Patents

Literature

33results about How to "Improve incompatibility" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

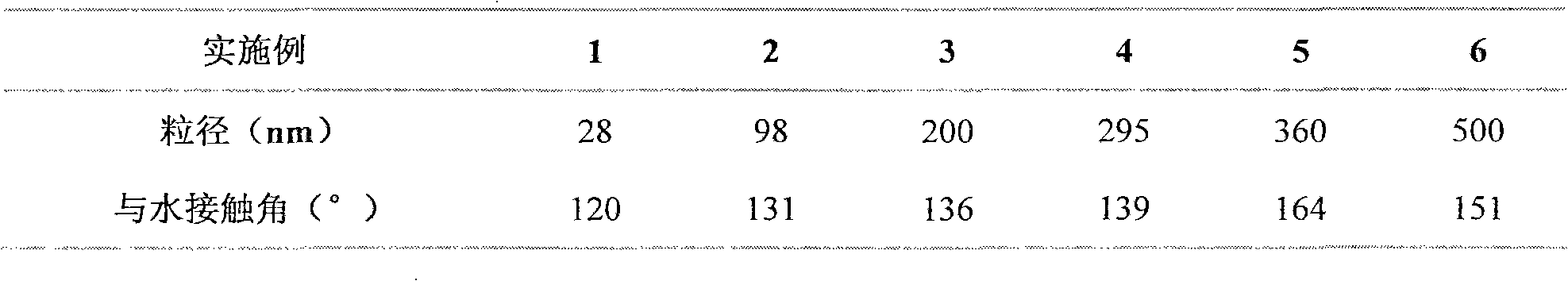

Method for preparing hydrophobic nano-silica with controllable grain diameter

InactiveCN101880478AGood dispersionHydrophobicPigment treatment with organosilicon compoundsSal ammoniacReaction temperature

The invention discloses a method for preparing hydrophobic nano-silica with a controllable grain diameter. The method comprises the following steps of: adding ammonia water and water into absolute ethanol and stirring the mixture for 0.5 to 1 hour at the temperature of between 20 and 70 DEG C; under an alkali condition, performing hydrolytic polycondensation to obtain nano-silica by using the absolute ethanol as solvent and tetraethoxysilane as a raw material; and preparing the hydrophobic nano-silica with the grain diameter in the range of between 20 and 500 nm by using a silane coupling agent as a hydrophobic modifier, wherein the using amount of ammonia water is 40 to 100 percent of the weight of the tetraethoxysilane; the using amount of the absolute ethanol is 12 to 25 times the weight of the tetraethoxysilane; and the using amount of the water is 30 to 150 percent of the weight of the tetraethoxysilane. The preparation method has the advantages of simpleness, easy operation and mild reaction condition. The hydrophobic nano-silica with the controllable grain diameter can be prepared by adjusting proportion and technological parameters of the materials.

Owner:SOUTH CHINA UNIV OF TECH

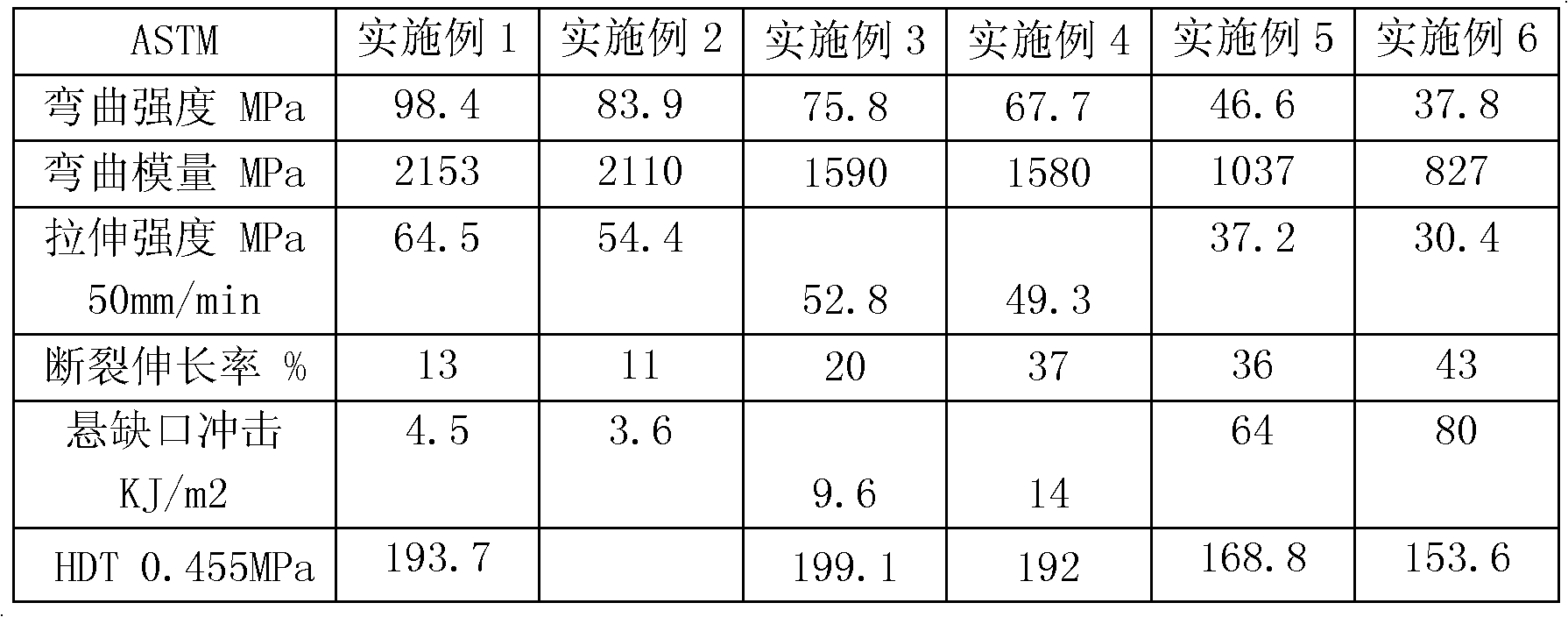

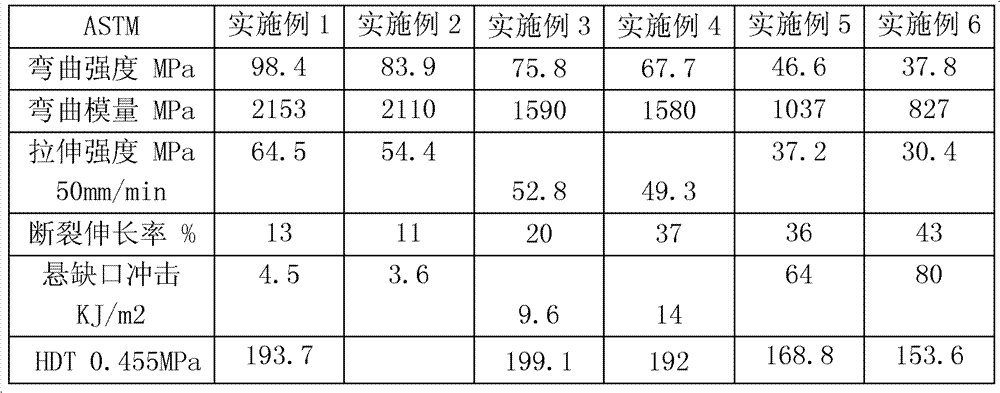

Toughened polyphenyl ether and nylon alloy and preparation method for toughened polyphenyl ether and nylon alloy

The invention discloses a toughened polyphenyl ether and nylon alloy and a preparation method for the toughened polyphenyl ether and nylon alloy. The toughened polyphenyl ether and nylon alloy comprises the following components in weight percentage: 20-60 percent of polyphenyl ether, 20-60 percent of polyamide, 5-20 percent of compatilizer, 5-20 percent of toughening agent and 1-2 percent of other additives. The incompatibility of the polyphenyl ether and nylon comprised by the invention is improved through the added compatilizer. Through changing the content of the toughening agent in the alloy material, the alloy material with different impact strength is obtained. A product prepared from the toughened polyphenyl ether and nylon alloy is capable of resisting the high temperature of at least 160 DEG C of a production line and the corrosion of dimethylbenzene and methylbenzene as solvents in spray paint; the contour dimension is kept unchanged; and the phenomena, such as stress cracking and the like, do not occur.

