Rotary jet engine

An engine and rotor technology, applied in the field of jet jet engines, can solve the problems of jet engine manufacturing difficulties, discontinuous sealing lines of triangular piston rotary engines, uneven force on pistons, etc., and achieve light weight, good sealing, and simple heat dissipation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

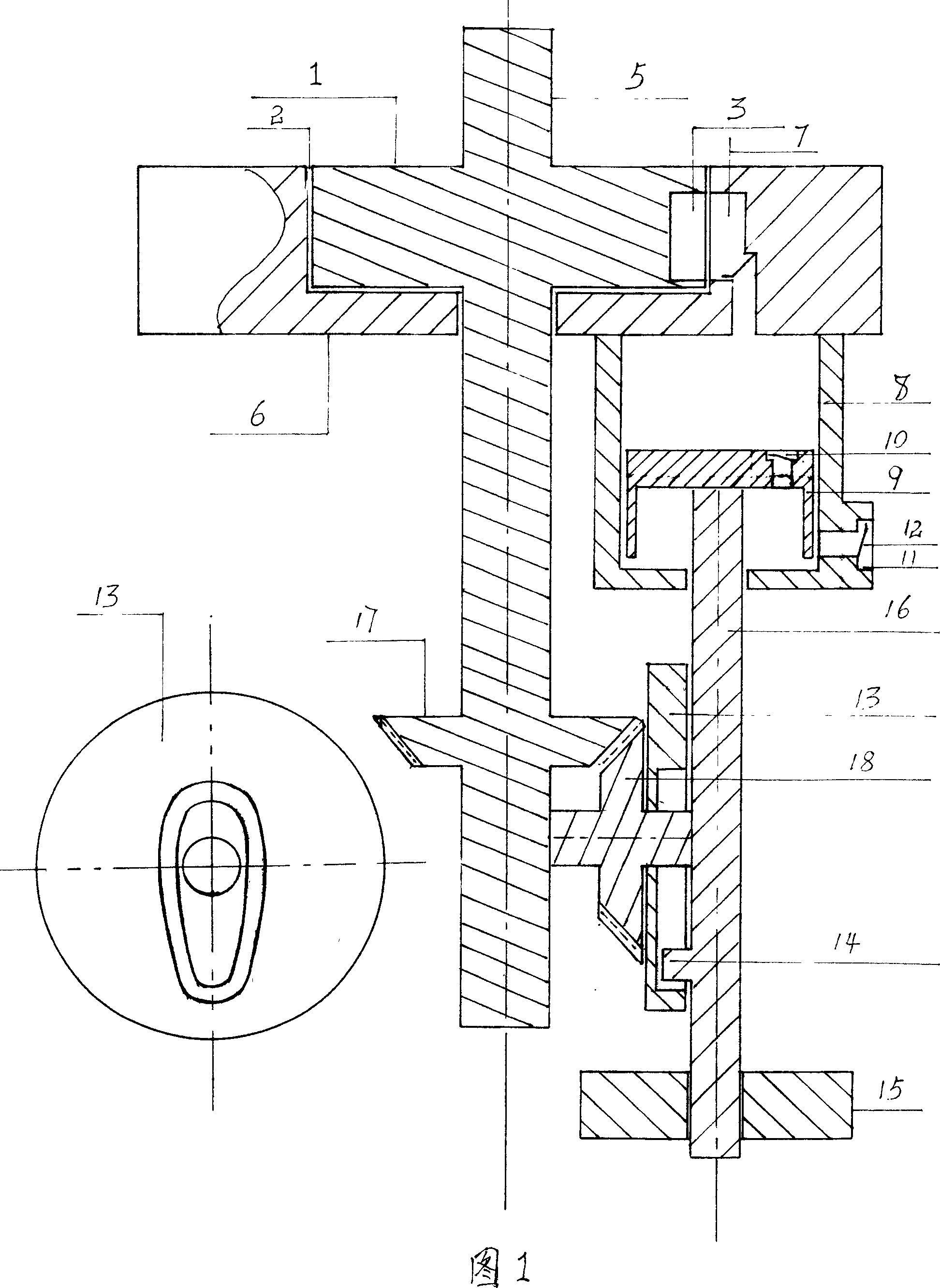

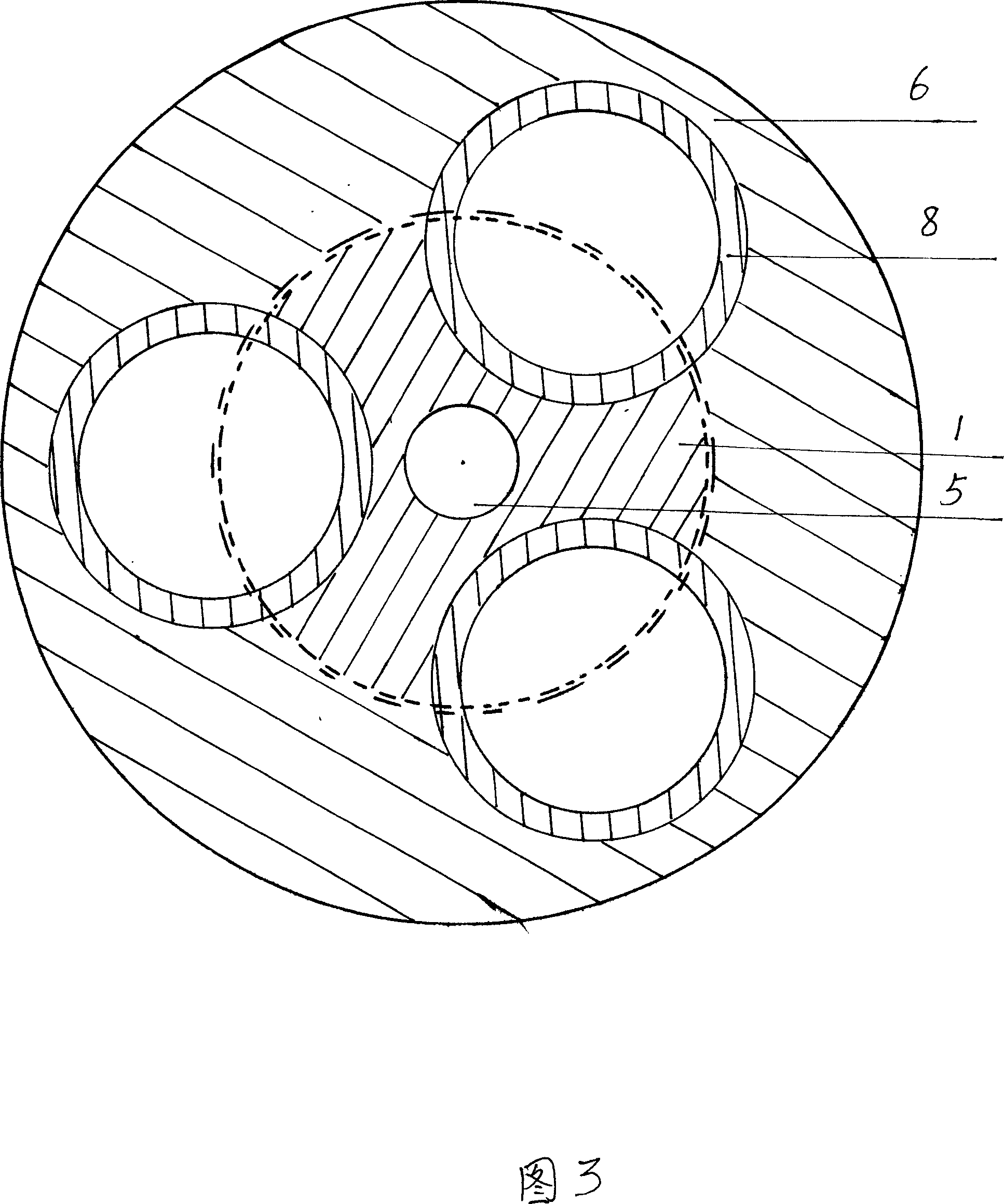

[0016] In Fig. 1, three cylinders 8 are fixed on the stator 6, a piston 9 is arranged in each cylinder, a piston check valve 10 is arranged on the piston 9, a square rod 16 is fixed on one end of the piston 9, and a square rod 16 is fixed on the square rod A certain position of 16 is fixed with a garden boss 14, and the garden boss 14 slides and places in the guide groove wheel 13, and a secondary bevel gear 18 is installed on the shaft of the guide groove wheel 13; Slide and import in the positioning square hole seat 15, an air inlet 11 is fixed on one end of the cylinder 8, and an air inlet check valve 12 is installed on the air inlet 11; On the rotor 1, three combustion chambers 3 (combustion expansion areas) and three sealing areas 2 are installed. The center of the rotor 1 is the rotating shaft 5, and the main bevel gear 17 is installed on the rotating shaft 5. The main bevel gear 17 and Auxiliary bevel gears 18 mesh with each other

