Dielectric phase shifter with novel conducting cavities

A phase shifter and dielectric technology, which is applied to waveguide-type devices, electrical components, circuits, etc., can solve the problems of large solder joint stress on inner conductors and corresponding pads, deterioration of electrical indicators and intermodulation, and inability to take mechanized methods. Achieve the effect of improving welding economy, reducing the risk of deformation by external force, and reducing potential intermodulation points

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] The present invention mainly adopts following technical scheme:

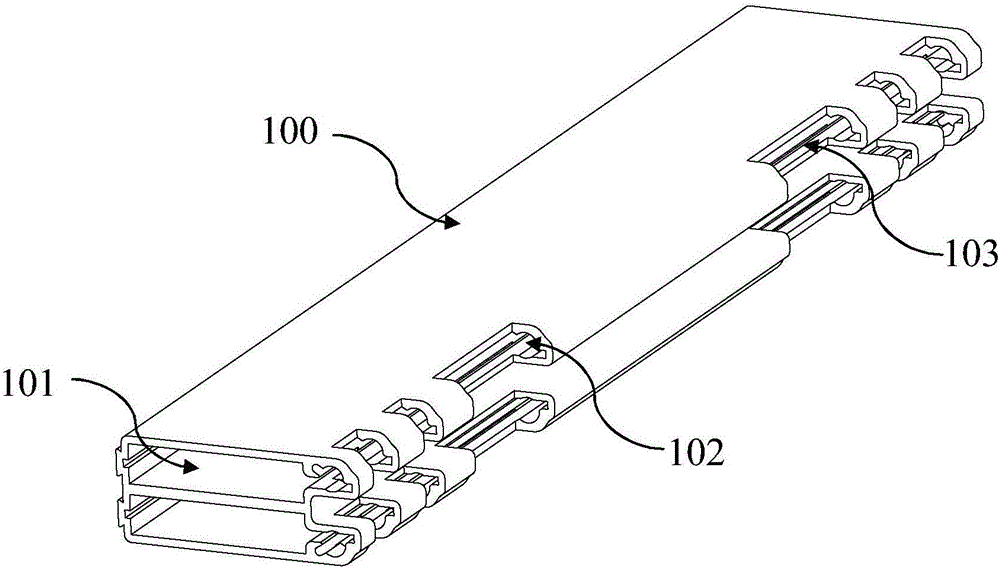

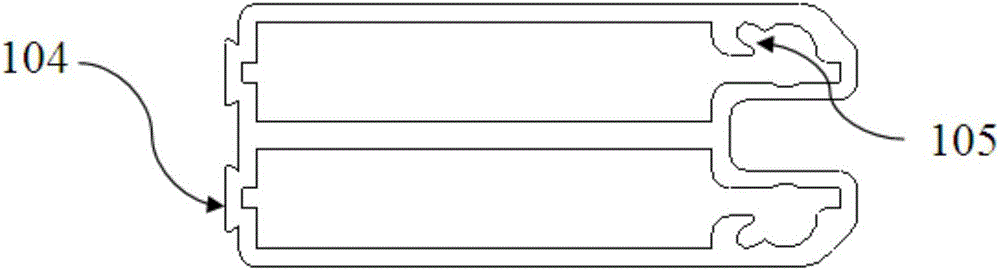

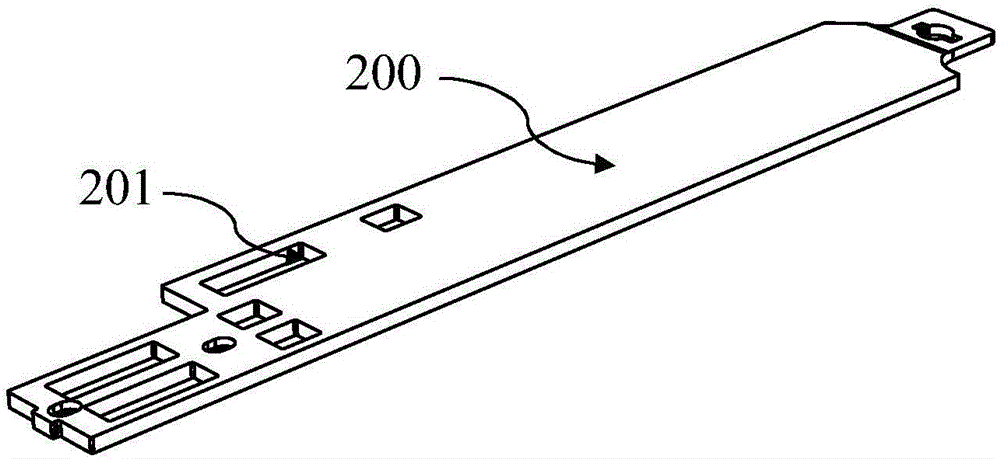

[0052] The cavity of the phase shifter is made of aluminum alloy extruded profile structure. The profile is divided into two rectangular cavities. There is a conduction cavity on one side of each single cavity, which is connected with the single cavity. There are two vertical cavity on the other side of the profile. Ribs for structural fixation. The conduction cavity is hollow with a circular hole with a diameter of 3.6mm, which can be matched with the outer conductor of the coaxial cable for welding. One side of the hole is a small groove with a width of 1.2mm, which can be used for tin entry and tinning, and passes through during welding. Reduce the conduction area to slow down the welding heat transfer. The 4 joints of the outer conductor of the coaxial cable in the external conduction chamber of the profile, the reserved width remains the same, and the other width 15mm is machined down to remove it, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com