Center-shaft-type cylindrical roller bearing

A cylindrical roller bearing and cylindrical roller technology, applied in the field of machinery, can solve the problems of high noise, low safety factor and low speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

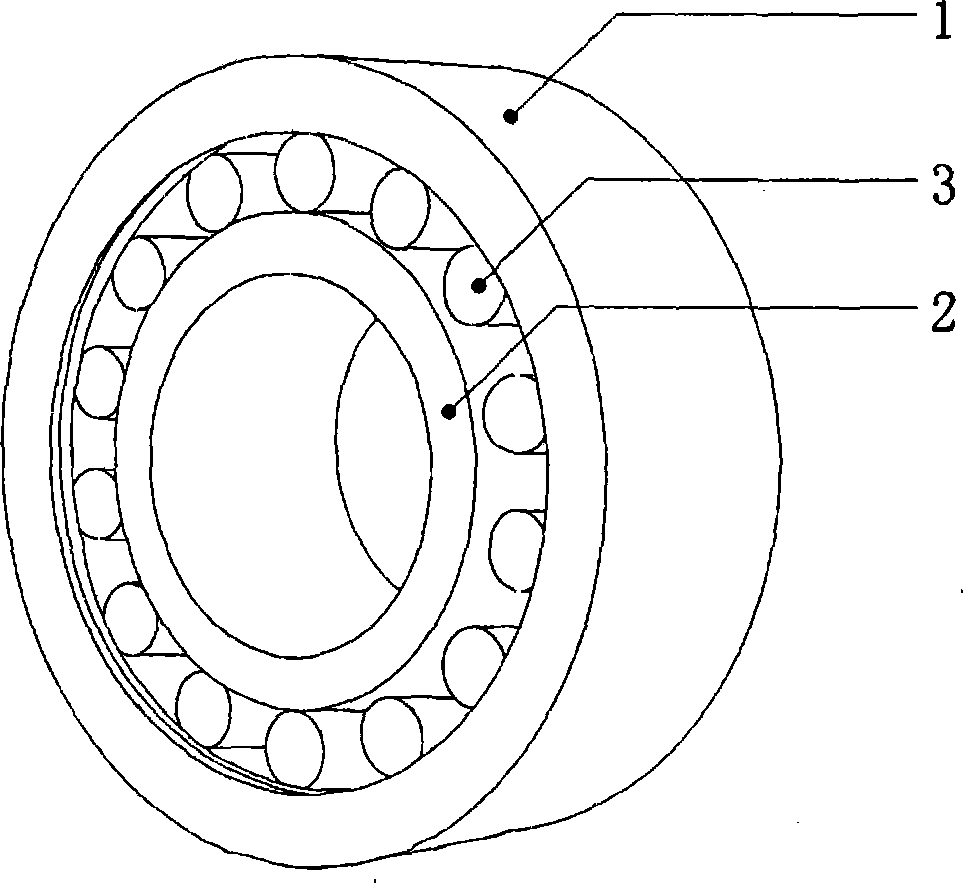

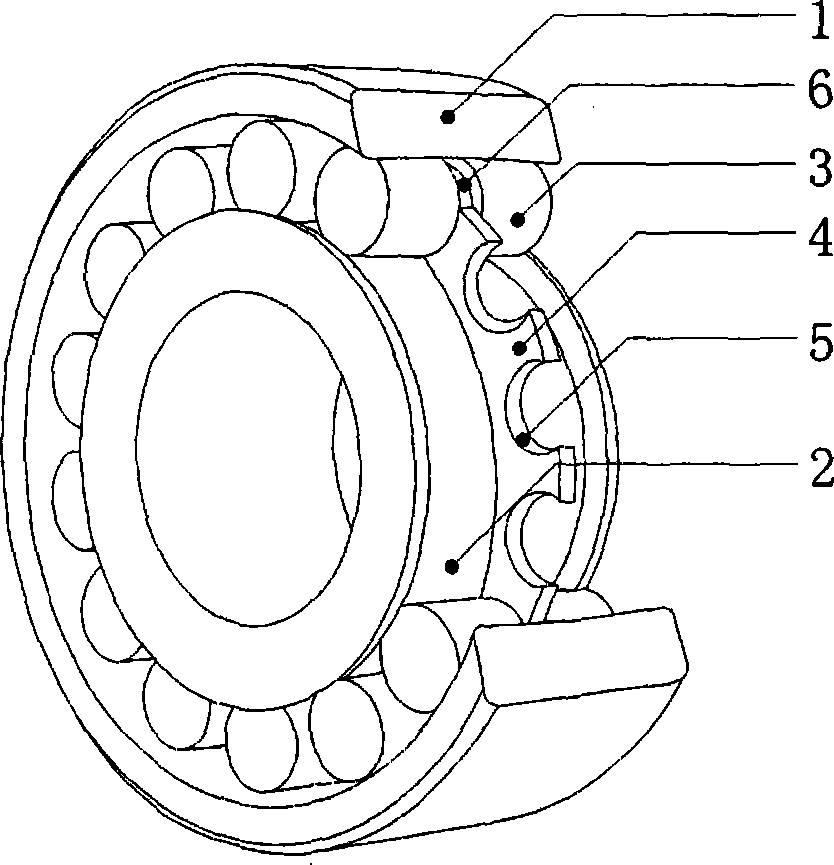

[0017] DETAILED DESCRIPTION OF THE PREFERRED EMBODIMENTS Inventing a central axis cylindrical roller bearing: specific examples figure 2 shown;

