160Mpa electro-hydraulic proportional control radial piston pump

An electro-hydraulic proportional, radial column technology, applied in the fields of electronics, machinery and hydraulics, can solve the problems of long import cycle, large lateral force of plunger and plunger sleeve, short life, etc., to achieve wide application occasions and work efficiency Improved, long working life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

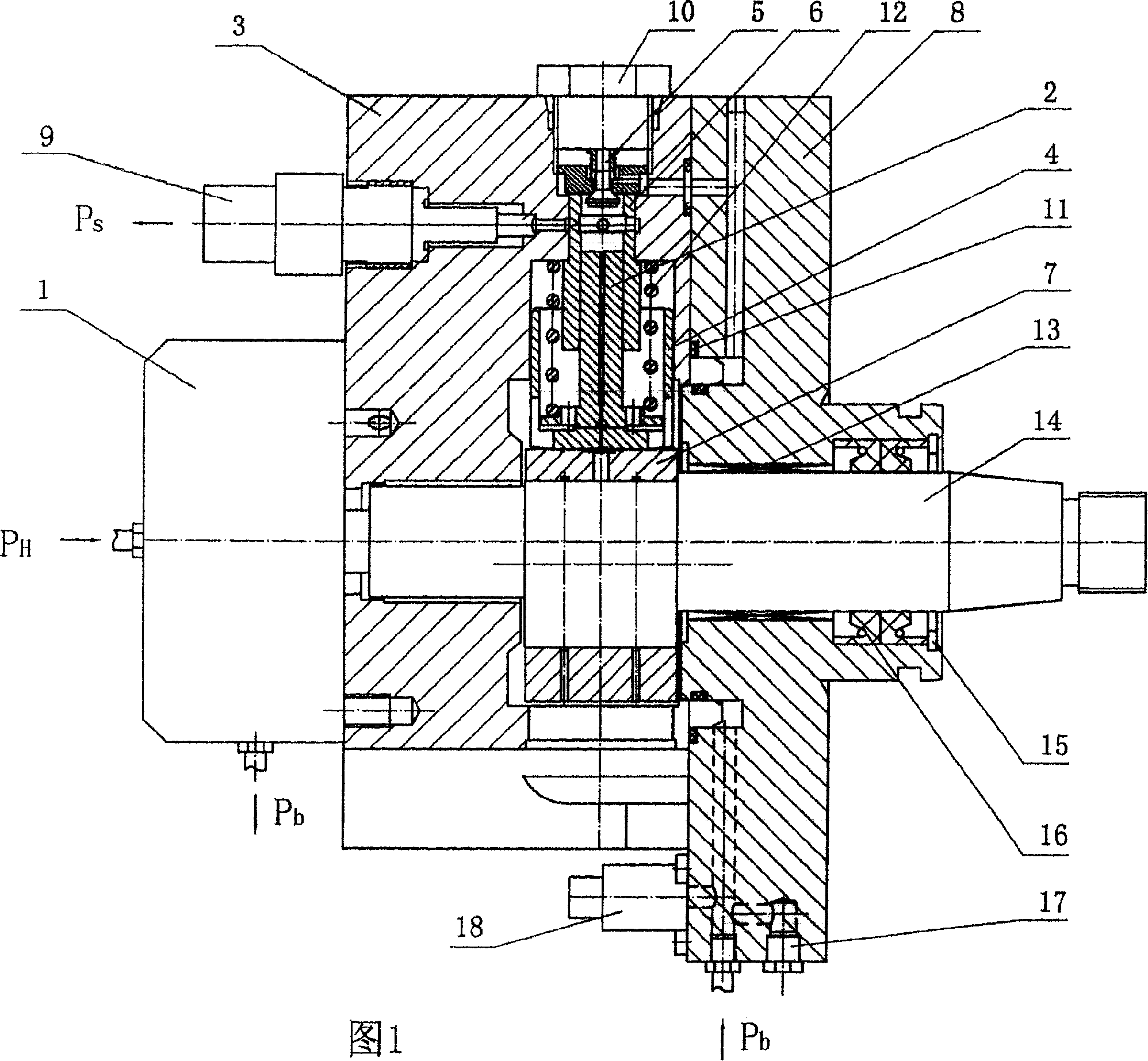

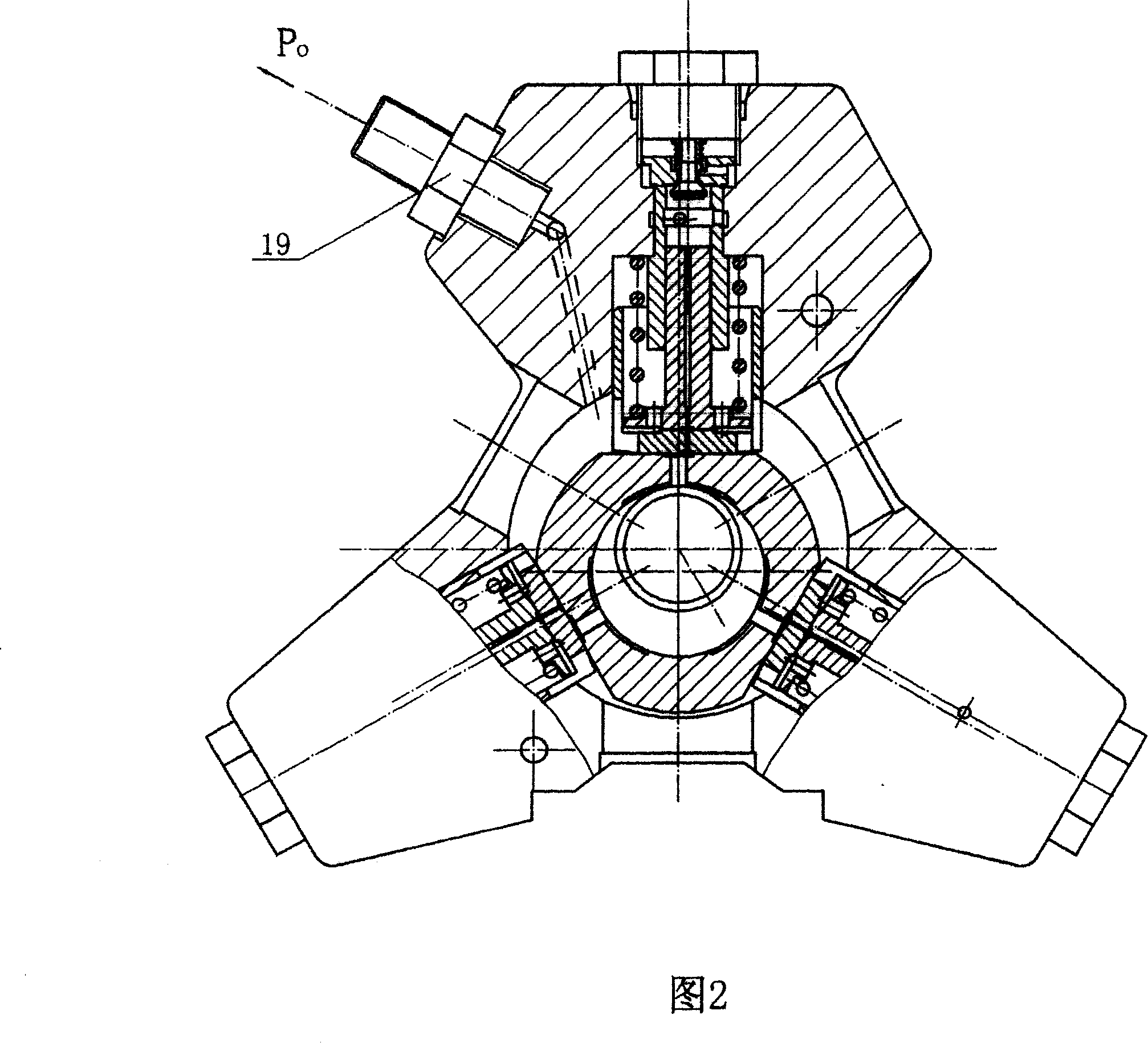

