Volute Design For Lower Manufacturing Cost and Radial Load Reduction

a technology of radial load reduction and valve design, which is applied in the direction of pump components, non-positive displacement fluid engines, pump components, etc., can solve the problems of increasing the difficulty of cleaning the casting properly, increasing the complexity of the casing, and long passage length of the cutwater farthest away, so as to reduce the radial load on the impeller and improve the pressure balance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

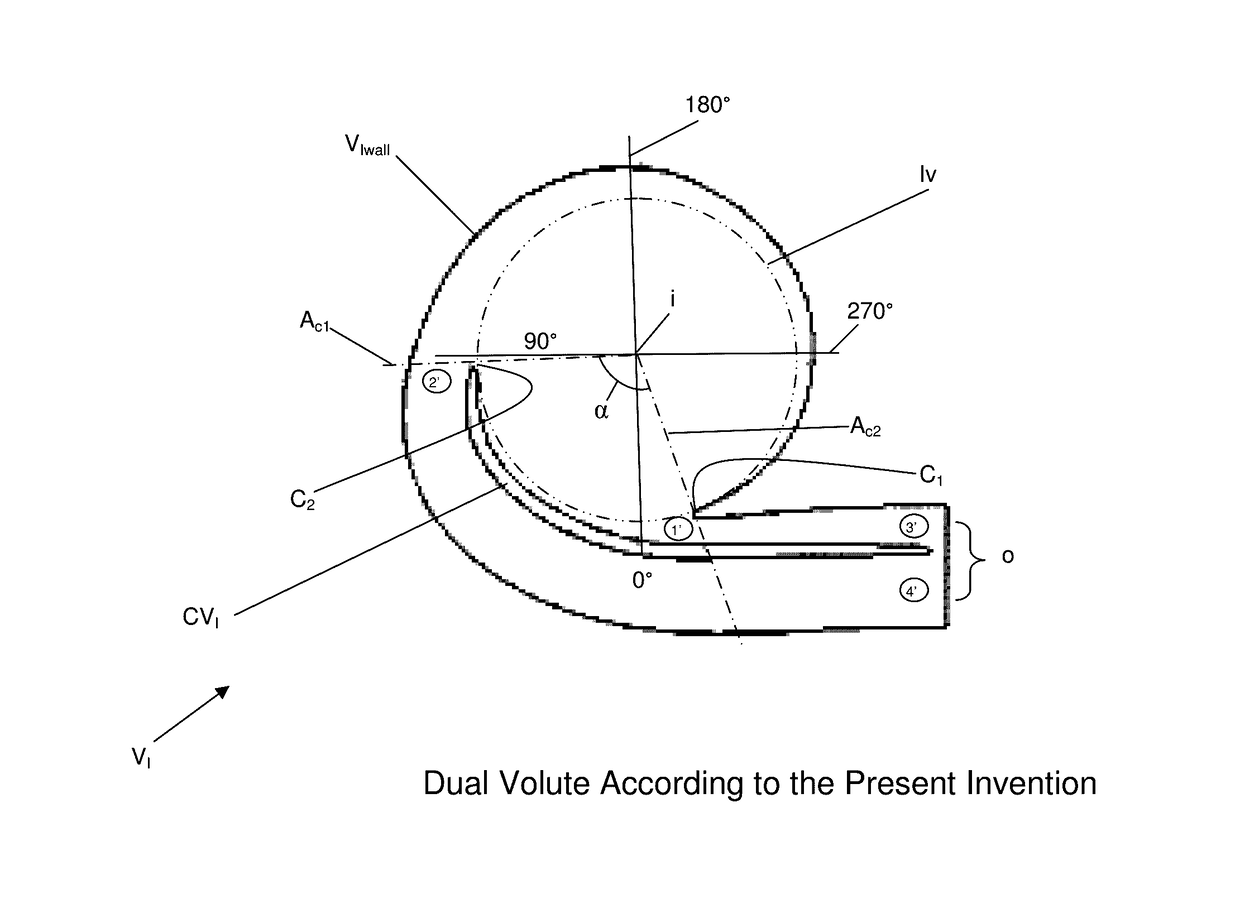

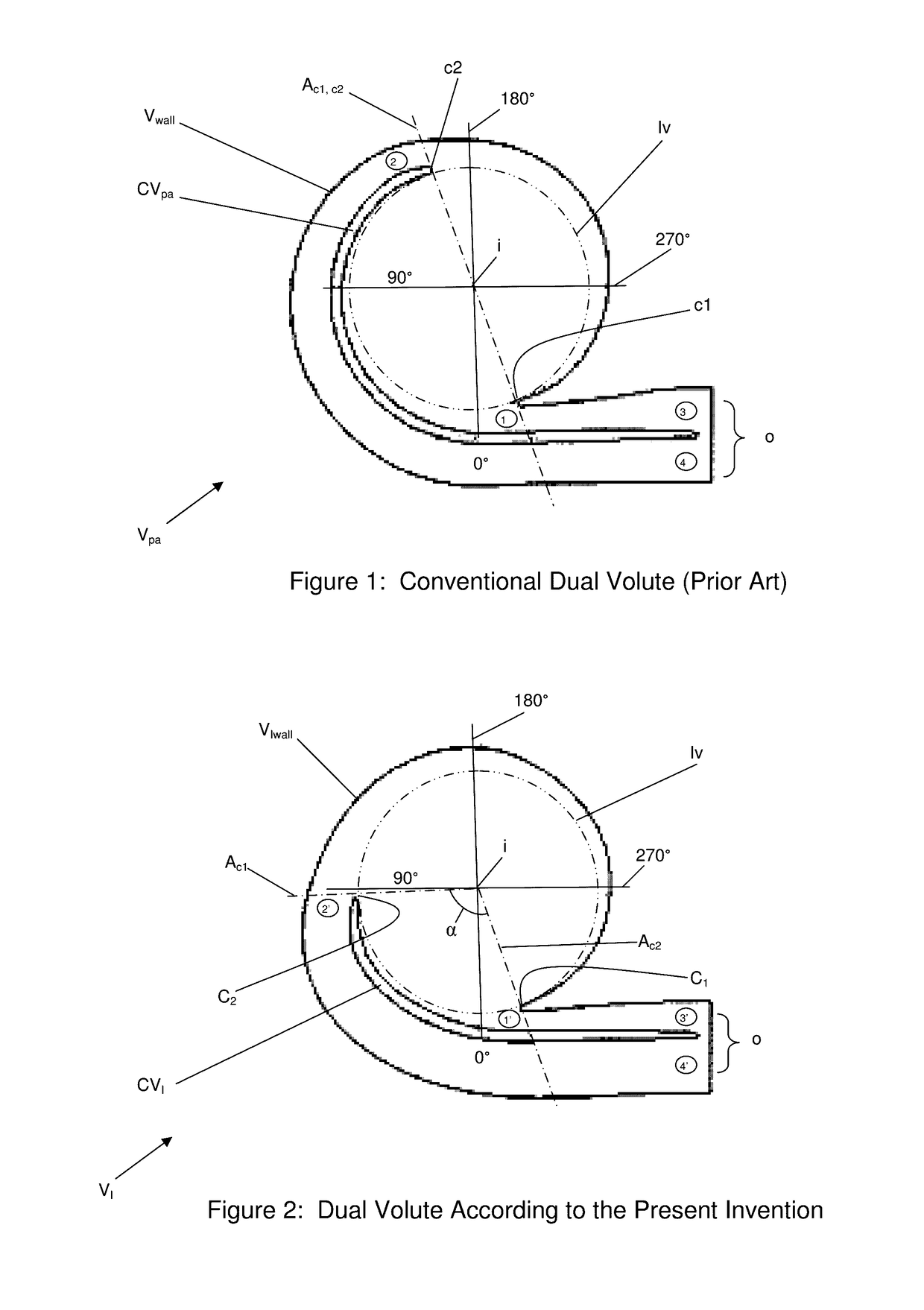

FIG. 2: The Basic Invention

[0033]FIG. 2 shows the present invention, e.g. in the form of a volute VI for configuring in relation to a pump (not shown), such as a double volute pump. The volute VI may include one or more of the following features:[0034]a volute wall Vwall;[0035]a pump inlet i (in) for receiving a fluid being pumped;[0036]a pump discharge o (out) for providing the fluid being pumped; and[0037]a casing vane CVI.

[0038]The casing vane CVI may be configured on the volute wall Vwall forming double volutes in the volute VI and being configured with an upper cutwater C2 farthest from the pump discharge o defining an upper cutwater throat area labeled 2′ (in a circle) and an end of passage 4′ (in a circle) for the upper cutwater C2, and also configured with a lower cutwater C1 closest to the pump discharge o defining a lower cutwater throat labeled 1′ (in a circle) and a corresponding end of passage 3′ (in a circle) for the lower cutwater C1.

[0039]The upper cutwater throat ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com