Engine camshaft assembly and motorcycle

A camshaft and engine technology, applied to engine components, machines/engines, mechanical equipment, etc., can solve problems such as decompression body fatigue fracture, large rotational inertia force and impact load, increase maintenance frequency, etc., and reduce manufacturing difficulty Small size, improved load-bearing capacity, and flexible movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

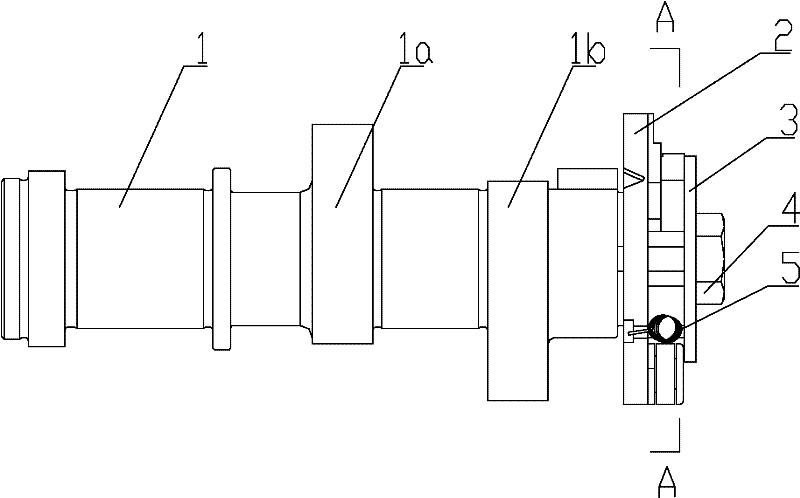

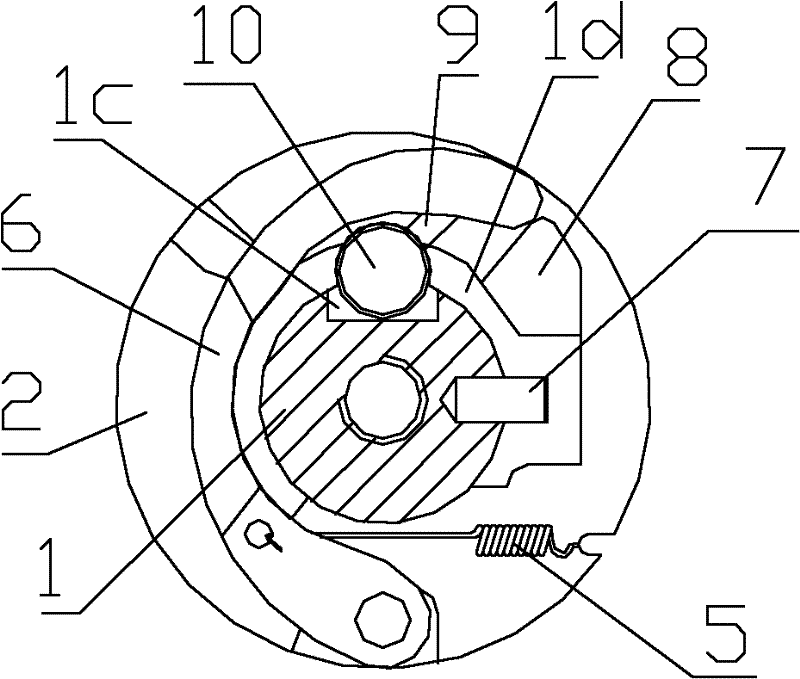

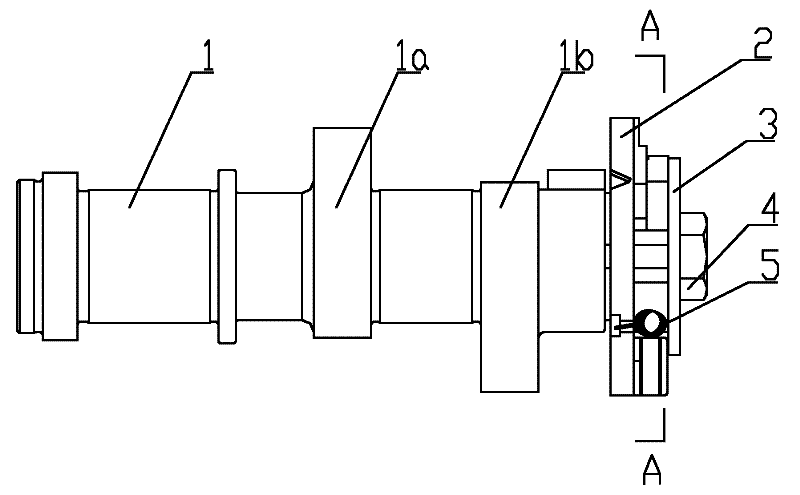

[0019] figure 1 It is a structural schematic diagram of the present invention, figure 2 based on figure 1 A sectional view along A-A, as shown in the figure: the engine camshaft assembly of this embodiment includes a camshaft 1 and a pressure reducing valve assembly, and the camshaft 1 is provided with an intake cam 1a and an exhaust cam 1b, the The pressure reducing valve assembly includes a pressure reducing valve body 2, a centrifugal block 6 and a fastening bolt 4, the pressure reducing valve body 2 is concentrically fixedly fitted with the camshaft 1 in the circumferential direction, and the fastening bolt 4 is threaded and screwed on the camshaft 1 and fasten the relief valve body 2 axially to the camshaft 1;

[0020] The camshaft 1 is provided with a shoulder that limits the position of the pressure reducing valve body, and the pressure reducing valve body 2 is provided with a central hole and is overlaid on the camshaft 1 through the central hole, and then pressed a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com