Owner:HEFEI GENIUS NEW MATERIALS

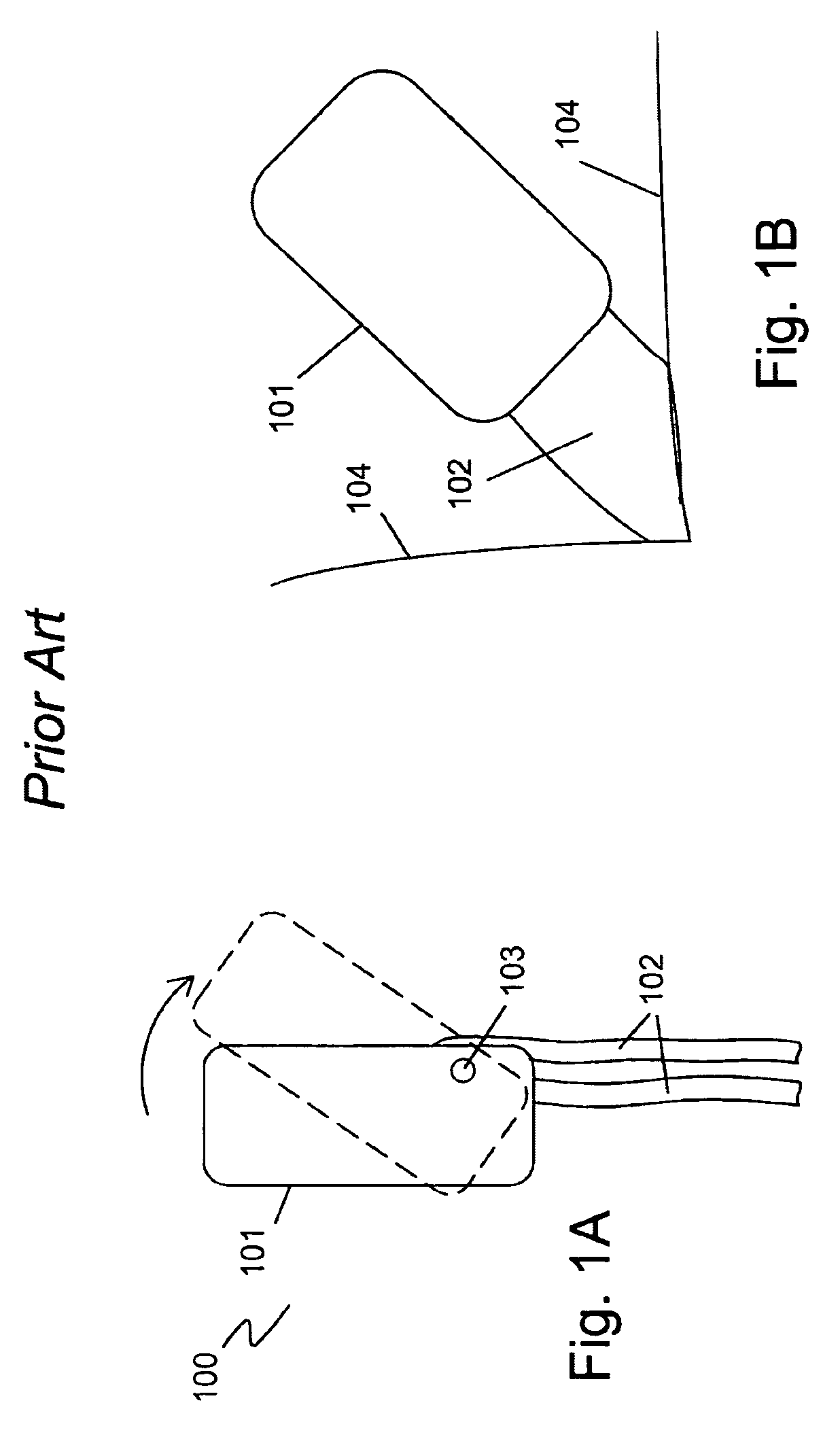

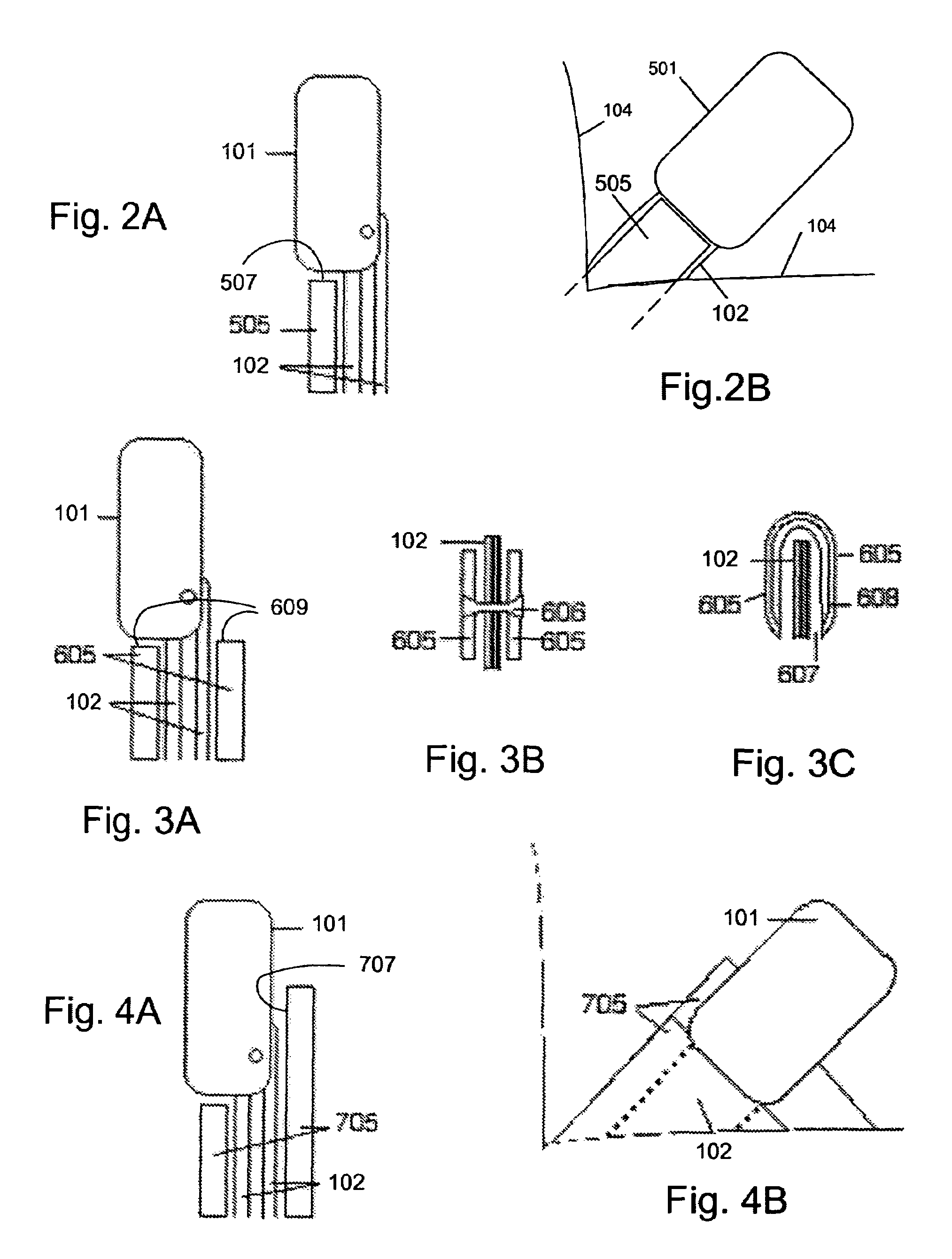

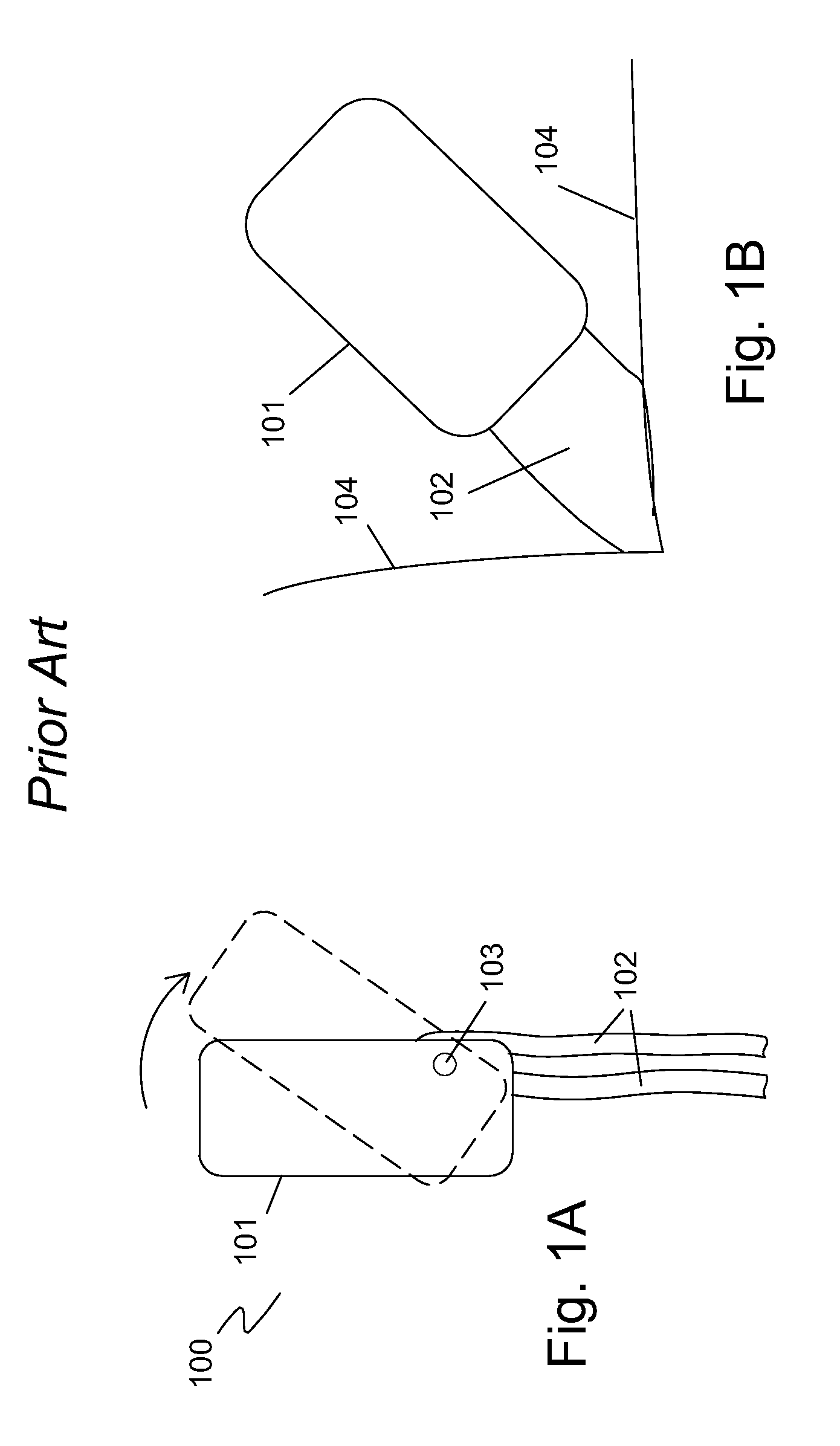

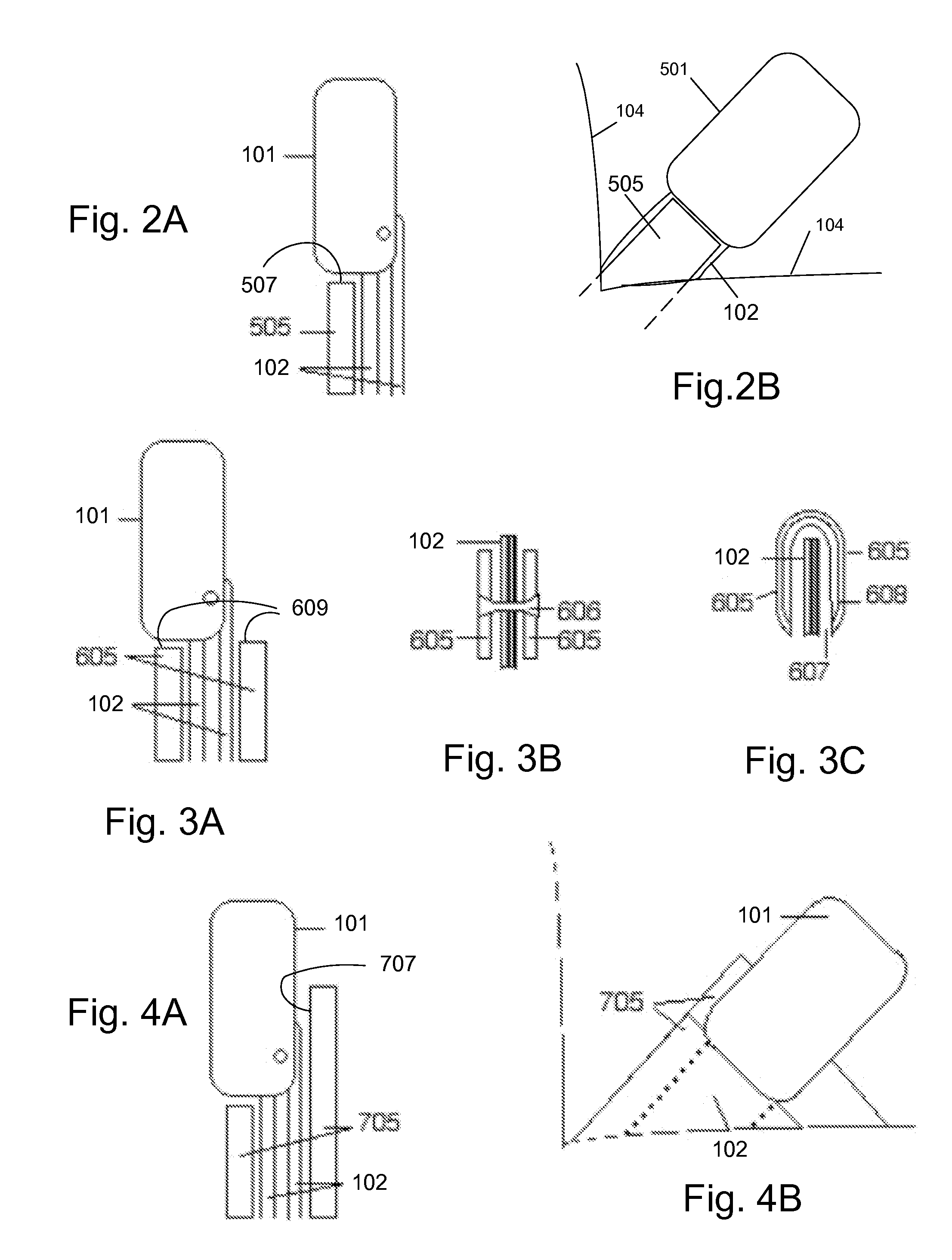

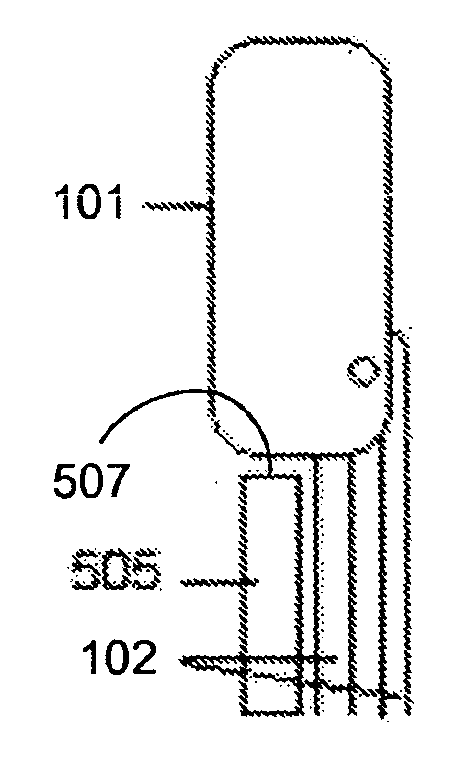

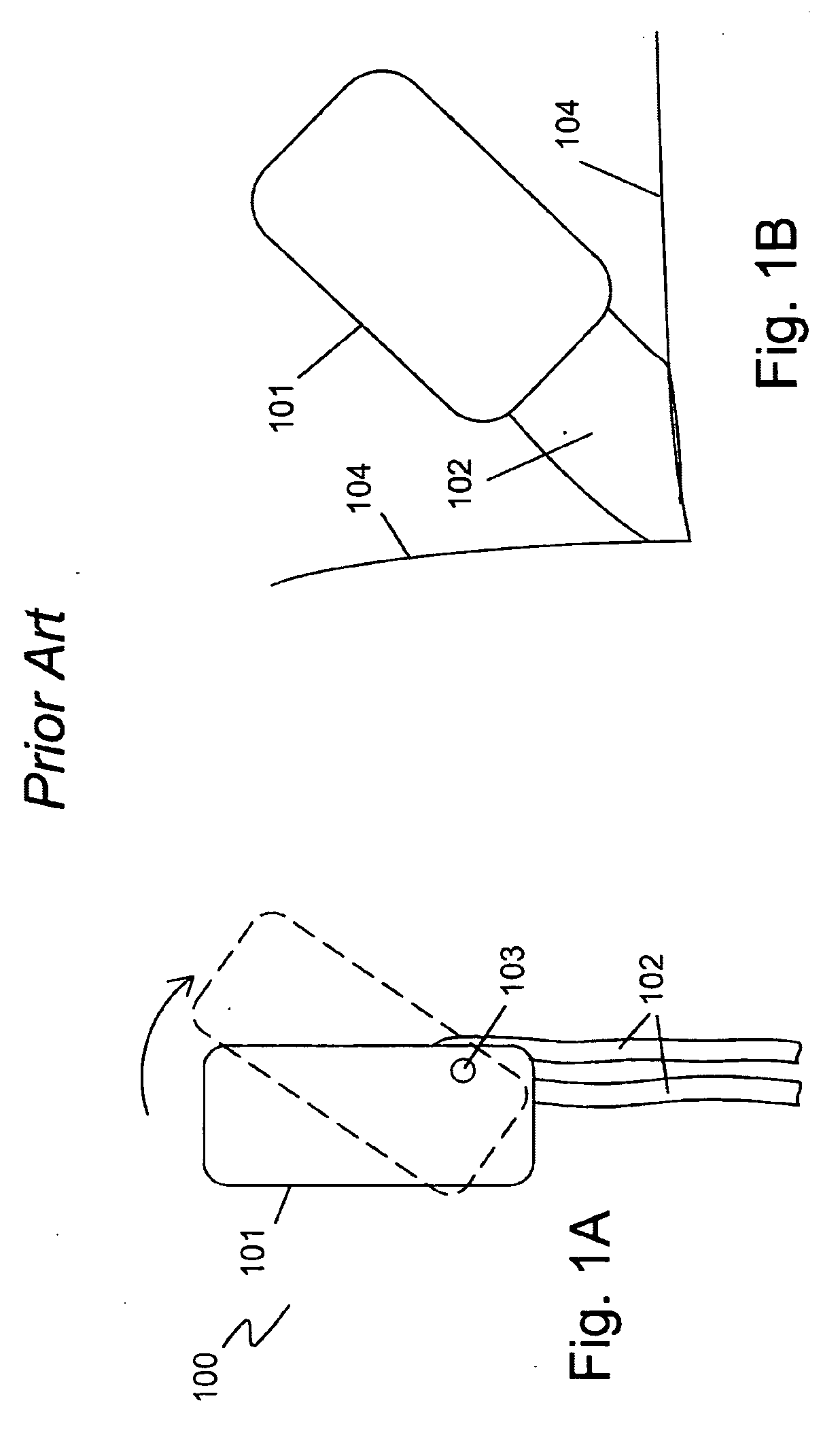

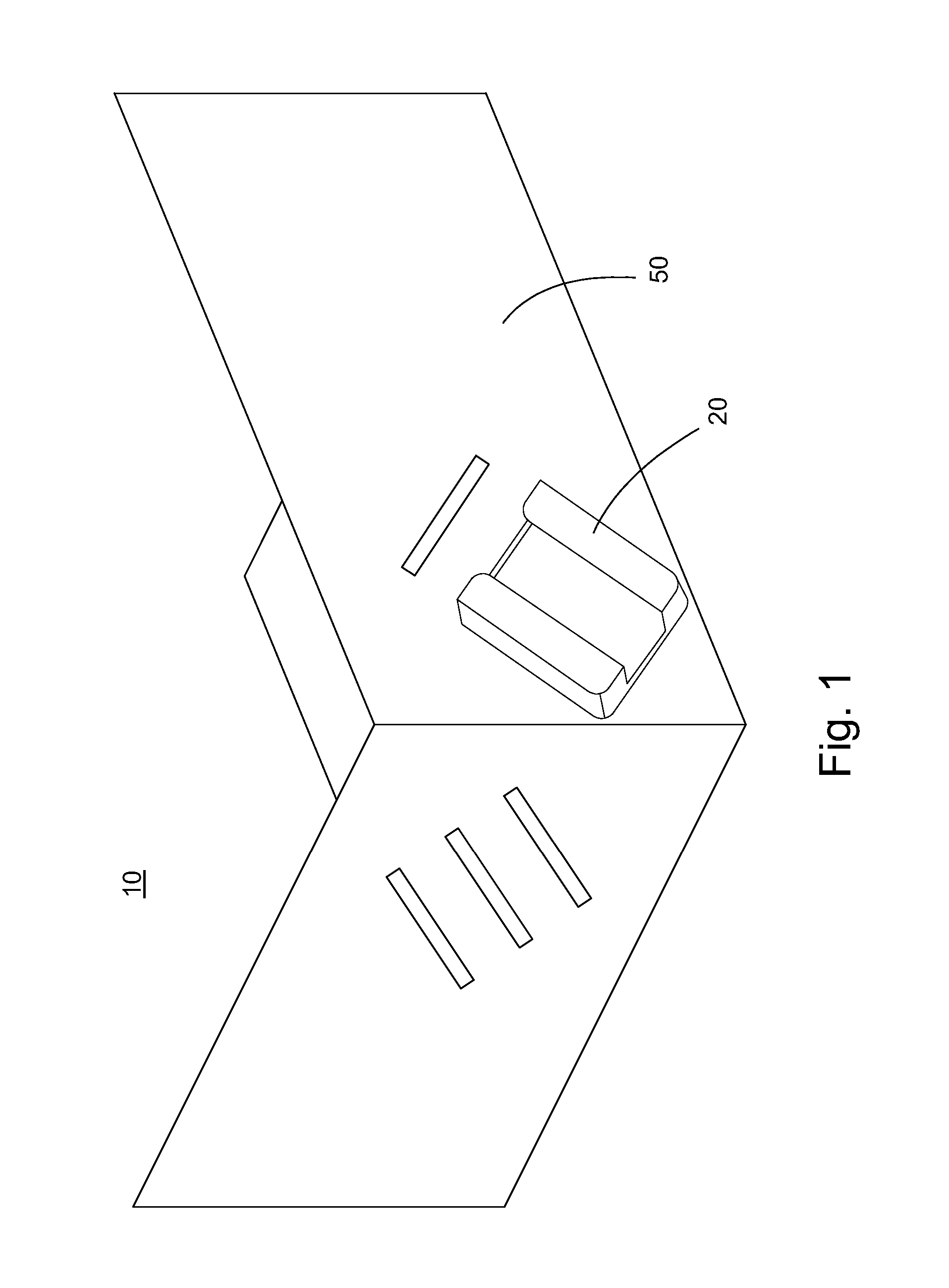

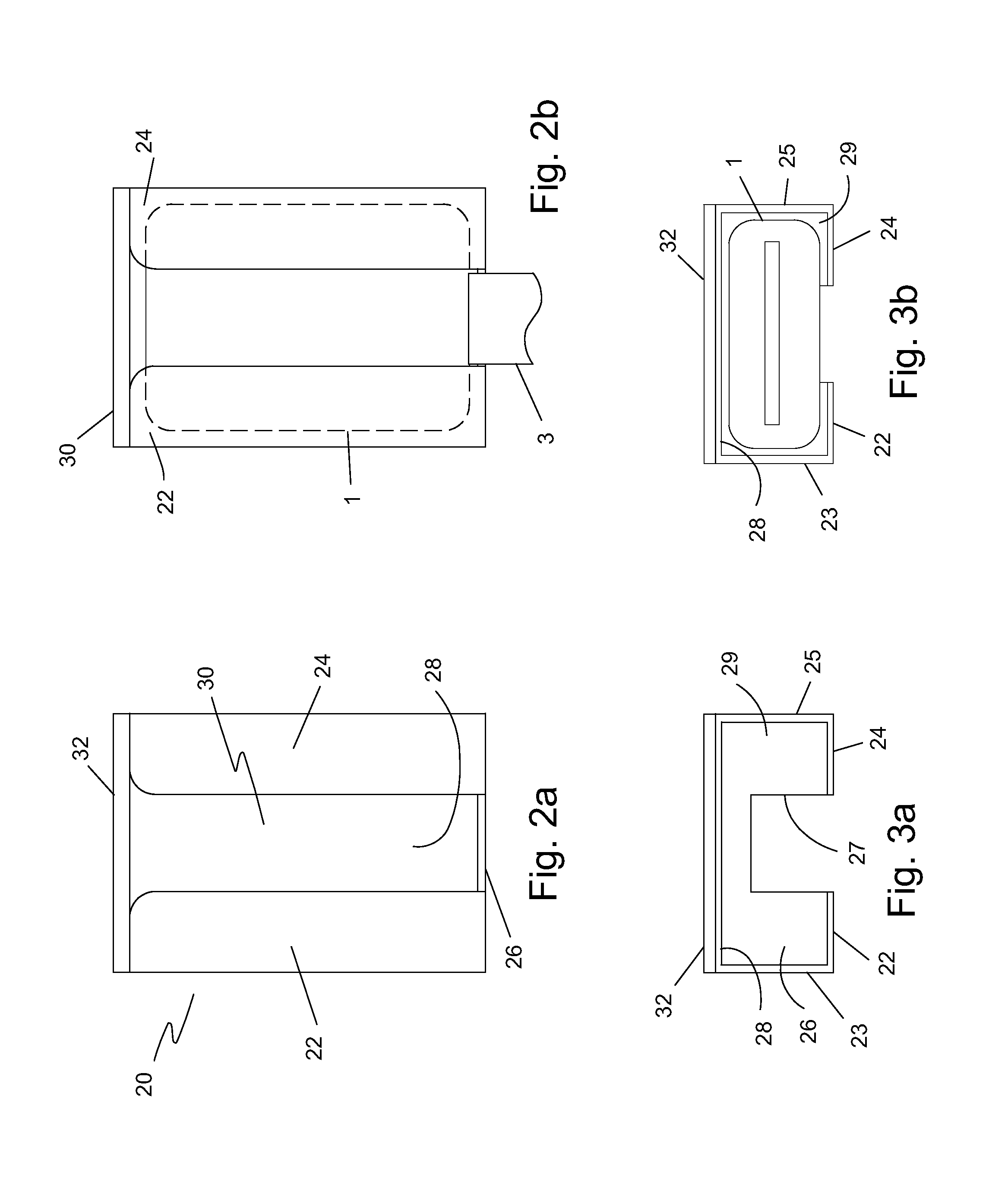

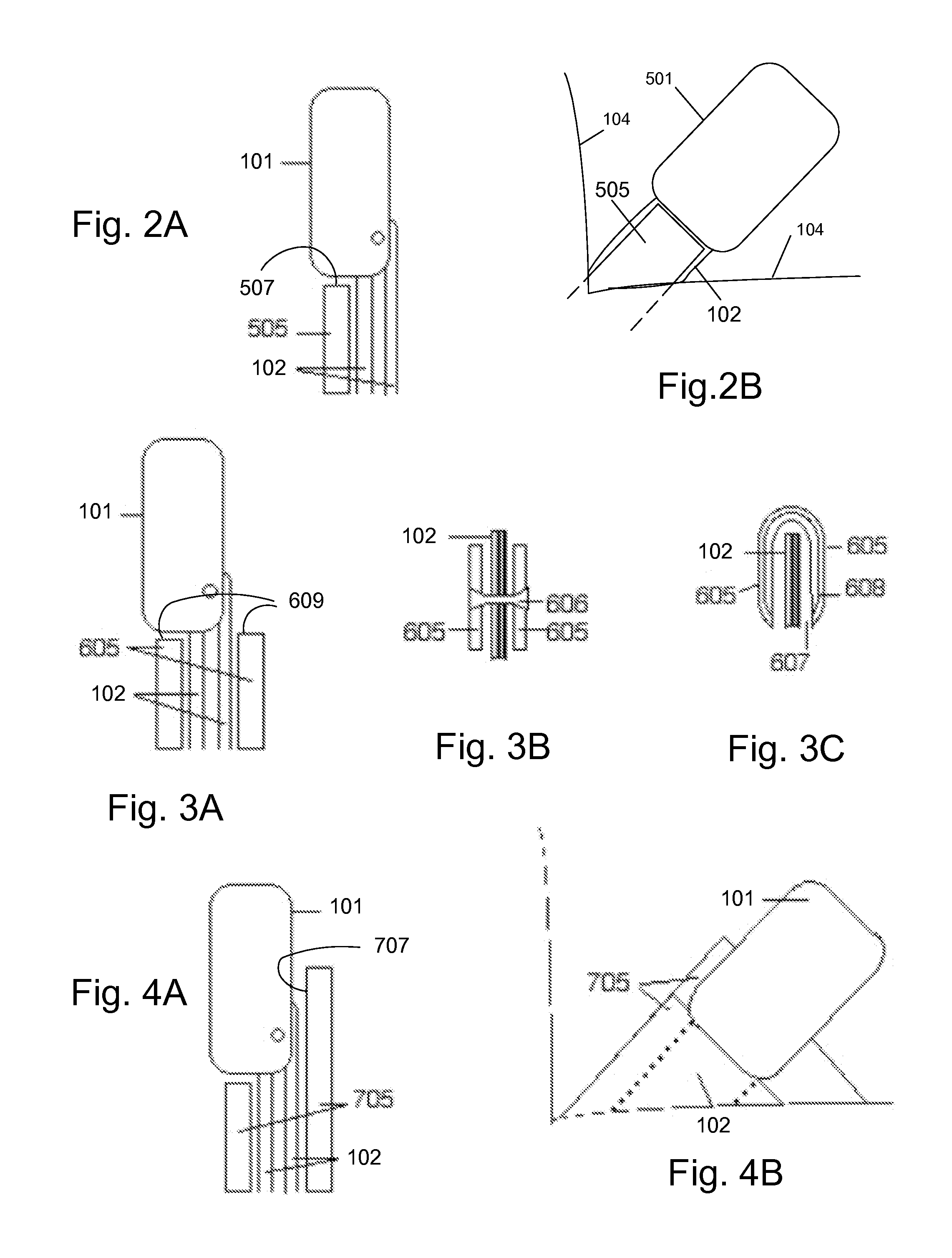

Seat belt buckle positioner

InactiveUS7648208B2Improve convenienceReduce difficultySafety beltsPedestrian/occupant safety arrangementSeat beltEngineering

A seat belt device for stabilizing and positioning a flexible vehicle seat belt buckle having a substantially rigid support structure configured for combining with a vehicle seat belt buckle to convert a movable, flexible vehicle seat belt buckle to a