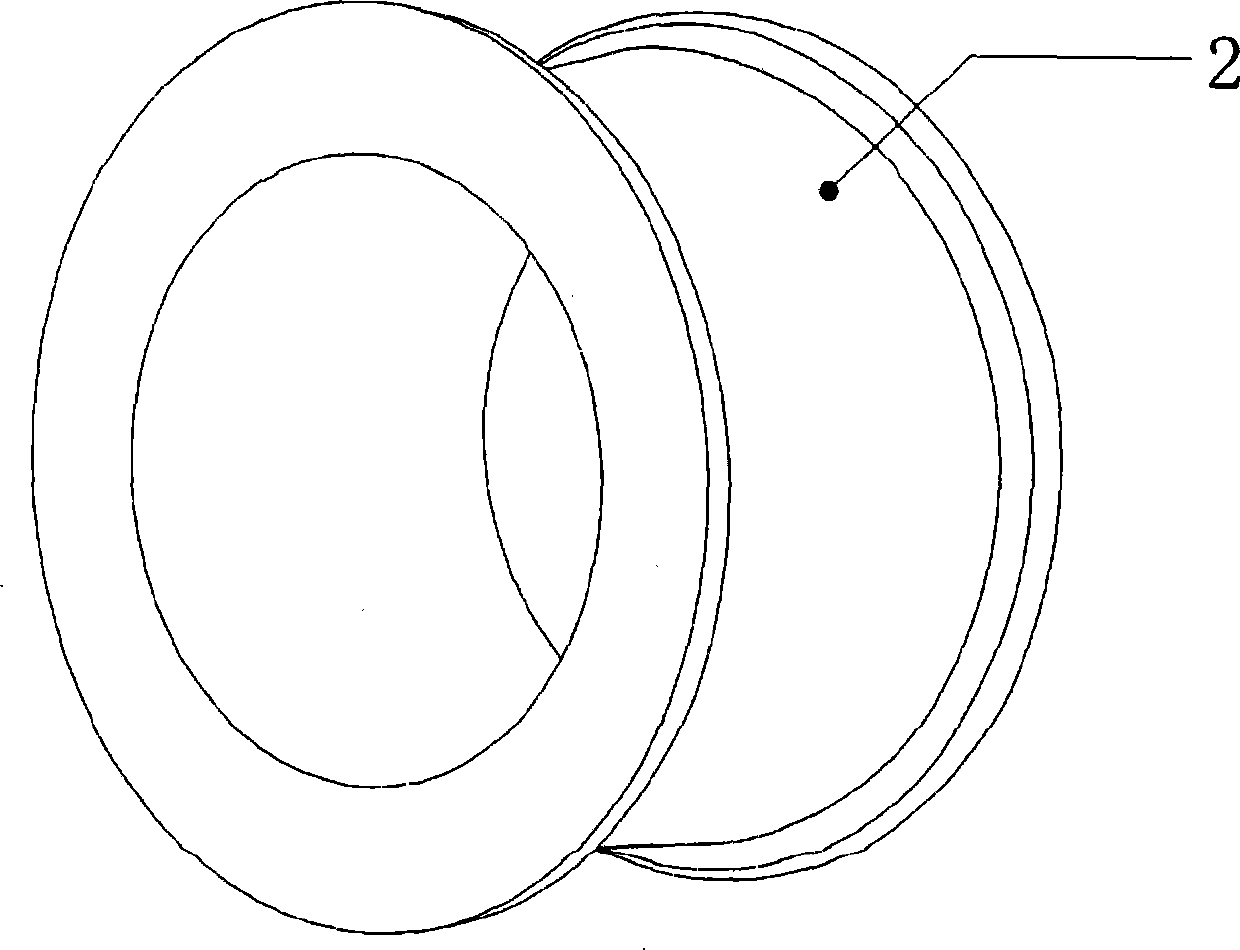

[0018] Installation steps: The outer circular raceway of the inner ring (2) is relatively matched with the annular C-shaped mouth cage (4) or (8), and the C of the C-shaped mouth shape cage (4) and (8) Insert the center shaft type cylindrical roller (3) on the shape mouth (5) or (9) to match it, then insert the inner ring (2) and the center shaft type cylindrical roller (3) to the inner hole of the outer ring Among them, the relative combination in the inner hole of (1) is figure 1 Bottom shaft cylindrical roller bearing shown here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com