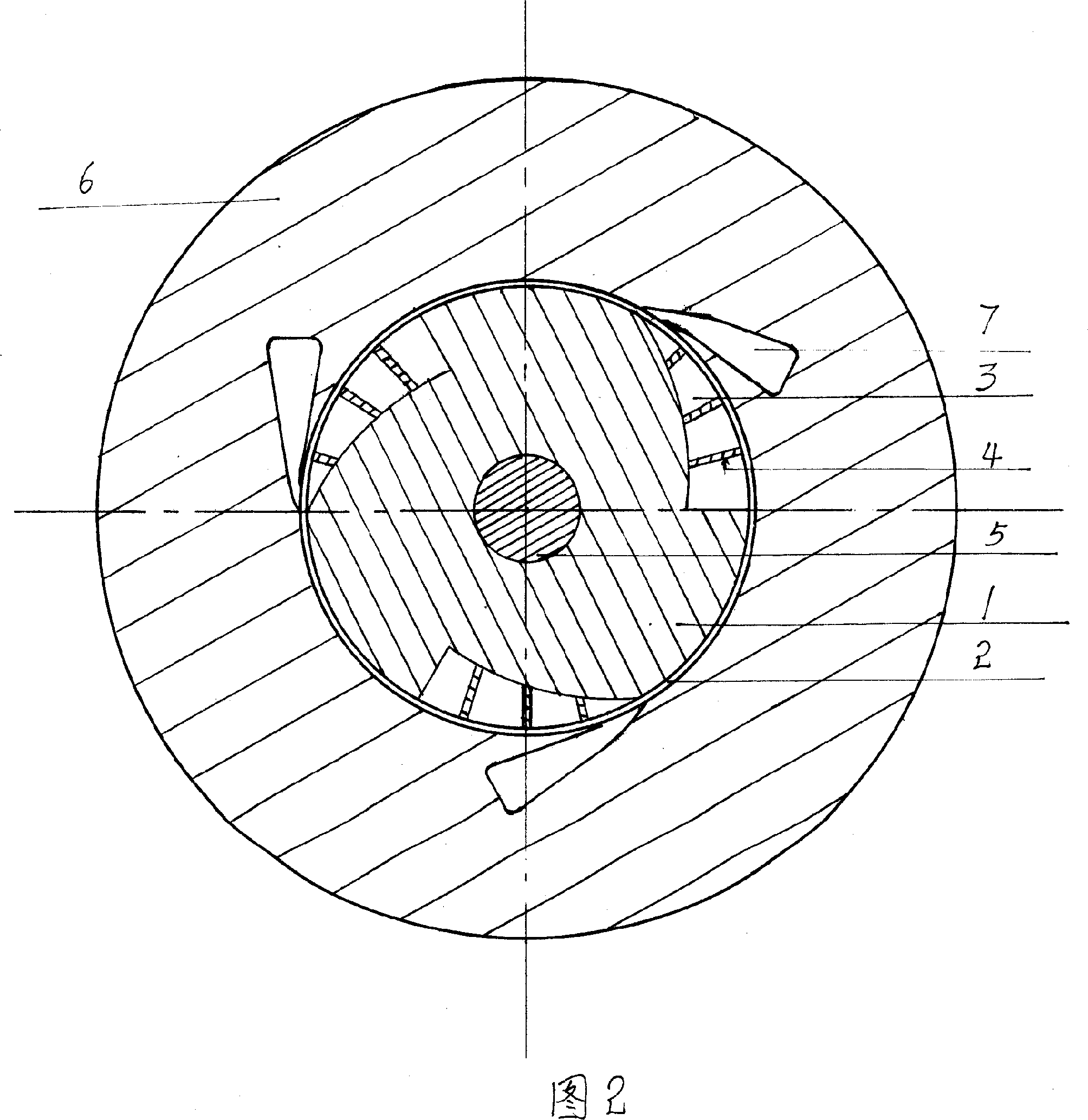

[0017] In Fig. 2, the rotor 1 is ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com