substantially stationary seat belt buckle for facilitating engagement of a seat belt latch. The support structure includes splinting configurations and wedging configurations.

Owner:WEINSTEIN ELISABETH +1

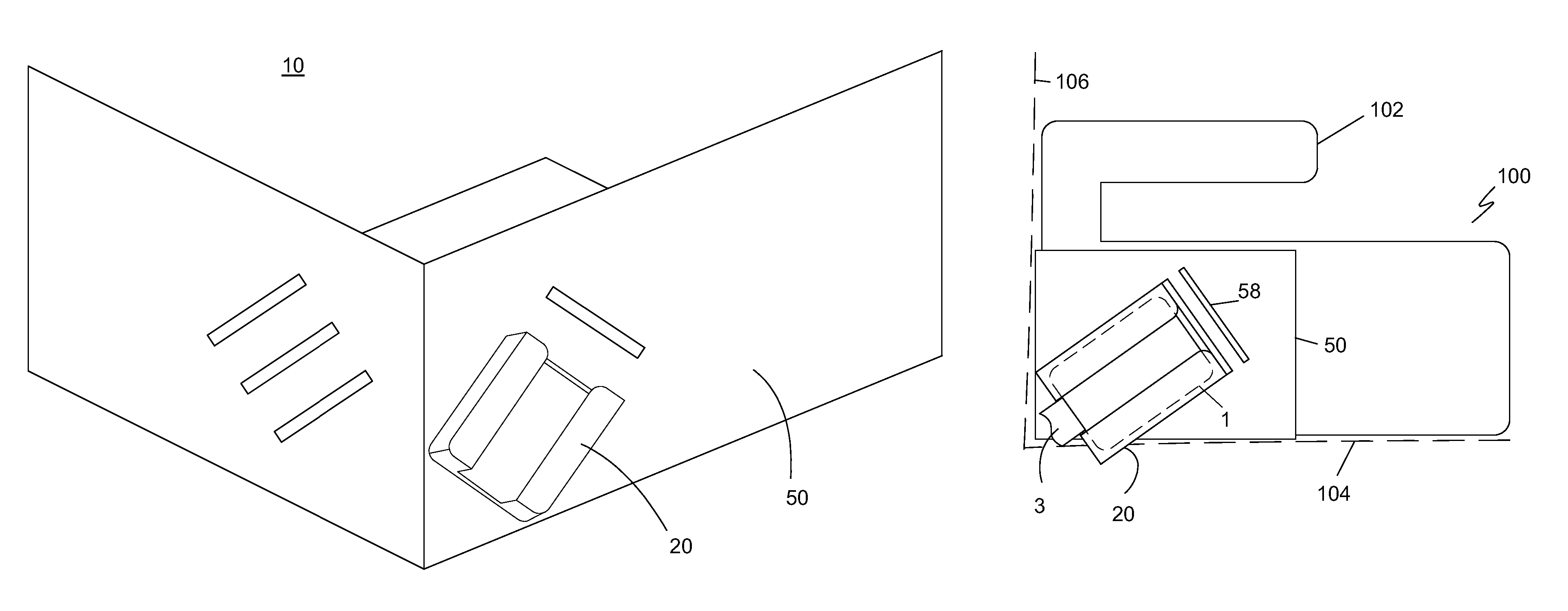

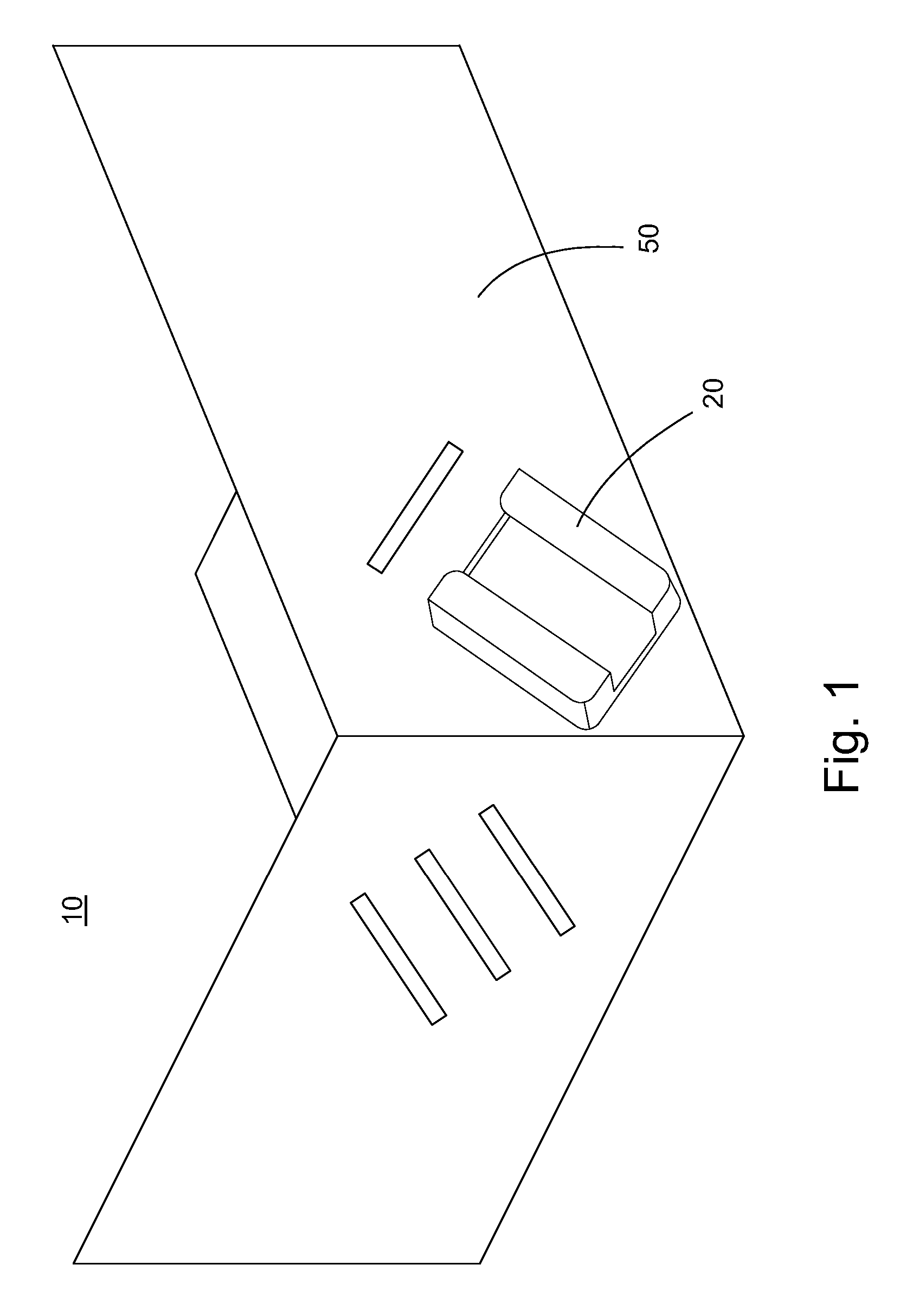

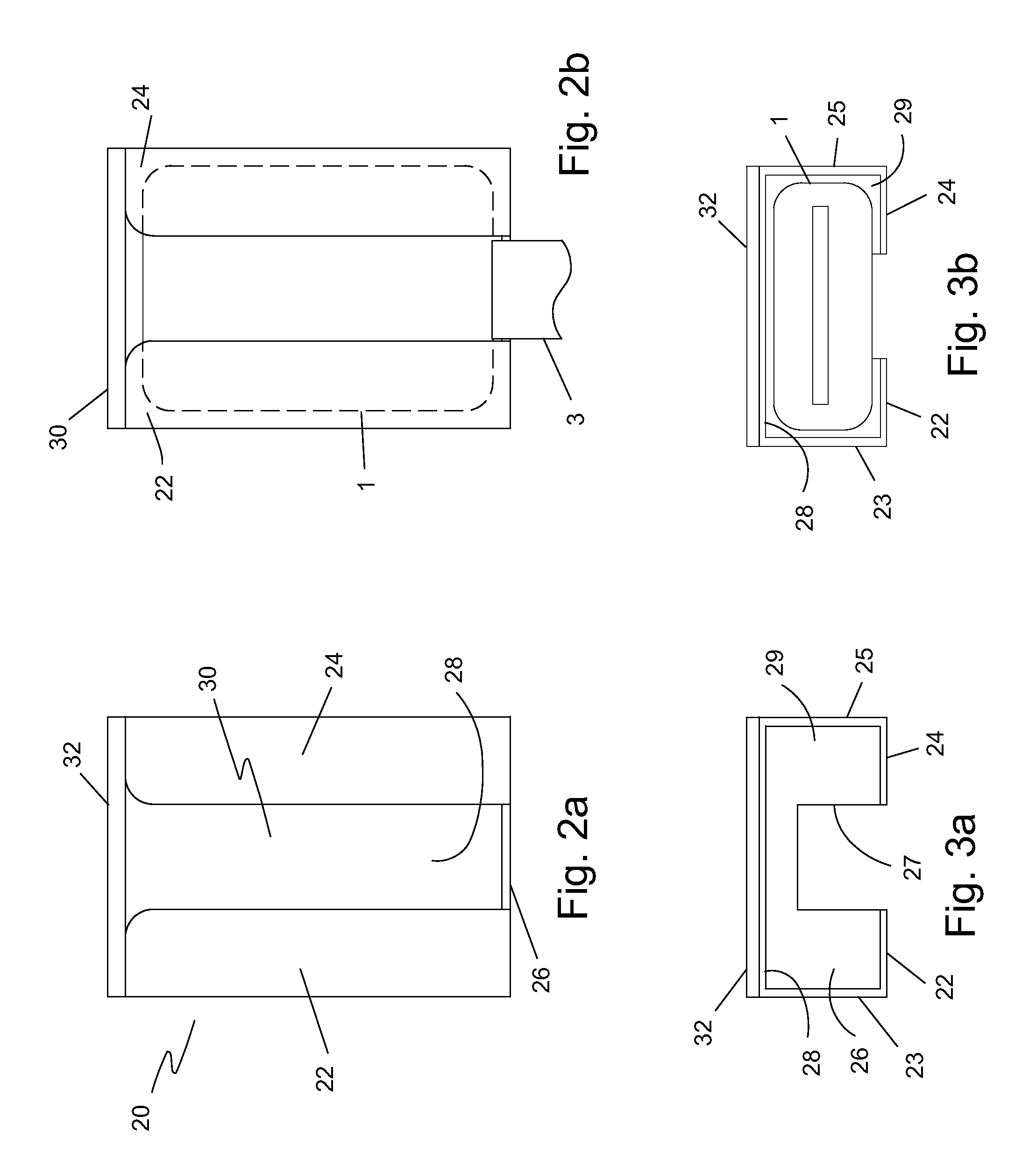

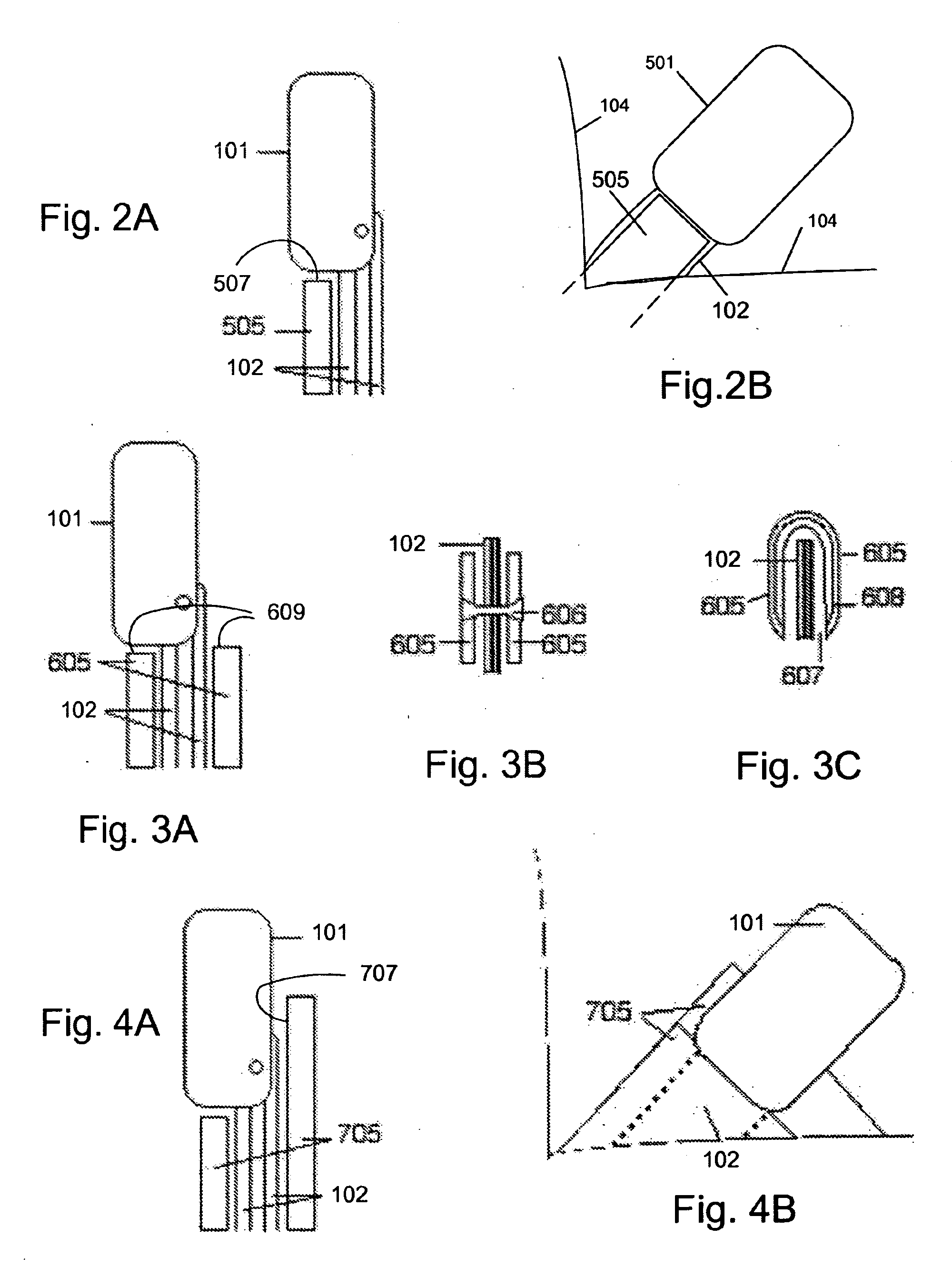

Seat belt buckle positioning system

InactiveUS7648209B2Improve convenienceReduce difficultyVehicle seatsSafety beltsSeat beltEngineering

A seat belt buckle positioning system for use with a child booster seat having a seat belt buckle holder that can grasp or envelope a vehicle seat belt buckle, and a seat belt buckle holder positioner to which the seat belt buckle holder can attach and be positioned at the side of the child booster seat.

