Cable bundle flange filling and sealing method

A technology of cable bundles and flanges, which is applied in the direction of pipes, pipes/pipe joints/pipe fittings, mechanical equipment, etc., and can solve problems such as low adhesion between glue and metal, poor sealing performance, and uneven glue surface. Achieve the requirements of ensuring air tightness, good sealing, and overcome the effect of uneven rubber surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

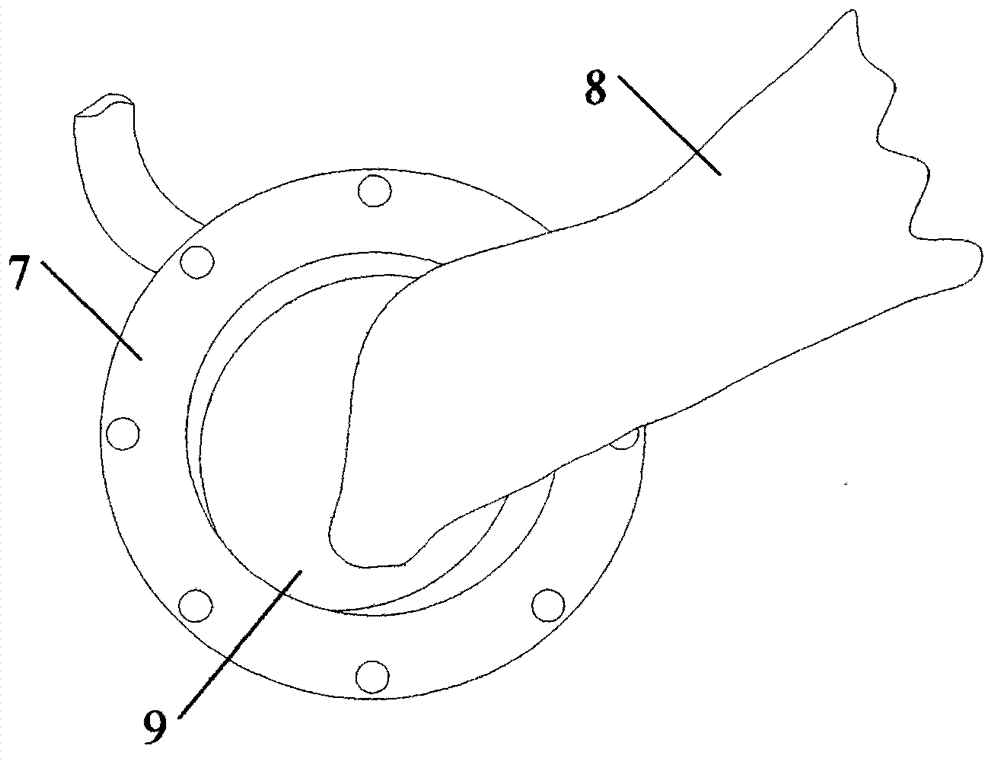

[0048] The cable bundle flange filling and sealing method of this embodiment mainly includes:

[0049]a. Silicone rubber sealing ring is used to seal the flange that needs to be poured;

[0050] In step a, the operation of sealing the flange that needs to be poured includes:

[0051] Mill a sealing groove on the inside of the opening of the flange that needs to be poured, and fill the sealing groove with a silicone rubber sealing ring that matches the sealing groove; the thickness of the sealing groove is 2 / 3 of the thickness of the bottom of the flange left and right (for example, 1.5 / 3);

