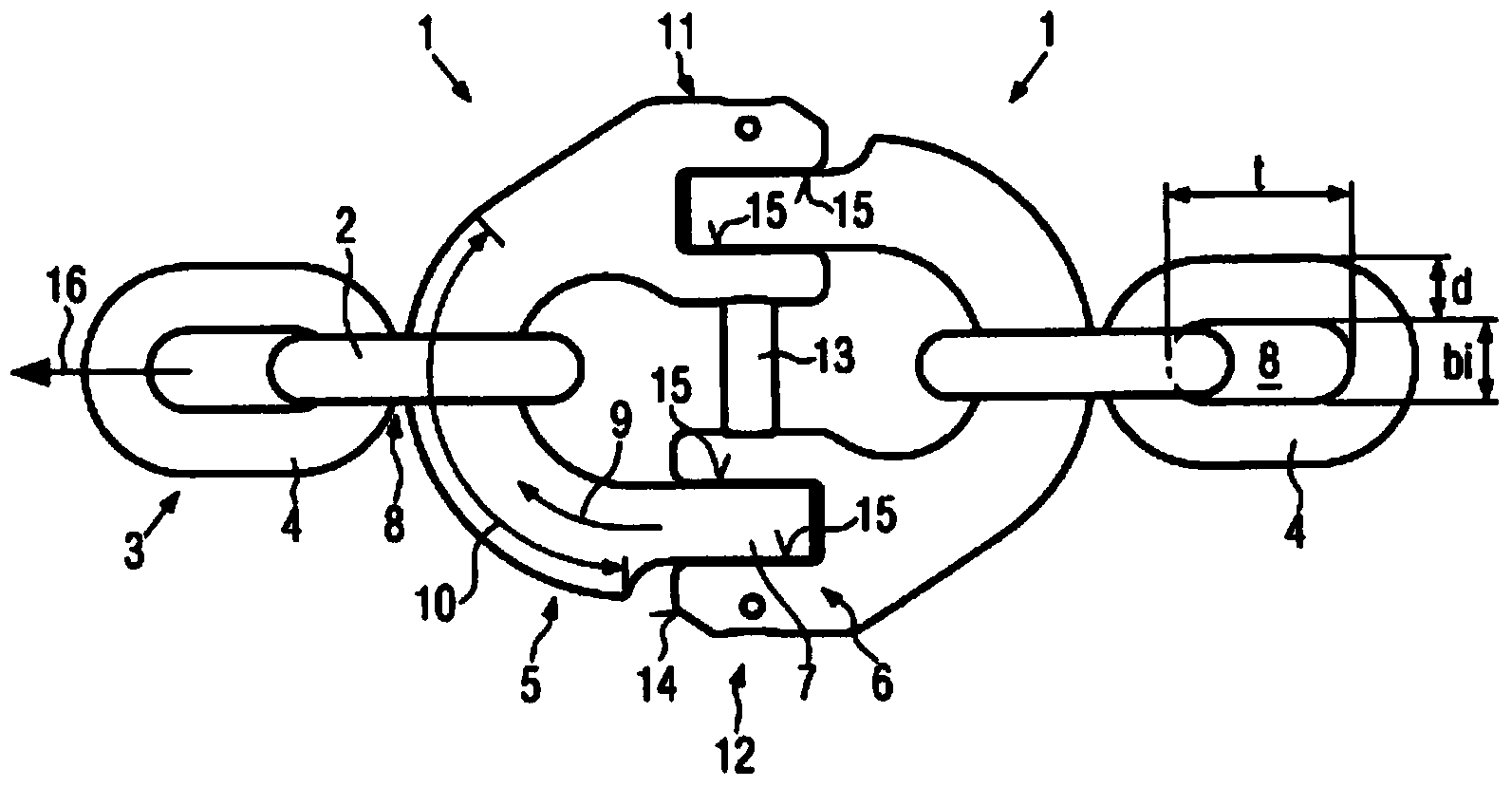

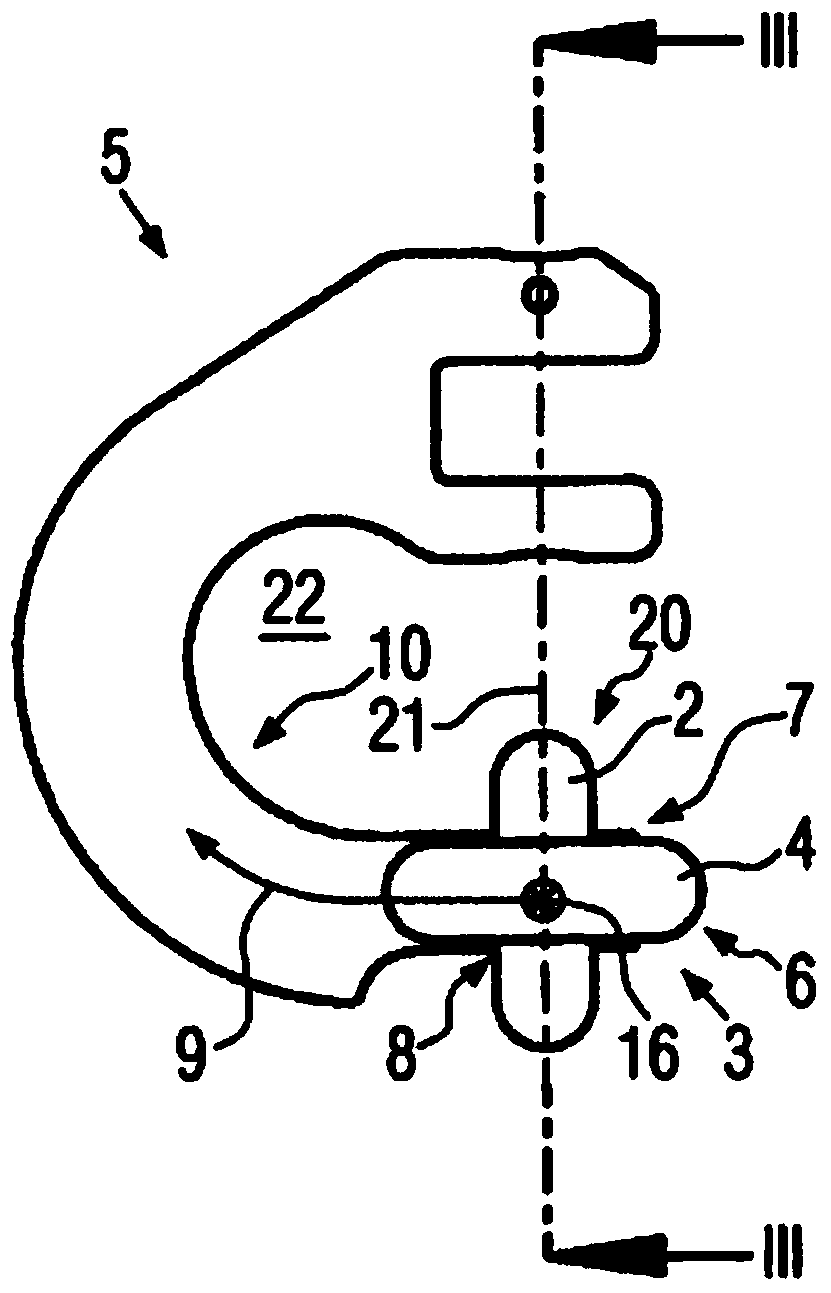

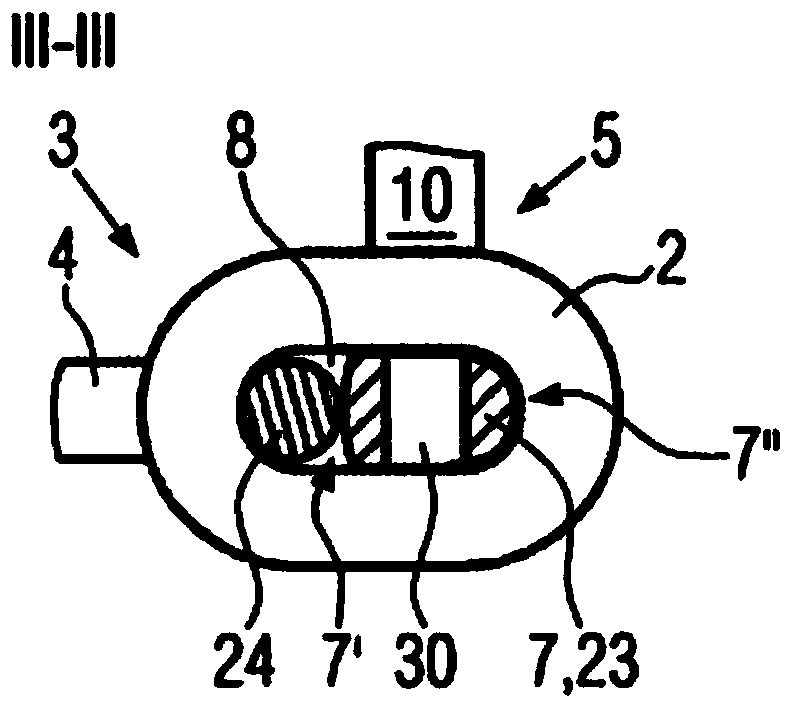

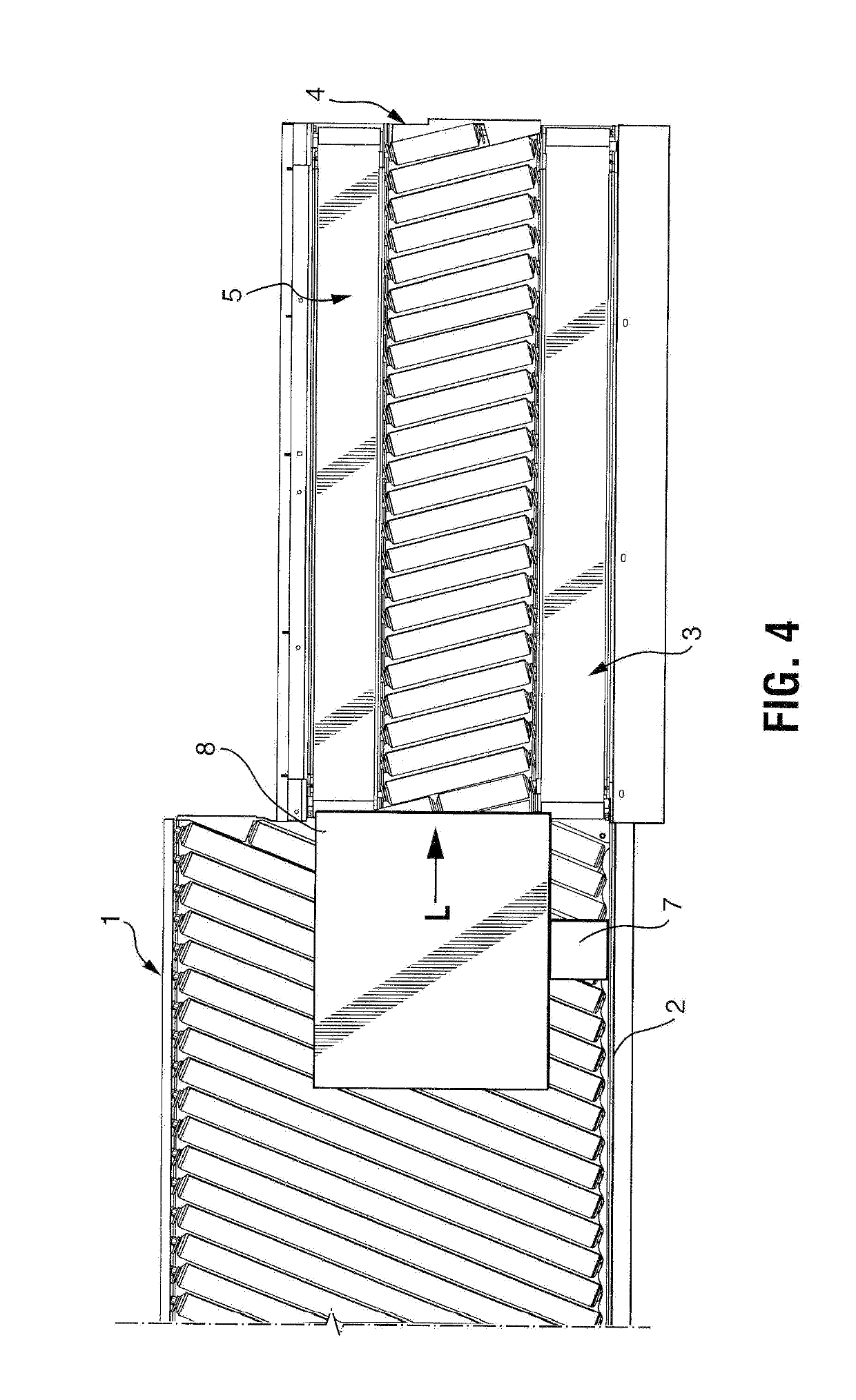

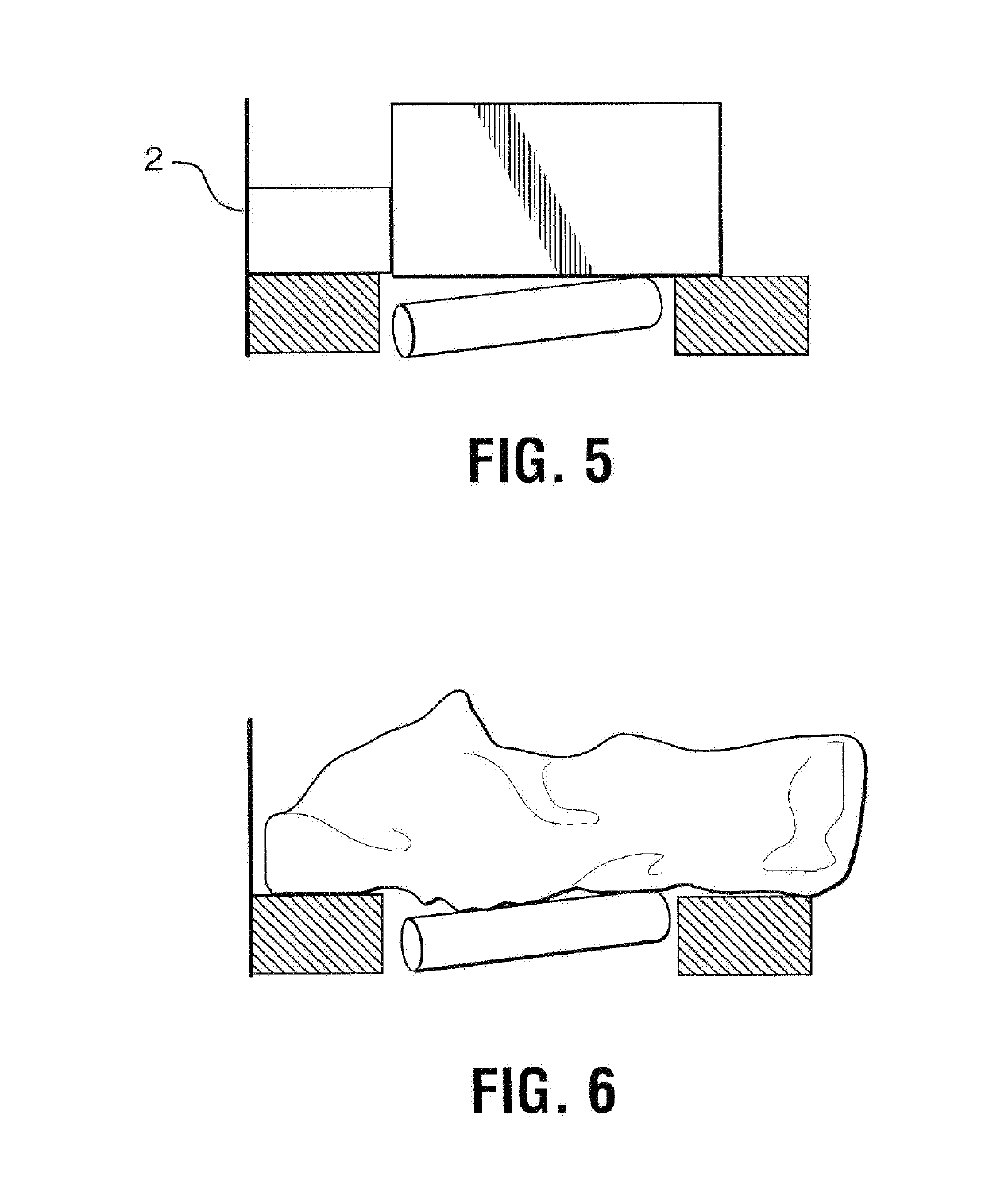

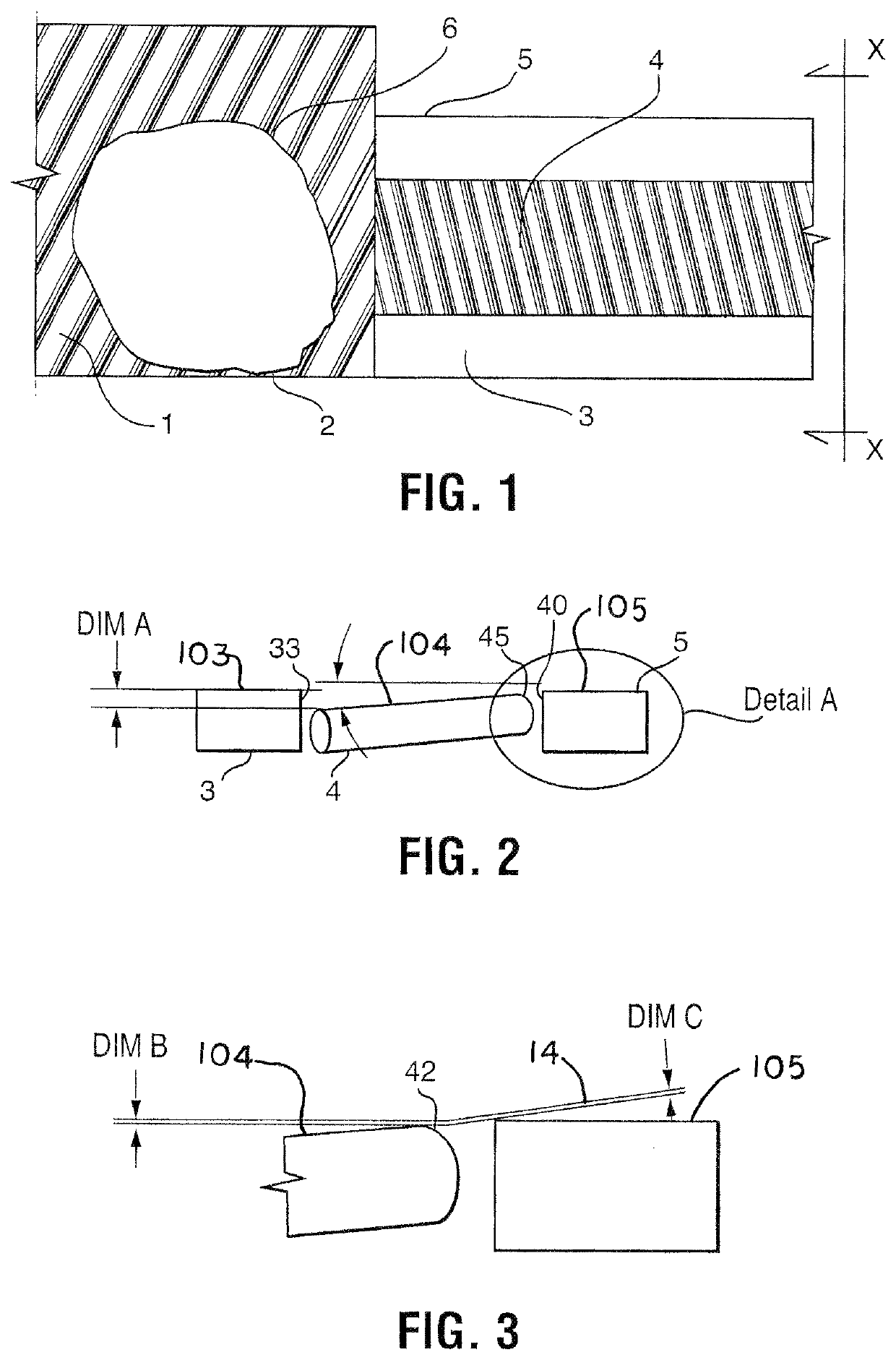

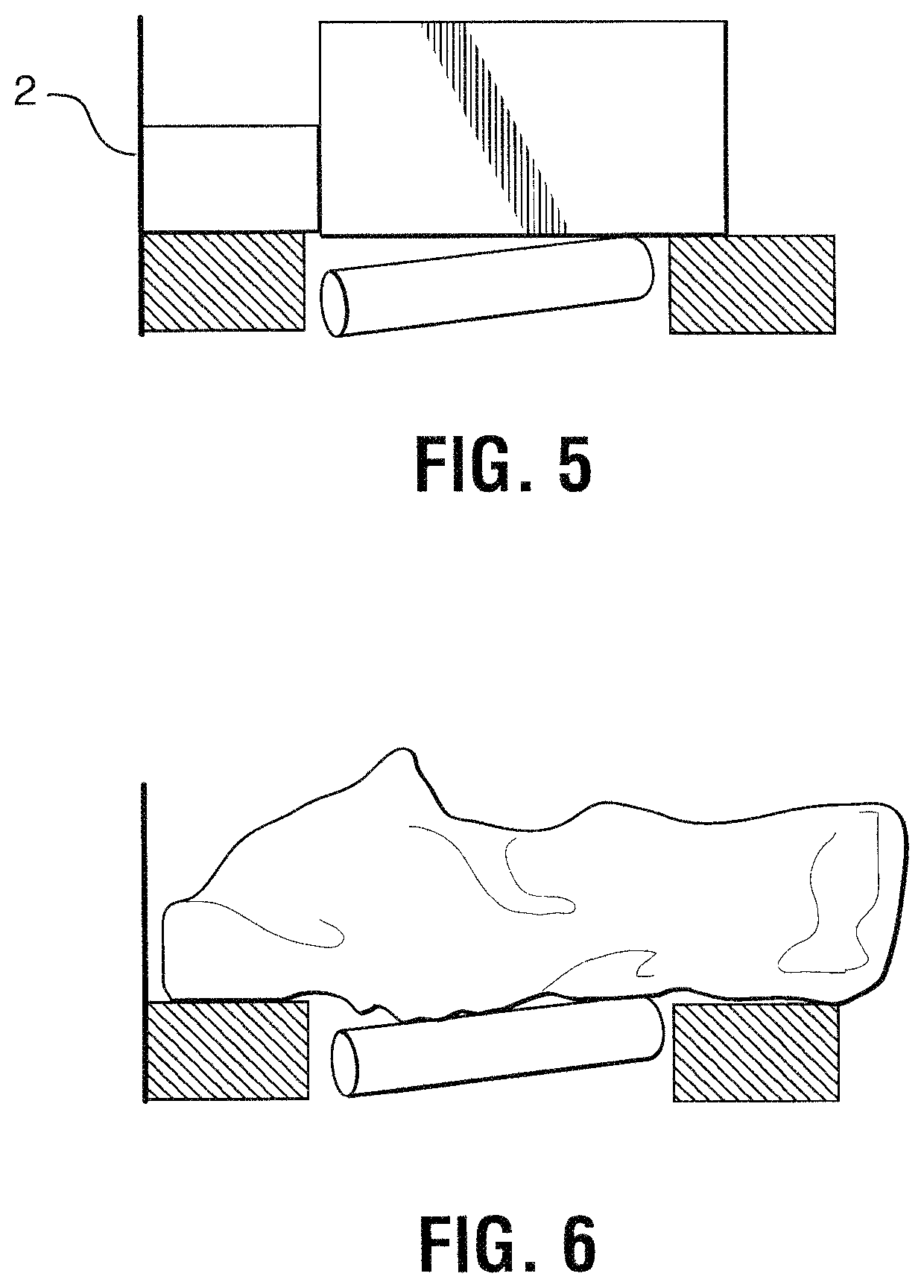

Device for attaching chain links

The invention relates to a device (1) for attaching an end link (2) of a chain strand (3) made of chain links (4) of a predetermined geometry. The device comprises a retaining device (5) comprising an insertion segment (7) at one end (6) that can be inserted in an opening (8) of the end link, and a retaining segment (5). The retaining segment comprises a cross section (28) on which the end link can be placed in a limited number of retaining positions, preferably only one single retaining position, from the insertion segment (7). The device further comprises a closure element (12) by which the end link can be permanently secured to the retaining device. In order to prevent tilting of the end link on the retaining device during operation, according to the invention the closure element forms a stop (14) by which a motion of the end link out of the retaining segment (10) in the direction of the insertion segment (7) is blocked.