Owner:WEINSTEIN ELISABETH +1

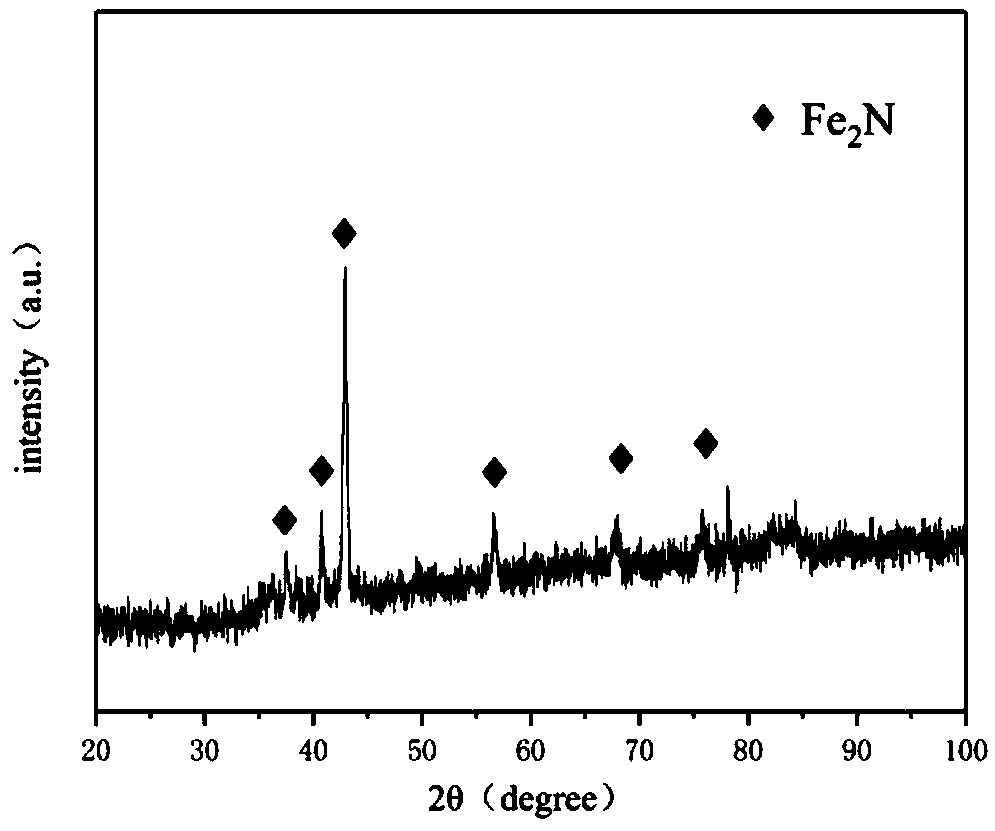

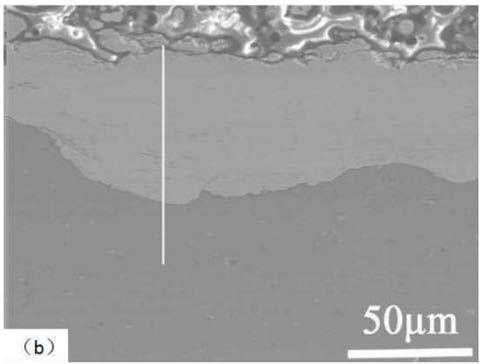

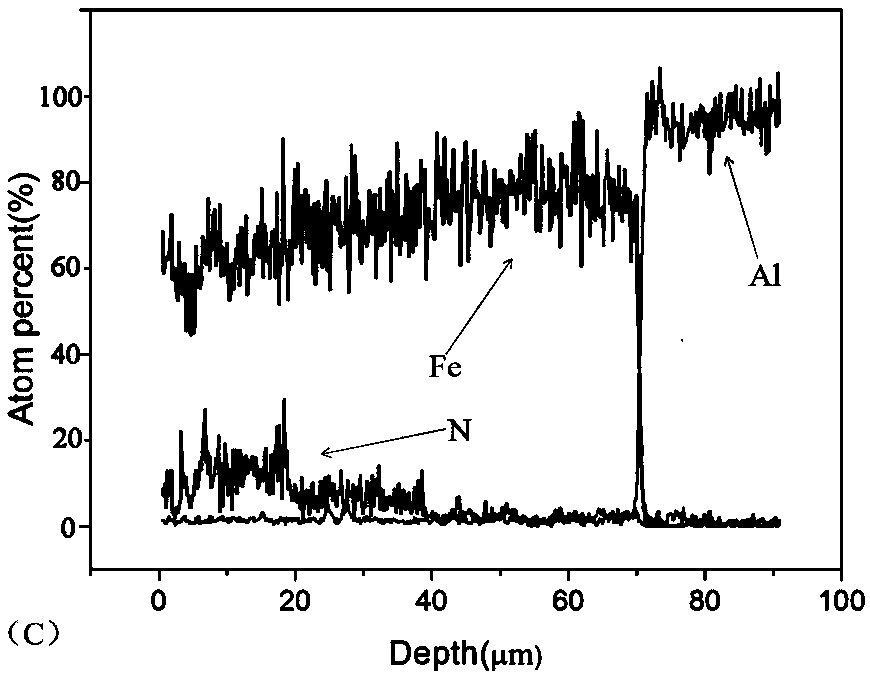

Method for preparing aluminum alloy surface composite gradient modified layer

InactiveCN109183020AImprove incompatibilityHigh hardnessSolid state diffusion coatingPressure inorganic powder coatingNano structuringBinding force

The invention discloses a method for preparing an aluminum alloy surface composite gradient modified layer. The method comprises the following steps: (1) pretreating the surface of an aluminum alloy material, namely grinding the surface with abrasive paper, sequentially washing respectively in alcohol and acetone solution to remove surface stains; (2) introducing a ferroalloy layer having a certain thickness and a nano-structure to the aluminum alloy surface by adopting a surface mechanical nano-alloying method; and (3) performing nitriding treatment at a certain temperature on the sample which is subjected to surface alloying treatment. By adopting the method, a modified layer having a gradient composite structure and excellent abrasion resistance is prepared on the surface of the aluminum alloy matrix, and has excellent compatibility and binding force with the matrix. Furthermore, the method is simple in process and low in cost, and is suitable for large-scale surface treatment of flat aluminum alloy materials.

Owner:HEFEI UNIV OF TECH

Specific ceramic lining composite pipe, pipe fitting and their producing method

InactiveCN1425865AImprove incompatibilityCorrosion preventionPipe protection against corrosion/incrustationPipe fittingPotassium silicate

The composite pipe and pipe fitting are carbon steel or cast iron pipe with coated special ceramic lining concreted to the base material. The composite paint for the special ceramic lining consists of diabase powder, quartz powder, graphite, ceramic powder, granite sand, fluorosilicate, and alkali sodium silicate solution or potassium silicate solution. The production process of the composite pipe and pipe fitting includes pre-treatment of the pipe or pipe fitting, mixing and grouting slurry, centrifugally solidification and acid pickling. The present invention has anticorrosion grade over grade 10, can resist + / -0.1 MPa pressure and 0-300 deg.c temperature for long period without falling, has good incompatibility and is also suitable for curved pipe and reduced pipes.

Owner:QIANGDUN ANTI CORROSION EQUIP ZIBO

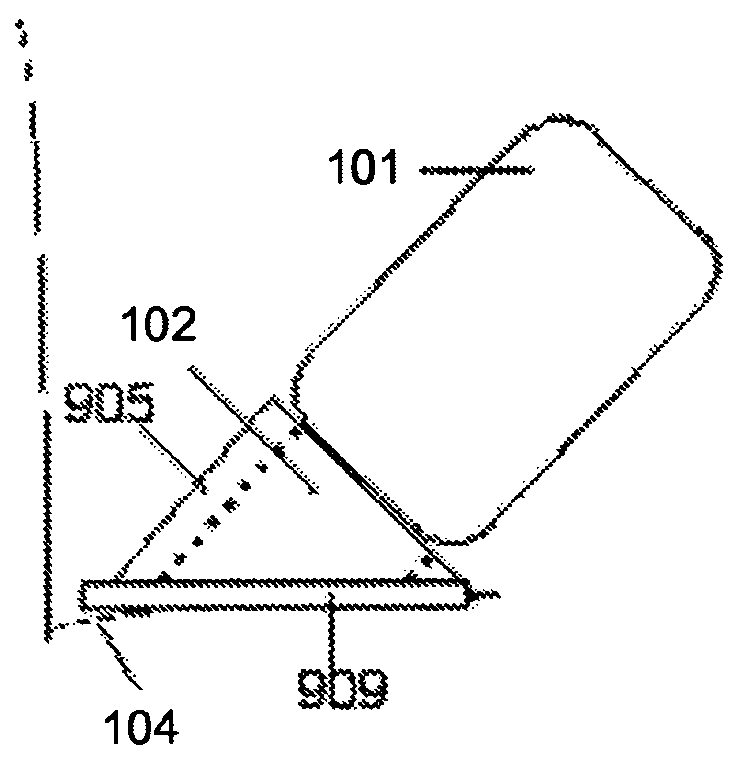

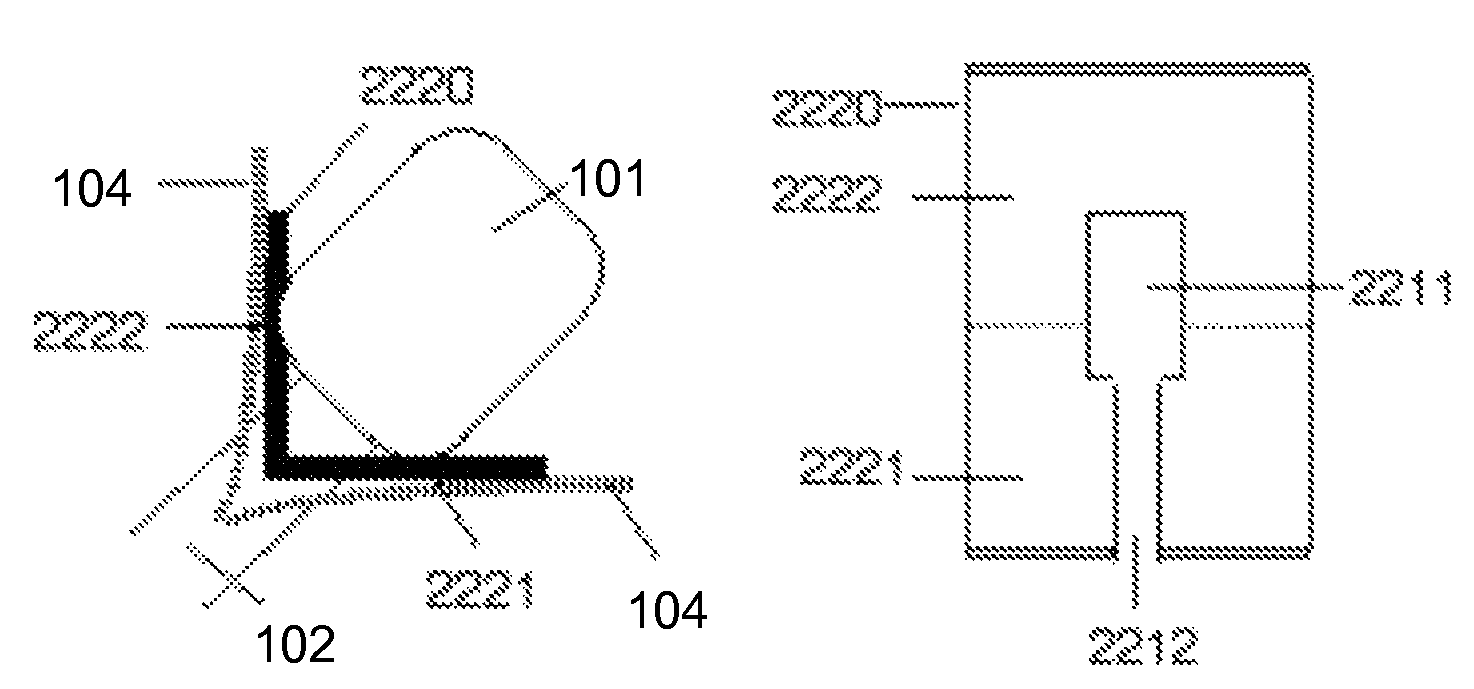

Seat belt buckle positioner

InactiveUS7862125B2Improve convenienceReduce difficultyVehicle seatsSafety beltsSeat beltEngineering

A seat belt device for stabilizing and positioning a flexible vehicle seat belt buckle having a substantially rigid support structure configured for combining with a vehicle seat belt buckle to convert a movable, flexible vehicle seat belt buckle to a substantially stationary seat belt buckle for facilitating engagement of a seat belt latch. The support structure includes splinting configurations and wedging configurations.

Owner:WEINSTEIN ELISABETH +1

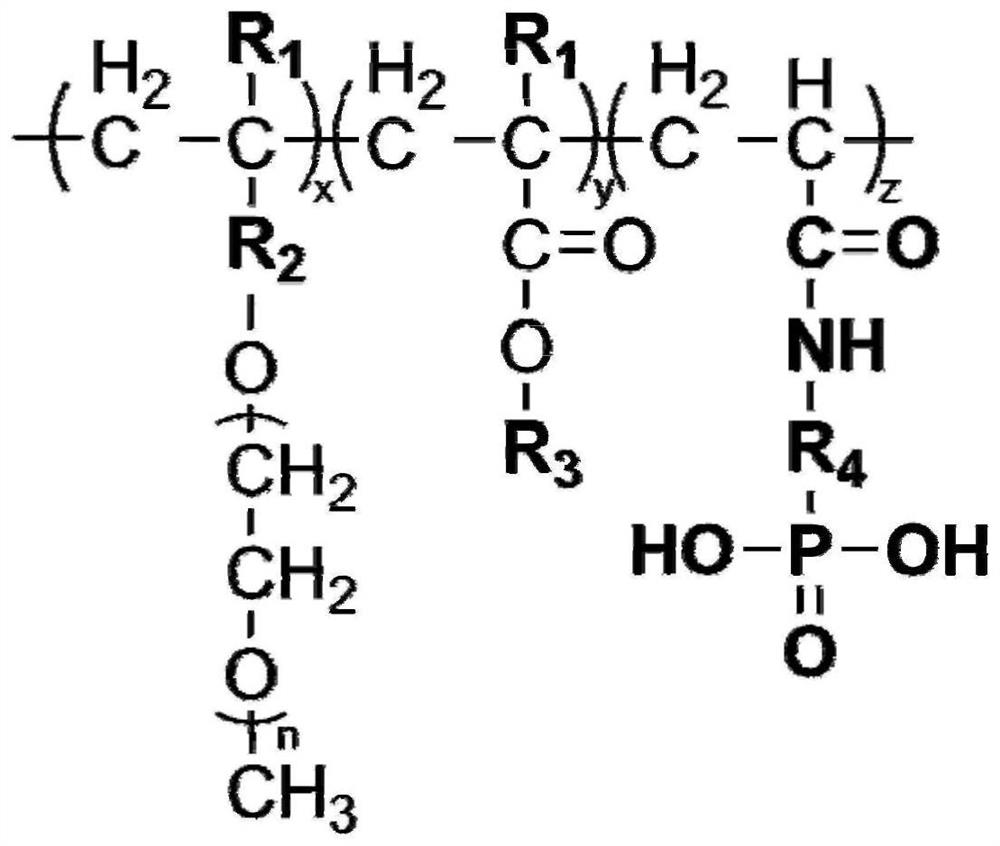

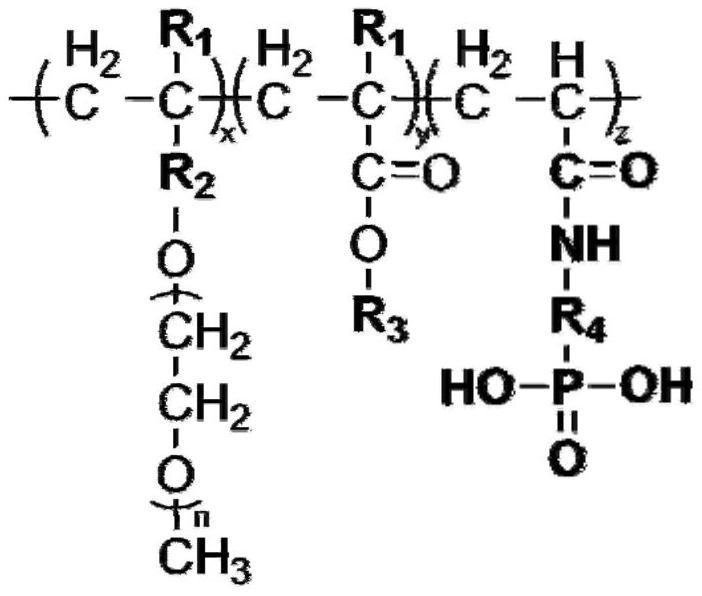

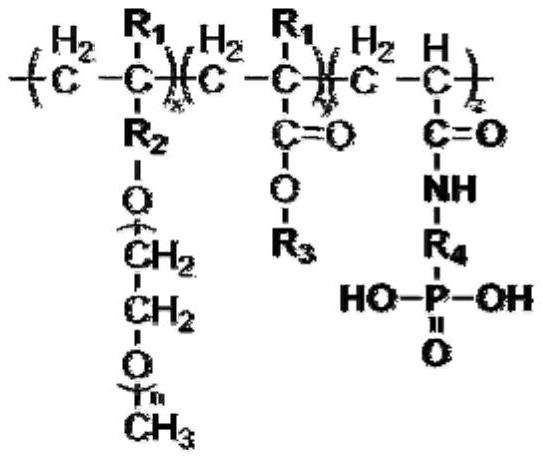

Phosphate-containing high-adaptability early-strength polycarboxylate superplasticizer, and preparation method and application thereof

InactiveCN112745464AImprove stabilitySimple preparation techniquePhosphoric Acid EstersPolymer science

The invention provides a phosphate-containing high-adaptability early-strength polycarboxylate superplasticizer, and a preparation method and application thereof, and relates to the technical field of concrete admixtures. The phosphate-containing high-adaptability early-strength polycarboxylic acid water reducer is prepared by copolymerizing 90 to 110 parts of unsaturated polyether macromonomer, 10 to 20 parts of unsaturated carboxylic acid and 1 to 6 parts of phosphate-containing acrylamide free radical. A polyacrylic acid derivative and a polyether side chain on the molecular chain of the water reducing agent provide dispersing performance, the phosphate ester-containing polyacrylamide improves the adaptability of the water reducing agent due to the existence of a phosphate group on one hand, and amido balances the retarding effect of the phosphate group on the other hand, and also improves the early strength effect of the product. Therefore, the cement early strength agent has better adaptability and early strength effect when being used for mixing different types of cement and high-mud-content aggregate concrete.

