Thrust reverser with pivoting grilles

A technology of thrust reverser and pivoting, which is applied in the direction of jet propulsion device, machine/engine, high-efficiency propulsion technology, etc., to achieve the effect of reducing radial load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

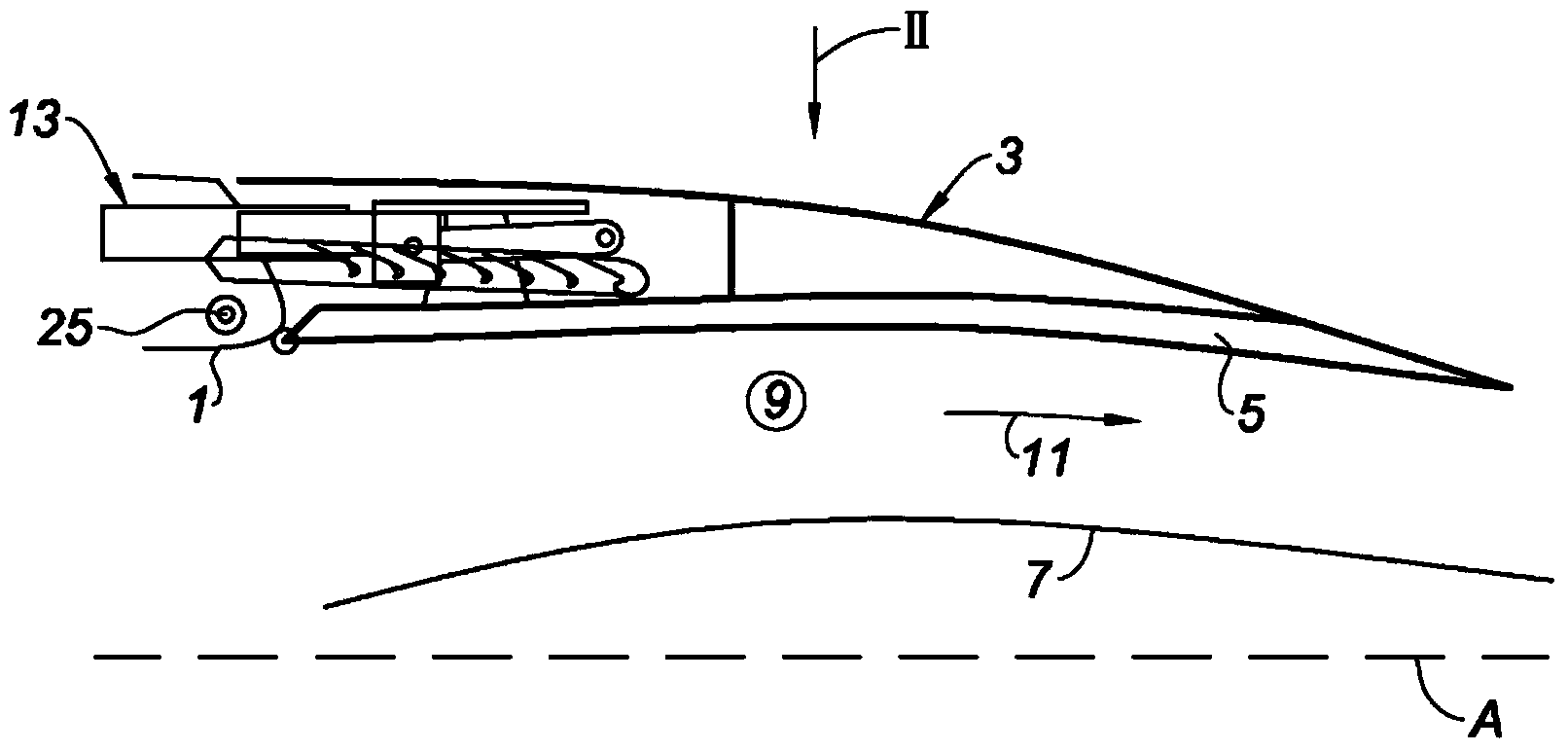

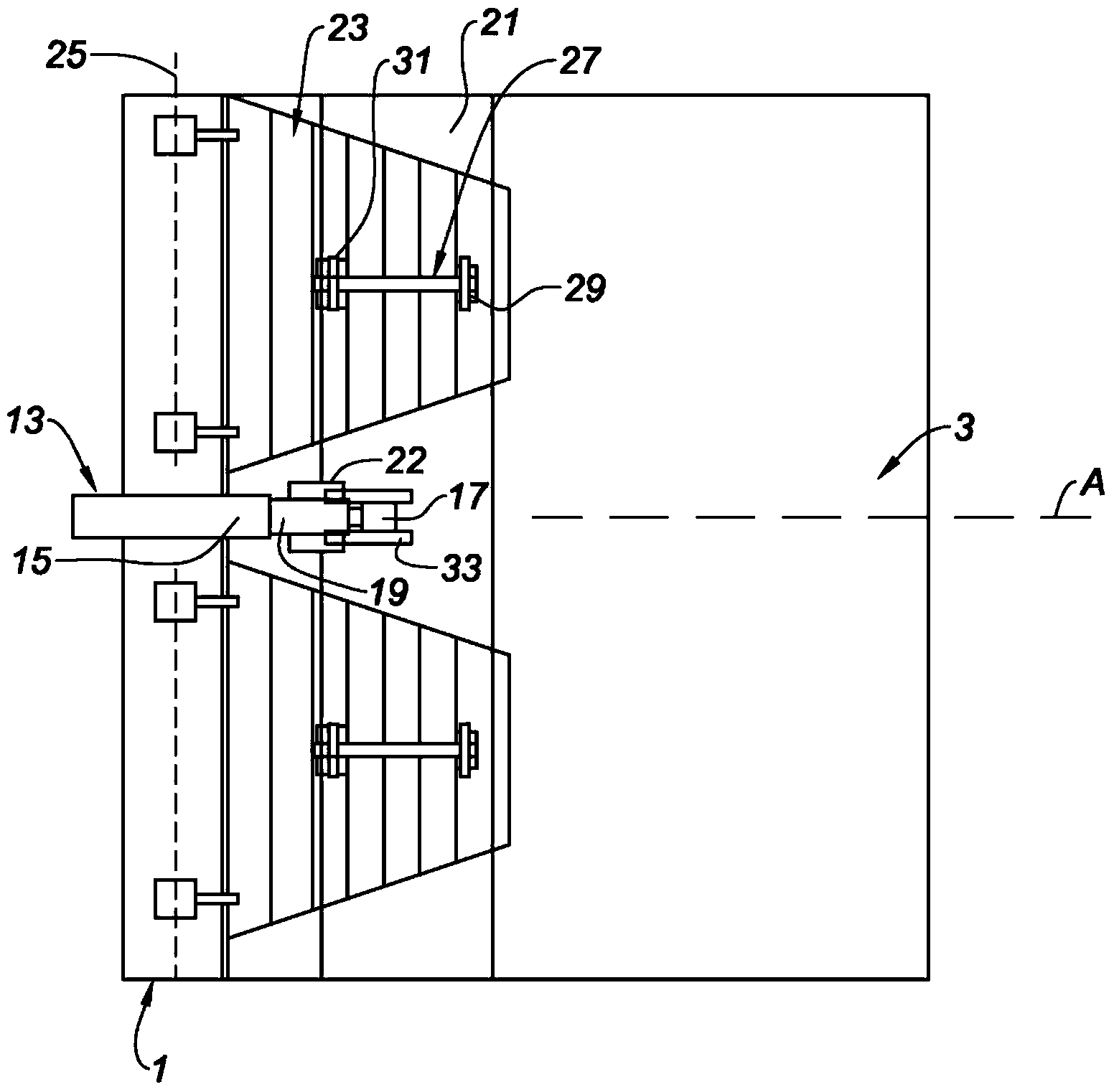

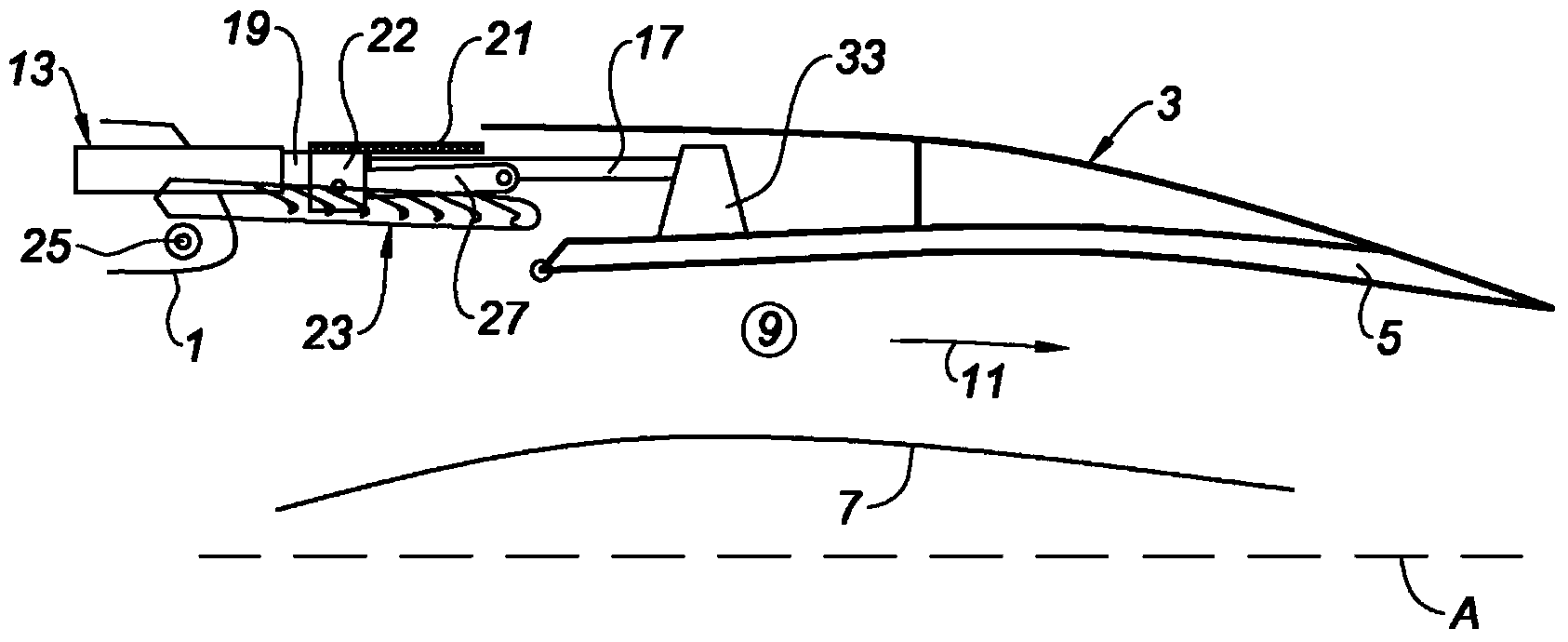

[0037] now refer to figure 1 and 2 , where it can be seen that the thrust reverser according to the invention comprises a fixed front frame 1 integrated into the fixed structure of the nacelle or the casing of the engine fan, and a fairing 3 slidably mounted relative to said fixed structure, e.g. , mounted to rails located on the upper beam (often referred to as "6 o'clock") and lower beam (often referred to as "12 o'clock") of the nacelle.

[0038] On its inner surface, the sliding fairing 3 comprises a coating 5 with sound-absorbing properties, which can in particular be formed in a honeycomb structure covered with a perforated skin.

[0039] The sliding cowl 3 and the cowling 7 surrounding the turbojet engine (not shown) define a cold air flow path 9, which is directed in the direction of the arrow 11 and ensures most of the thrust of the propulsion assembly formed by the nacelle and its turbojet engine .

[0040] sliding cover 3 in as figure 1 and 2 The location shown...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com