Integral plug-in valve core assembly for hand-operated direction valve

A manual reversing valve and cartridge valve technology, which is used in mining equipment, earthwork drilling, pillars/supports, etc., can solve the problems of poor anti-pollution ability, inconvenient disassembly and assembly, and achieve low movement resistance, easy replacement and Maintenance, compact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

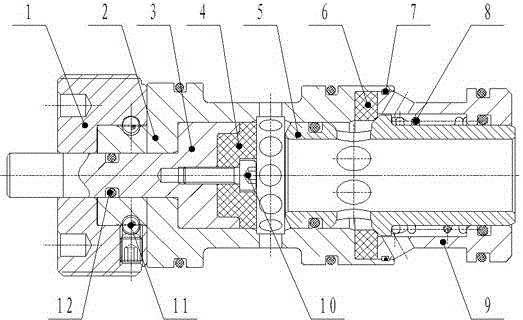

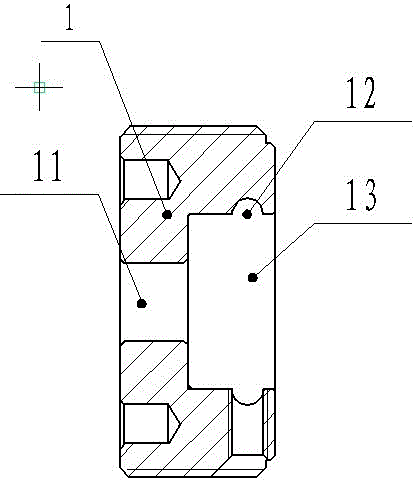

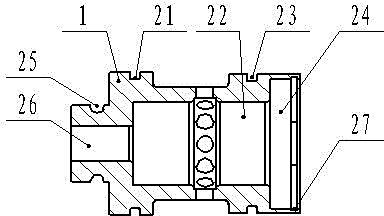

[0017] Such as figure 1 As shown, an integral cartridge type valve core assembly for a manual reversing valve, which includes a screw plug 1, a valve sleeve 2, a valve stem assembly, a valve core 5, a valve seat 6, a wire key 7, a high pressure valve sleeve 9 and a steel Ball 11, the screw plug 1 is composed of a left cavity 11, a right cavity 13, and a groove 12 along the circumference of the right cavity 13, which are sequentially connected in the axial direction. The outer surface of the screw plug 1 is provided with threads; the screw plug 1 The steel ball 11 is rotationally connected with the valve sleeve 2. The valve sleeve 2 is mainly composed of a left cavity 26, a middle cavity 22 and a right end cavity 24 which are sequentially connected in the axial direction. The middle position of the middle cavity 22 is along the circumference. A plurality of through holes are arranged in the direction, the right end of the right end cavity 24 is provided with an expansion groove...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com