Owner:GUANGZHOU INSTITUTE OF BUILDING SCIENCE CO LTD

Method for preparing modified nanometer silicon powder

The invention discloses a preparation method of modified nano-silicon powder, which comprises the following steps: a: preparing solution 1; b: putting nano-silicon powder into solution 1 for alkali treatment; c: performing acid treatment for nano-silicon powder ; d: Prepare carboxylated nano-silicon powder; e: Dissolve carboxylated nano-silicon powder in solvent to prepare solution 2, adjust pH value with hydrochloric acid, add coupling agent and hydroquinone dropwise to solution 2 to obtain reaction system, and the resulting reaction system was processed to obtain solution 3; f: adjust the pH value of solution 3 with ammonia water, and keep it warm to obtain modified nano-silica sol; g: dry, centrifugally wash, then wash with water, and vacuum-dry to obtain modified nano-silica sol Silica fume. The invention has simple process flow, mild process conditions, low energy consumption, strong operability, low cost, greatly shortens the reaction time and improves the reaction efficiency.

Owner:JIANGSU TIANHENG NANO SCI & TECH

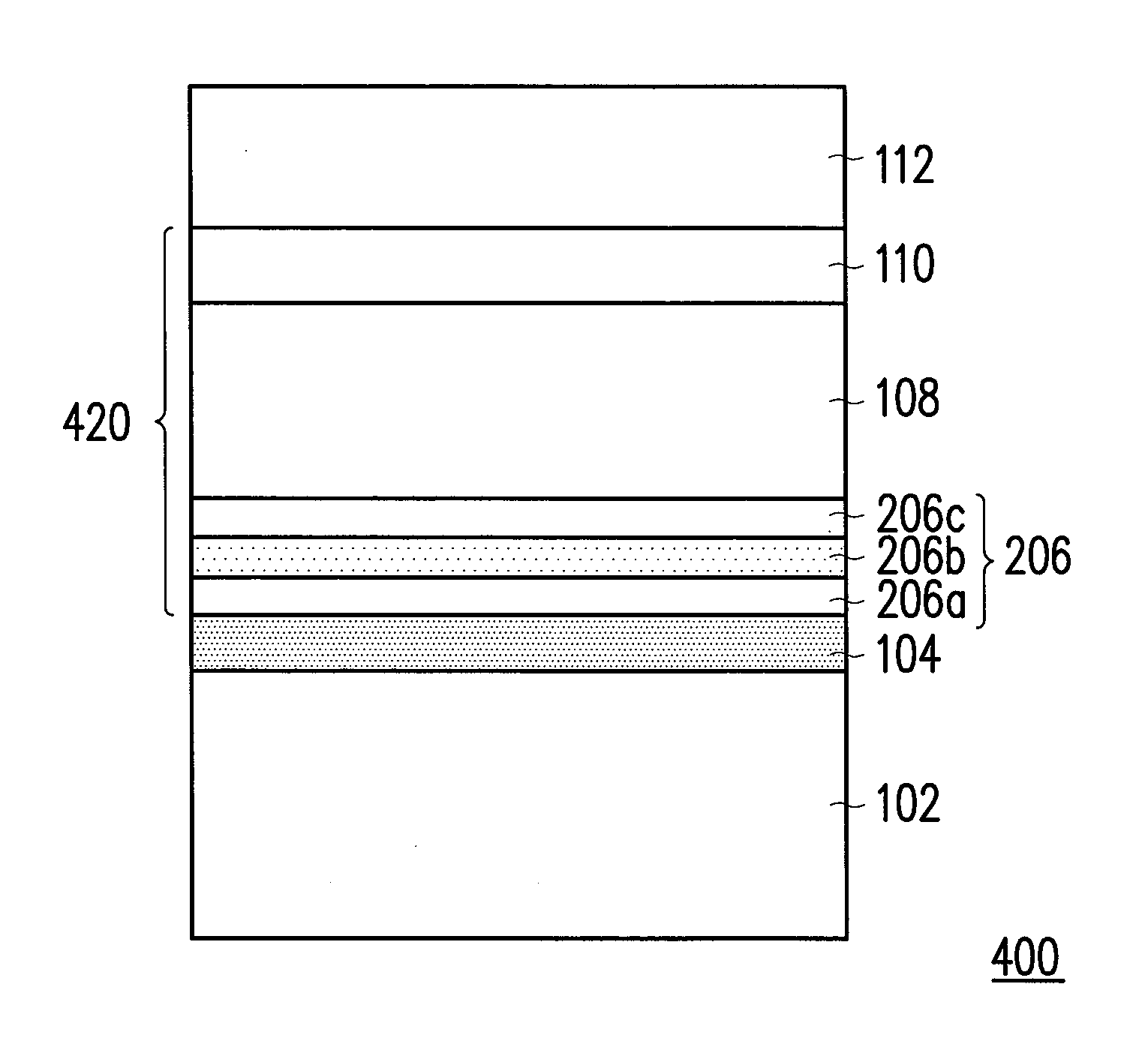

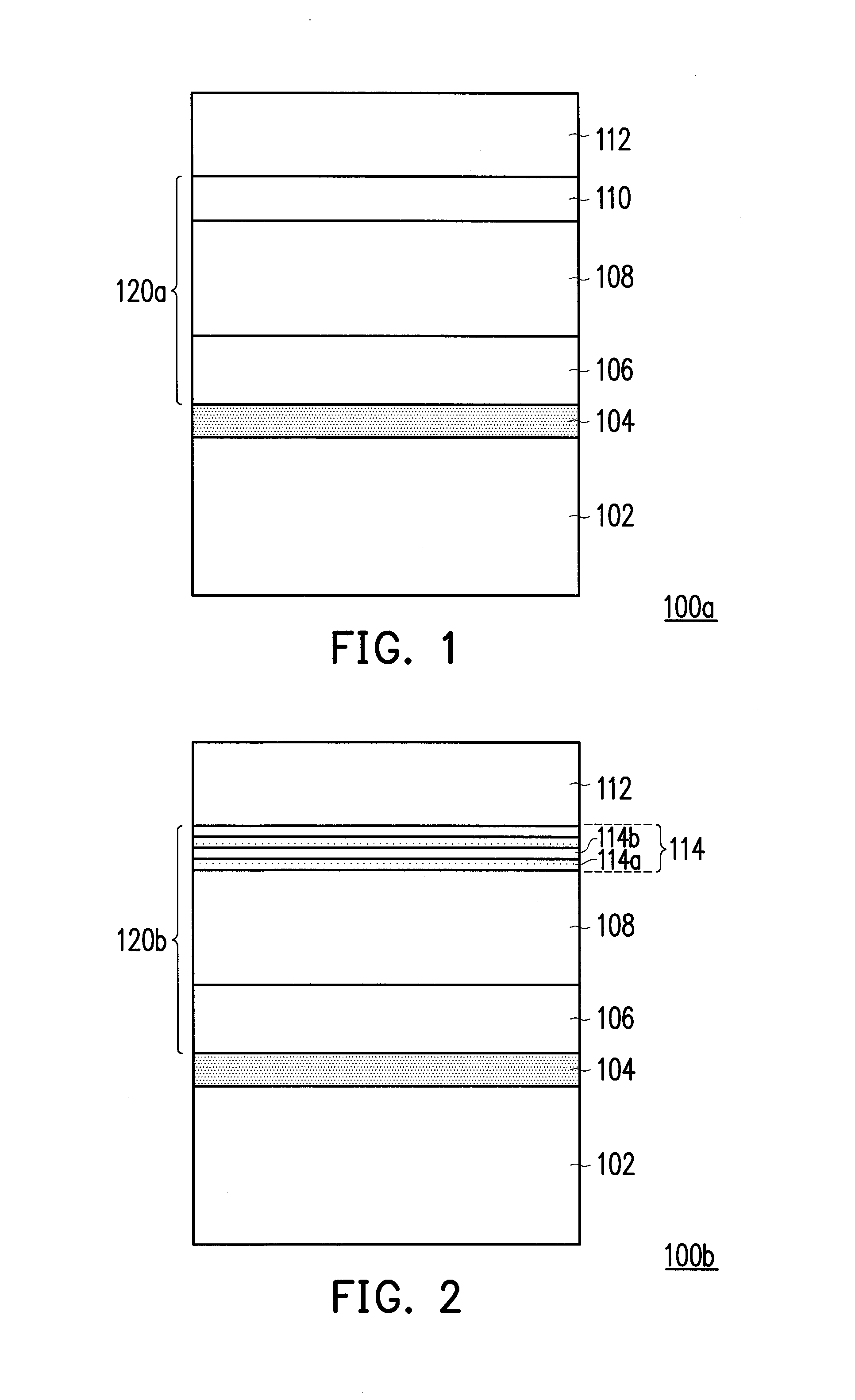

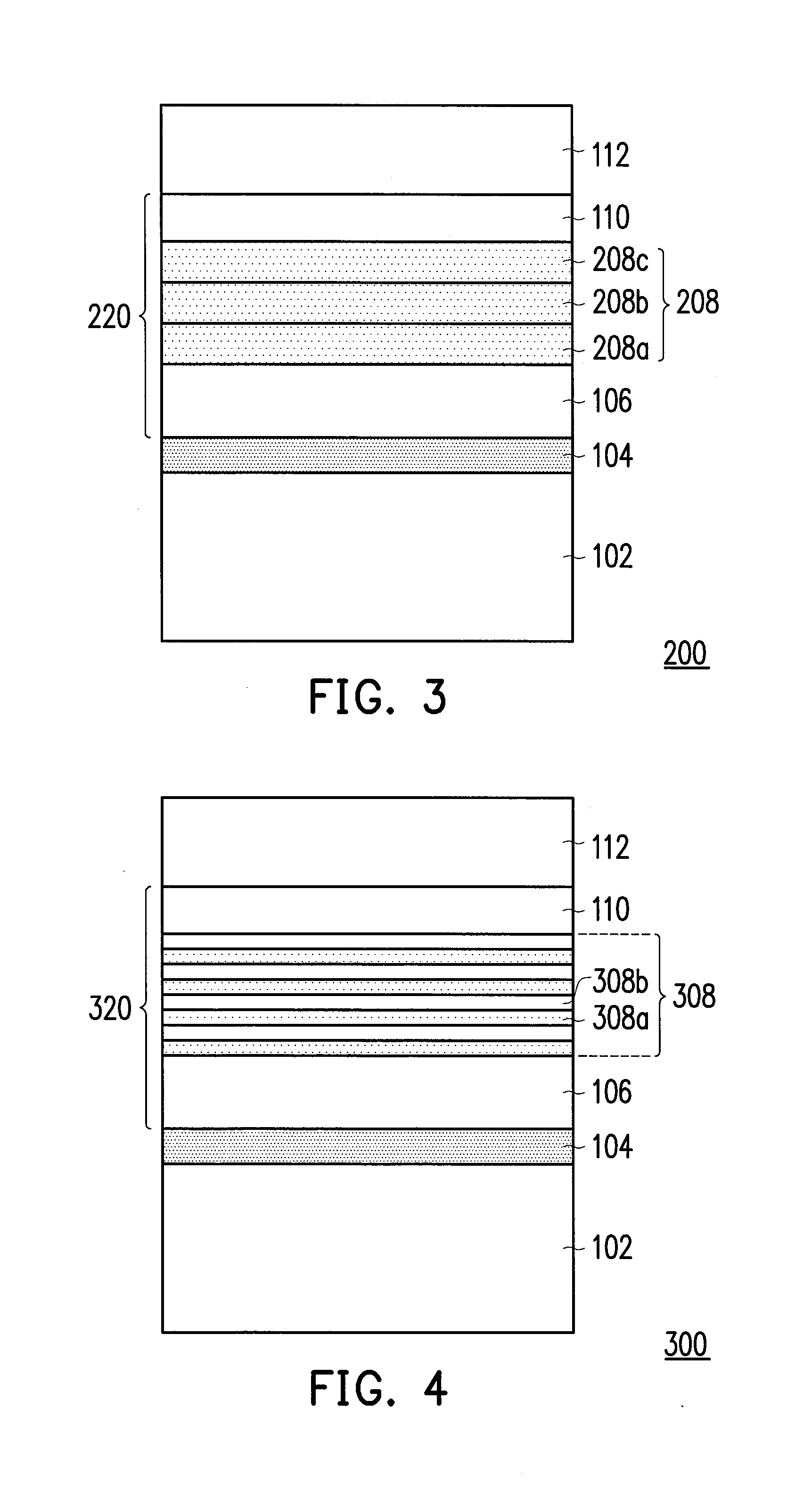

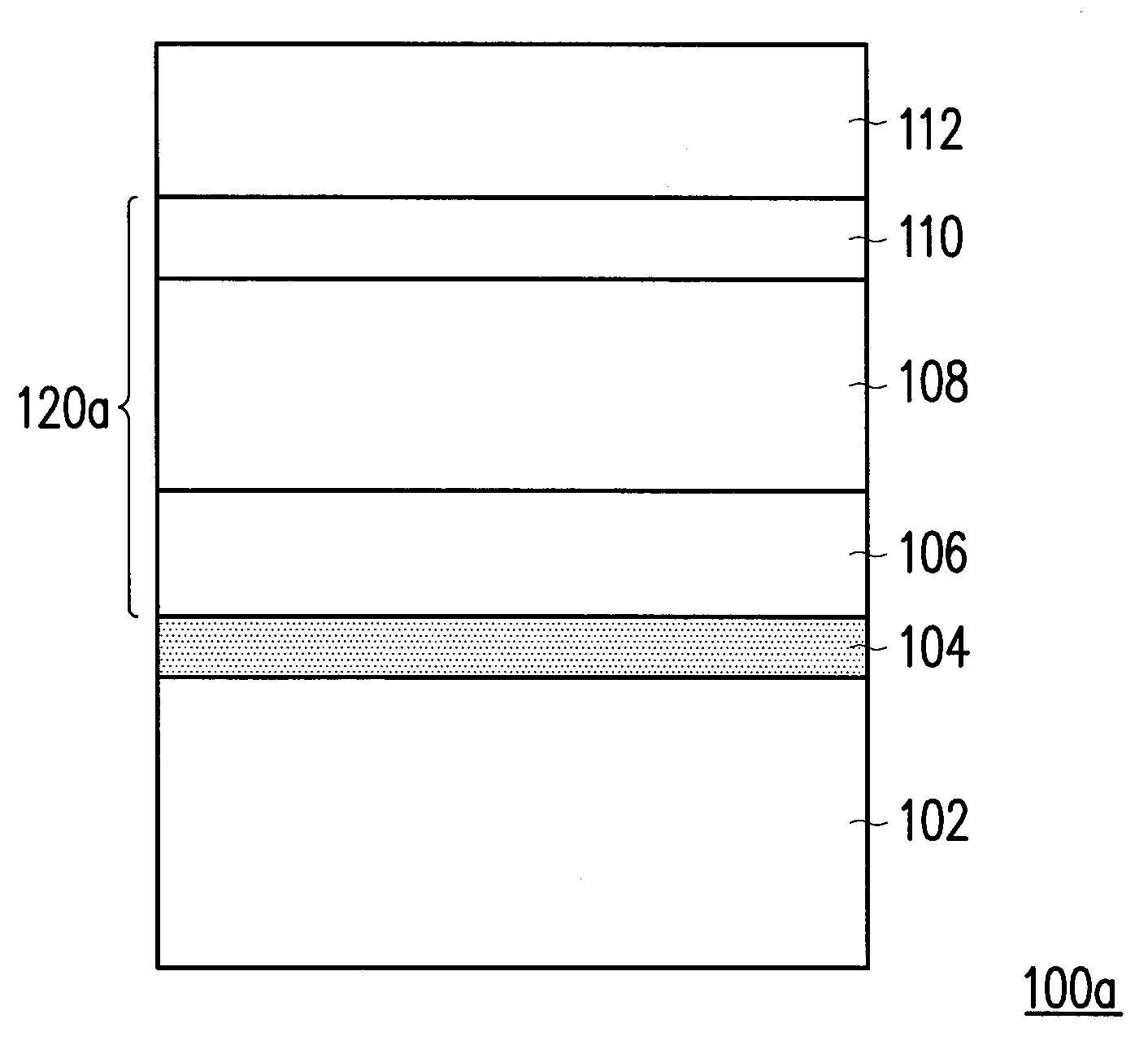

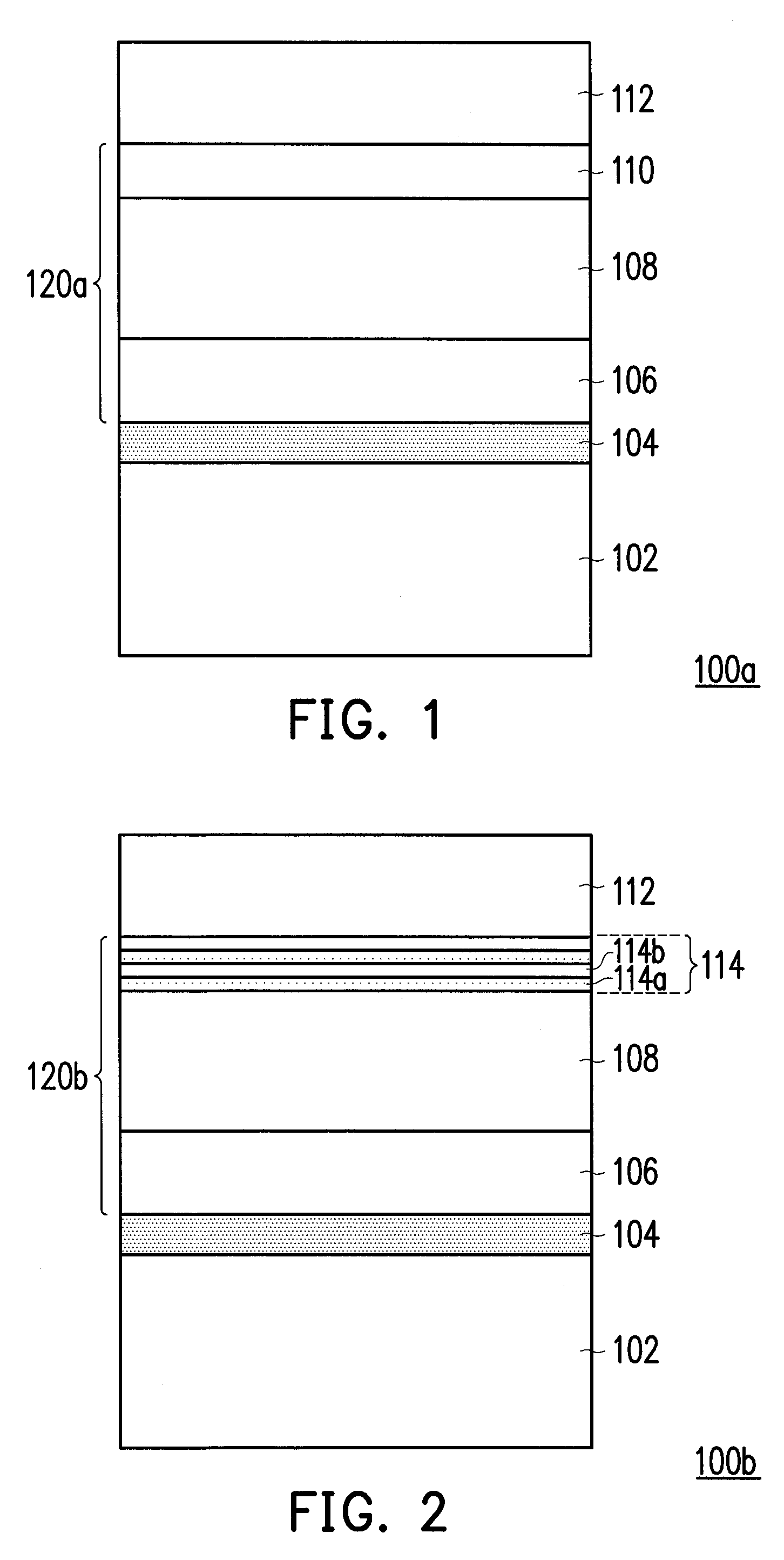

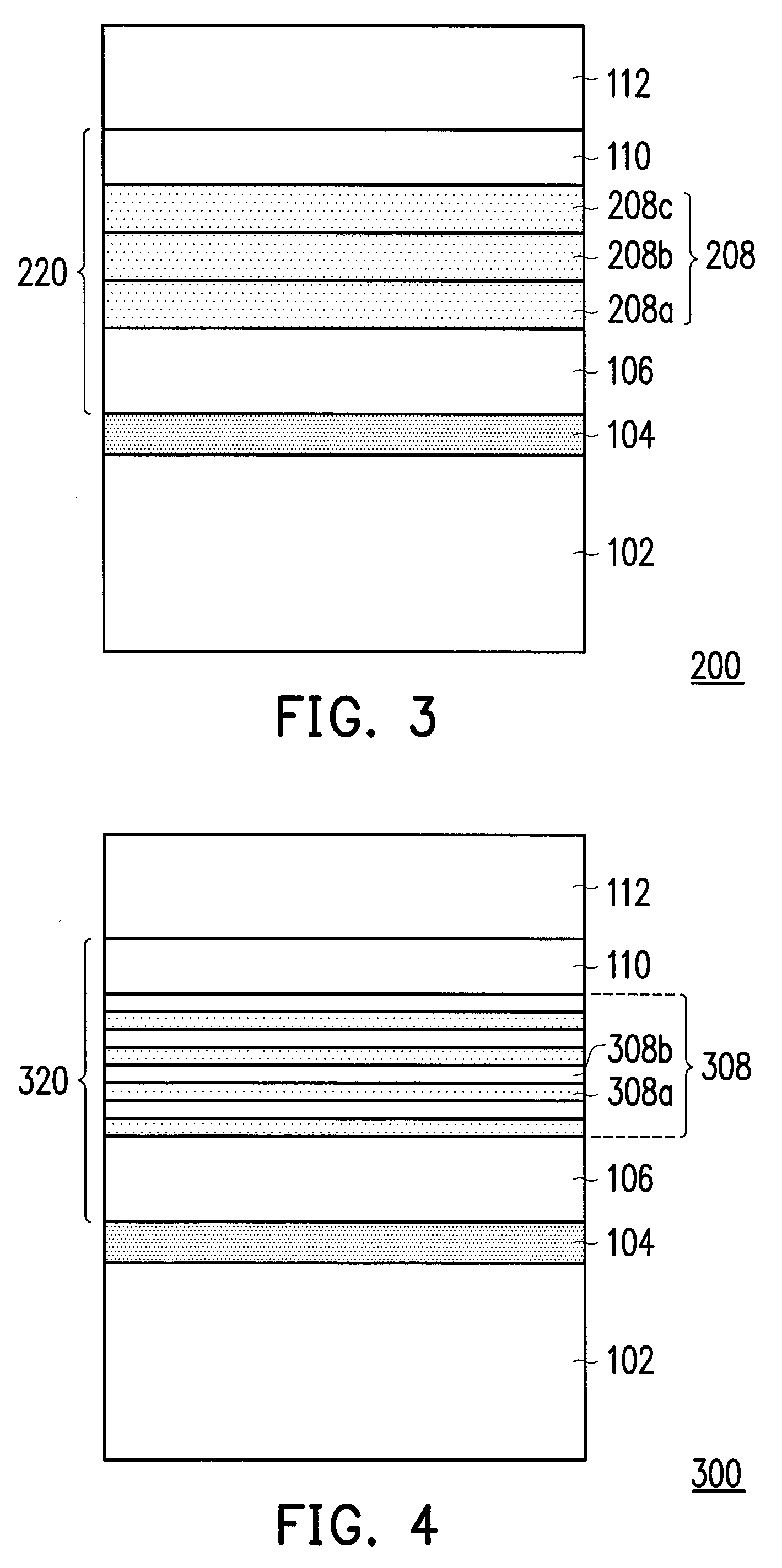

Nitride semiconductor structure

InactiveUS20160020346A1Reduce crackingEliminate generationSemiconductor/solid-state device manufacturingSemiconductor devicesSemiconductor structureNucleation

A nitride semiconductor structure is provided. The nitride semiconductor structure includes a substrate, a SiC nucleation layer, a composite buffer layer and a nitride semiconductor layer. The SiC nucleation layer is located on the substrate. The composite buffer layer is located on the SiC nucleation layer. The nitride semiconductor layer is located on the composite buffer layer. Besides, the nitride semiconductor structure is an AlN free semiconductor structure.

Owner:EPISIL PRECISION INC

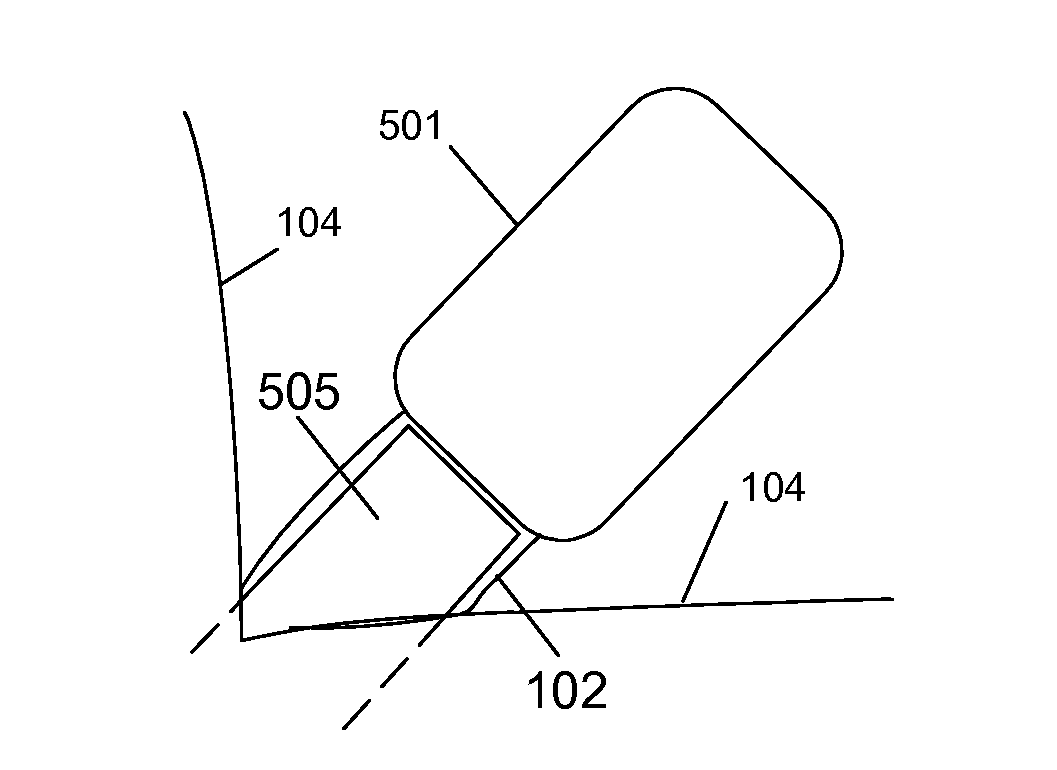

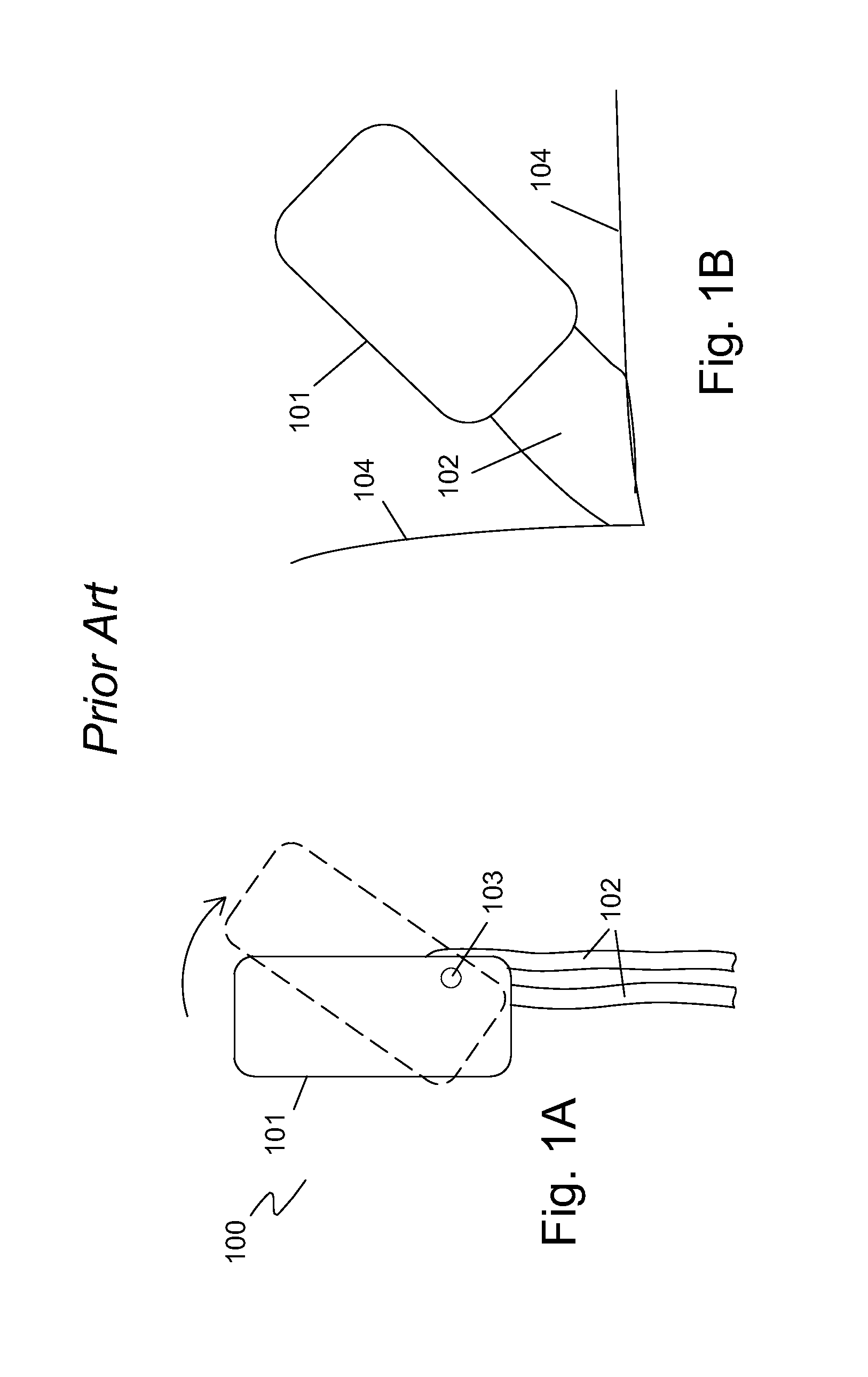

Seat Belt Buckle Positioner

InactiveUS20070205651A1Improve convenienceReduce difficultySafety beltsPedestrian/occupant safety arrangementSeat beltBelt safety

A seat belt device for stabilizing and positioning a flexible vehicle seat belt buckle having a substantially rigid support structure configured for combining with a vehicle seat belt buckle to convert a movable, flexible vehicle seat belt buckle to a substantially stationary seat belt buckle for facilitating engagement of a seat belt latch. The support structure includes splinting configurations and wedging configurations.

Owner:WEINSTEIN ELISABETH +1

Seat Belt Buckle Positioning System

