Rotor for rotation type displacement pump

A positive displacement pump, rotary technology, applied in the field of positive displacement pumps, can solve the problems that the rotor is easily stuck in the pump body, affects the delivery work of the positive displacement pump, reduces the service life of the positive displacement pump, etc., achieves simple structure, improved service life, and easy processing Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

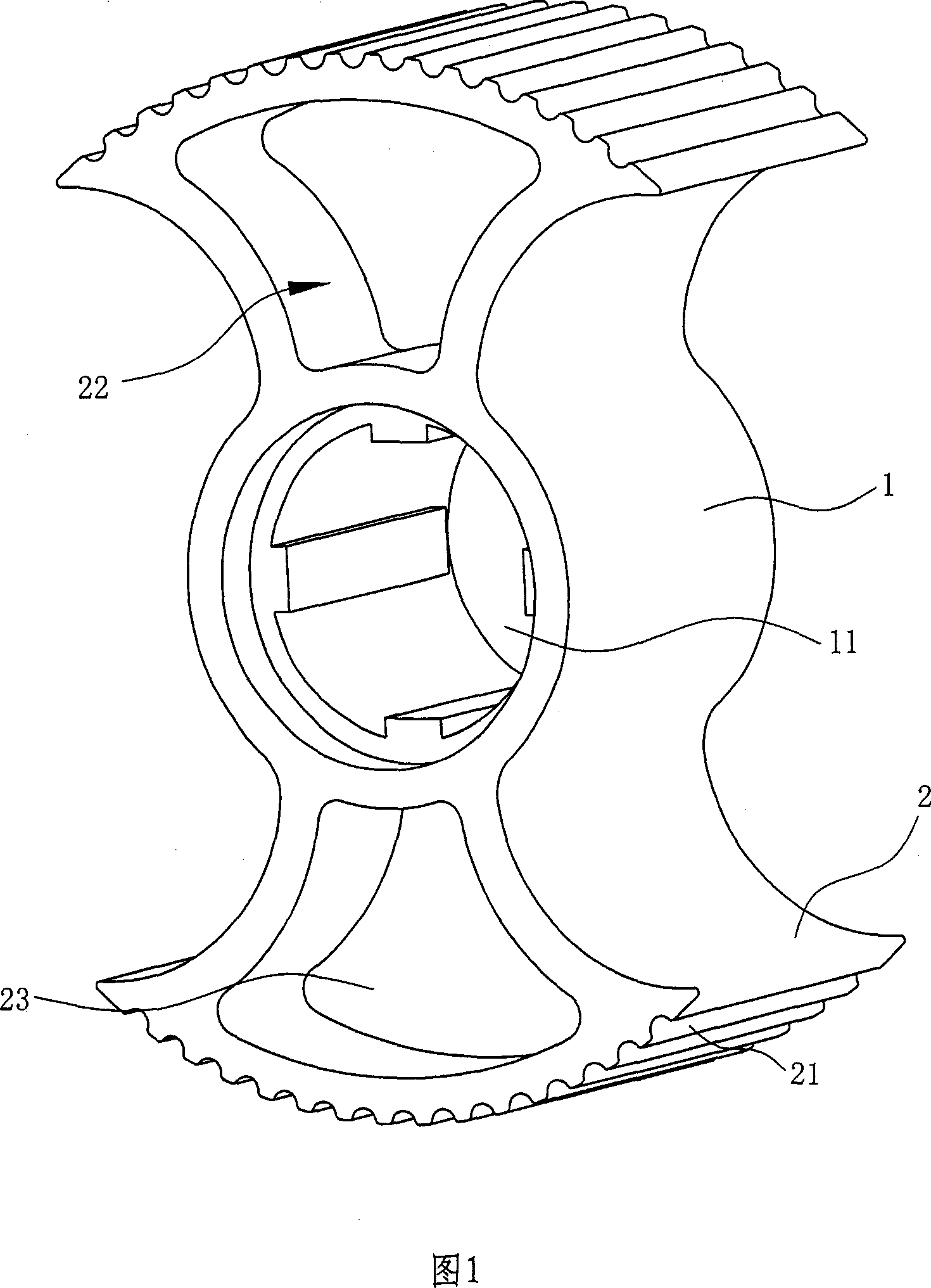

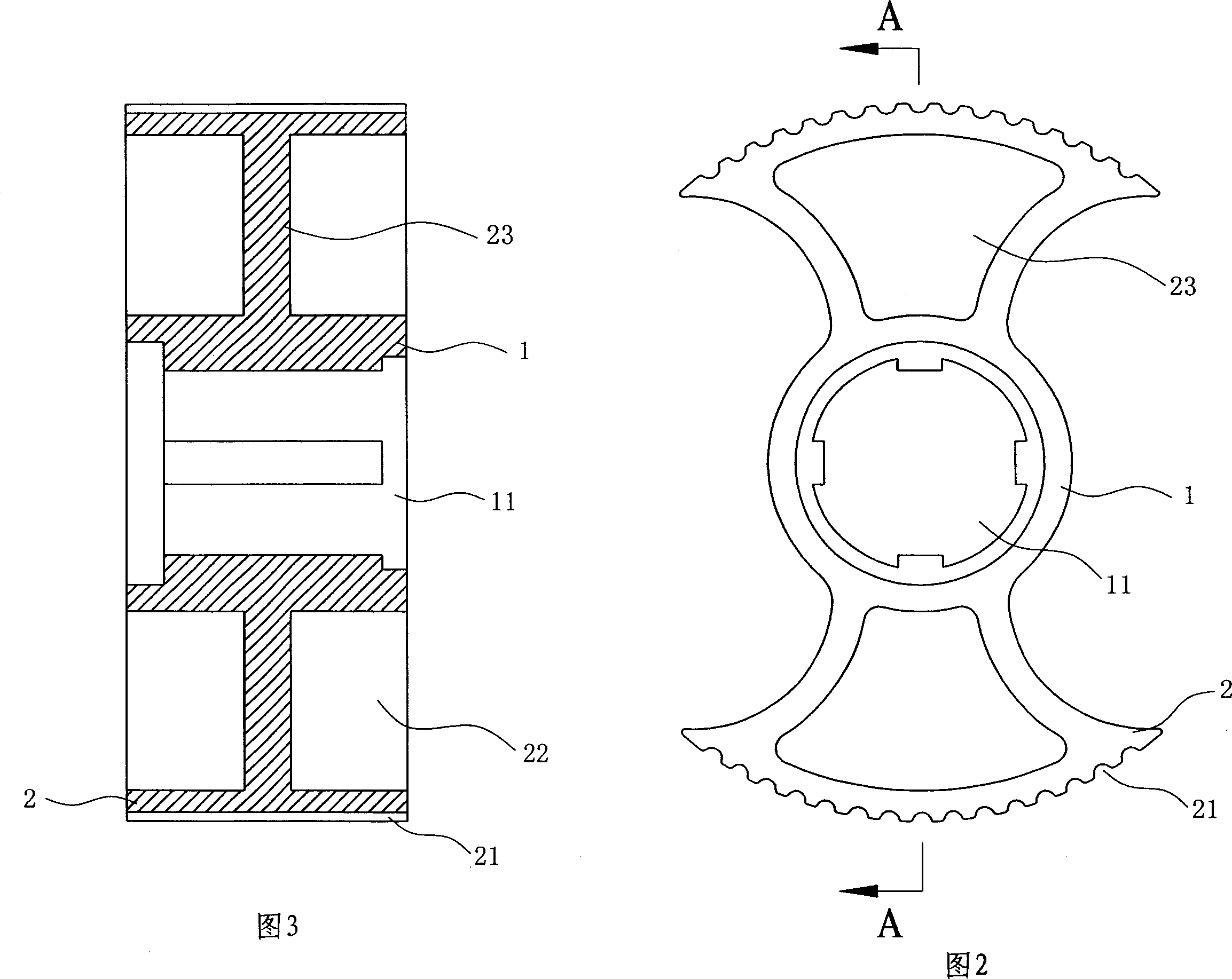

[0014] As shown in Figures 1 to 3, the rotor for a rotary positive displacement pump includes a body 1 with a shaft hole 11 in the center and blades 2 symmetrically centered on the shaft hole 11. In this embodiment The blade 2 is provided with two pieces;

[0015] Wherein, the end surface of the blade 2 is provided with a plurality of grooves 21 parallel to the axial direction of the rotor, and the cross section of the grooves 21 is semicircular;

[0016] Moreover, the blades 2 are provided with concave cavities 22 on both sides tangential to the axial direction of the rotor, and the corresponding concave cavities 22 on both sides cooperate to naturally form a partition wall 23 to separate the blades 2 from front to back. .

[0017] When working, the rotor is driven by the main shaft pierced in the shaft hole 11, and rotates in the pump body...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com