Solution treatment and granular medium cold forming method for high-strength aluminum alloy pipe fitting

A solid solution treatment and granular medium technology, applied in heat treatment furnaces, heat treatment equipment, improvement of process efficiency, etc., can solve problems such as poor stability and low strength of formed pipe fittings, and achieve low hardness, low investment cost, and low energy consumption. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] The high-strength aluminum alloy pipe fitting solid particle medium cold expansion forming method of the present invention is as follows, as figure 1 Shown:

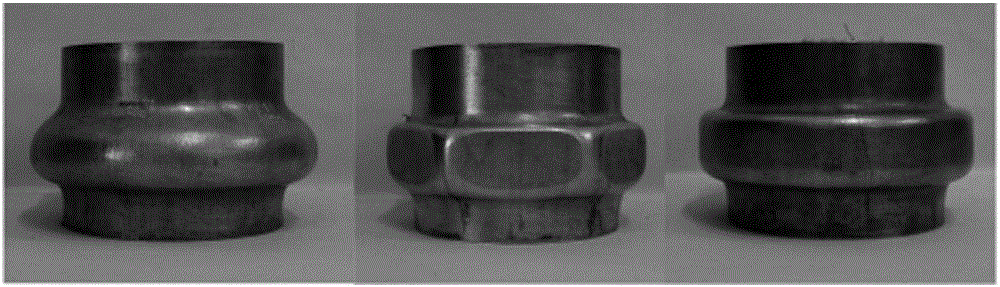

[0024] (1) First cut the AA6061 extruded pipe to make a pipe blank, such as image 3 As shown, put it into a box-type heating furnace for solid solution treatment, the heating temperature is generally 560 ° C, the holding time is 2 hours, water quenching after the treatment, the transfer time is 4 seconds, and the water temperature is 25 ° C. In order to avoid the influence of natural aging, The treated tube blank needs to be stored at -10°C low temperature, such as Figure 4 shown;

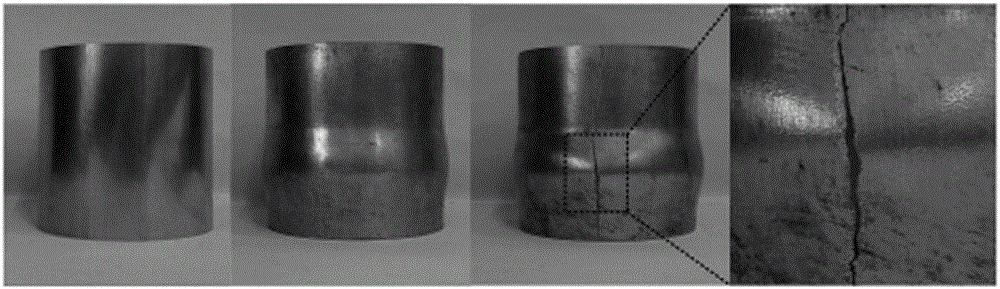

[0025] (2) The tube blank after solid solution treatment is subjected to high pressure bulging in the granular medium at room temperature, the outer wall of the tube blank is wrapped with polytetrafluoroethylene for lubrication, the tube blank is put into the mold, filled with granular medium, and the mold is installed The indente...

Embodiment 2

[0028] The high-strength aluminum alloy pipe fitting solid particle medium cold expansion forming method of the present invention is as follows, as figure 1 Shown:

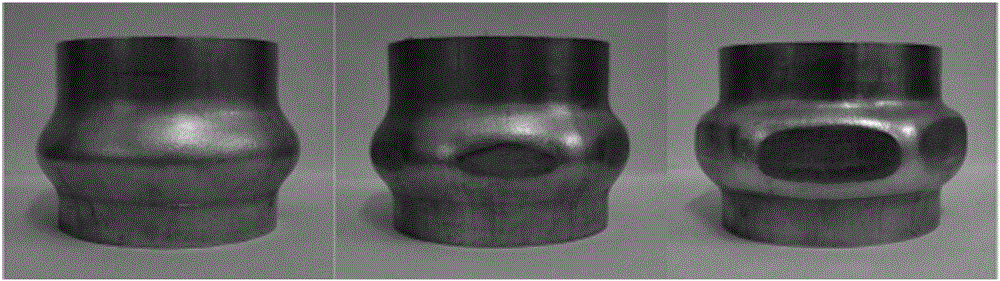

[0029] (1) First cut the AA7075 extruded pipe to make a pipe blank, and put it into a box-type heating furnace for solid solution treatment. The heating temperature is generally 470°C, and the holding time is 1.5h. After the treatment, it is quenched in water and the transfer time is 3s. ,, the water temperature is 25°C, in order to avoid the influence of natural aging, the treated tube blanks need to be stored at -15°C, such as Figure 5 shown;

[0030] (2) The tube blank after solid solution treatment is subjected to high pressure bulging in the granular medium at room temperature, the outer wall of the tube blank is wrapped with polytetrafluoroethylene for lubrication, the tube blank is put into the mold, filled with granular medium, and the mold is installed The indenter and the gland are closed until they c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com