Owner:RUD KETTENFABRIK RIEGER & DIETZ GMBH & CO

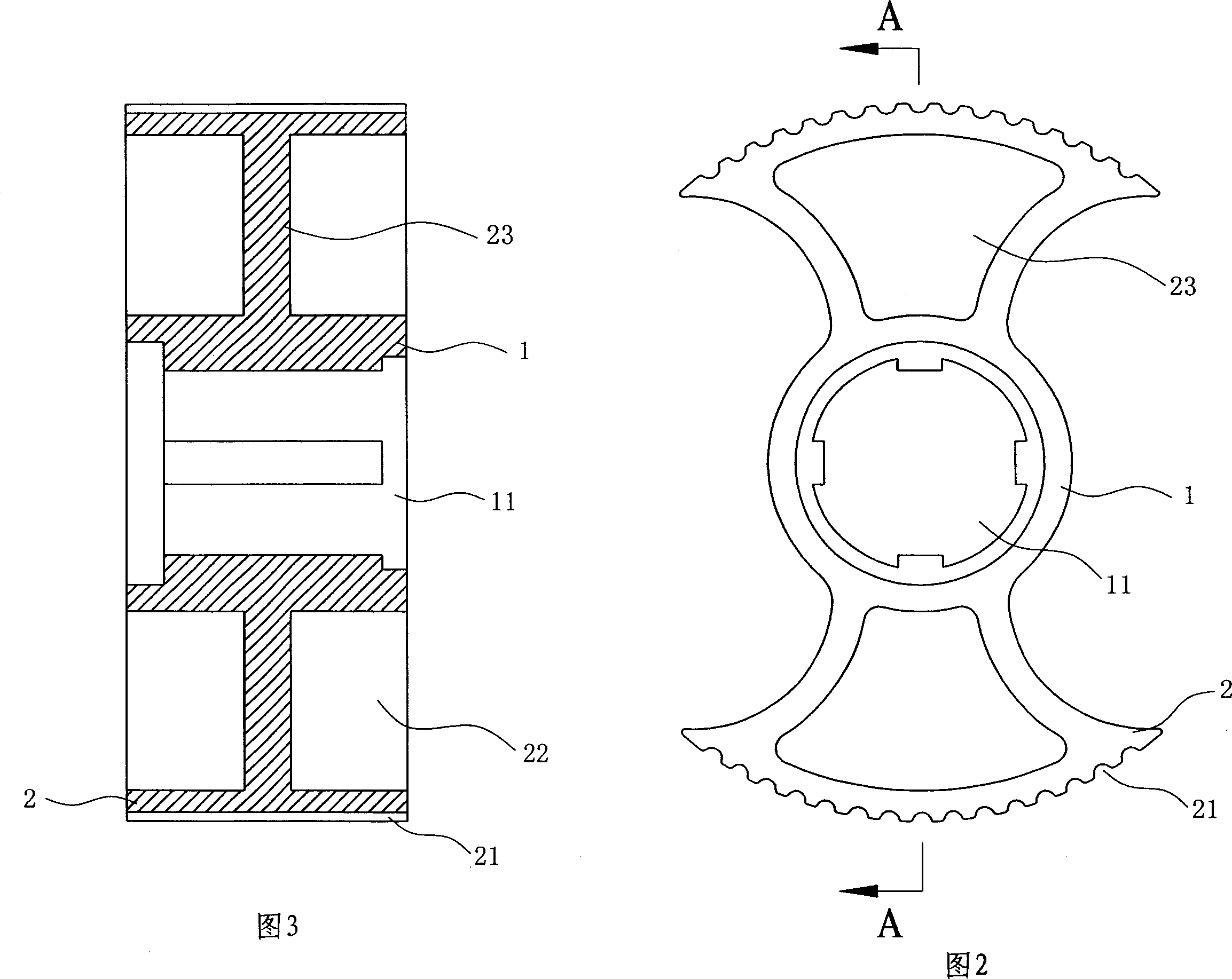

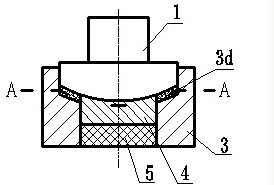

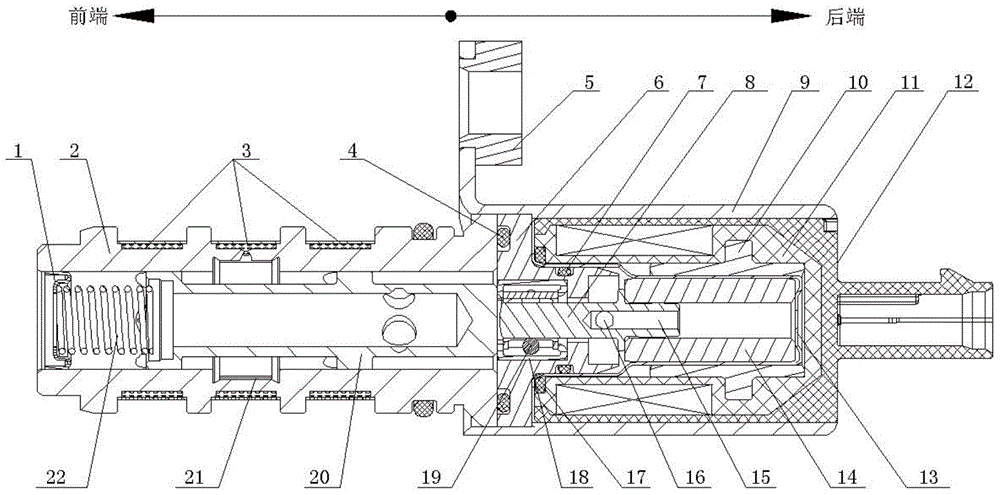

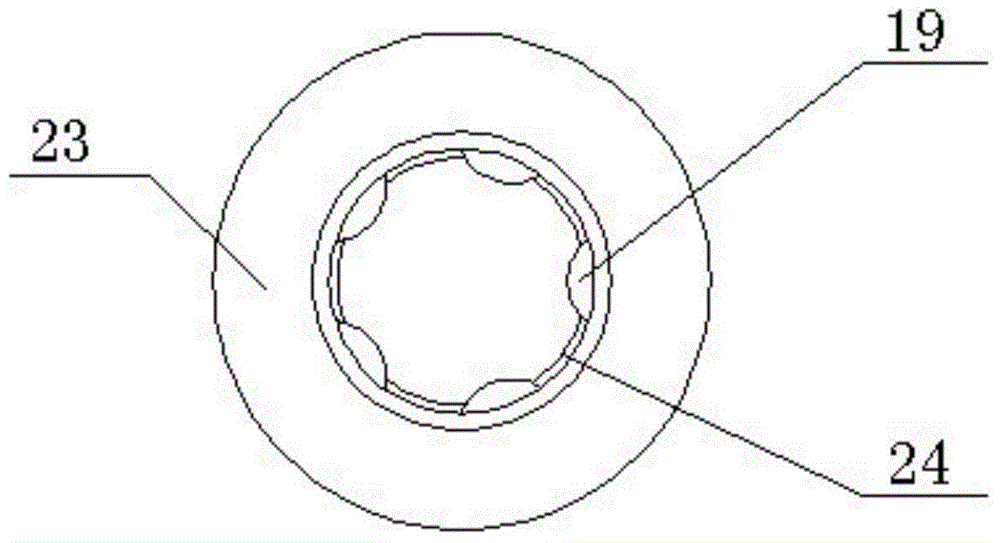

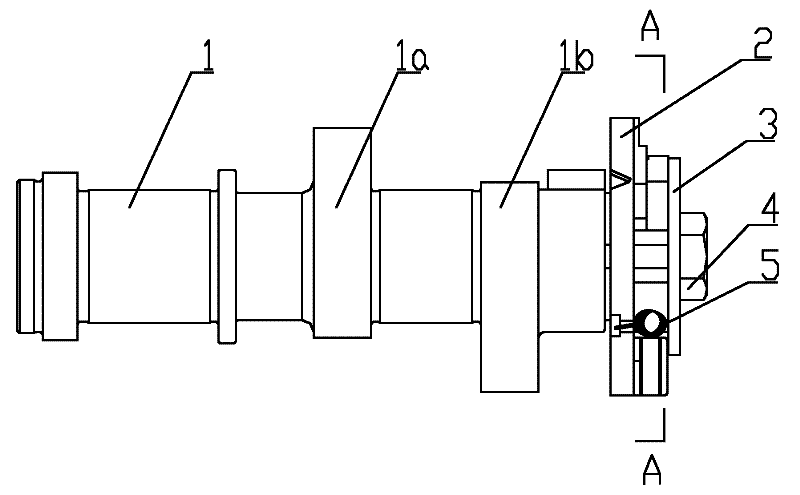

Engine oil control valve with guiding structure

ActiveCN104454061AReduce friction surfaceReduce friction and wearMachines/enginesNon-mechanical valveMagnetic coreEngine valve

The invention provides an engine oil control valve with a guiding structure. The engine valve control valve comprises a valve element (20), a pole shoe (6), a magnetic core shaft (8), a magnetic core (14) and an electromagnetic solenoid assembly (12). A guiding sleeve (13) is arranged between the magnetic core (14) and a rear yoke sleeve (10) on the electromagnetic solenoid assembly (12), the magnetic core shaft (8) is fixedly connected with the magnetic core (14), the guiding structure with balls (19) is arranged between the magnetic core shaft (8) and the pole shoe (6), sliding friction is adopted between one end of the magnetic core (14) and the guiding sleeve (13), and rolling friction is adopted between the other end of the magnetic core (14) and the balls (19) through the magnetic core shaft (8). A stressed supporting point of the magnetic core can be transferred to the balls, the length of the arm of force of the acting force of the valve element to the magnetic core shaft is reduced, radial loads borne by the magnetic core and the guiding sleeve on the right side of the balls are reduced, abrasion of the magnetic core and the guiding sleeve is effectively lowered, and the service life of the engine oil control valve is effectively prolonged.

