Device for preparing semi-solid alloy melt and process for preparing AlSi9Mg semi-solid alloy

A semi-solid and alloy technology, which is applied in the field of semi-solid alloy forming, rheological forming process, inclined cooling shear frequency conversion vibration device, can solve the problems that hinder large-scale popularization and application, heating temperature is difficult to control, and heating equipment is complicated. Achieve the effects of improving the solidification structure, simple structure, and increasing the probability of nucleation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

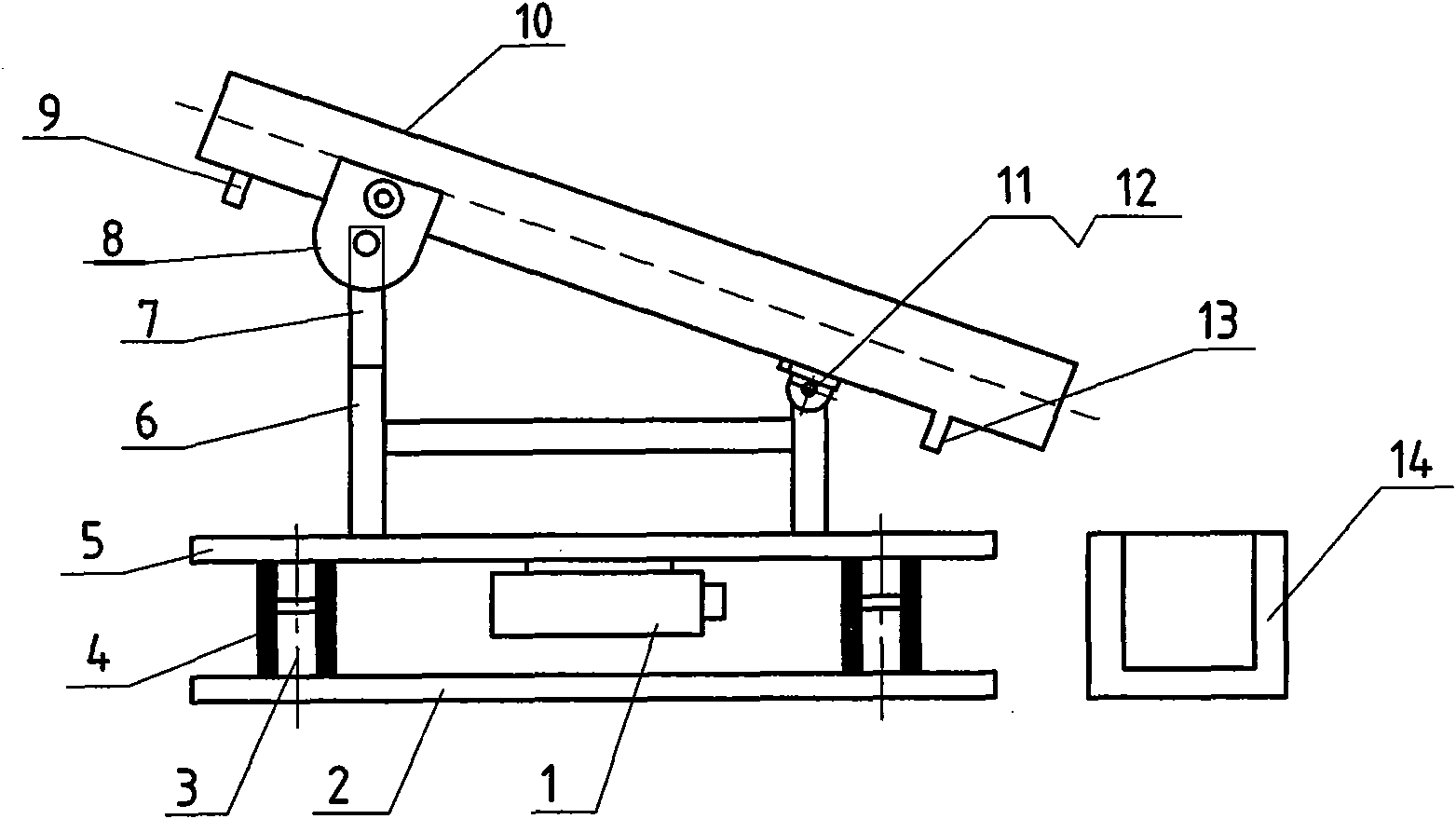

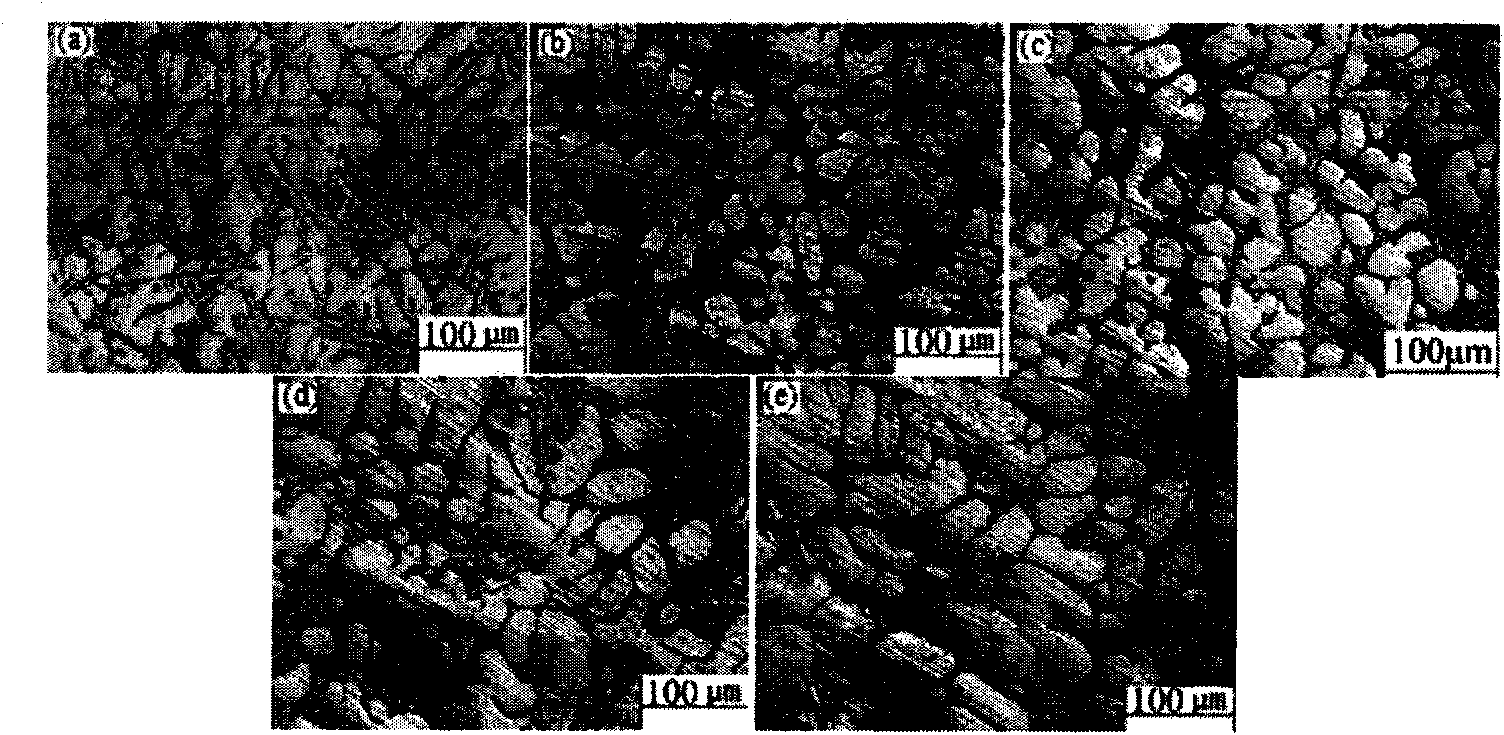

[0043] The process of preparing a semi-solid AlSi9Mg alloy melt or blank using the device for preparing a semi-solid alloy melt of the present invention comprises the following steps:

[0044] The first step: Put the aluminum-silicon alloy ingot and pure aluminum ingot into the electric resistance crucible boiler, heat up to 690℃~710℃ after they are completely melted, and then add the preheated aluminum-manganese master alloy.

[0045] The second step: at 680° C. to 700° C., press pure Mg wrapped in aluminum foil into the alloy liquid, and the weight of Mg accounts for 0.4% of the weight of the alloy liquid.

[0046] Step 3: After all the furnace materials are melted, refine with nitrogen at 700°C to 720°C to degas and remove slag from the alloy liquid.

[0047] Step 4: After refining, raise the temperature of the alloy solution to 720°C to 740°C for modification treatment, using sodium salt or Al-Sr alloy as the modification agent.

[0048] Step 5: At a certain inclination a...

Embodiment 2

[0055]Utilize the device for preparing semi-solid alloy melt of the present invention to prepare the rheological die-casting of semi-solid AlSi9Mg alloy except comprising the first to the fifth steps of preparing semi-solid AlSi9Mg alloy melt described in embodiment 1, also include Follow the steps below:

[0056] A. Preheat the mold to 200℃~220℃, apply water-based or wax-based paint inside the mold, and connect the mold to the front end of the die-casting machine.

