Crystal oscillator welding method

A welding method and crystal oscillator technology, applied in the direction of electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve the problems of crystal and chip coordination error, large area occupied by the circuit, and affect the stability of the chip, so as to ensure air tightness Requirements, improvement of production efficiency, welding reliability and the effect of high yield rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The crystal oscillator welding method of the present invention will be further described below in conjunction with the examples, but the present invention is not limited thereby.

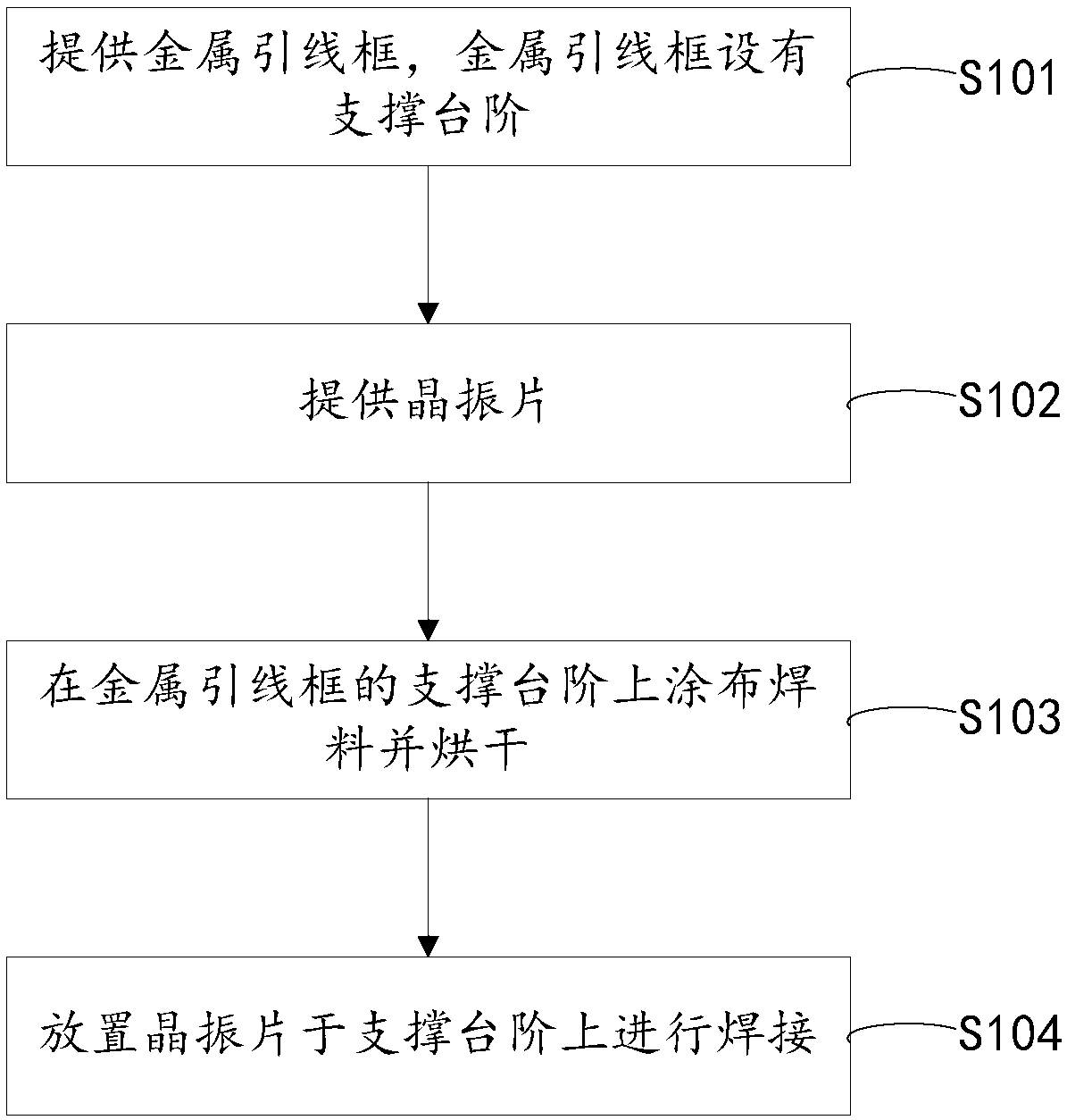

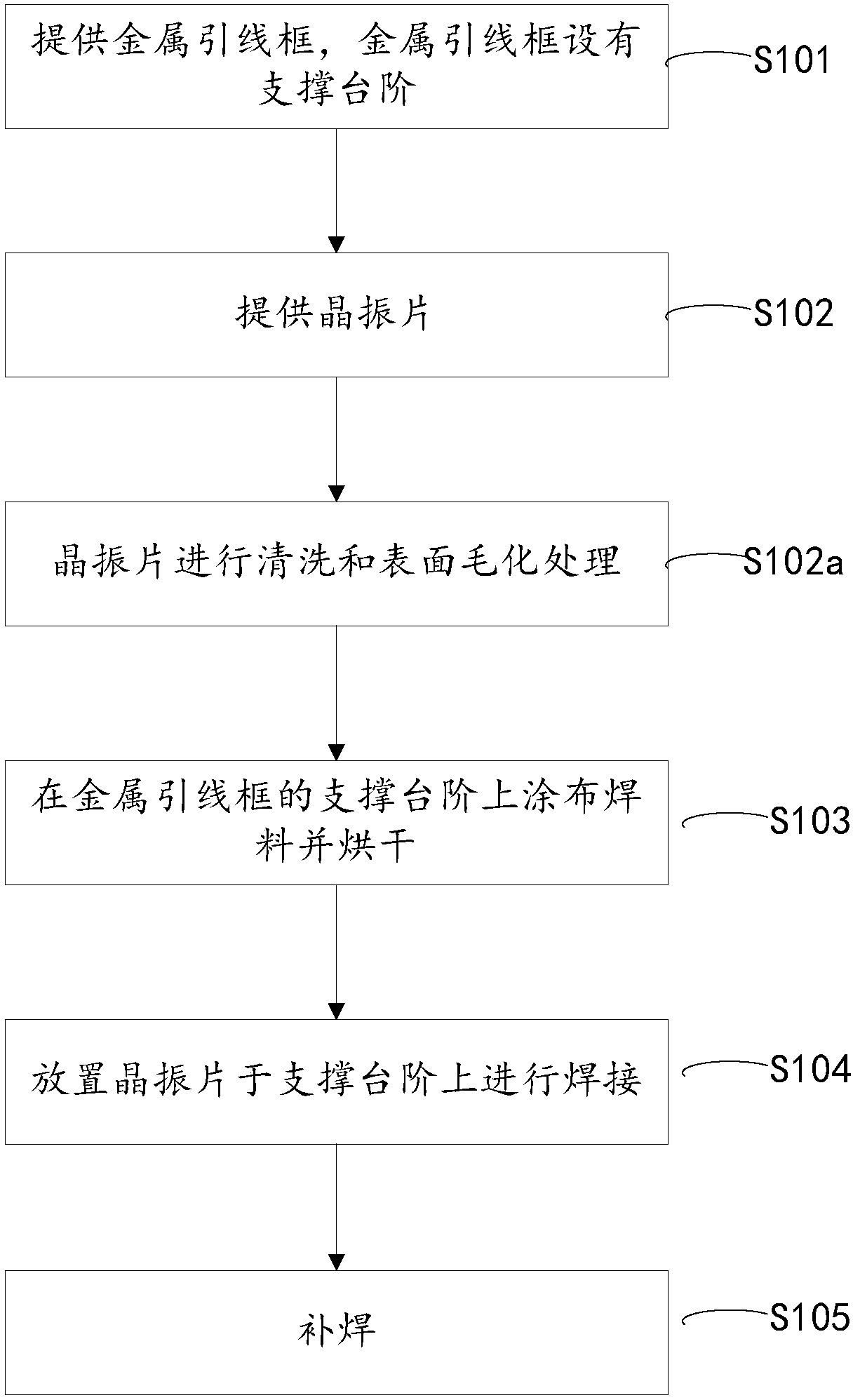

[0022] Please refer to figure 1 , an embodiment of the crystal oscillator welding method of the present invention comprises the following steps:

[0023] S101, providing metal lead frame with supporting steps;

[0024] S102, providing a crystal oscillator;

[0025] S103, coating and drying solder on the supporting steps of the metal lead frame;

[0026] S104, placing the crystal oscillator on the supporting step for welding.

[0027] The welding method of the present invention has low welding temperature, high efficiency, good reliability, and low cost. The method does not require metallization, expensive vacuum coating equipment and precious metal targets, and does not have a long, complicated and time-consuming intermediate treatment process. defects, shorten the total welding time, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com