Owner:MIANYANG FULIN PRECISION MACHINING

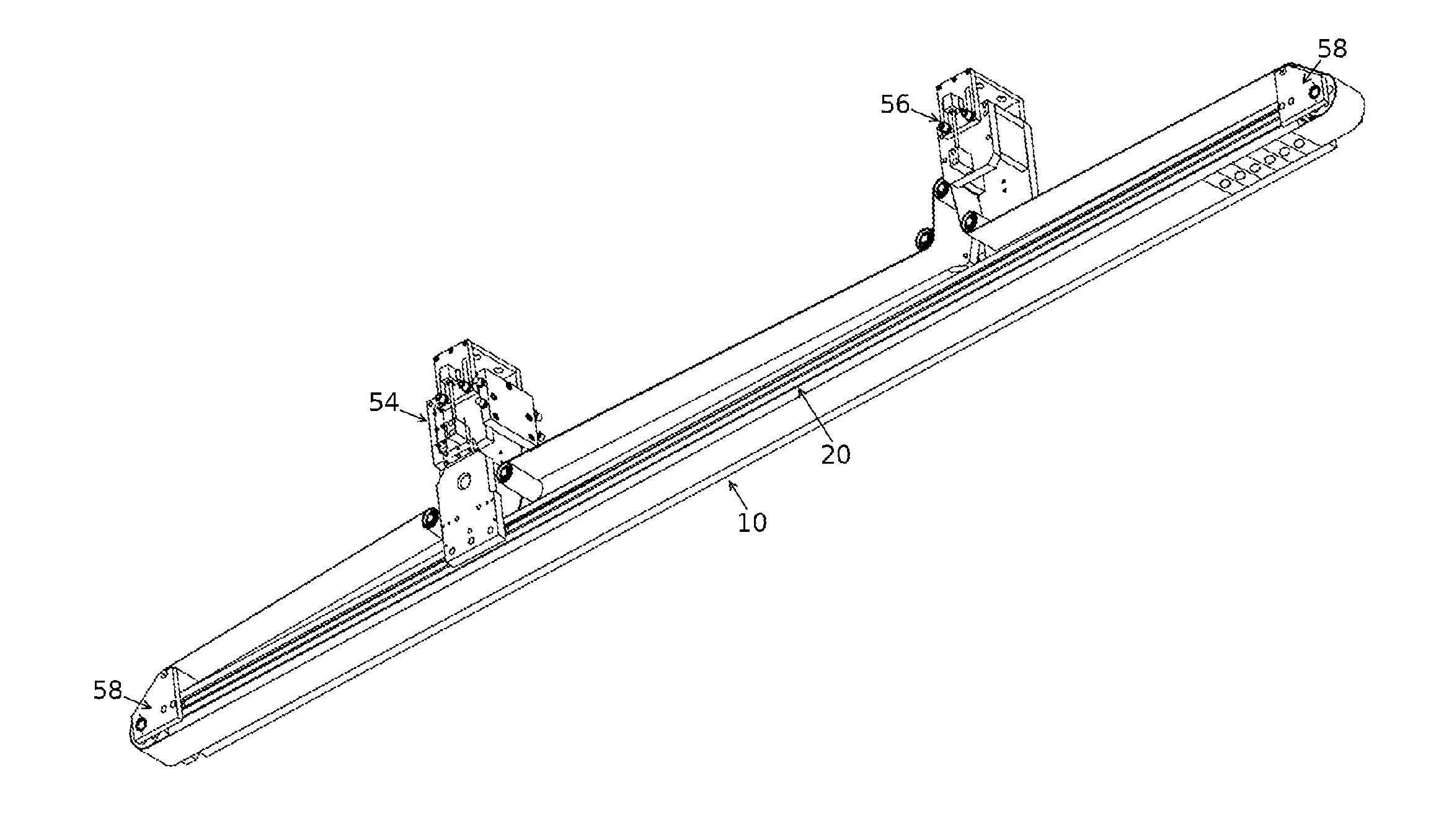

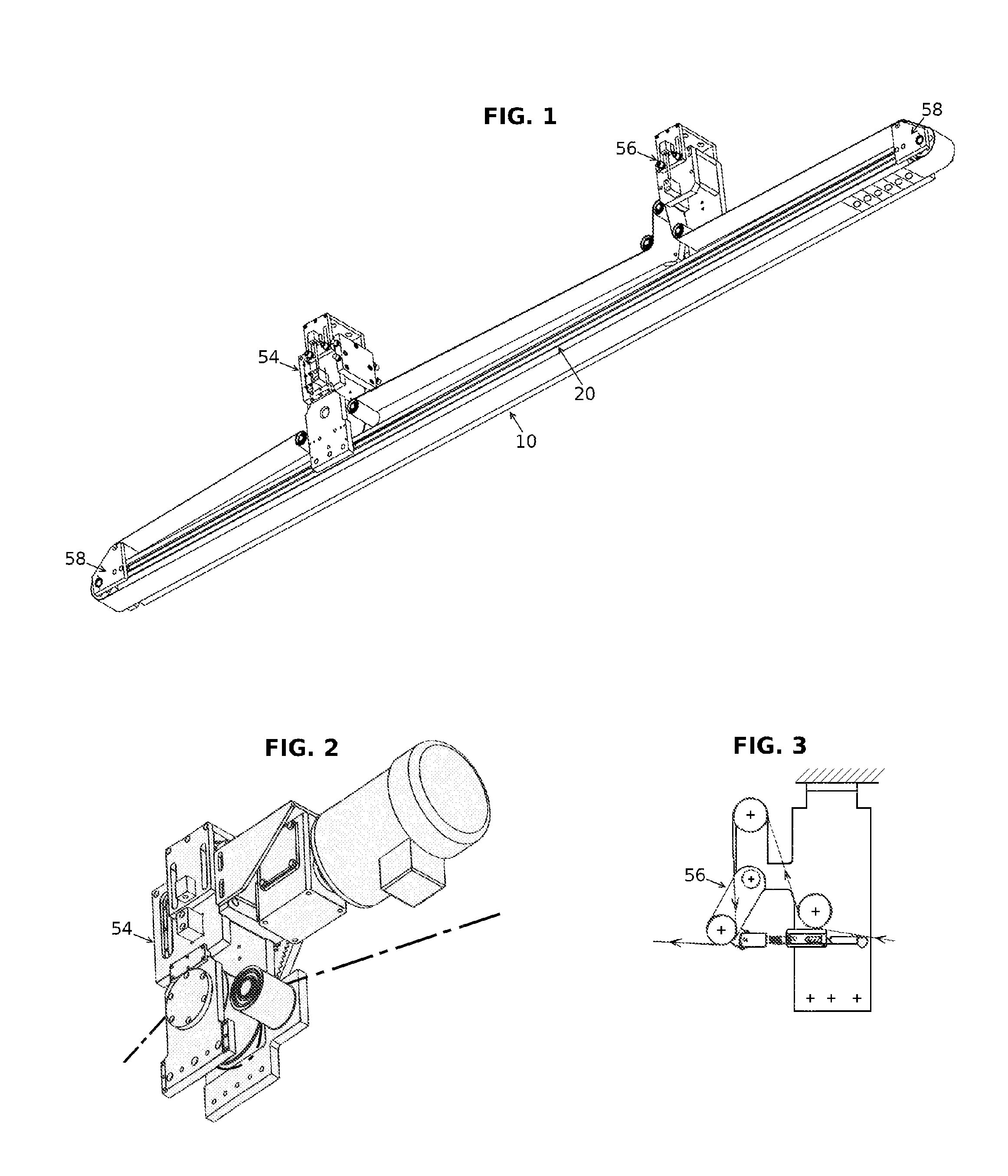

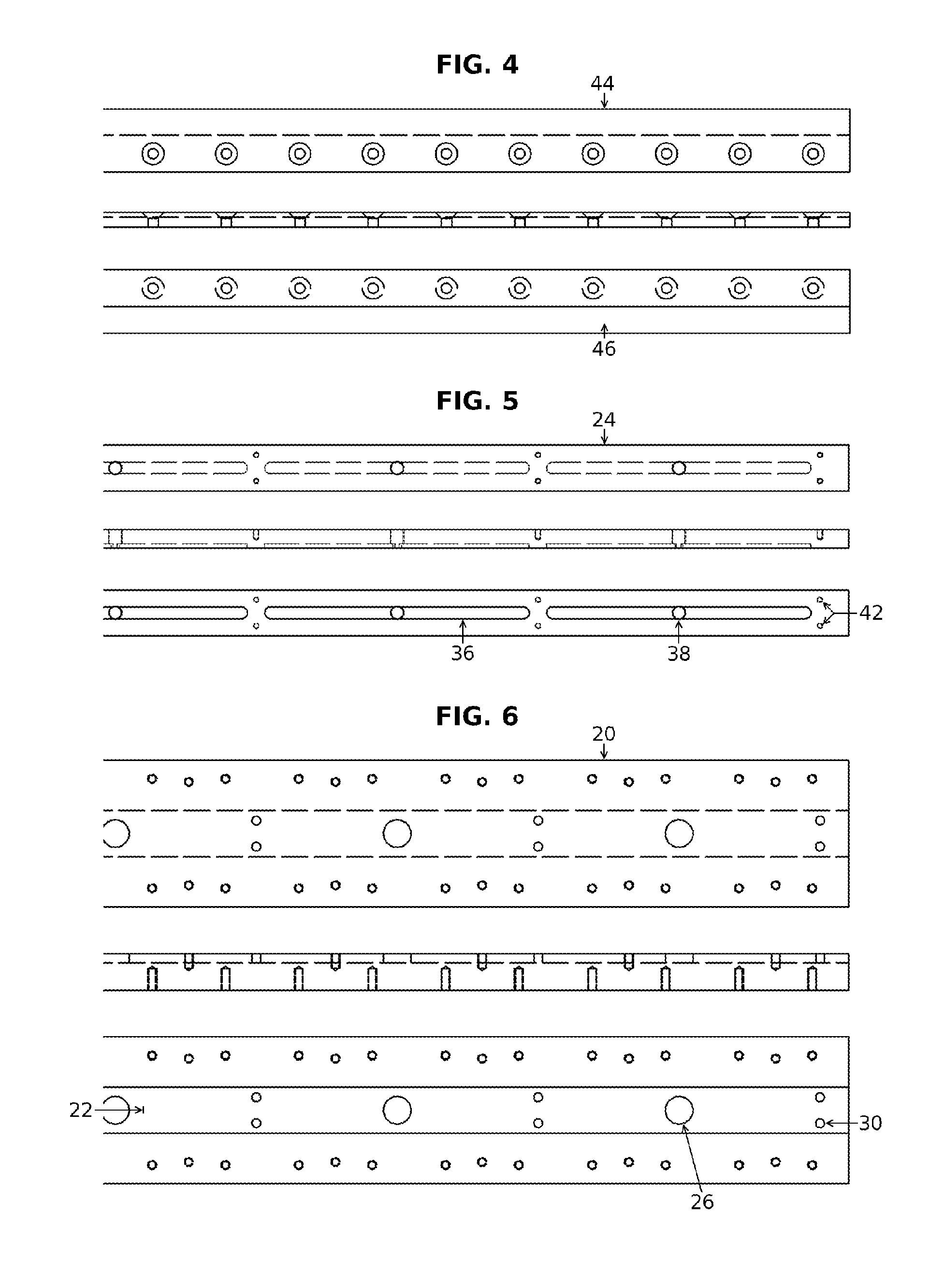

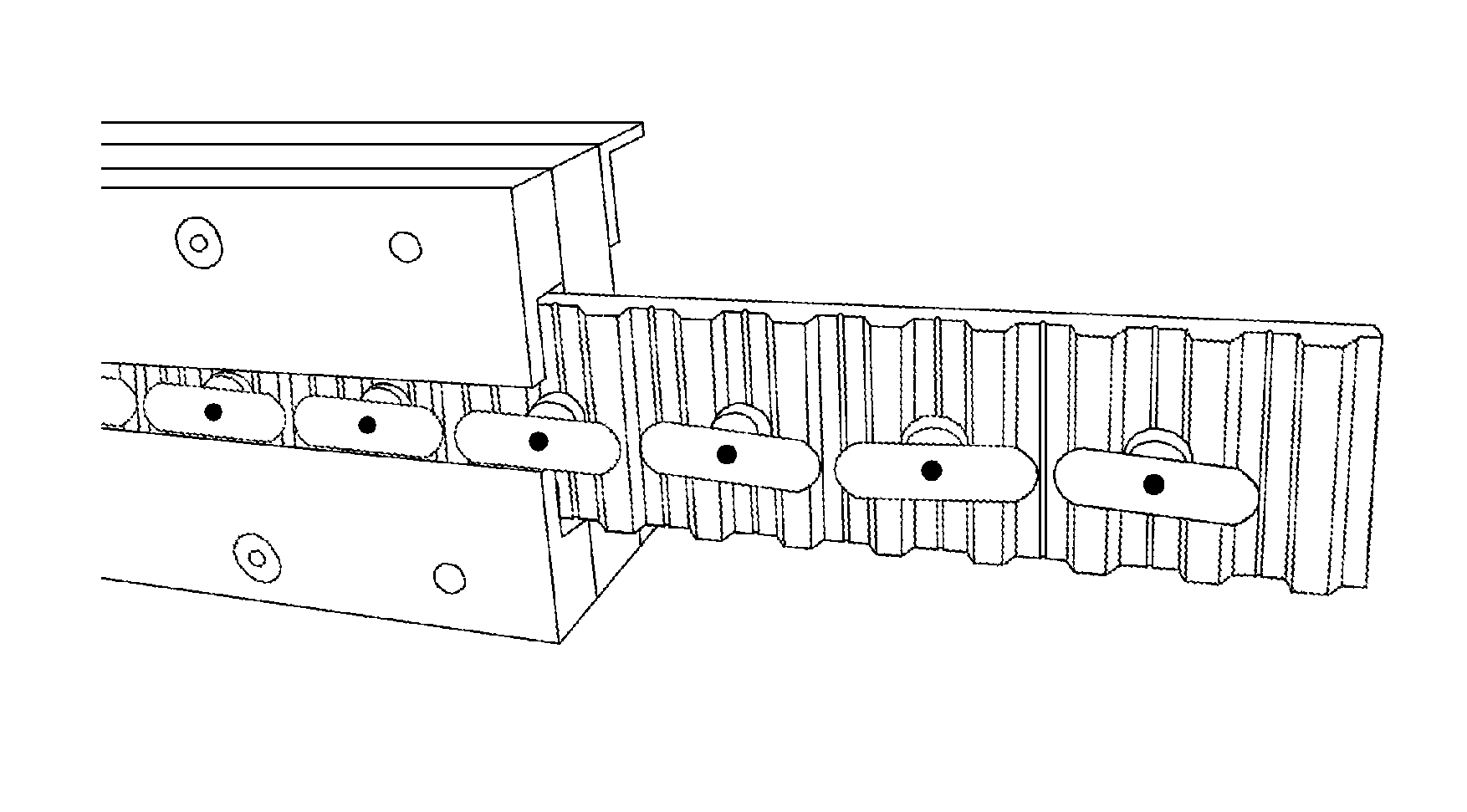

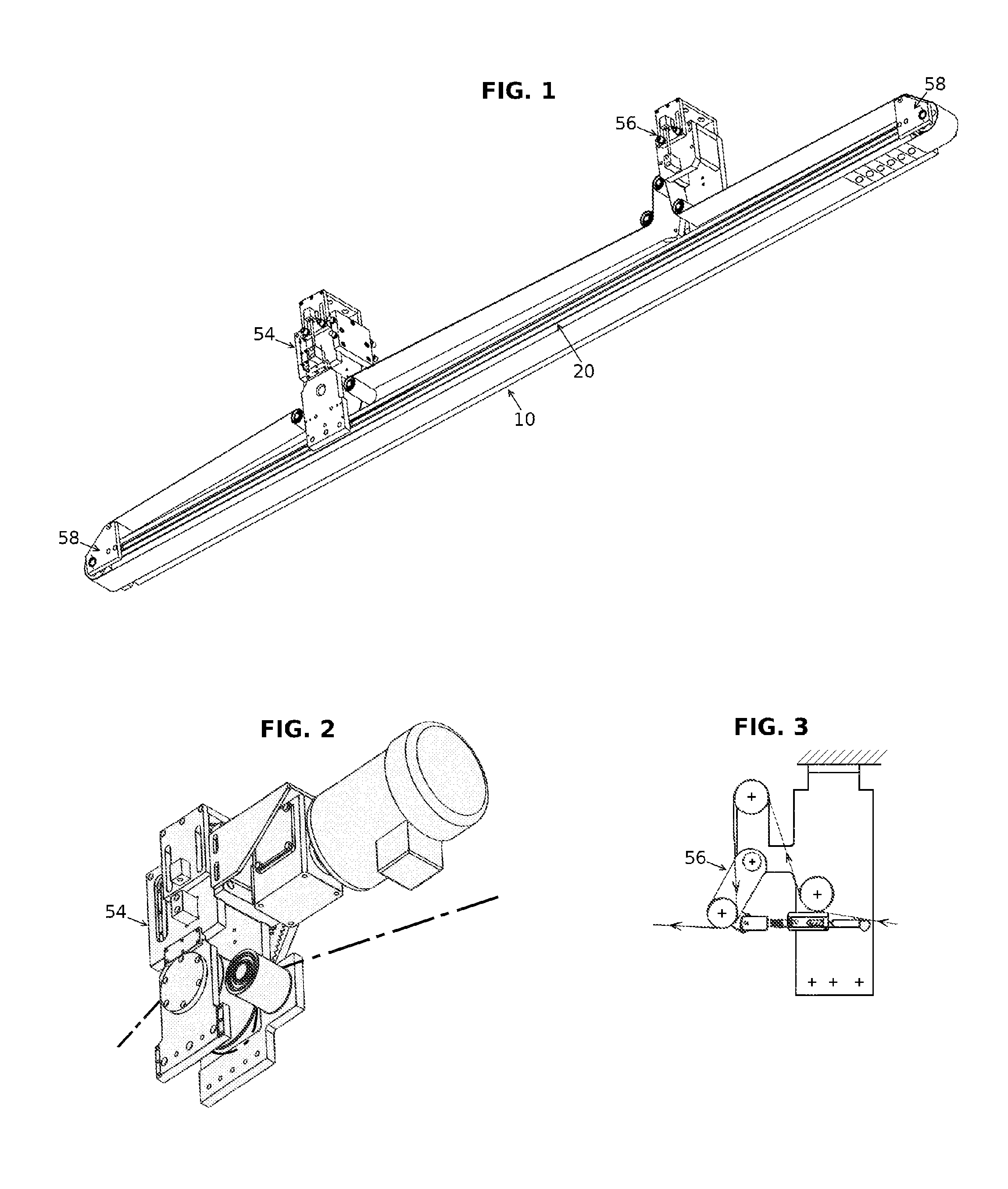

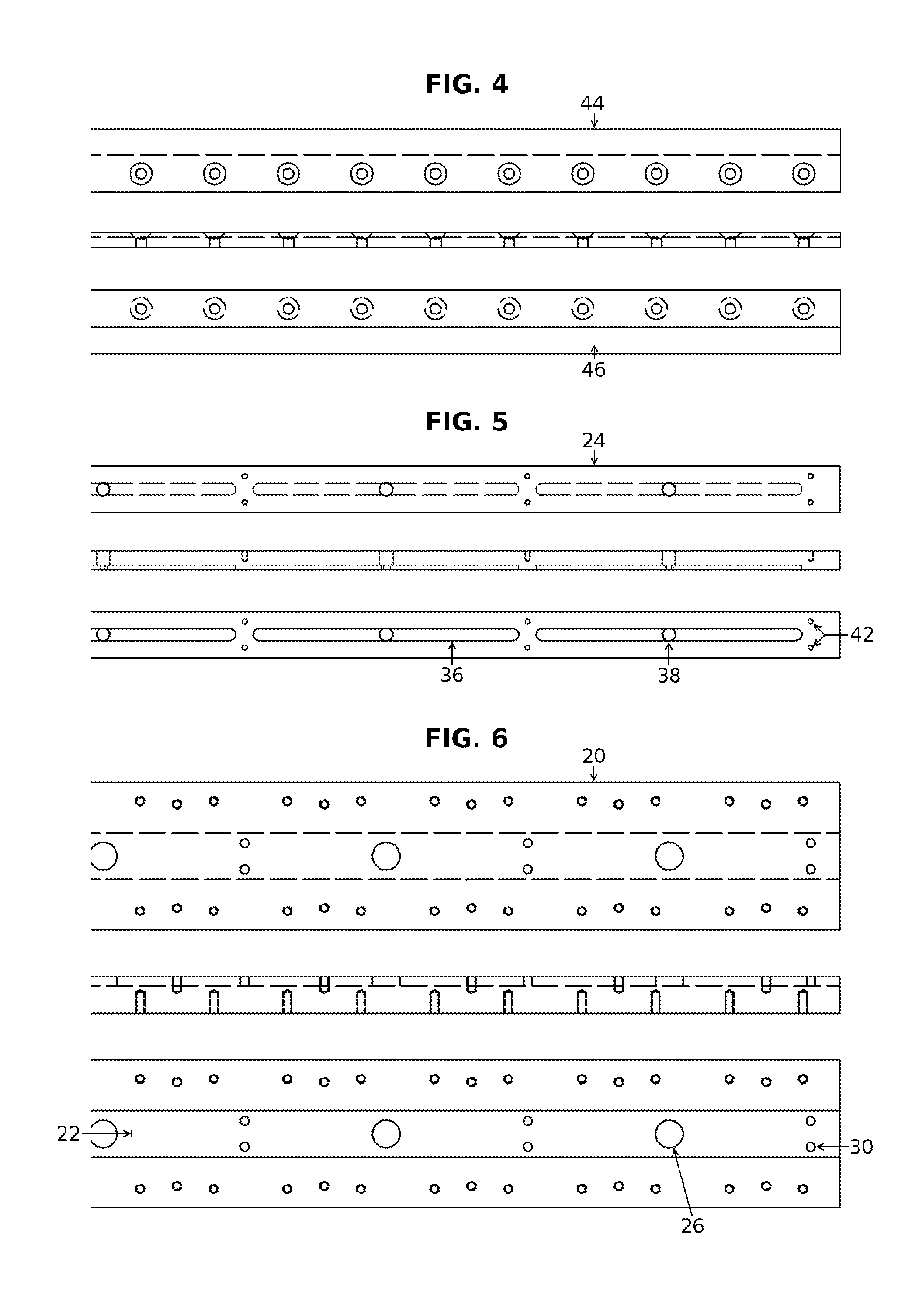

Inverted Vacuum Belt Conveyor System

ActiveUS20160096685A1High current-carrying capacitySave time and materialConveyorsEngineeringConveyor system

This invention is a vacuum belt conveyor designed to operate inverted and move articles suspended from its lower side rather than laying on top. This is achieved by the use of a matching toothed drive roller and toothed belt having its teeth facing outward and pierced between strategic teeth with vacuum cups secured through the holes. Vacuum is applied when needed to sections of a vacuum rail spring loaded against the smooth inner surface of the belt, the rail having a machined vacuum groove in horizontal alignment with the holes in the belt to provide vacuum to the cups. The belt and suspended articles secured to it by suction are held to the main frame by two retaining rails having clearance allowing passage of the cups.

Owner:SHERWOOD BERNARD J

Inverted vacuum belt conveyor system

This invention is a vacuum belt conveyor designed to operate inverted and move articles suspended from its lower side rather than laying on top. This is achieved by the use of a matching toothed drive roller and toothed belt having its teeth facing outward and pierced between strategic teeth with vacuum cups secured through the holes. Vacuum is applied when needed to sections of a vacuum rail spring loaded against the smooth inner surface of the belt, the rail having a machined vacuum groove in horizontal alignment with the holes in the belt to provide vacuum to the cups. The belt and suspended articles secured to it by suction are held to the main frame by two retaining rails having clearance allowing passage of the cups.