InactiveUS20070205644A1Reduce difficultyImprove complianceVehicle seatsSafety beltsSeat beltEngineering

A seat belt buckle positioning system for use with a child booster seat having a seat belt buckle holder that can grasp or envelope a vehicle seat belt buckle, and a seat belt buckle holder positioner to which the seat belt buckle holder can attach and be positioned at the side of the child booster seat.

Owner:WEINSTEIN ELISABETH +1

High-smoothness PP and PE extinction master batch and preparation method and application thereof

ActiveCN111808369AFully blockedReduce cloggingMicroorganism based processesFermentationPolymer sciencePolypropylene

The invention provides a high-smoothness PP and PE extinction master batch and a preparation method and application thereof. The preparation method comprises the following steps: firstly, carrying outprimary blending, extrusion and granulation on polypropylene, a delustering agent and a slipping agent thereby obtaining modified polypropylene, and then carrying out secondary blending, extrusion and granulation on the modified polypropylene, polyethylene and coupling agent to obtain the high-smoothness PP and PE extinction master batch. According to the technical key point, the PP and PE extinction master batch with high smoothness is obtained by adjusting the proportion relation of the PP and the PE and improving the extinction agent and the slipping agent, and the obtained product has extinction property and smoothness and has excellent market popularization value.

Owner:WUXI HUANYU PACKAGING MATERIALS CO LTD

Seat belt buckle positioner

InactiveUS20100078986A1Improve convenienceReduce difficultyVehicle seatsSafety beltsSeat beltEngineering

A seat belt device for stabilizing and positioning a flexible vehicle seat belt buckle having a substantially rigid support structure configured for combining with a vehicle seat belt buckle to convert a movable, flexible vehicle seat belt buckle to a substantially stationary seat belt buckle for facilitating engagement of a seat belt latch. The support structure includes splinting configurations and wedging configurations.

Owner:WEINSTEIN ELISABETH +1

Nitride semiconductor structure

InactiveUS9419160B2Reduce crackingEliminate generationSemiconductor/solid-state device manufacturingSemiconductor devicesSemiconductor structureNucleation

A nitride semiconductor structure is provided. The nitride semiconductor structure includes a substrate, a SiC nucleation layer, a composite buffer layer and a nitride semiconductor layer. The SiC nucleation layer is located on the substrate. The composite buffer layer is located on the SiC nucleation layer. The nitride semiconductor layer is located on the composite buffer layer. Besides, the nitride semiconductor structure is an AlN free semiconductor structure.

