Welding method of copper and copper alloy

A welding method, copper alloy technology, applied in the direction of welding equipment, welding medium, welding equipment, etc., can solve the problems of high welding temperature, high thermal conductivity, and reduced corrosion resistance of copper and copper alloys, and achieve high physical properties and mechanical properties. performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

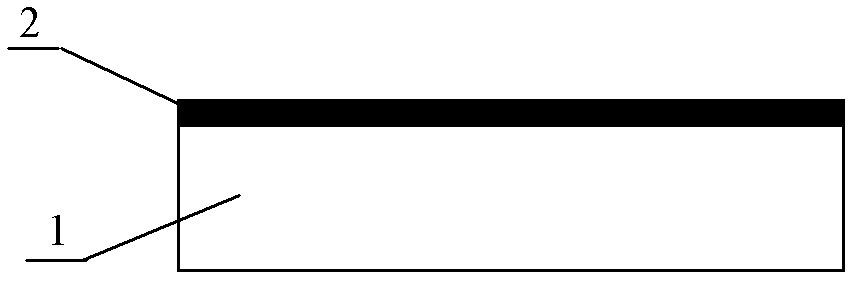

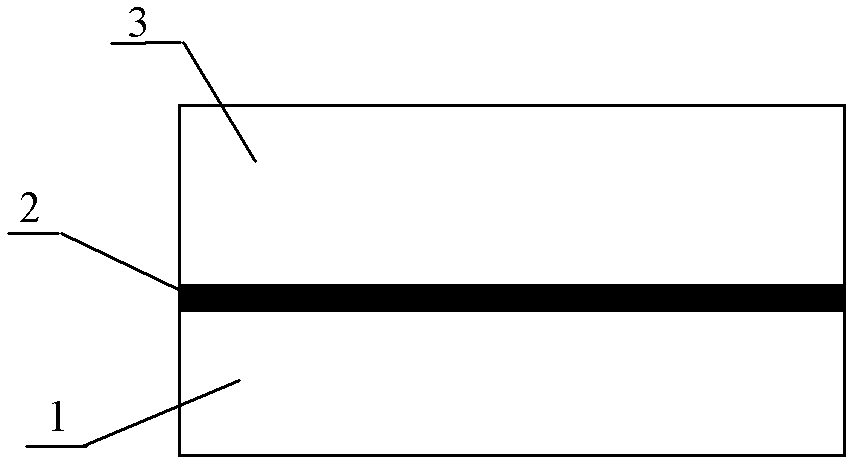

[0015] Embodiment 1: will contain 20% Cu, 15% Zn, the silver-copper-zinc strip material that surplus is Ag, laminate on the surface of pure copper strip material, the processing method of rolling at room temperature, make two kinds of strip materials compress into The solid whole makes it a composite strip of silver copper indium (2) and copper alloy layer (1), and then undergoes a series of diffusion heat treatment and rolling processing to compound a layer of AgCuZn alloy layer on the surface of the pure copper strip. The composite ratio is listed as 1:3, and the total thickness is 1.5mm for welding between pure copper and brass.

Embodiment 2

[0016] Embodiment 2: will contain 20%Cu, 2%Sn, the silver-copper-tin strip material that surplus is Ag, layer on tin bronze strip material surface, the processing method of rolling at room temperature, two kinds of strip materials are pressed together into The solid whole makes it a composite strip of silver alloy layer (2) and copper alloy layer (1), and then undergoes a series of diffusion heat treatment and rolling processing to compound a layer of AgCuSn alloy layer on the surface of the tin bronze strip. The composite ratio is listed as 1:10, and the total thickness is 0.8mm. It is used for welding between pure copper and tin bronze.

Embodiment 3

[0017] Embodiment 3: the silver-copper-indium strip material that contains 24% Cu, 15% In, and the balance is Ag, is laminated on the surface of zinc-nickel-nickel strip material, and the processing method of rolling at room temperature makes two kinds of strip materials press together to form The solid whole makes it a composite strip of silver alloy layer (2) and copper alloy layer (1), and then undergoes a series of diffusion heat treatment and rolling processing to compound a layer of AgCuIn composite solder on the pure copper sheet, The composite ratio is listed as 1:8, and the total thickness is 2.5mm. It is used for welding between tin bronze and zinc white copper.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com