Owner:SHERWOOD BERNARD J

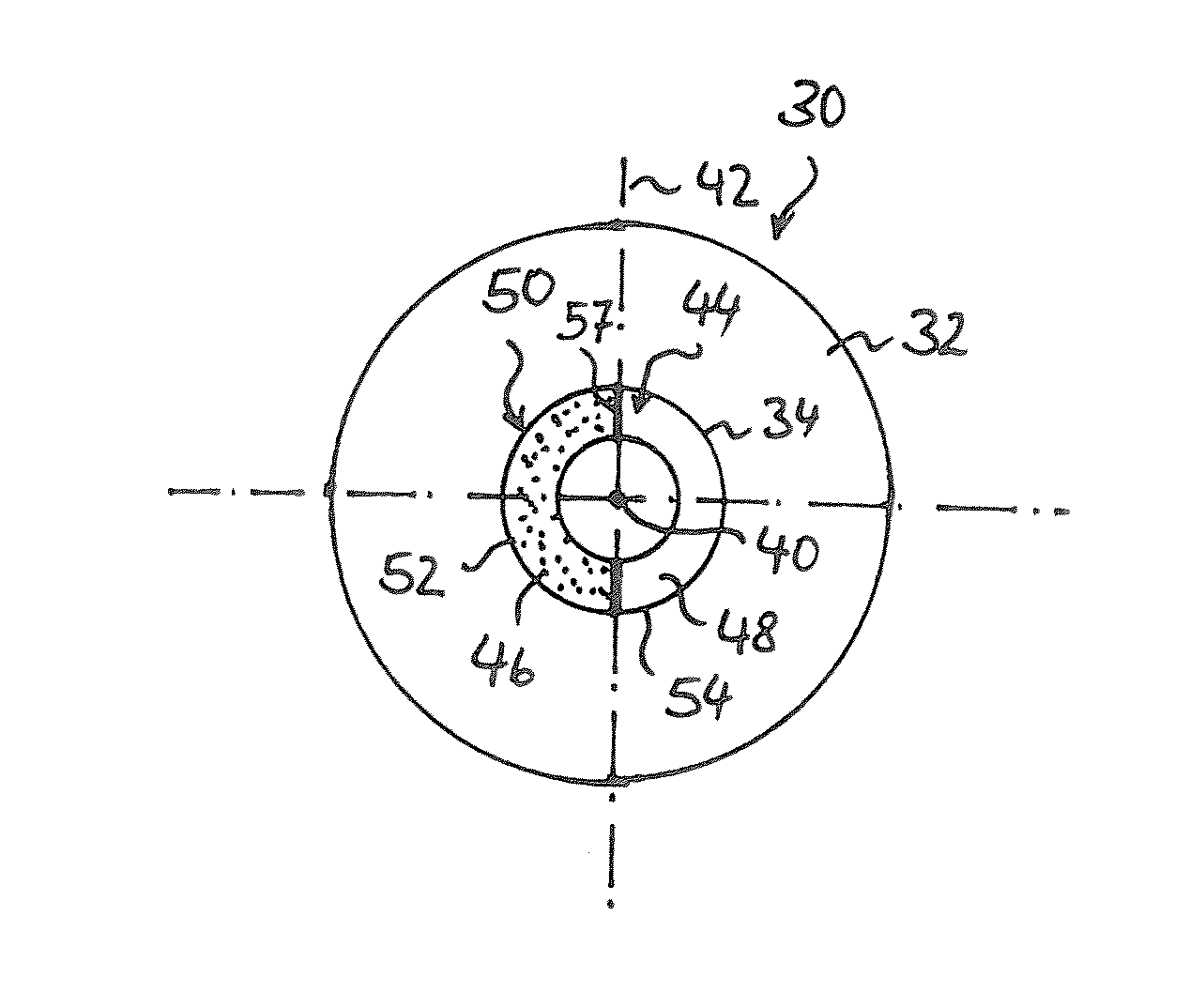

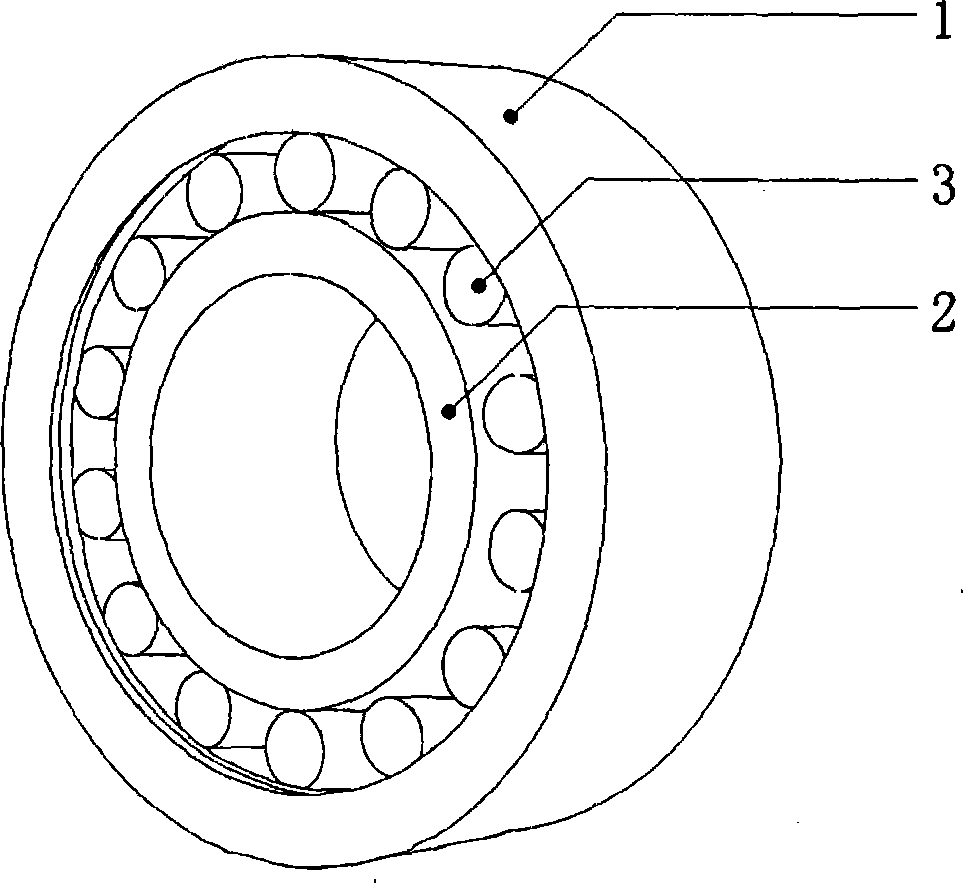

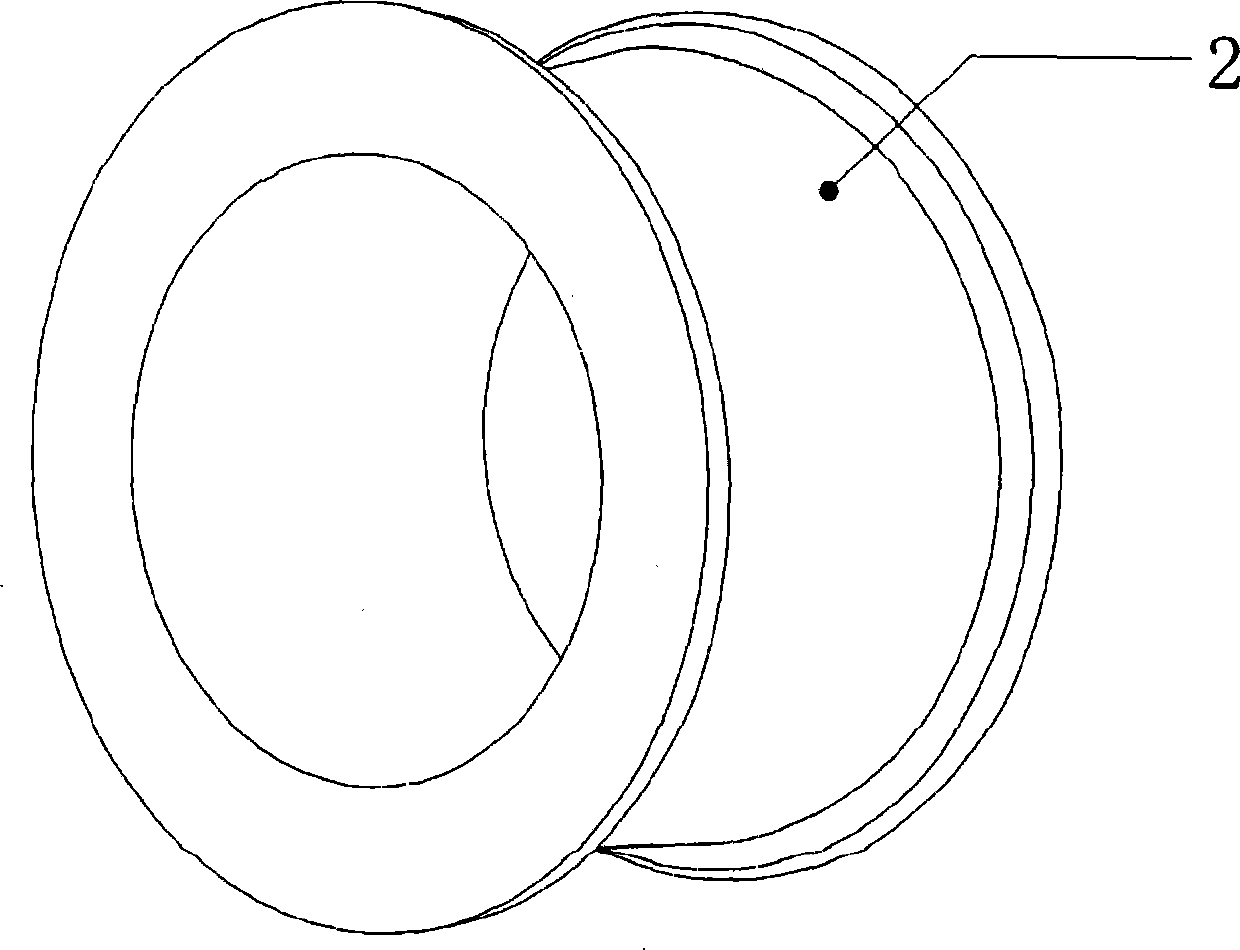

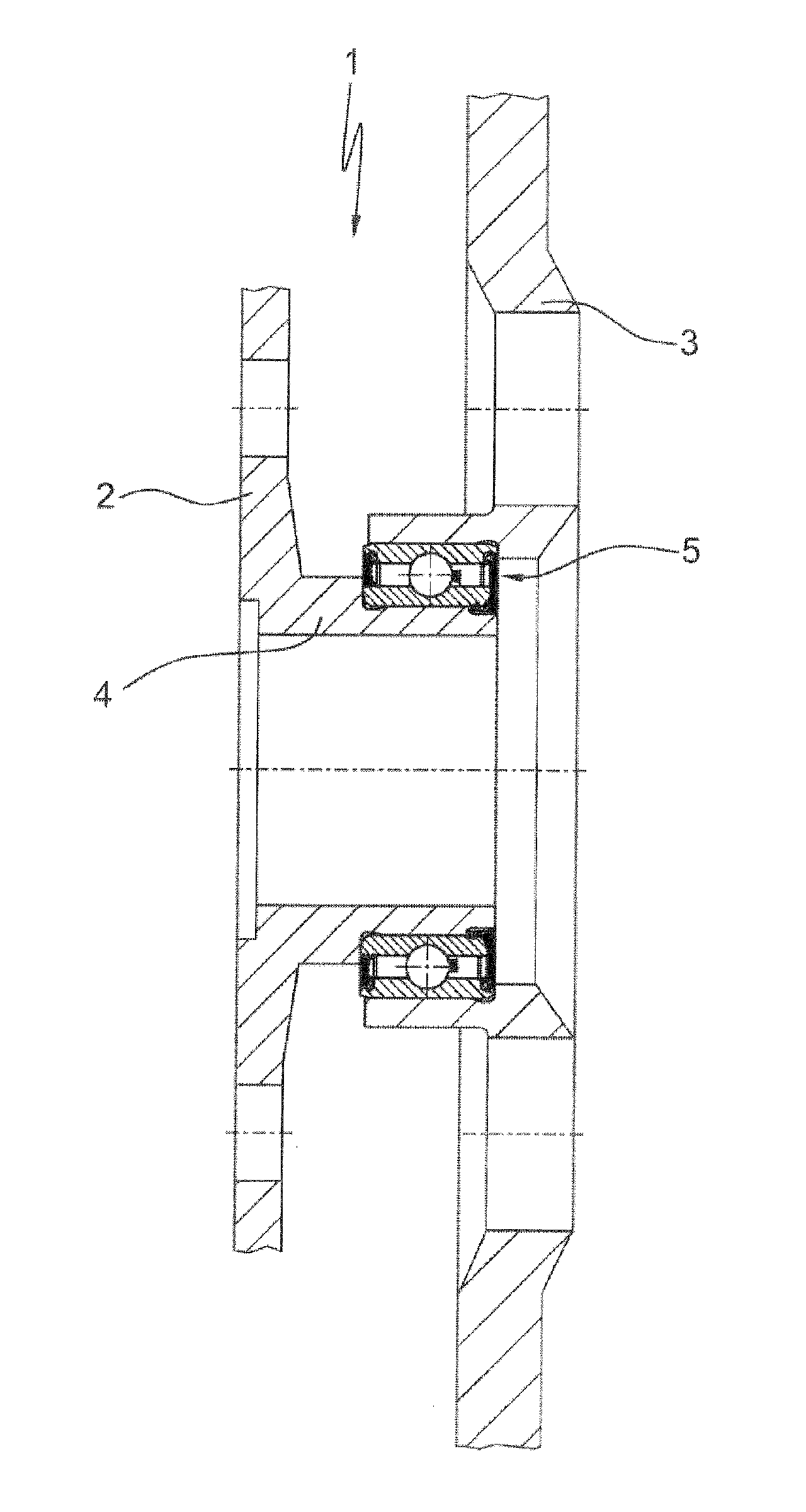

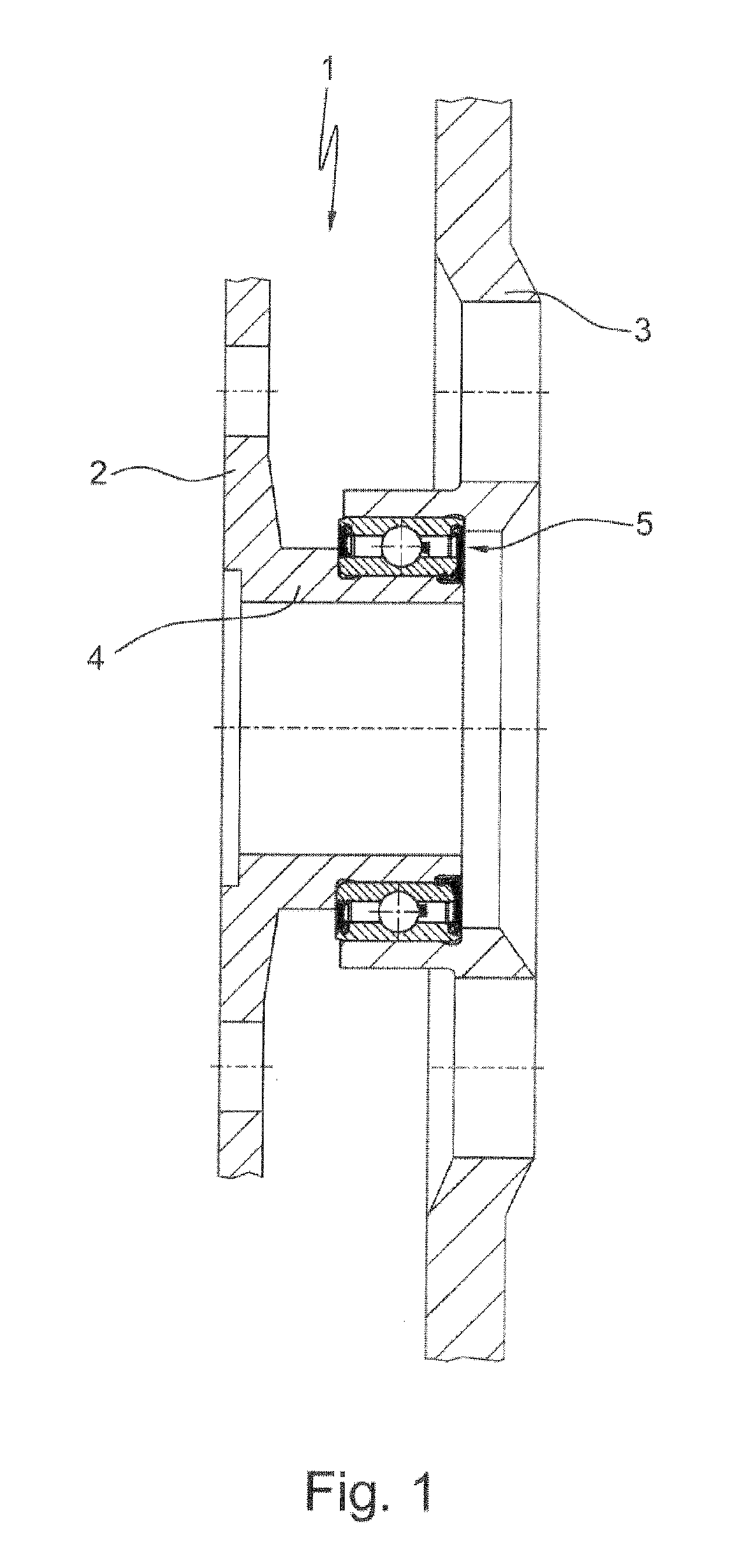

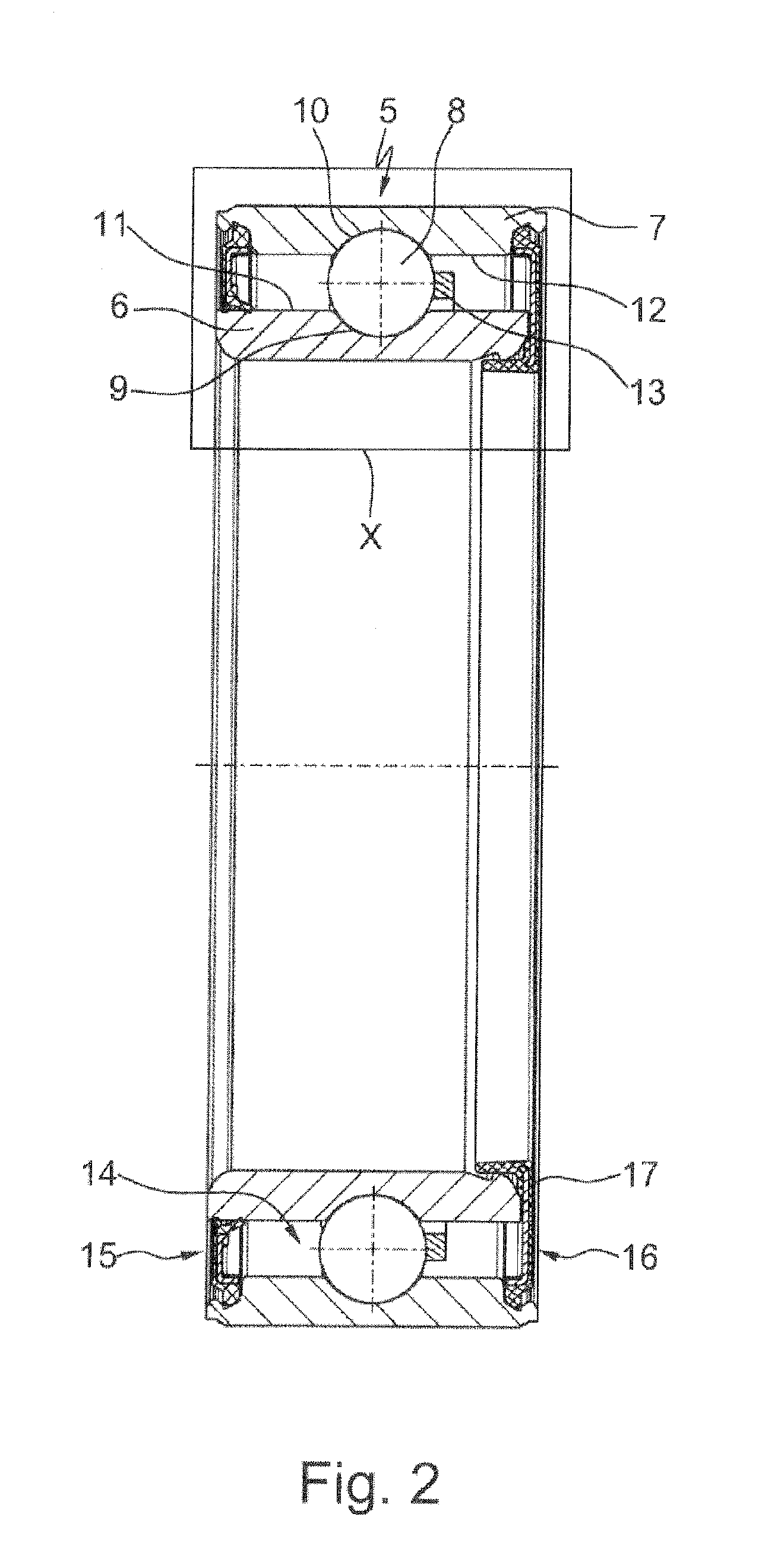

Rolling bearing, particularly single-row deep groove ball bearing for a dual mass flywheel in a motor vehicle

InactiveUS20120114278A1Reduce friction surfaceNo wearBall bearingsBearing componentsBall bearingEngineering

A single-row deep groove ball bearing made substantially of an inner ring and an outer ring disposed coaxially thereto and balls disposed between the rings. The balls roll in deep groove tracks in an outer face of the inner ring and in an inner face of the outer ring, and the balls are held at equal distances to each other in the circumferential direction by a housing. The interior of the bearing is sealed by two circular ring-shaped seals axially opposite each other. At least one of the seals is a lip seal, which has an angular profile. A shape-stable radial seal leg of the seal is attached to the outer ring and forms a gap seal with an axial side of the inner ring, and a sealing lip, which is an overpressure valve, is disposed under the inner ring and slidingly contacts the inner face of the inner ring.

Owner:SCHAEFFLER TECH AG & CO KG

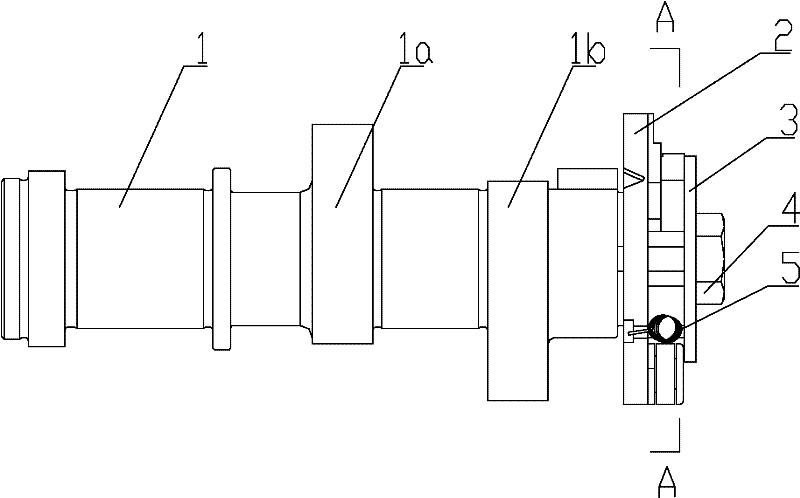

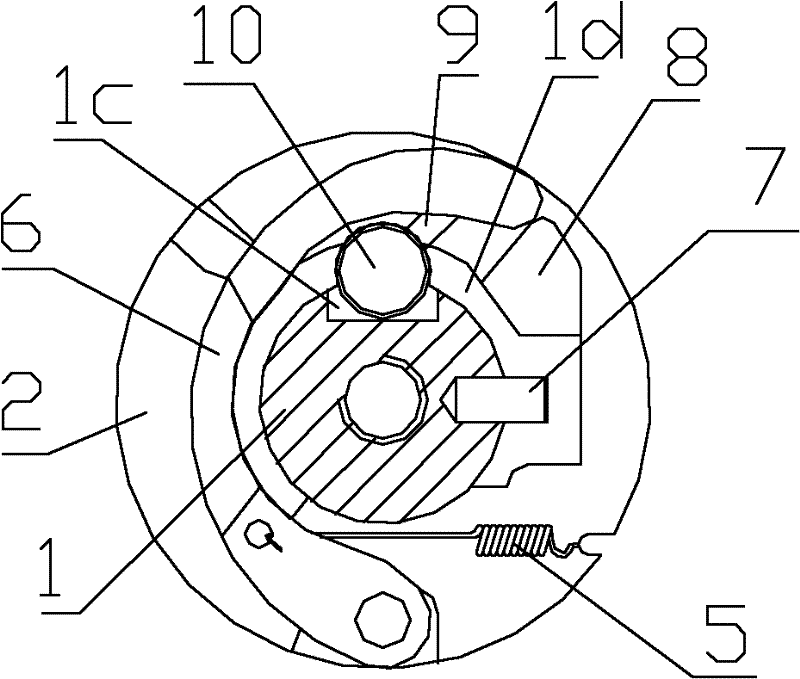

Engine camshaft assembly and motorcycle

InactiveCN102226417AReduce friction surfaceFlexible movementValve arrangementsMachines/enginesDegrees of freedomEngineering

The invention relates to an engine camshaft assembly and a motorcycle. The assembly comprises a camshaft and a pressure relief assembly; a timing component and the pressure relief assembly are respectively positioned at two ends of the camshaft; the pressure relief assembly comprises a pressure relief valve body, a centrifugal block and a fastening bolt. The engine camshaft assembly provided by the invention has the following advantages: the pressure relief valve body is pressed tightly and fixed through a bolt, a compression base plate, a flange on the pressure relief valve body and a shaft shoulder on the camshaft, the compression contact area of the flange can be increased, the reliability of fastening is ensured, the axial degree of freedom of the pressure relief valve body is restricted, and simultaneously the circumferential degree of freedom of the pressure relief valve body also can be limited to a certain extent; by virtue of the circumferential direction limit structure of the pressure relief valve body, the operation reliability of the pressure relief assembly is ensured; the mounting structure has high integration, the positioning effect is also good, and the mounting errors can be avoided better; and simultaneously the pressure relief valve body can bear, transmit and counteract the rotary inertia force and impact loading generated by the high-speed rotation of an engine, the fatigue and crack phenomena do not occur, and the service life is ensured.

