Drive device of adjustable rotating platform

A technology of driving device and rotary table, which is applied in the field of conveying machinery, can solve problems such as shaft fatigue fracture, achieve the effect of reducing radial load and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

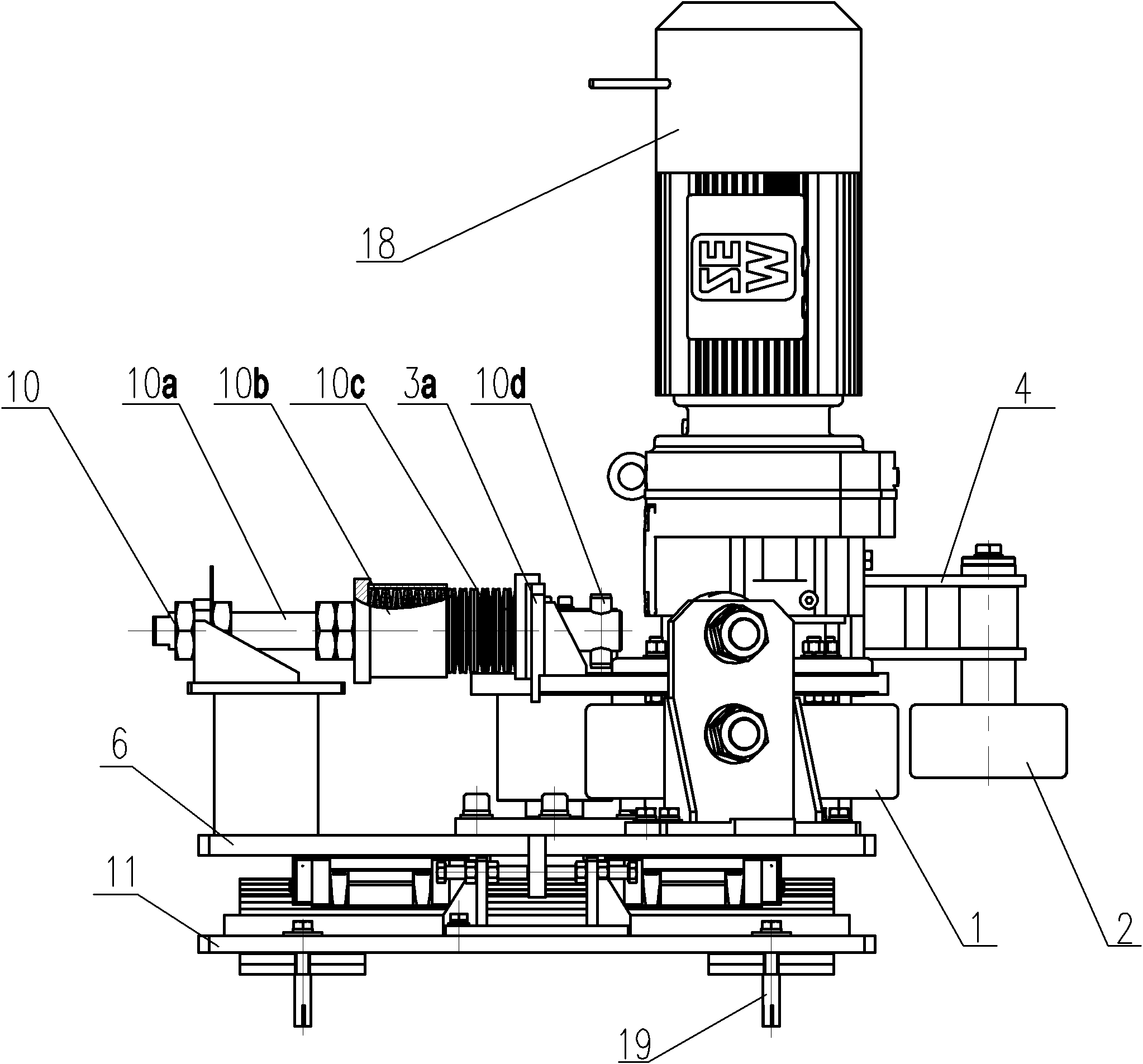

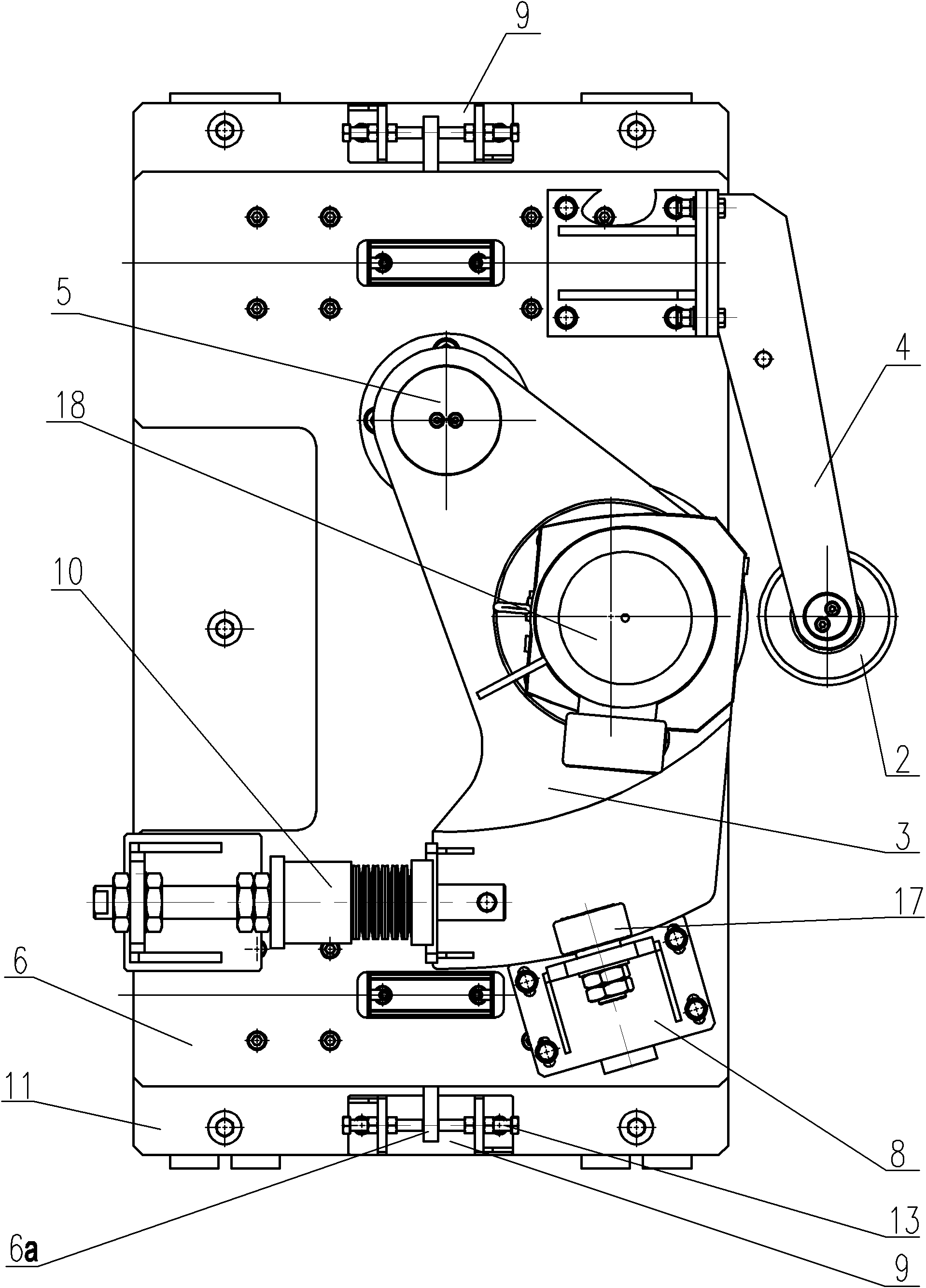

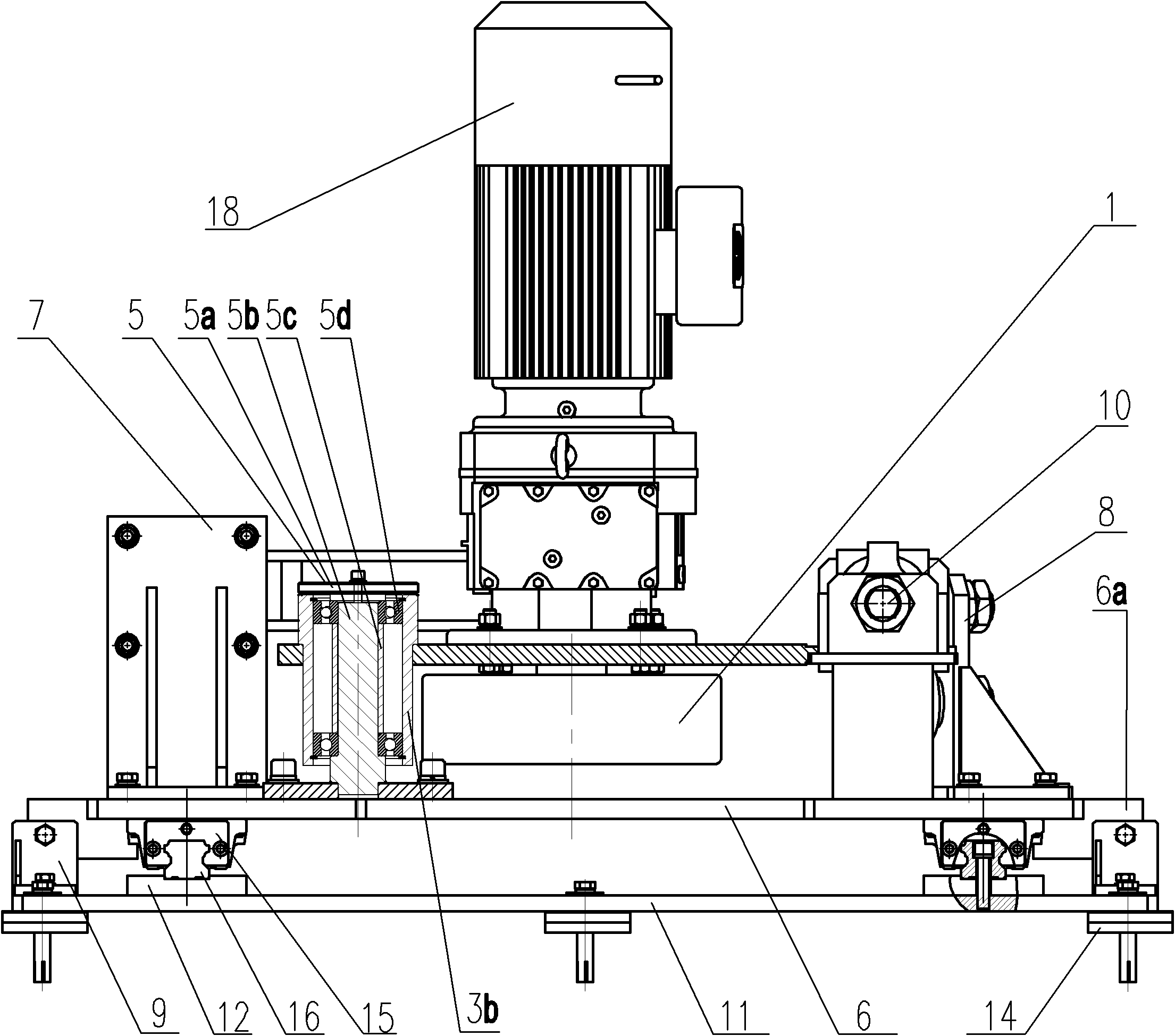

[0014] The present invention will be further described below in conjunction with specific drawings and embodiments.

[0015] As shown in the figure, the present invention mainly consists of a friction driving wheel 1, a friction driven wheel 2, a swing arm 3, a baffle plate 3a, a sleeve 3b, a driven arm 4, a rotary assembly 5, an end cover 5a, a flange shaft 5b, a shaft Sleeve 5c, bearing 5d, seat plate 6, side plate 6a, follower arm support 7, cam follower bearing support 8, fixed seat 9, rotating elastic pushing device 10, threaded pull rod 10a, spring 10b, spring sleeve 10c , pin 10d, base plate 11, backing plate 12, washer 13, adjusting backing plate 14, slide block 15, linear guide rail 16, cam follower bearing 17, geared motor 18, expansion bolt 19 and pull bar 20 etc. parts constitute.

[0016] The adjustable rotary table driving device includes an expansion bolt 19 installed on the base plate 11, and an adjustment backing plate 14 is arranged on the expansion bolt 19 b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com