Vacuum efficient electric arc melting furnace system

A kind of electric arc melting furnace, electric arc furnace technology, applied in furnace, furnace cooling, charge and other directions, can solve problems such as poor air tightness, and achieve the effect of improving the success rate, increasing the surface area, and reducing the time of vacuuming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

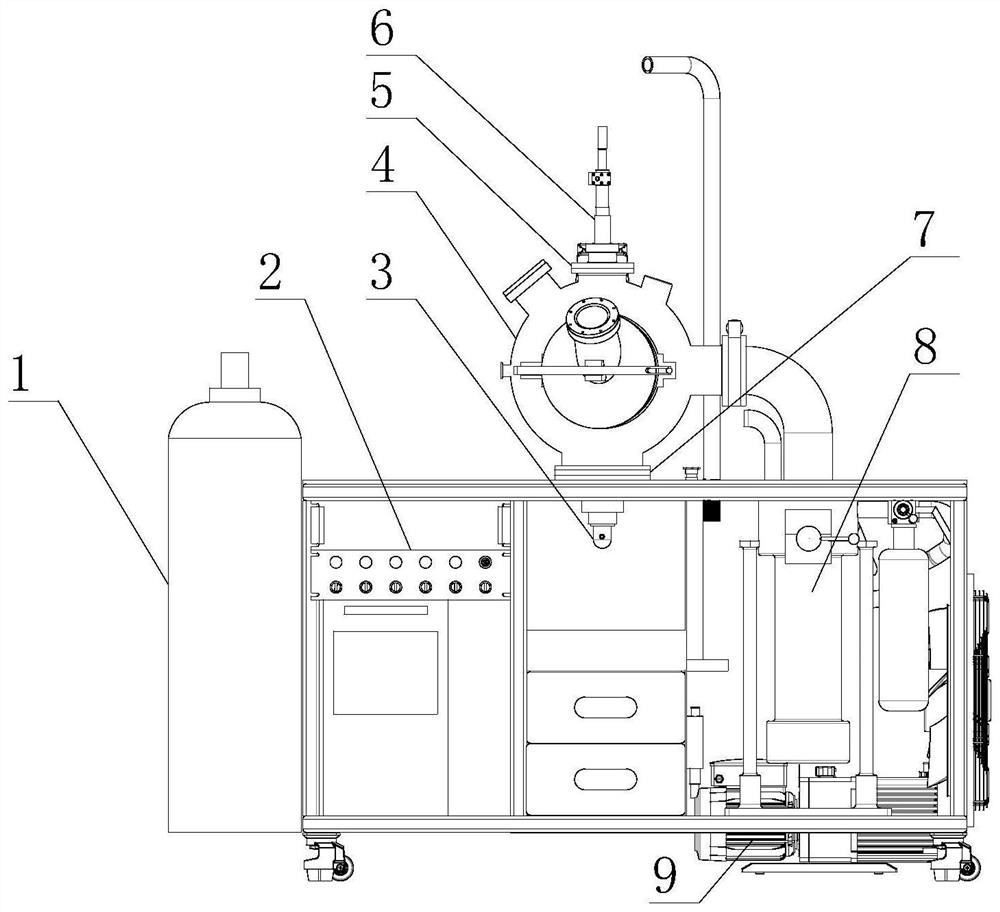

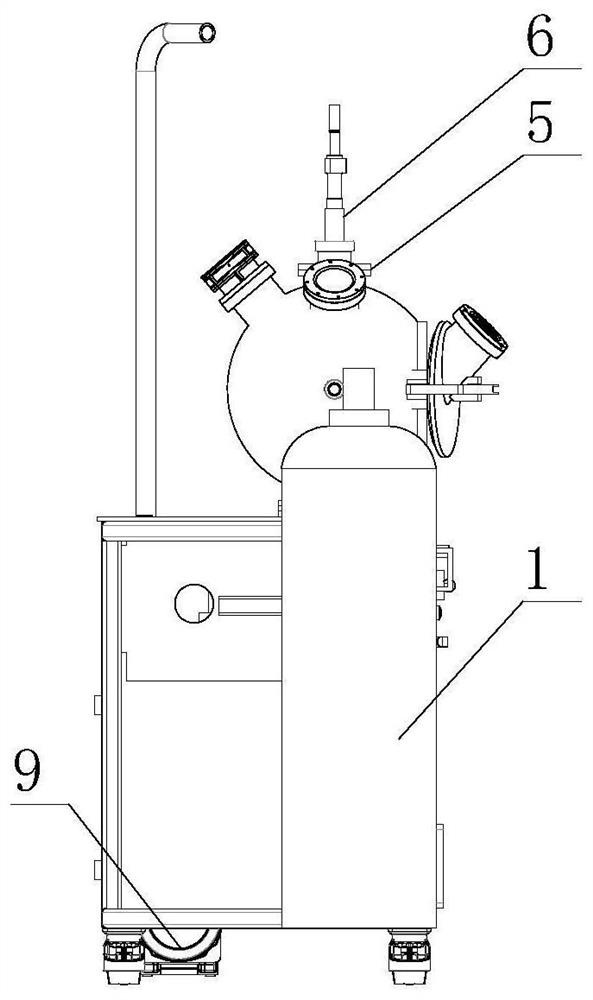

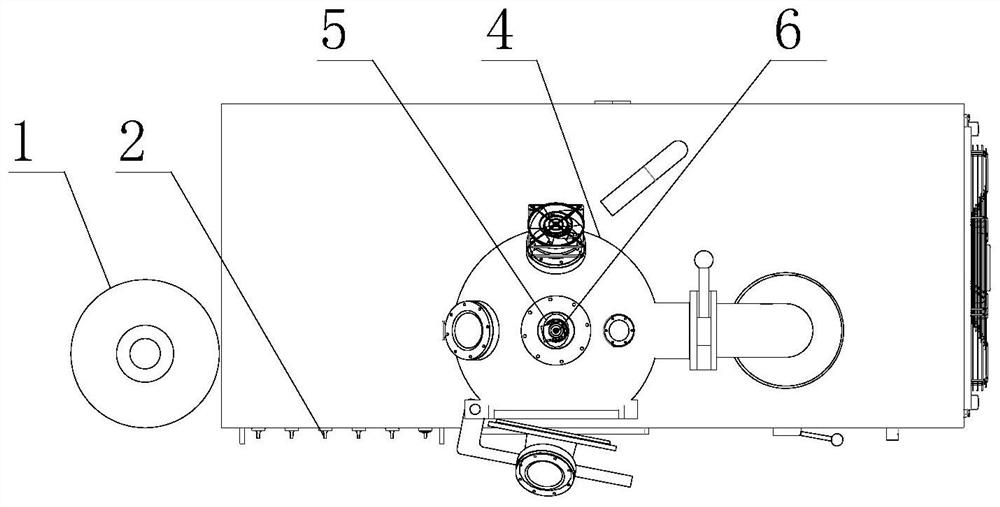

[0069] Such as figure 1 , figure 2 and image 3 As shown, the vacuum high-efficiency electric arc melting furnace system includes an argon tank 1, an electric arc furnace 4, a diffusion pump 8, and a vacuum pump 9. It is filled with argon gas, and a control panel 2 is set above the electric arc furnace 4. The electric arc furnace 4 is controlled through the control panel 2. The top of the electric arc furnace 4 is connected with the rocker base 5 and the rocker 6, and the bottom of the electric arc furnace 4 is The crucible 7 is connected to the copper cap 3, the side of the electric arc furnace 4 is connected to the diffusion pump 8 through the pipeline, the electric arc furnace 4 is connected to the vacuum pump 9 through the gas pipeline, and the valve cover 12 of the vacuum switching valve on the electric arc furnace 4 is set as an integrated structure , control the electric arc furnace 4 to evacuate by turning on the vacuum pump 9 .

[0070] Yet another embodiment of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal conductivity | aaaaa | aaaaa |

| thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com