Owner:CHONGQING LONCIN MOTOR

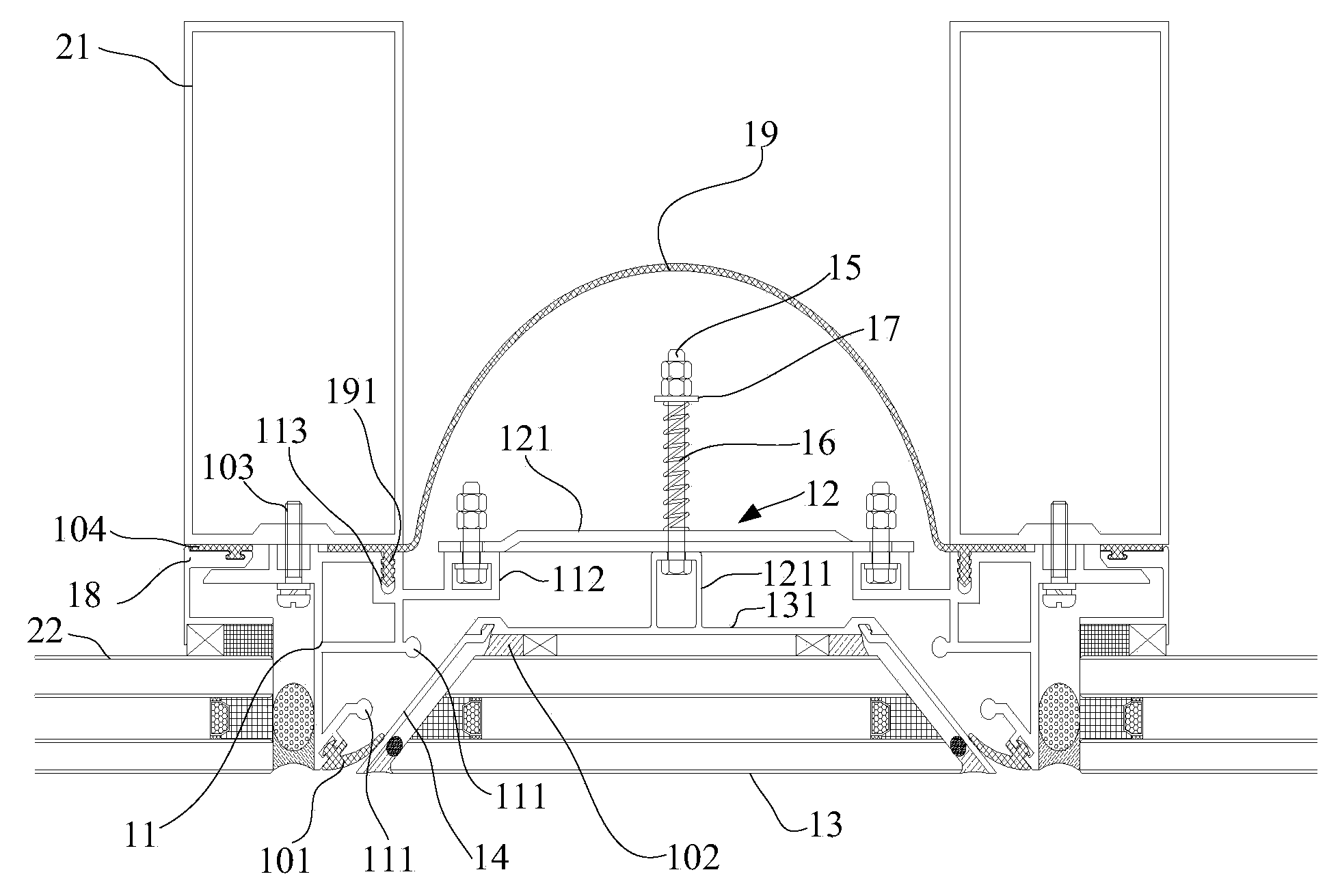

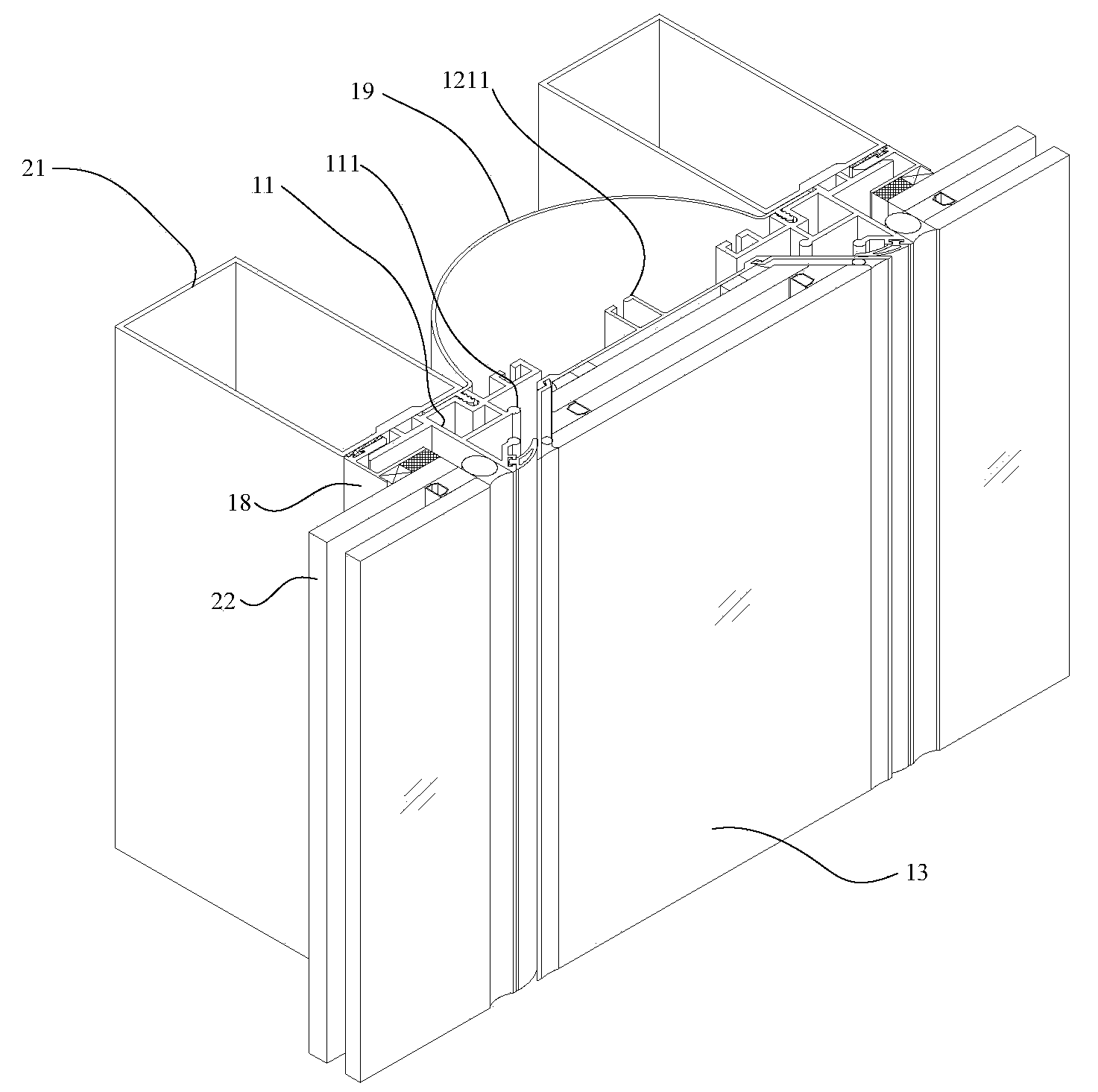

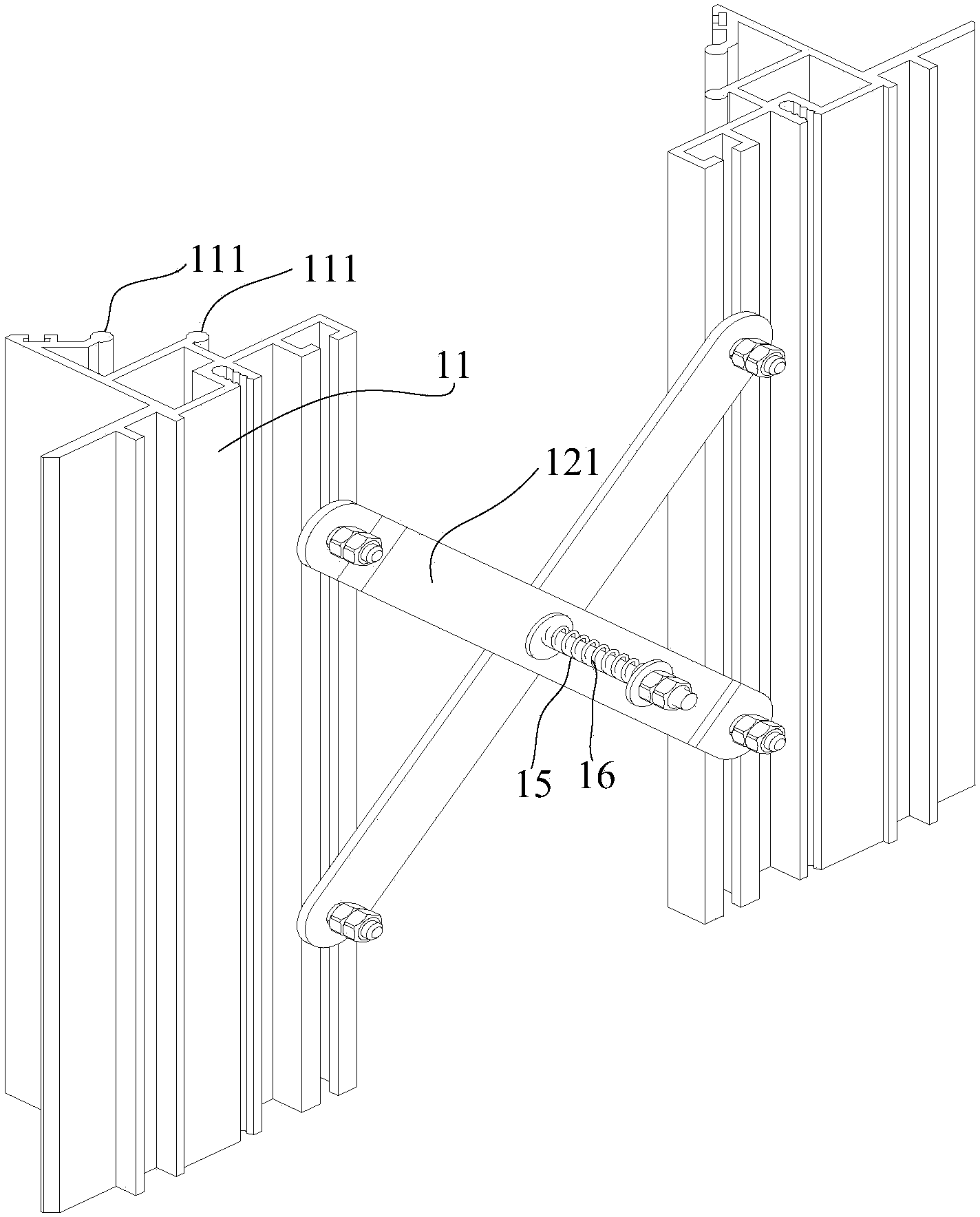

Curtain wall expansion joint structure and curtain wall employing same

The invention discloses a curtain wall expansion joint structure and a curtain wall employing the curtain wall expansion joint structure, relating to the technical field of curtain walls. The curtain wall expansion joint structure is used for solving the problem of expansion joint structures of glass curtain walls in the prior art that a glass panel is inconveniently to move outwards due to the fact that the friction face between a glass retaining edge and a fixing frame is relatively large. The curtain wall expansion joint structure comprises the fixing frame, wherein the fixing frame is fixedly connected with a connecting member, the glass panel is arranged at the inner side of the fixing frame, the surface of the glass panel is covered with the glass retaining edge, and spherical bulges are formed on the surface, opposite to the glass retaining edge, of the inner side of the fixing frame; the surface, close to the connecting member, of the glass panel is connected with a first connecting unit; a bolt is arranged in the first connecting unit in a penetrating manner, penetrates through the connecting member and fixedly connects the glass panel with the connecting member; an anti-seismic spring sleeves the threaded portion of the bolt, and a retaining member is arranged at the end part of the threaded portion of the bolt and is used for limiting the anti-seismic spring. The curtain wall expansion joint structure is applied to the glass curtain walls.

Owner:CCDI INT SHENZHEN DESIGN CONSULTANTS

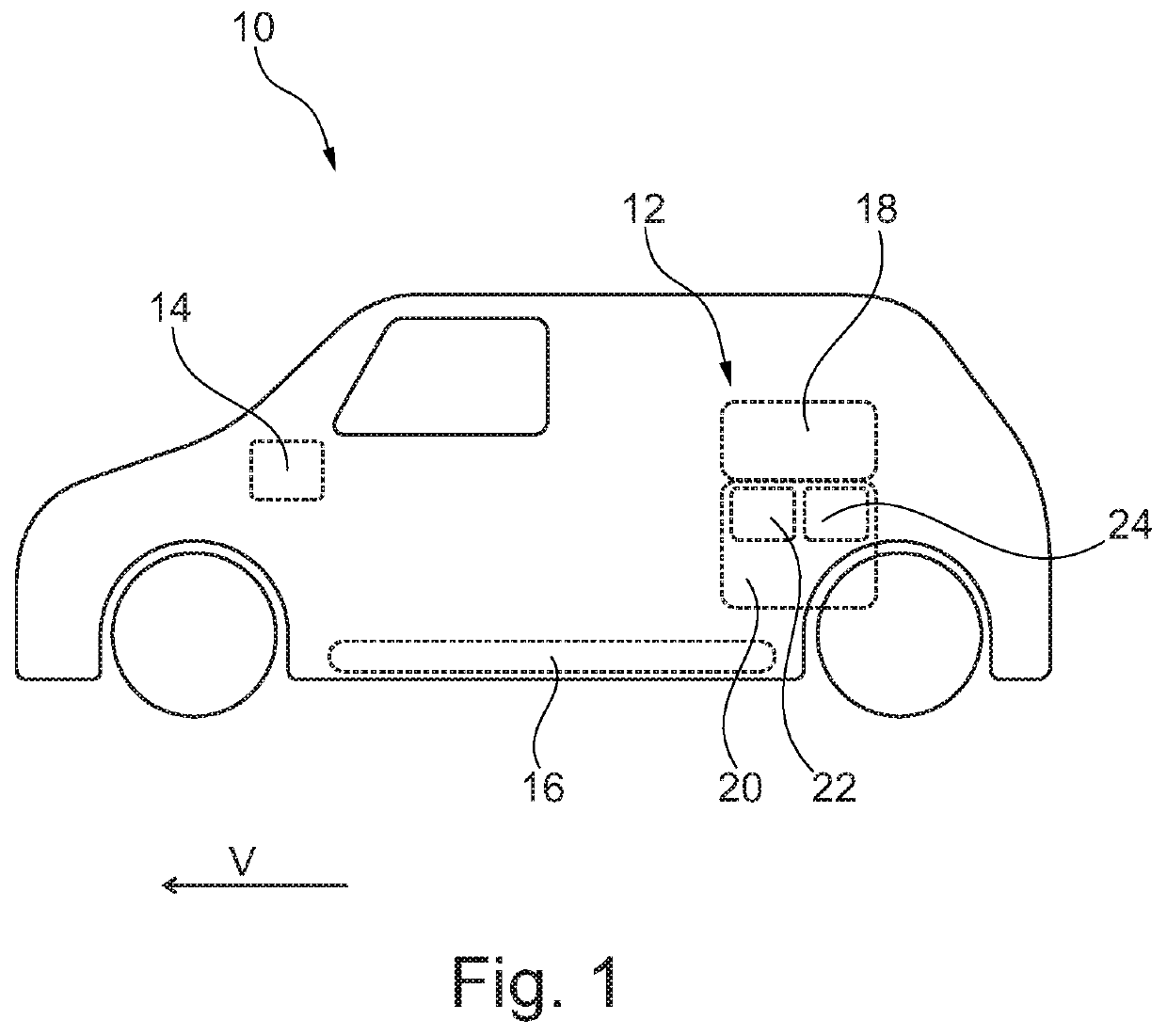

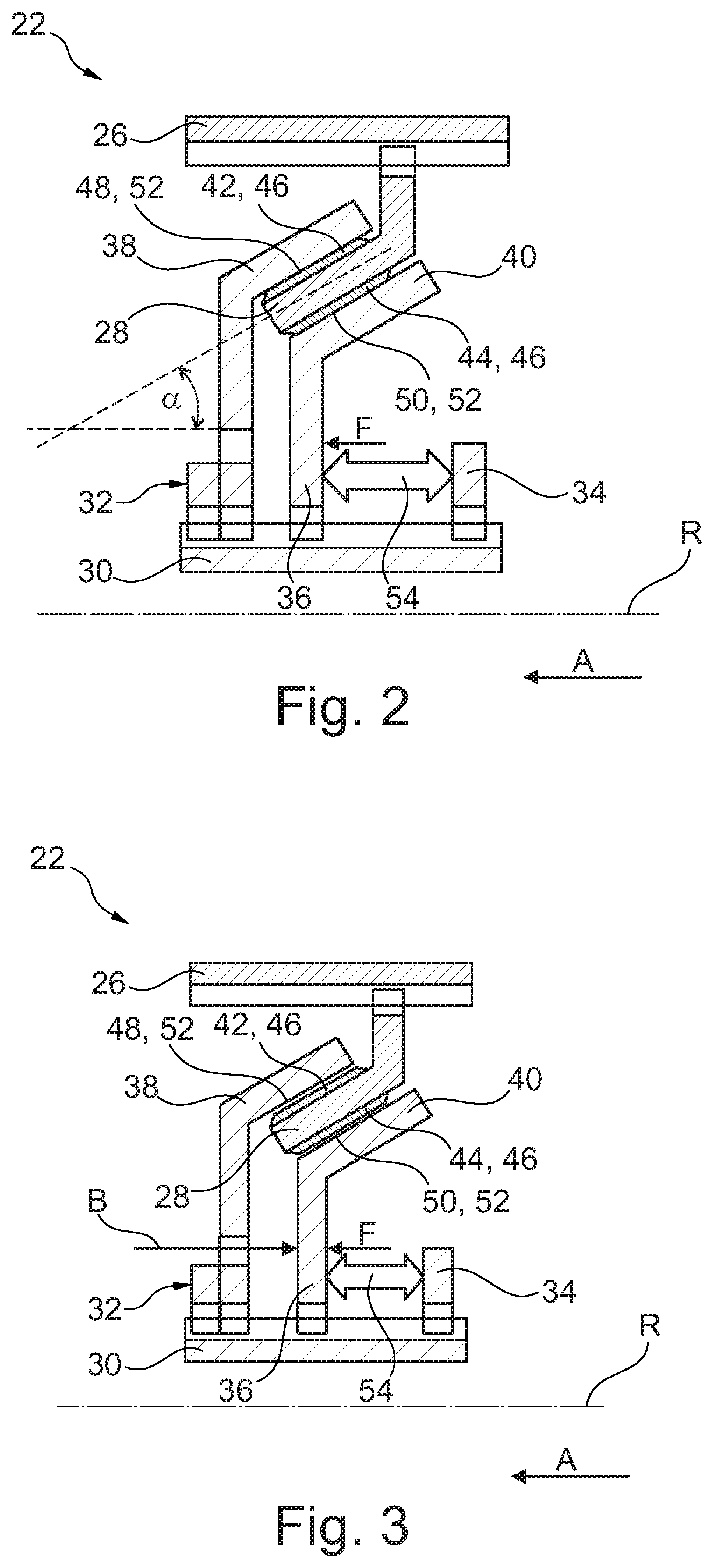

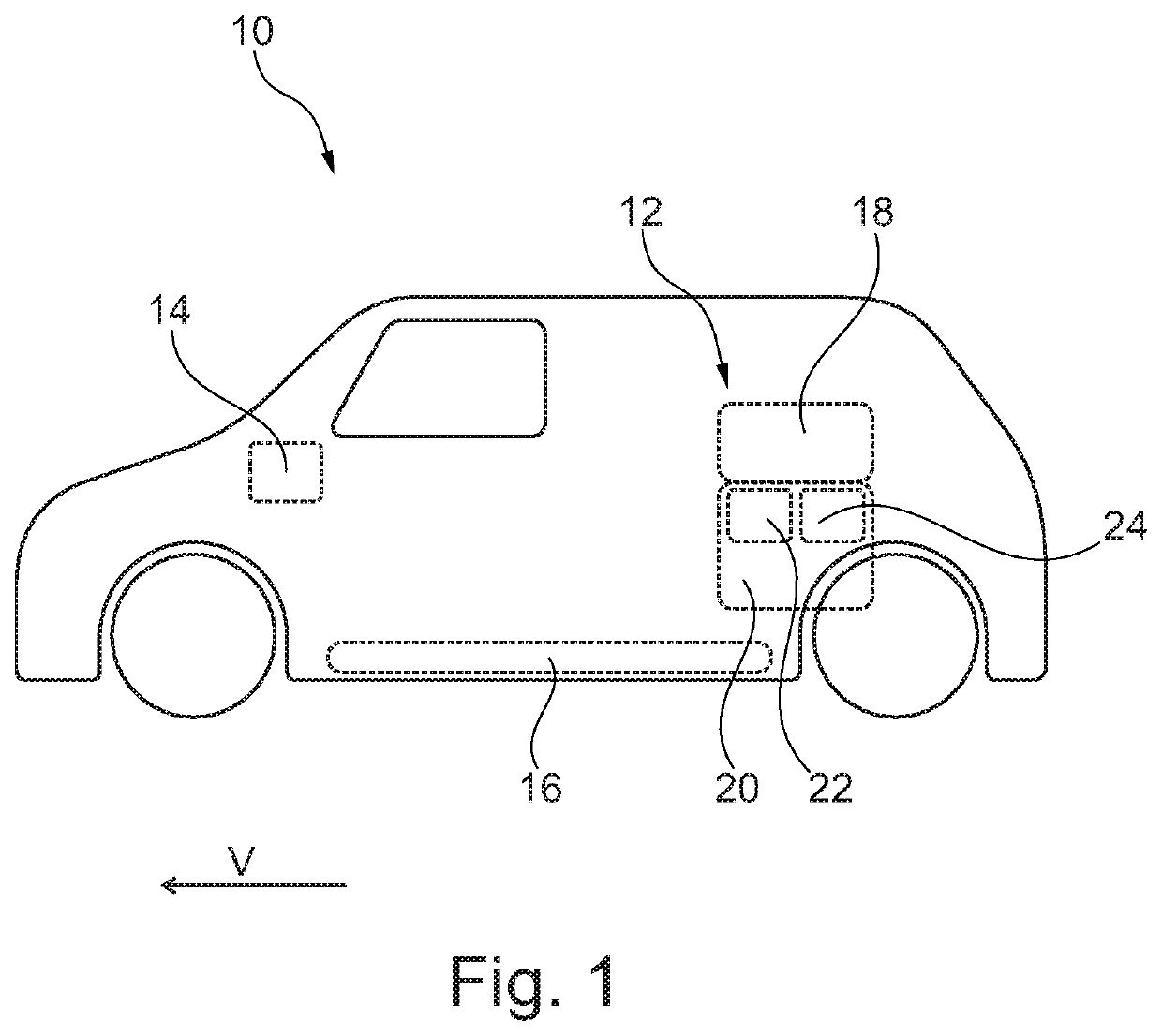

Drivetrain of an electrically driven vehicle and electrically driven vehicle

ActiveUS11015658B2Increase rangeReduce the numberFriction clutchesFriction liningDrivetrainElectric cars

Electrically driven vehicle including a drivetrain with an electric motor which forms the drive of the vehicle, and a frictionally engaging clutch. The clutch is a normally closed clutch with conical friction elements, which rest against each other in pairs in a closed position and transmit torque.

