Canopy air tightness test fixture

A technology for testing fixtures and cockpit covers, applied in the field of fixture tooling, can solve the problems of sealing failure, scrapping of hatch cover parts, affecting the test efficiency of the air tightness test of the cockpit cover, etc., to ensure the sealing performance and improve the sealing performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

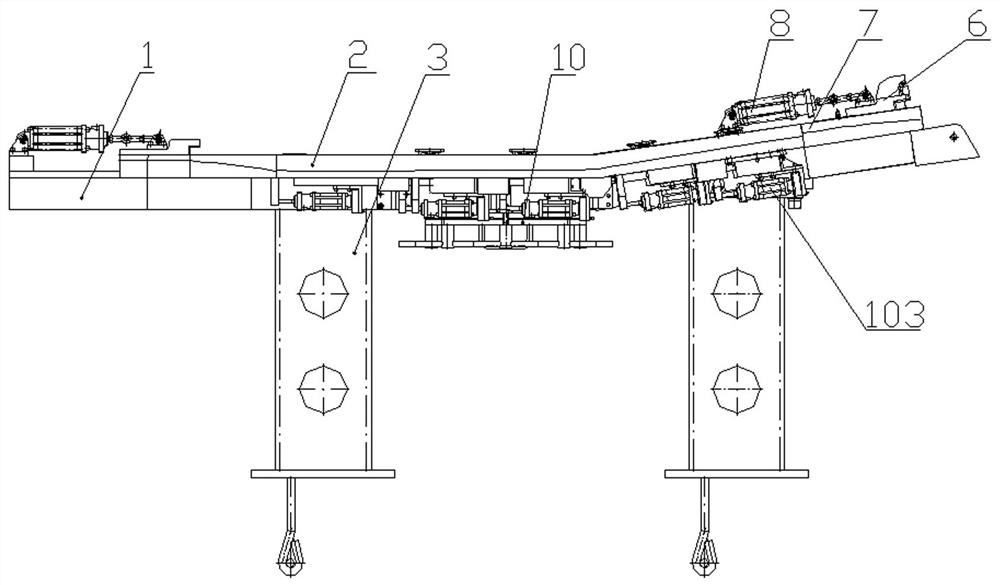

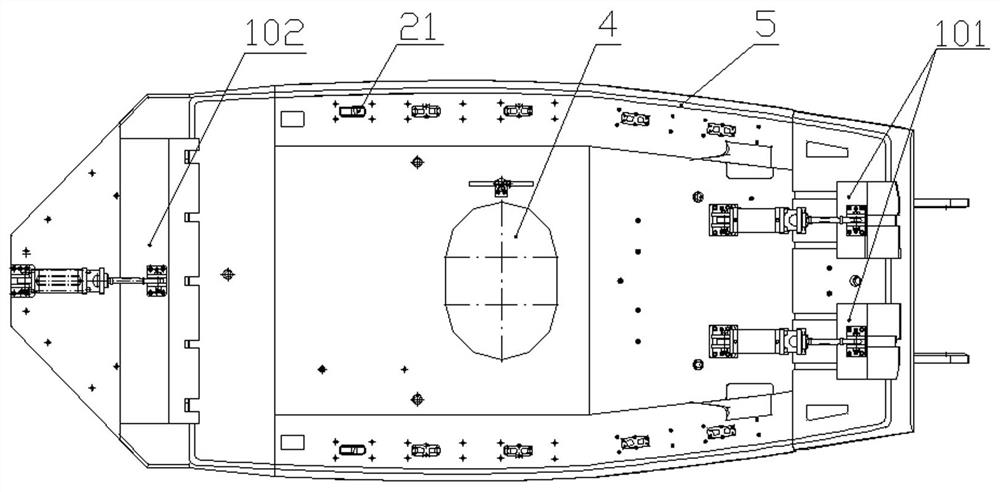

[0019] A canopy airtightness test fixture, the fixture is used to clamp the airtightness test of the canopy of the existing small aircraft, so the description of the overall structure of the fixture is explained from the perspective of the position of the canopy of the aircraft, The position of the test fixture where the front end of the canopy is located is the front end of the test fixture, the position of the test fixture where the rear end of the canopy is located is the rear end of the test fixture, and the two sides of the canopy are the two sides of the test fixture.

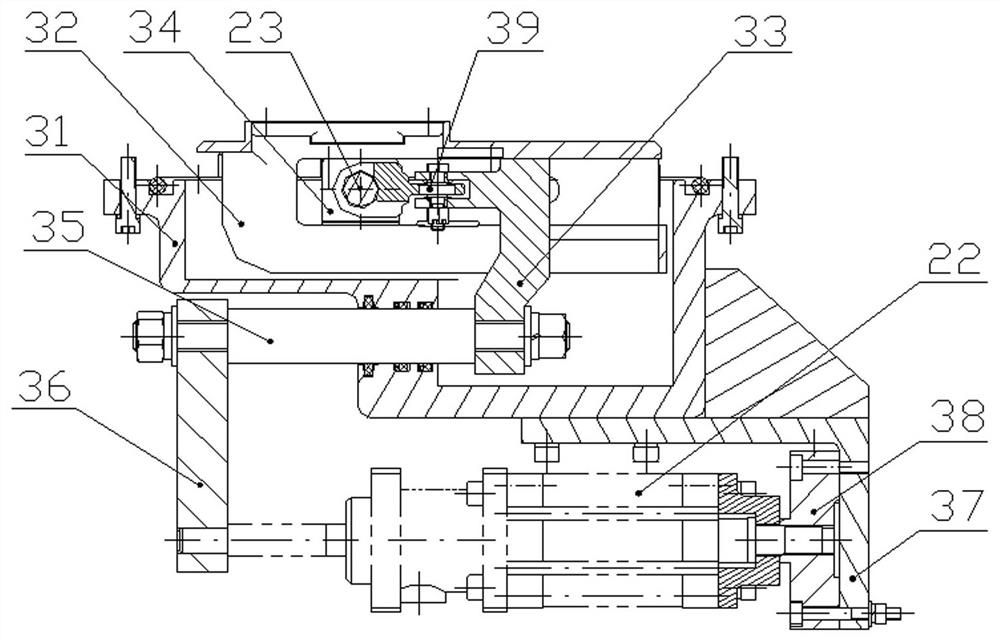

[0020] like figure 1 and figure 2 As shown, the specific structure of the canopy airtightness test fixture is as follows: the upper surface of the base 1 of the frame structure is positioned and connected to the airtight platform 2, and the lower surface of the base 1 is respectively provided with columns 3 before and after; There is a sealing rubber ring 5, and the outer pressure applying device compre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com