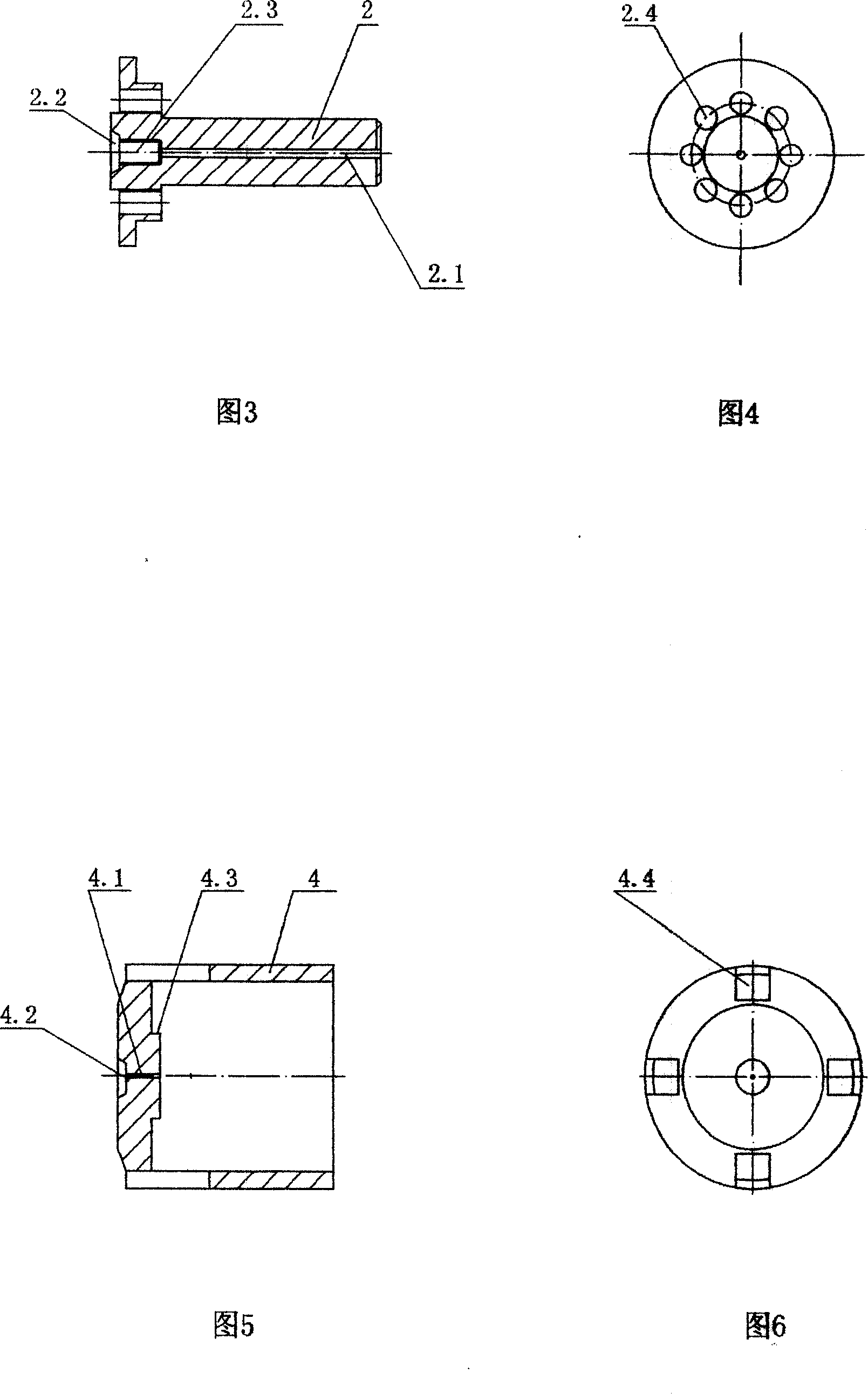

[0015] The present invention consists of a stator 7, an eccentric shaft on the transmission shaft 14, a large plunger 4, a plunger 2, a plunger sleeve 6, a casing 3 and a pump cover 8 to form a closed working volume, and the stator 7 is arranged on the transmission shaft in the middle of the main oil pump 14, the upper end of the stator 7 is provided with a large plunger 4, the large plunger 4 is provided with a plunger 2, the plunger 2 is externally sleeved with a plunger sleeve 6, the upper end of the plunger sleeve 6 is connected to the oil suction valve 5, and the housing 3 is installed An oil discharge valve 9, because the eccentric shaft (rotor) on the stator 7 and the transmission shaft 14 is provided with an eccentricity e, when the eccentric shaft on the transmission shaft 14 rotates, the volume of the upper cavity of the plunger 2 increases to absorb oil, and the oil is drawn from the The low-pressure oil Pb discharged from the charge pump 1 enters the upper chamber o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com