Owner:HOERBIGER ANTRIEBSTECHN HLDG

Drivetrain of an electrically driven vehicle and electrically driven vehicle

ActiveUS20200049205A1Increase rangeReduce the numberFriction clutchesFriction liningDrivetrainElectric cars

A drivetrain of an electrically driven vehicle has a frictionally engaging normally closed clutch with conical friction elements, which rest against each other in pairs in a closed position and transmit torque. In addition, an electrically driven vehicle with such a drivetrain is provided.

Owner:HOERBIGER ANTRIEBSTECHN HLDG

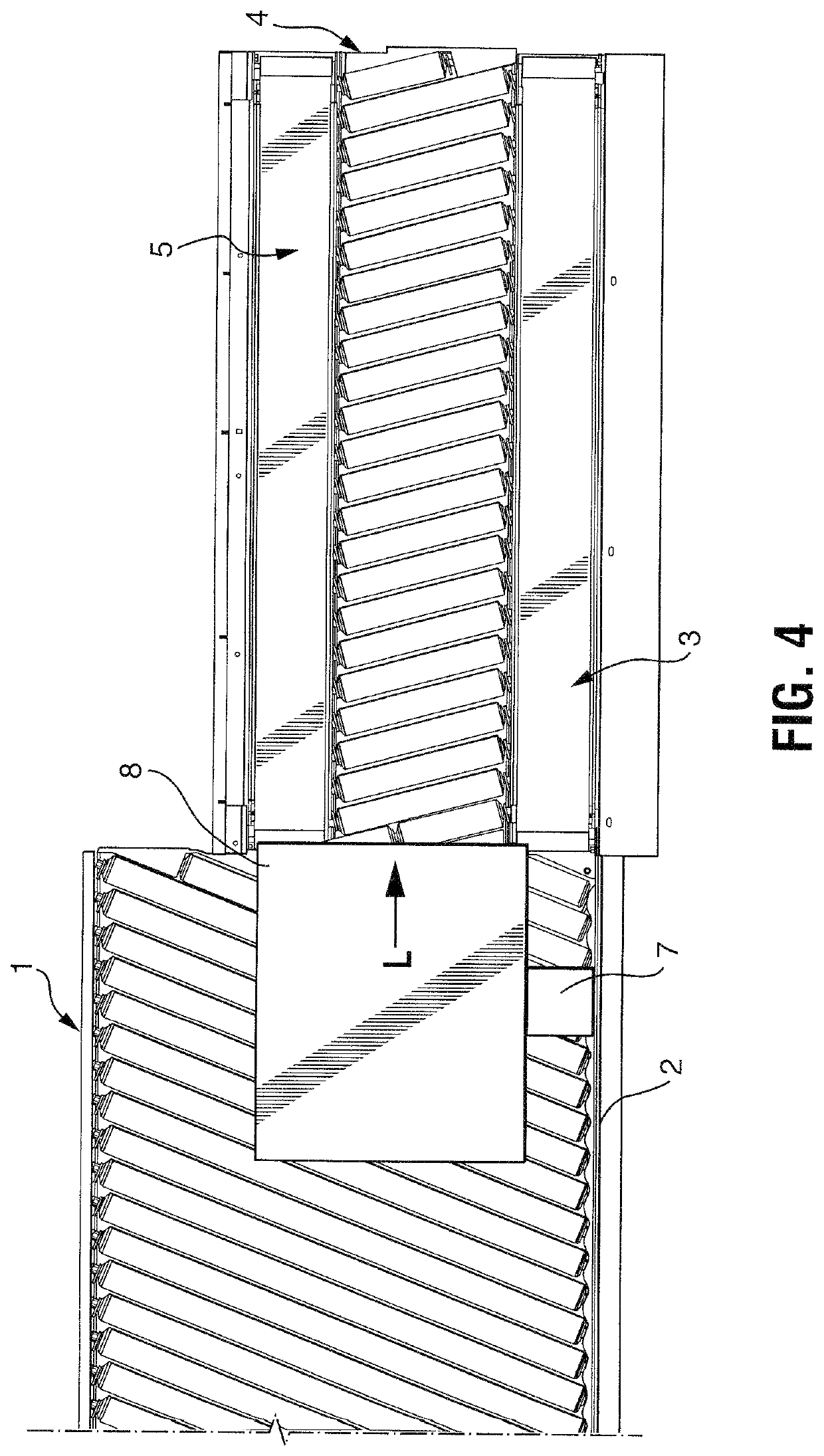

Singulator conveyor assembly for separating parcels

A singulator conveyor system having conveying surfaces arranged in adjacent parallel configuration for separating and moving side by side packages. The singulator includes a first conveyor conveying lane having a high friction surface for conveying articles forward along a vertical side wall. A second conveyor conveying lane adjacent thereto has a lower friction surface including both forward and lateral conveying forces urging parcels forward and away from the first conveyor conveying lane and side wall. The lateral receiving edge of the second conveyor conveying lane is below the outer lateral edge of the first conveyor conveying lane and the conveying surface is transversely inclined and angled laterally upward having an elevated outer side edge even with or below the lateral receiving edge of an adjacent third conveyor conveying lane having a high friction conveying surface. The conveying surface of the second conveyor forms an inclined plane extending above an inner receiving side edge of the adjacent third conveyor conveying lane.

Owner:FIVES INTRALOGISTICS SA

Singulator conveyor assembly for separating parcels

ActiveUS10583999B2Increase frictionReduce frictionConveyor partsRoller-waysClassical mechanicsStructural engineering

Owner:FIVES INTRALOGISTICS SA

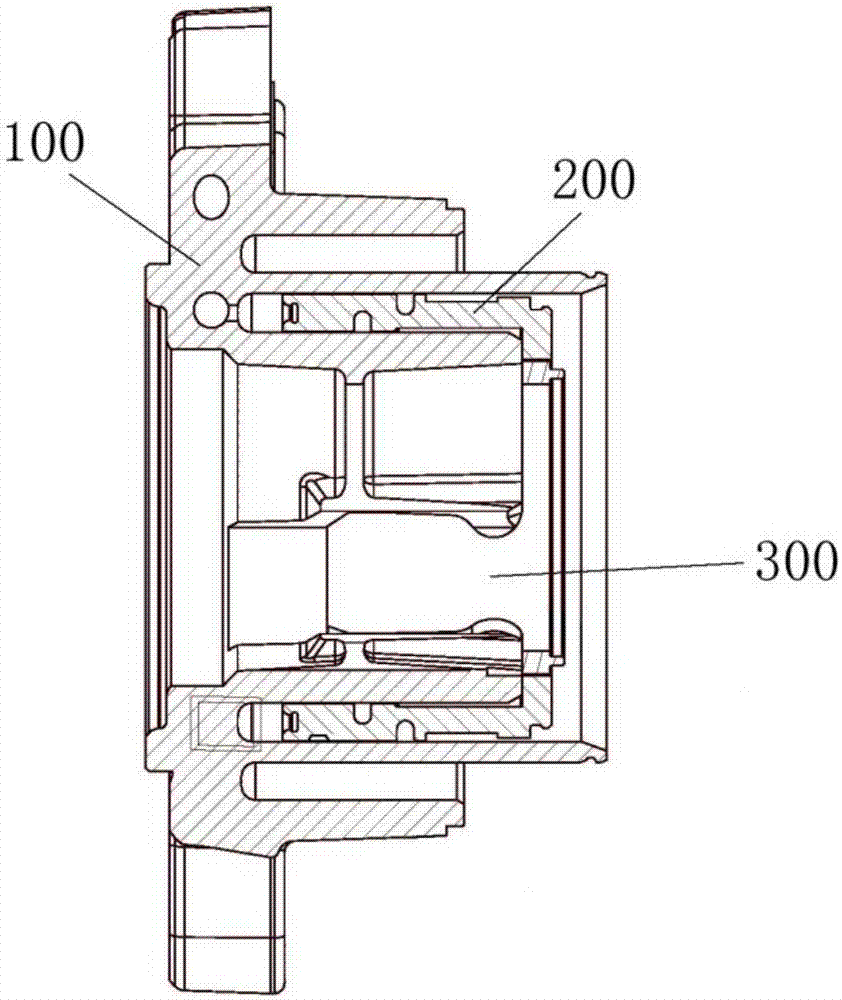

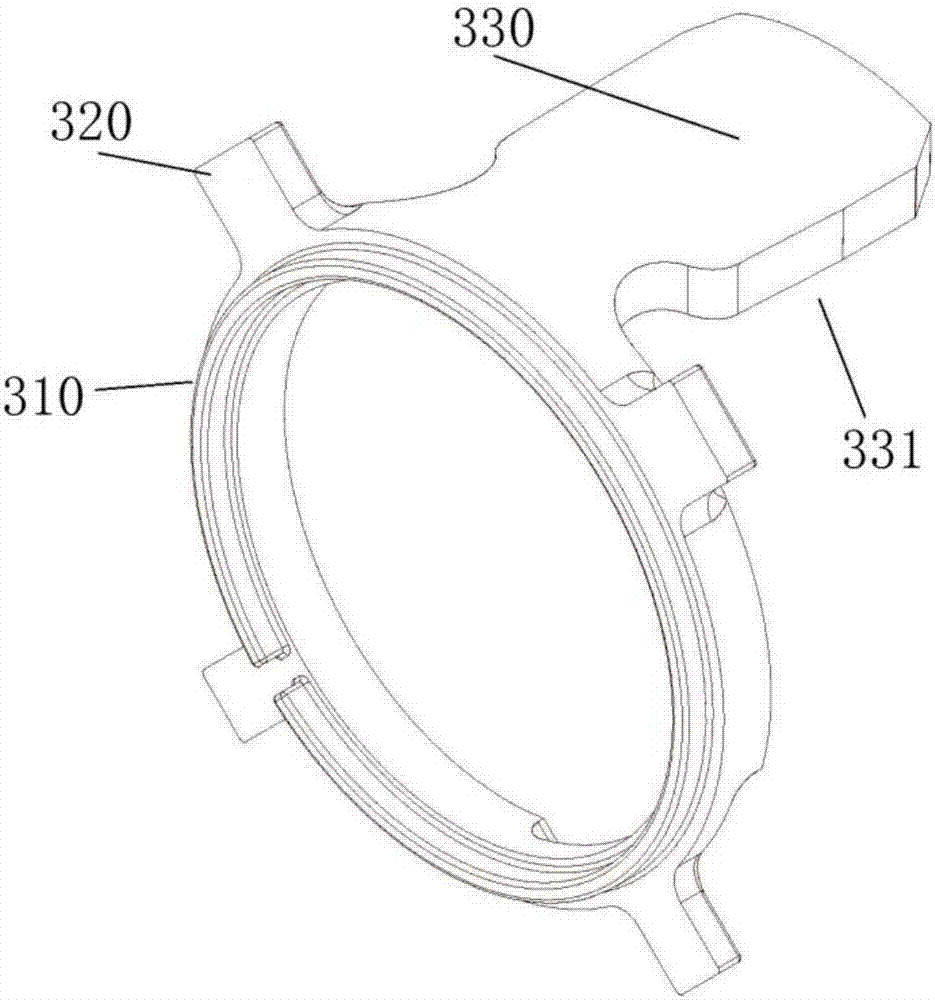

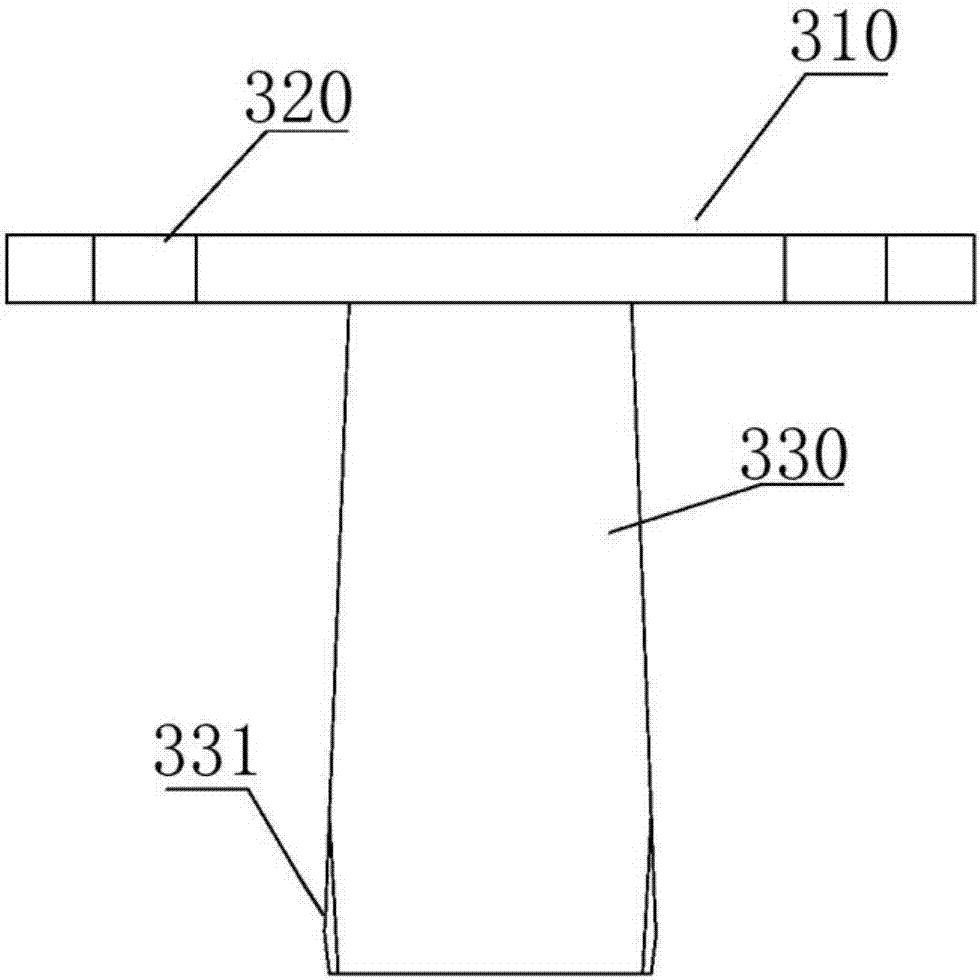

Locking ring for release bearing

PendingCN107013602AExtended service lifeNo costMechanical actuated clutchesBearing componentsFriction reductionMechanical engineering

The invention provides a locking ring for a release bearing. The locking ring comprises a ring-shaped connecting ring, a clamping lug and a lock tongue, wherein the clamping lug extends outwards along the radial direction of the outer edge of the connecting ring, and the lock tongue is vertical to the plane with the connecting ring and axially extends; the clamping lug is clamped into a corresponding clamping groove of a sliding sleeve of the release bearing, and the lock tongue is inserted into a corresponding lock groove in a shell of the release bearing. The locking ring has the advantages of simple structure and convenient processing and can further increase the lubrication level and reduce frictional loss on the basis of effectively avoiding radially rotating among the parts of the release bearing, and thus the service life of the release bearing is prolonged.

Owner:福缔汽车(太仓)有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com