Owner:EPISIL PRECISION INC

Toughened polyphenyl ether and nylon alloy and preparation method for toughened polyphenyl ether and nylon alloy

The invention discloses a toughened polyphenyl ether and nylon alloy and a preparation method for the toughened polyphenyl ether and nylon alloy. The toughened polyphenyl ether and nylon alloy comprises the following components in weight percentage: 20-60 percent of polyphenyl ether, 20-60 percent of polyamide, 5-20 percent of compatilizer, 5-20 percent of toughening agent and 1-2 percent of other additives. The incompatibility of the polyphenyl ether and nylon comprised by the invention is improved through the added compatilizer. Through changing the content of the toughening agent in the alloy material, the alloy material with different impact strength is obtained. A product prepared from the toughened polyphenyl ether and nylon alloy is capable of resisting the high temperature of at least 160 DEG C of a production line and the corrosion of dimethylbenzene and methylbenzene as solvents in spray paint; the contour dimension is kept unchanged; and the phenomena, such as stress cracking and the like, do not occur.

Owner:HEFEI GENIUS NEW MATERIALS

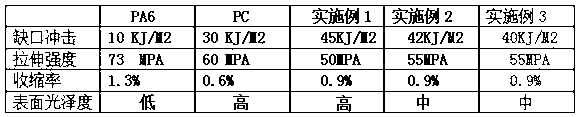

Highlight anti-warping nylon PA6/PC (Polyamide 6/Polycarbonate) alloy

InactiveCN110003640AOvercome deficienciesMaintain heat aging resistanceNylon materialEngineering plastic

The invention discloses a highlight anti-warping nylon PA6 / PC (Polyamide 6 / Polycarbonate) alloy which comprises the following components in parts by weight: 50-70 parts of a polyamide resin (PA6), 30-50 parts of polycarbonate (PC), 0.02-0.05 part of an antioxidant 1098, 0.02-0.05 part of an antioxidant 626 and 0.5-2 parts of a lubricant. The alloy disclosed by the invention has the characteristicsof being high in glare, smooth in surface, free of warping, stable in size, and the like, can be used as engineering plastics of structures and appearance parts of electronic appliances, electric appliances, automobiles, and the like, is prepared from safe and environmental-friendly materials, and can be widely applied to products such as structure parts and appearance parts with requirements ofhigh glare and stable sizes in fields such as household electric appliances, machinery and automobiles.

Owner:SUZHOU WEIRUICHENG NEW MATERIAL

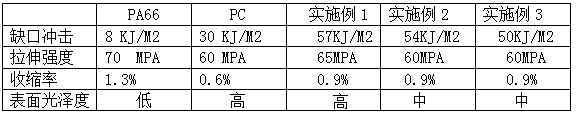

High-gloss anti-warping toughened nylon PA66/PC alloy

The invention discloses high-gloss anti-warping toughened nylon PA66 / PC alloy and a preparation method thereof. The alloy comprises the following components in parts by weight: 60-80 parts of polyamide resin (PA66), 20-40 parts of polycarbonate (PC), 5-15 parts of a compatilizer, 0.02-0.05 part of an antioxidant 1098, 0.02-0.05 part of an antioxidant 626 and 0.5-2 parts of a lubricant. The alloy has the characteristics of high gloss, smooth surface, toughening, warping prevention, dimensional stability and the like, is used for engineering plastics of structures and appearance parts of electronics, electric appliances, automobiles and the like, is prepared from safe and environment-friendly raw materials, and is widely applied to structural parts, appearance parts and other products with high gloss, good toughness and dimensional stability requirements in the fields of household appliances, machinery, automobiles and the like.

Owner:SUZHOU WEIRUICHENG NEW MATERIAL

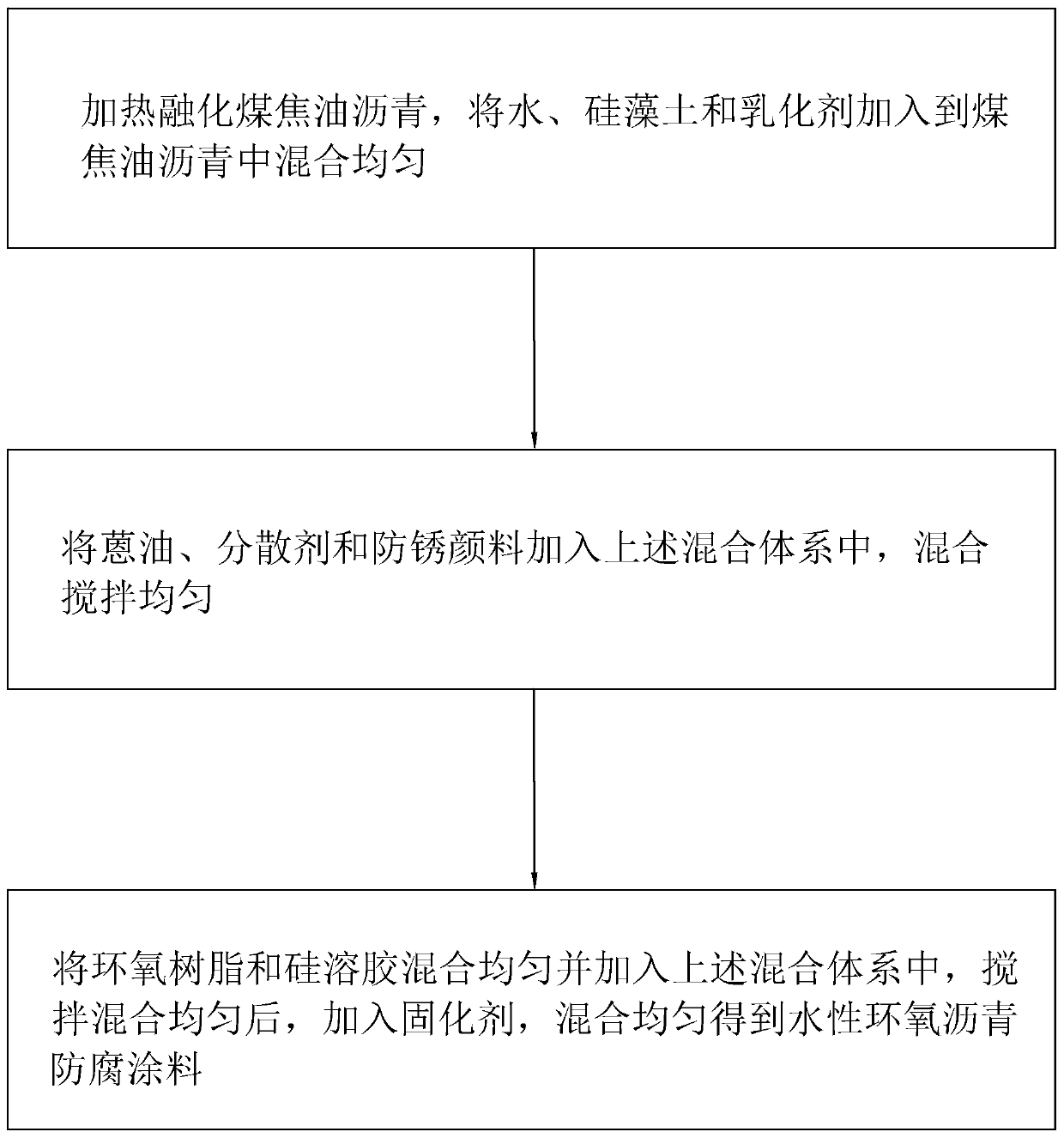

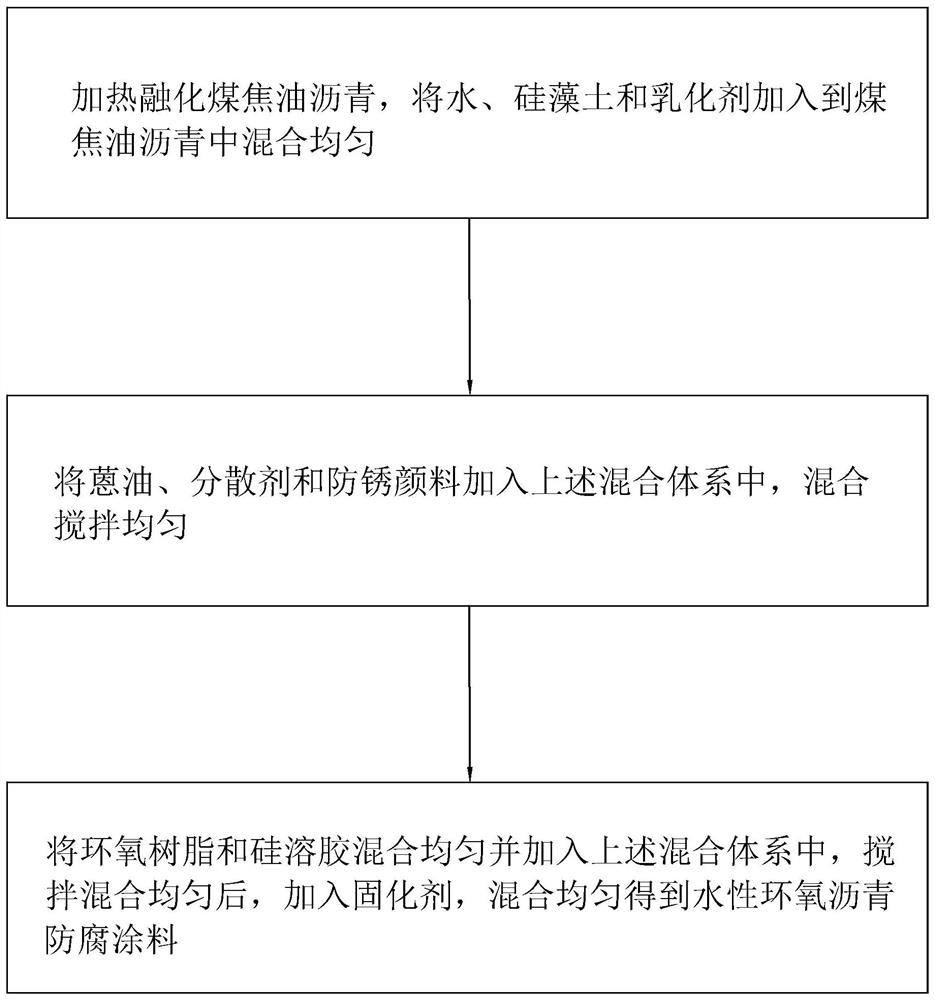

Waterborne epoxy asphalt anti-corrosive paint and processing technology thereof

ActiveCN110105848AImprove incompatibilityGood compatibilityAnti-corrosive paintsEpoxy resin coatingsAsphaltMaterials science

The invention discloses a waterborne epoxy asphalt anti-corrosive paint and a processing technology thereof, and relates to the technical field of asphalt anti-corrosive paints. The waterborne epoxy asphalt anti-corrosive paint is characterized by being prepared from, by weight, 15-30 parts of water, 30-45 parts of epoxy resin, 25-35 parts of coking coal oil asphalt, 6-9 parts of silica sol, 10-20parts of anthracene oil, 5-10 parts of diatomite, 0.1-3 parts of a dispersing agent, 0.1-3 parts of an emulsifier, 30-40 parts of a curing gent and 1.5-2.5 parts of an anti-rust pigment. The waterborne epoxy asphalt anti-corrosive paint prepared according to the formula has the advantages that the compatibility is good, and a prepared paint film has excellent anti-corrosive performance and excellent mechanical performance.

Owner:安徽欣苗新材料科技有限公司

Composite coating for thermonuclear fusion reactor magnet support component and preparation method thereof

InactiveCN110885959AHigh resistivityImprove corrosion resistanceMolten spray coatingSuperimposed coating processMaterials scienceSurface preparation

The invention provides a composite coating for a thermonuclear fusion reactor magnet support component and a preparation method, which belong to the technical field of material surface treatment. Thecomposite coating comprises a transition layer and an insulating layer which are sequentially arranged on the to-be-treated surface of the thermonuclear fusion reactor magnet support component; the transition layer comprises a Ni5Al layer; and the insulating layer comprises an Al2O3-3TiO2 insulating layer. The composite coating is well combined with a matrix, has excellent low-temperature thermalshock resistance and insulating property under high load, and meets the technical requirements of an international thermonuclear fusion experimental reactor on a magnet support component. The preparation method comprises the steps: the transition layer and the insulating layer are sequentially sprayed on the to-be-treated surface of a to-be-treated thermonuclear fusion reactor magnet support component, wherein the thermonuclear fusion reactor magnet support component comprises at least one of a gasket, a coating sleeve and a top chuck. The method is simple, easy to operate and beneficial to preparation of the composite coating which is uniform in structure and good in performance.

Owner:GUANGDONG INST OF NEW MATERIALS

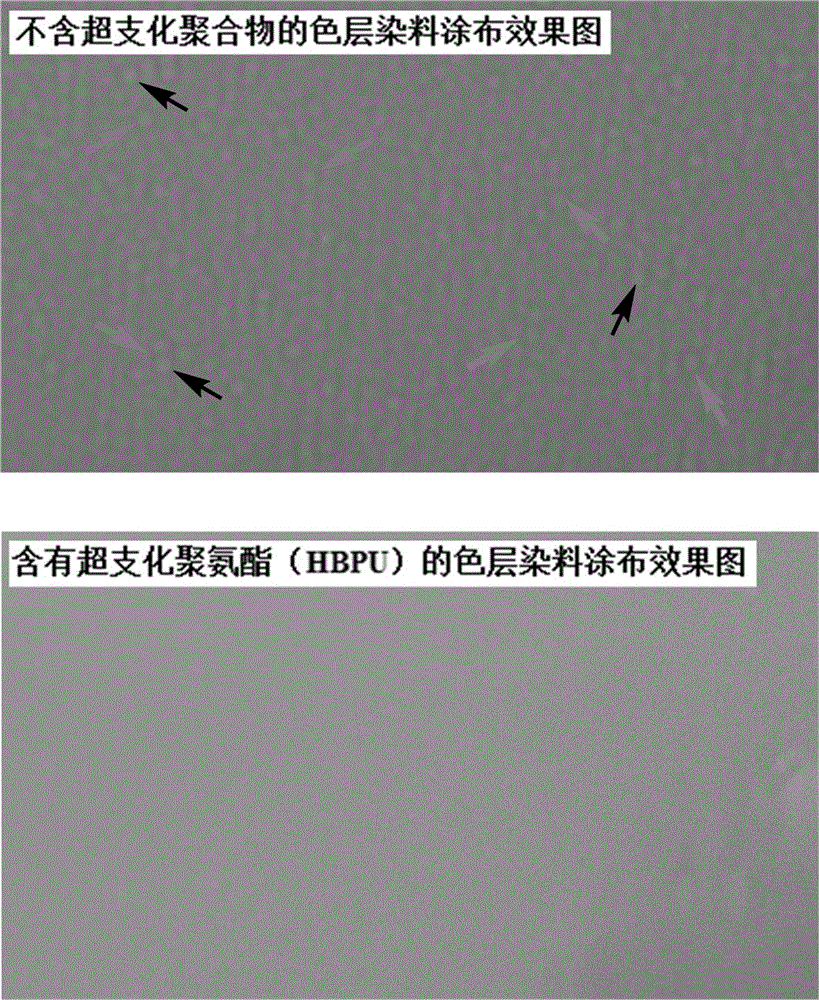

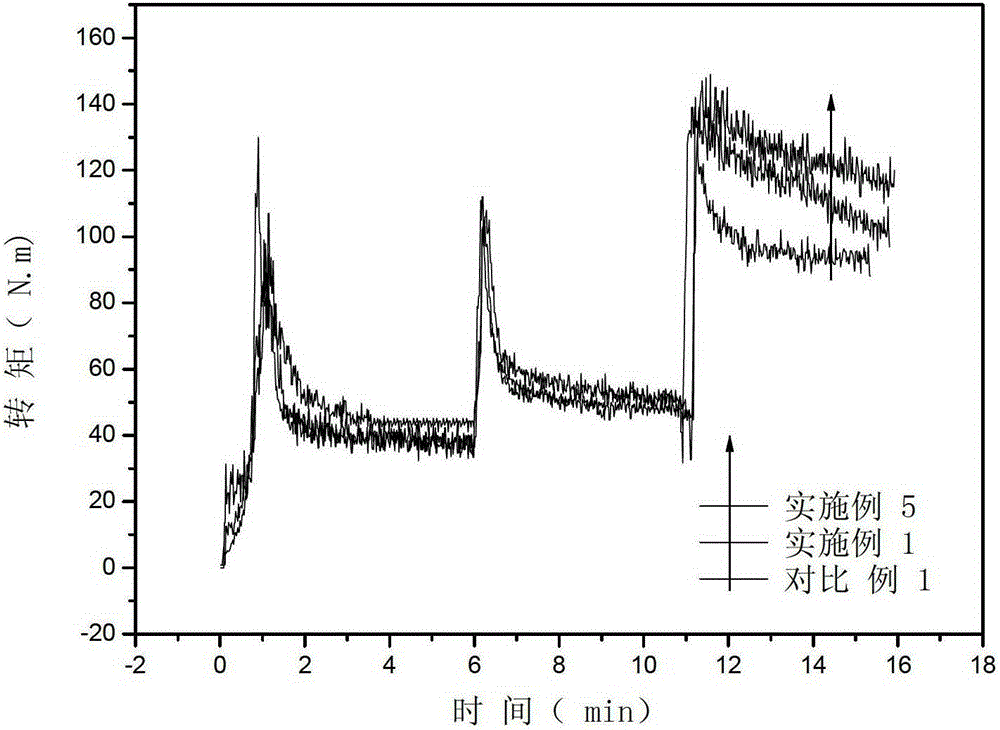

A kind of anodized aluminum chromatographic dye containing hyperbranched polymer and preparation method thereof

ActiveCN104962152BUnique three-dimensional spherical space structureImprove solubilityPolyurea/polyurethane coatingsSpherical spaceAcrylic resin

The invention belongs to the field of high polymer materials and relates to alumite chromatographic dye containing a hyperbranched polymer. The alumite chromatographic dye consists of the following components in parts by mass: 20-40 parts of acrylic resin, 20-40 parts of polyurethane resin, 1-5 parts of other resins, 7-20 parts of dye toner, 1-10 parts of hyperbranched polymer, 0.5-1.0 part of auxiliaries and 60-80 parts of solvent. The invention also discloses a preparation method of the alumite chromatographic dye containing the hyperbranched polymer. The preparation method comprises the following steps: putting an appropriate amount of solvent to a reaction kettle, and keeping the temperature in the kettle to 25-60 DEG C; putting the dye toner, the hyperbranched polymer and the auxiliaries to the kettle at one step and stirring for 1-4 hours; adding the acrylic resin, the polyurethane resin and other resins in sequence, controlling the temperature to 15-70 DEG C and stirring for 2-6 hours; finally enabling the materials to flow into a storage tank through a kettle body device for later use, wherein the internal temperature of the storage tank is 10-40 DEG C. The hyperbranched polymer has a three-dimensional spherical space structure, contains a large amount of polar and non-polar functional groups in chain segments and at the chain ends, has excellent dissolving property and low viscosity and has the capability of improving the problem that resin and dye toner are insoluble to each other in alumite chromatographic dye.