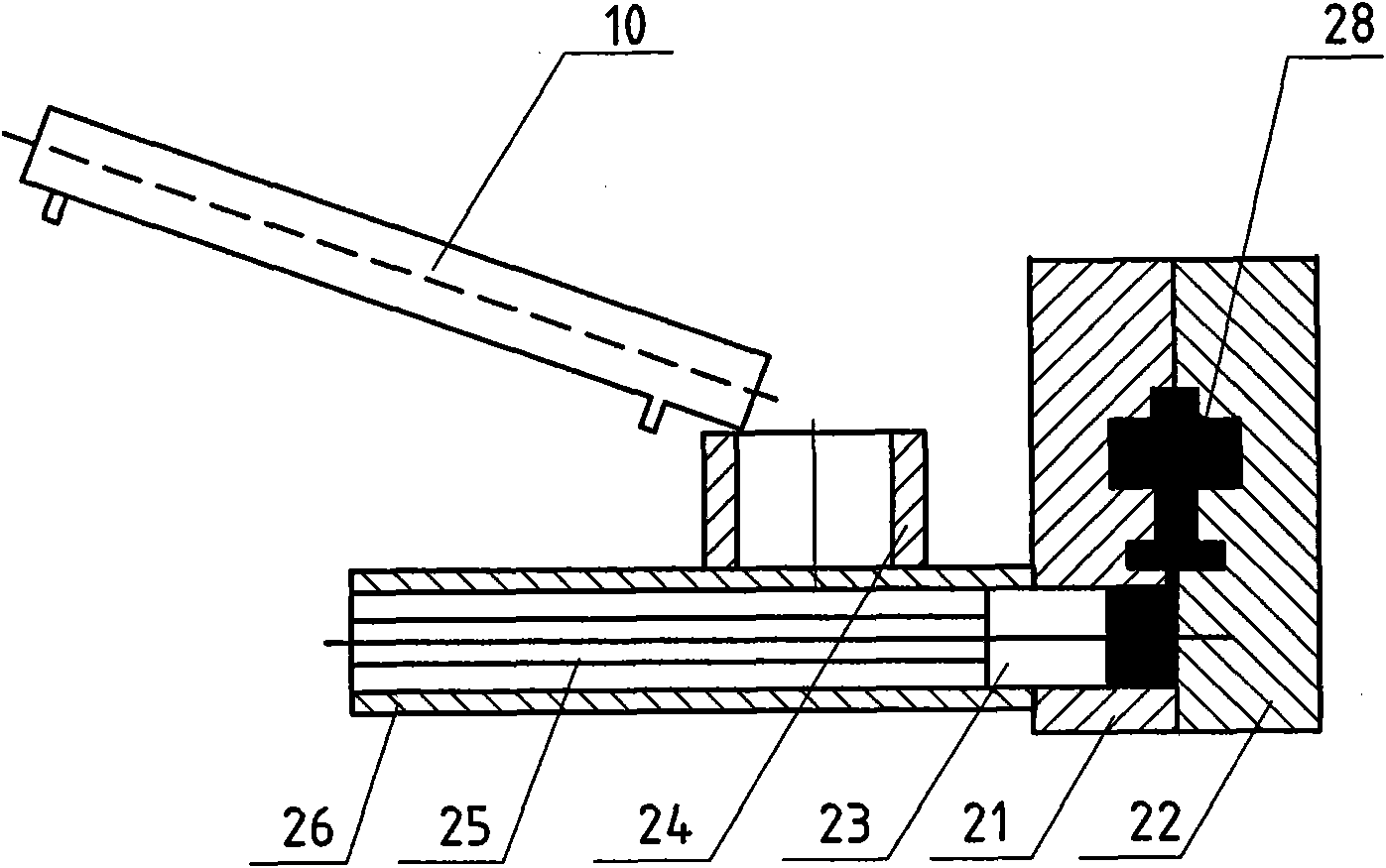

[0057] B. Adjust the position of the U-shaped cooling tank so that the liquid outlet of the U-shaped cooling tank 10 is aligned with the material receiving port of the rheological die-casting equipment, and the prepared semi-solid alloy melt is directly poured into the pressure chamber of the rheological die-casting equipment.

[0058] C. Die-casting is carried out under the conditions that the specific injection pressure is 40MPa-80MPa, and the filling speed is 1.2m / s-2.5m / s.

[0059] D. Hold the pressure for 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com