Up-lock reliability test device capable of realizing lock ring horizontal position adjustment

A technology of lateral position and test device, which is used in the testing of measuring devices, transmission devices, mechanical parts, etc., can solve the problems of artificial adjustment of the lateral position of the lock ring, low overall stiffness, etc., and achieves light weight, small size, easy operation. handy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

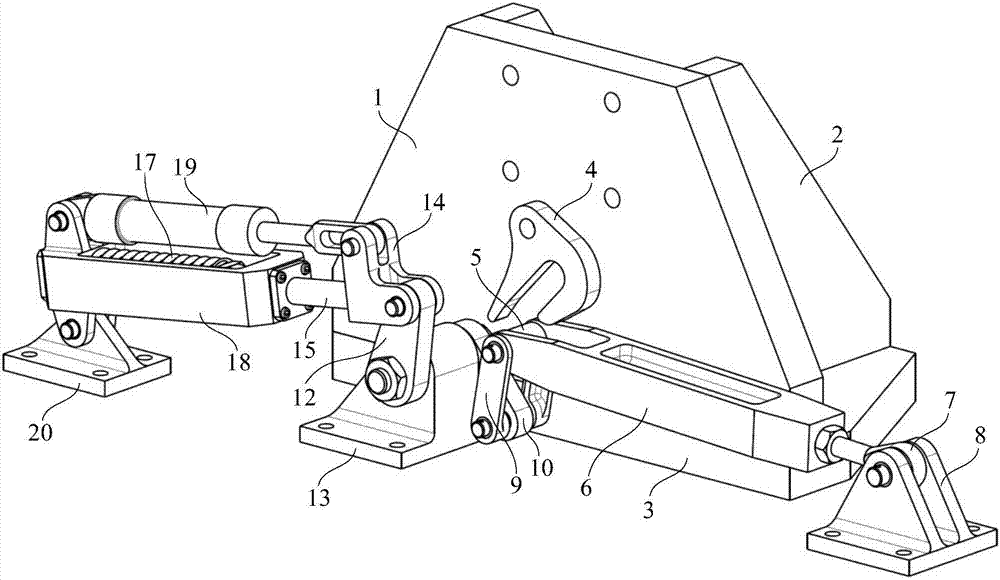

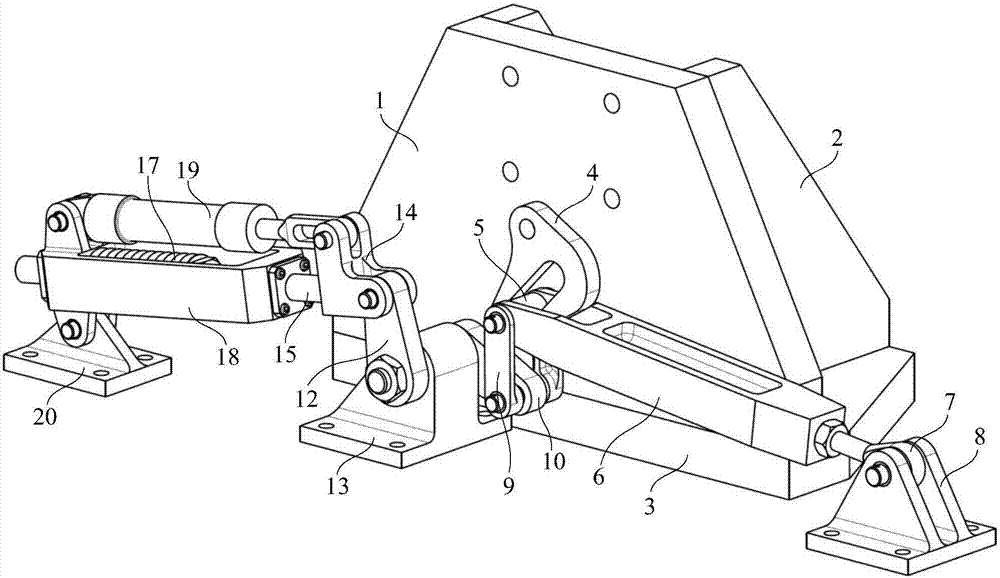

[0027] Specific implementation mode one: the following combination Figure 1 to Figure 9 Describe this embodiment, the upper lock reliability test device that can realize the lateral position adjustment of the lock ring described in this embodiment, it includes a support stand, it also includes a lock ring module, a crank module and a loading drive module;