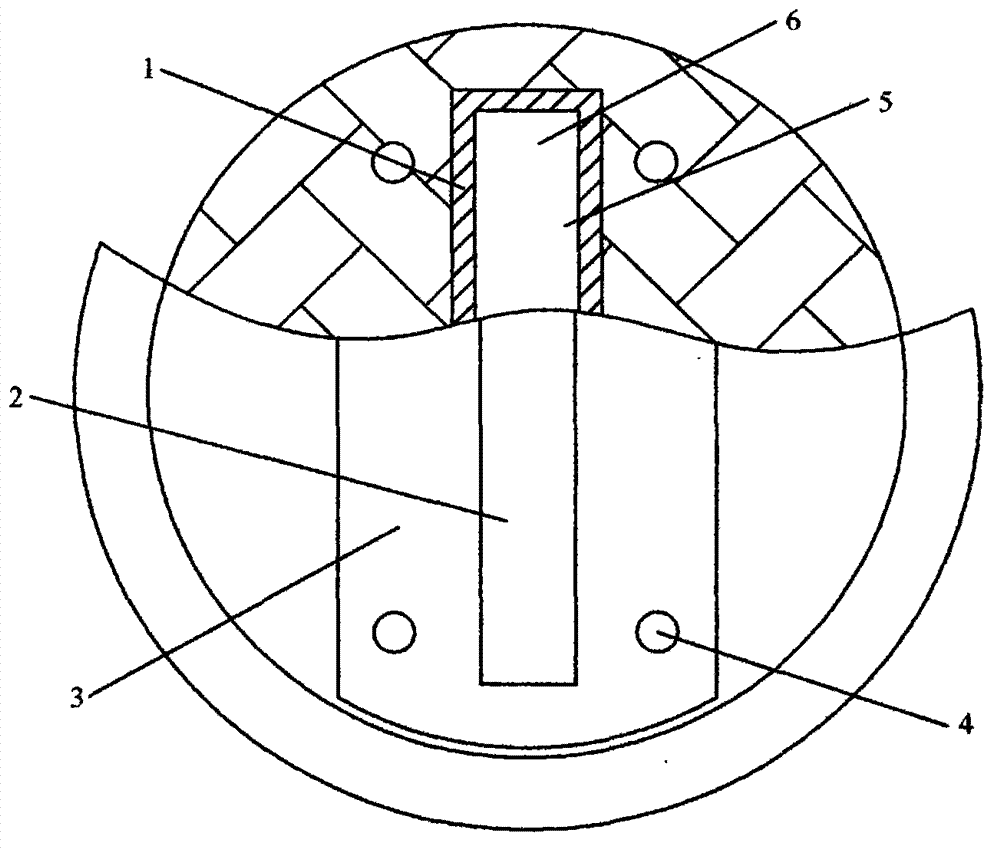

[0052] b. Through the opening on the sealed flange, pour the fluid silicone rubber into the flange in layers until the filling surface is flush with the inner surface of the flange;

[0053] In step b, the operation of pouring the fluid silicone rubber into the flange plate in layers, specifically includes:

[0054] When the thickness of each layer of perfusion glue is 2.5mm, after the ...

Embodiment 2

[0062] Different from the above-mentioned embodiments, the cable bundle flange filling and sealing method of this embodiment mainly includes:

[0063] a. Silicone rubber sealing ring is used to seal the flange that needs to be poured;

[0064] In step a, the operation of sealing the flange that needs to be poured includes:

[0065] Mill a sealing groove on the inside of the opening of the flange that needs to be poured, and fill the sealing groove with a silicone rubber sealing ring that matches the sealing groove; the thickness of the sealing groove is 2 / 3 of the thickness of the bottom of the flange left and right (e.g. 2.5 / 3);

[0066] b. Through the opening on the sealed flange, pour the fluid silicone rubber into the flange in layers until the filling surface is flush with the inner surface of the flange;

[0067] In step b, the operation of pouring the fluid silicone rubber into the flange plate in layers, specifically includes:

[0068] When the thickness of each lay...

Embodiment 3

[0076] Different from the above-mentioned embodiments, the cable bundle flange filling and sealing method of this embodiment mainly includes:

[0077] a. Silicone rubber sealing ring is used to seal the flange that needs to be poured;

[0078] In step a, the operation of sealing the flange that needs to be poured includes:

[0079] Mill a sealing groove on the inside of the opening of the flange that needs to be poured, and fill the sealing groove with a silicone rubber sealing ring that matches the sealing groove; the thickness of the sealing groove is 2 / 3 of the thickness of the bottom of the flange ;

[0080] b. Through the opening on the sealed flange, pour the fluid silicone rubber into the flange in layers until the filling surface is flush with the inner surface of the flange;

[0081] In step b, the operation of pouring the fluid silicone rubber into the flange plate in layers, specifically includes:

[0082] When the thickness of each layer of perfusion glue is 1.5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com