[0028] The uplock is installed on the supporting platform, and the lock ring module, the crank module and the loading drive module are arranged under the uplock;

[0029] The support stand includes an upper lock installation plate 1, a reinforcing plate 2 and a base plate 3, the upper position lock installation plate 1 is vertically installed on the base plate 3, and the reinforcement plate 2 is fixedly connected to the side of the upper position lock installation plate 1 and fixed on the base plate 3; the upper position The lock is installed on the upper lock mounting plate 1;

[0030] The lock ring module includes a loc...

specific Embodiment approach 2

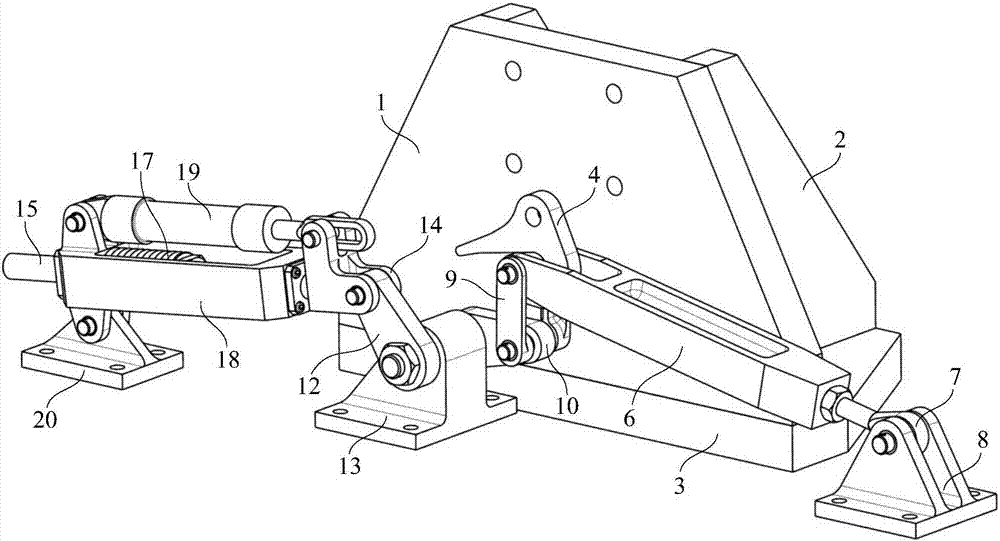

[0042] Specific implementation mode two: the following combination Figure 8 with Figure 9 Describe this embodiment, this embodiment will further explain Embodiment 1, there are steps at both ends of the rotating shaft 11, the No. 1 crank 10 and the No. 2 crank 12 are respectively connected to the low steps on both sides of the rotating shaft 11, and are locked by mounting nuts; The No. 1 crank 10 and the No. 2 crank 12 are fixed with the rotating shaft 11 through flat keys or splines.

[0043] Figure 8 with Figure 9 As shown, there are steps at both ends of the rotating shaft 11 for installing the No. 1 crank 10 and the No. 2 crank 12. There are threads on the outside of the steps for installing nuts, thereby locking the two cranks. The two cranks are fixed with the rotating shaft 11 through flat keys or splines. The rotating shaft 11 is installed in the shaft hole on the crank support 13 in a horizontal manner.

specific Embodiment approach 3

[0044] Specific implementation mode three: the following combination Figure 8 This embodiment will be described. This embodiment will further describe Embodiment 1 or 2. The included angle between the No. 1 crank 10 and the No. 2 crank 12 is 120°.

[0045] In order to prevent the No. 2 crank 12 from interfering with the screw joint 14 during the movement, an included angle of 120° is set between the No. 1 crank and the No. 2 crank. The connecting rod 9 is installed between the lock ring 5 and the number one crank 10 .

[0046] During the use of the test device in the test process, by screwing in or out the lock ring adjusting rod 7, the radius of the lock ring 5 swinging up and down can be adjusted and controlled, thereby adjusting the lateral position of the lock ring 5. During the adjustment of the lateral position of the lock ring 5, since the lock ring adjustment rod 7 is connected to the rocker support 8 through a pin, the rotation angle of the lock ring adjustment rod ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com