Owner:YANGZHOU XIANGHUA NEW MATERIAL TECH CO LTD

A kind of high smoothness pp and pe matting masterbatch, preparation method and application

ActiveCN111808369BFully blockedReduce cloggingMicroorganism based processesFermentationMasterbatchPolymer science

The invention provides a high smoothness PP and PE matting masterbatch, preparation method and application. Firstly, polypropylene, matting agent and smoothing agent are blended, extruded and granulated for the first time to obtain modified polypropylene. Then, the modified polypropylene, polyethylene and coupling agent are blended and extruded for the second time to obtain a high smoothness PP and PE matt masterbatch. The technical key lies in the proportion of polypropylene and polyethylene. The adjustment of the relationship and the improvement of the matting agent and the smoothing agent give consideration to the matting and smoothness of the obtained product, and have excellent marketing value.

Owner:WUXI HUANYU PACKAGING MATERIALS CO LTD

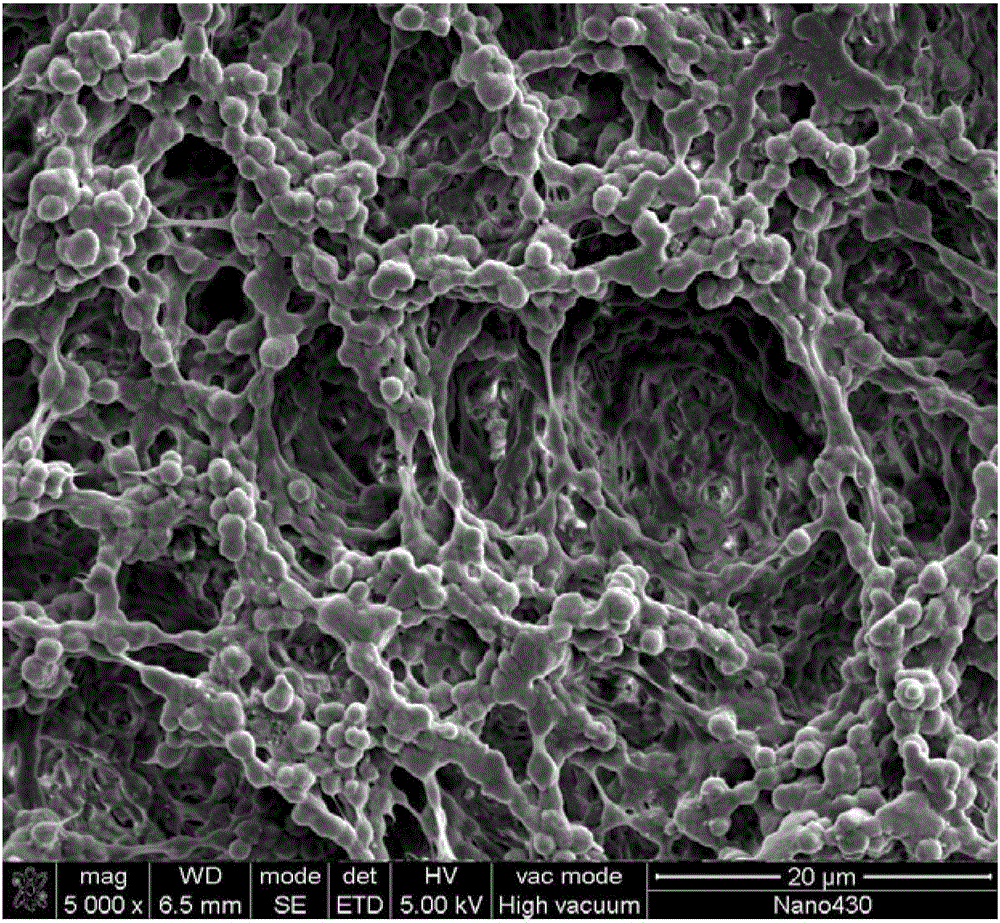

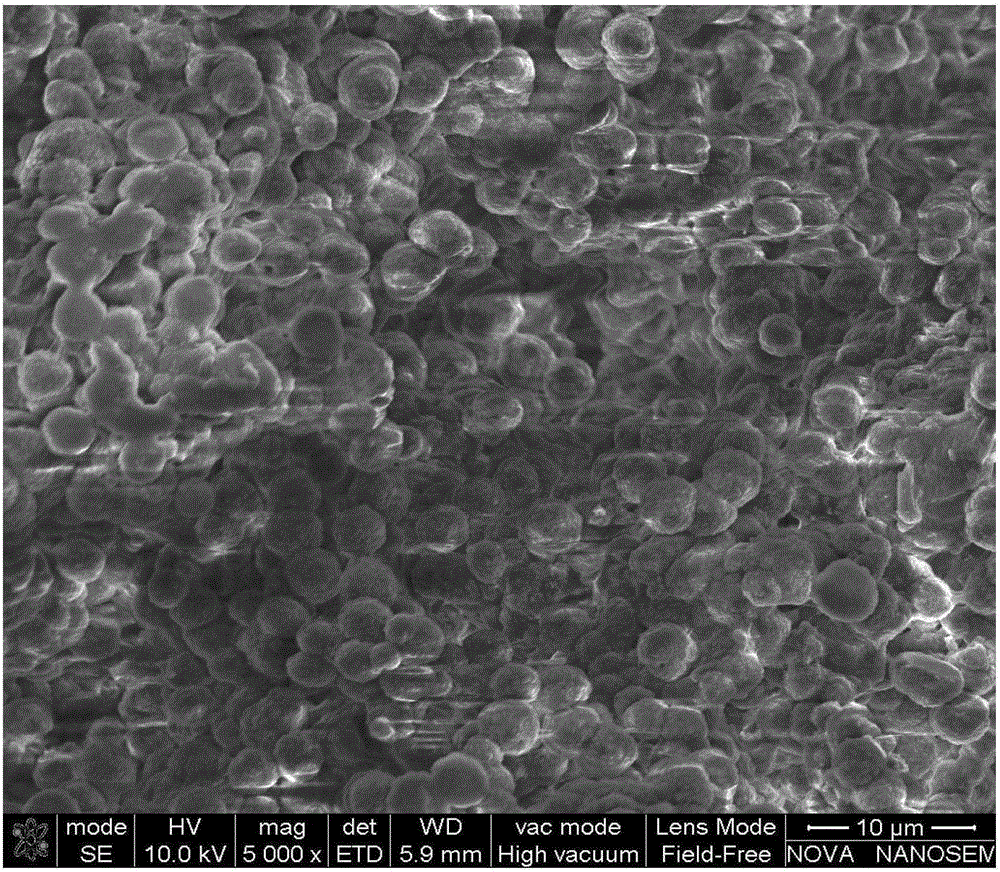

Dynamically vulcanized fluoroplastic/fluororubber/silicone rubber thermoplastic elastomer and preparation method thereof

The invention discloses a dynamic vulcanized fluoroplastic / fluororubber / silicon rubber thermoplastic elastomer and a preparation method thereof. The thermoplastic elastomer comprises the following raw materials in parts by mass: 10-80 parts of fluoroplastic, 5-80 parts of fluororubber, 5-85 parts of silicone rubber, 1-10 parts of acid acceptor, 1-20 parts of interfacial modifier, 0.1-5 parts of cross-linking agent and 0.1-10 parts of cross-linking aid. The preparation method comprises the following steps of: uniformly mixing the fluoroplastic, the fluororubber, the acid acceptor, the silicon rubber and the interfacial modifier at 175-330 DEG C; and adding the cross-linking agent and the cross-linking aid under a high-speed shear condition to carry out dynamic vulcanization on rubber to obtain the thermoplastic elastomer. The fluoroplastic / fluororubber / silicon rubber thermoplastic elastomer has high mechanical strength, has the characteristics of excellent high-temperature and low-temperature resistance, chemical resistance, oil resistance, capability of repeated processing and the like and can be widely applied to the fields of aerospace industry, automobile industry, information and electronics industry, chemical industry, new energy resources, electric power industry, environmental protection and the like.

Owner:SOUTH CHINA UNIV OF TECH

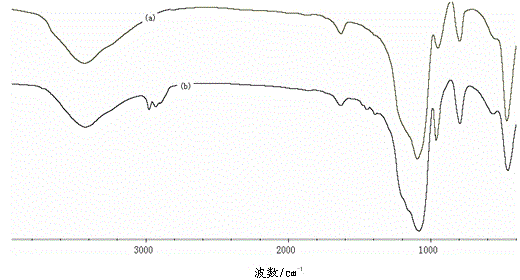

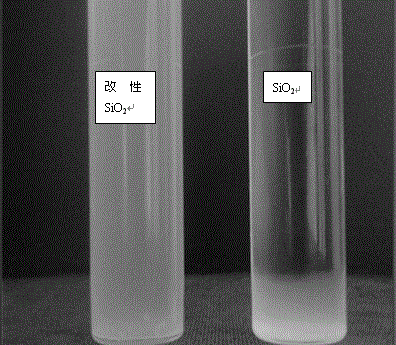

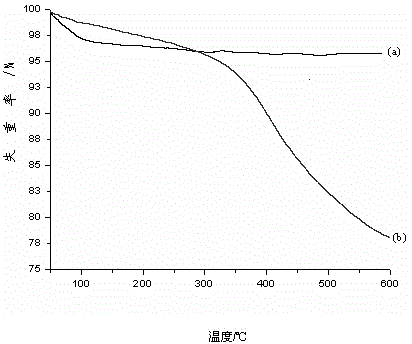

Preparation method of modified nano silicon dioxide

ActiveCN102863823BPrevent secondary reunionsReduce hydrolysisPigment treatment with organosilicon compoundsDispersitySilicon dioxide

The invention relates to a surface-modified nano silicon dioxide and a preparation method thereof, particularly a method for preparing lipophilic nano silicon dioxide by in-situ modification by a sol-gel process, belonging to the field of functional nano materials. The invention adopts a sol-gel process to prepare the nano silicon dioxide under the common catalytic action of acid and alkali, and performs in-situ modification on the nano silicon dioxide by using a silane coupling agent, so that the nano silicon dioxide becomes lipophilic instead of hydrophilic. The wetting property and dispersity of the modified nano silicon dioxide in the polymer are improved.

Owner:宿迁益创智能科技有限公司

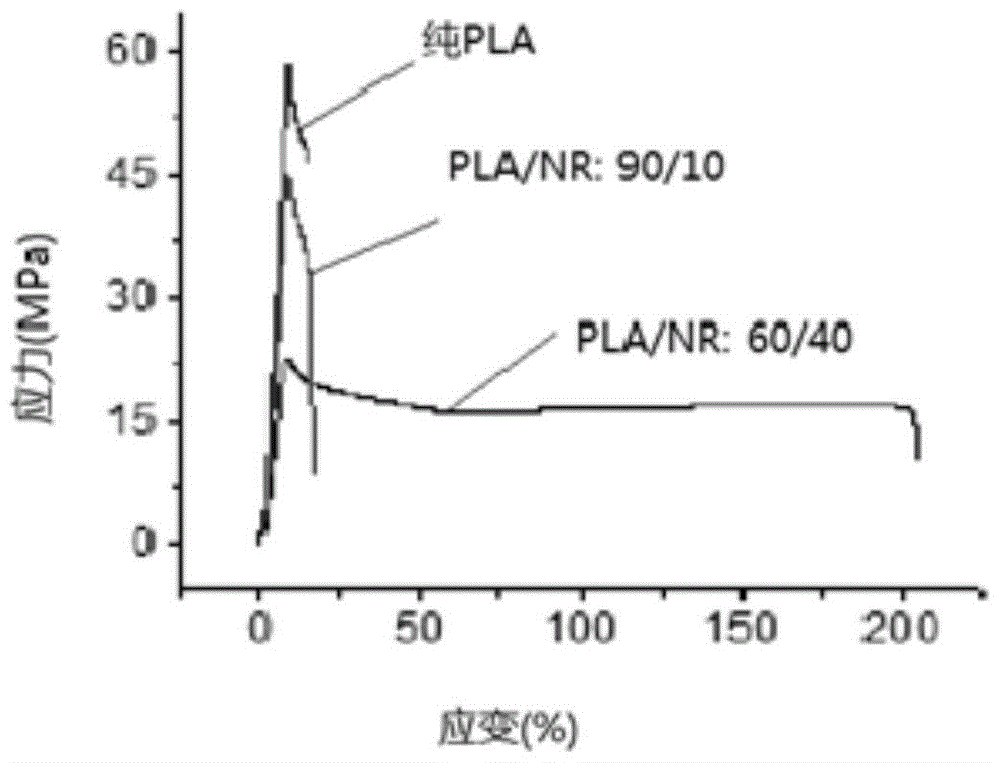

Dynamically vulcanized polylactic acid plastic/rubber thermoplastic elastomer and preparation method thereof

The invention discloses a dynamically vulcanized polylactic acid plastic / rubber thermoplastic elastomer and a preparation method thereof. In parts by mass, its raw materials include the following components: 20-90 parts of polylactic acid, 10-80 parts of rubber, 0.1-1 part of antioxidant, 1-10 parts of interface modifier, and 0.1-4.8 parts of crosslinking agent , 0.1-4.2 parts of auxiliary cross-linking agent; during preparation, mix polylactic acid, antioxidant, rubber and interface modifier evenly at a temperature of 150-190 ° C, and add cross-linking agent and auxiliary cross-linking agent under high-speed shearing The crosslinking agent dynamically vulcanizes the rubber phase to obtain a polylactic acid plastic / rubber thermoplastic elastomer prepared by dynamic vulcanization. The polylactic acid plastic / rubber thermoplastic elastomer obtained in the present invention has high mechanical strength, excellent impact performance, repeatable processing and other characteristics, and can be widely used in medical treatment, automobile industry, agricultural production, packaging, clothing, information electronics industry, chemical industry , new energy and environmental protection.

Owner:SOUTH CHINA UNIV OF TECH

A kind of ppo/pbt composite material for industrial large parts and preparation method thereof

InactiveCN101787199BImprove incompatibilitySolve the defect of peelingPolymer scienceEconomic benefits

The invention relates to a PPO / PBT composite material used for industrial large-scale parts and a preparation method thereof. The composite material comprises the following components in terms of weight percentage: 30% to 55% of polyphenylene ether (PPO), polyparaphenylene Butylene glycol diformate (PBT) 8-25%, toughening agent 13.6-32%, compatibilizer 6-15%, antioxidant 0.2-0.8%, lubricant 0.2-0.6%, flame retardant 1-6 %. The invention improves the incompatibility between PPO and PBT materials due to the structure by adopting a suitable compatibilizer, and solves the defect of peeling of PPO / PBT composite materials in the injection molding process, and poor fluidity, which is difficult to form The defects of large parts greatly improve the comprehensive performance of PPO / PBT composite materials, making forming parts easier and more widely used, and the preparation process is simple and low cost, which can achieve good economic benefits.

Owner:SHENZHEN KEJU NEW MATERIAL

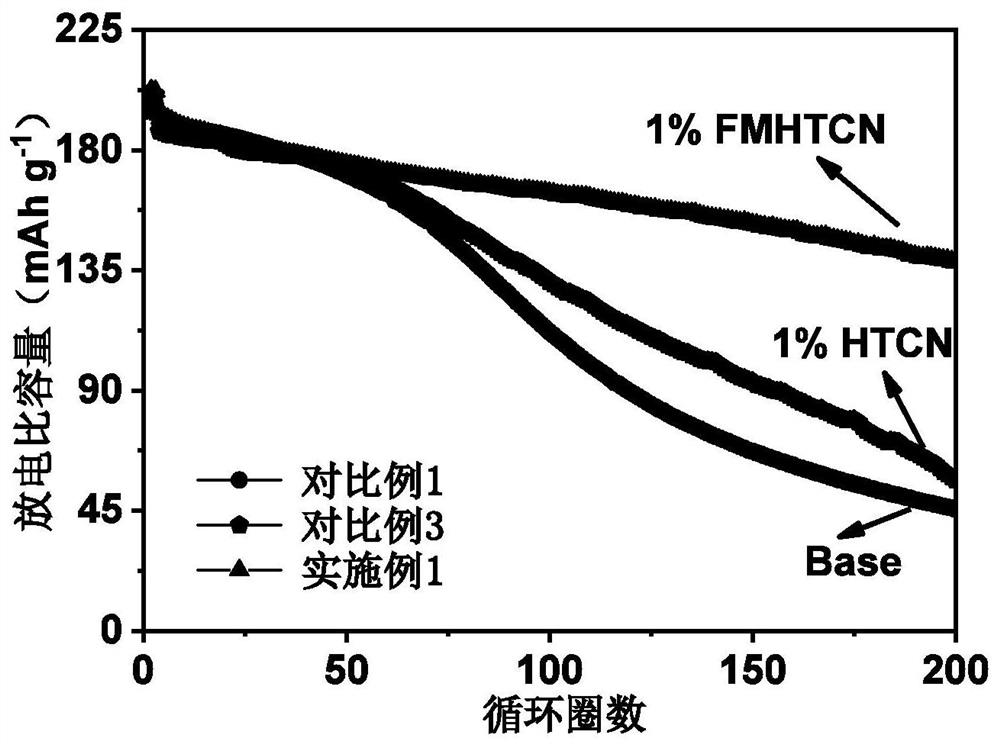

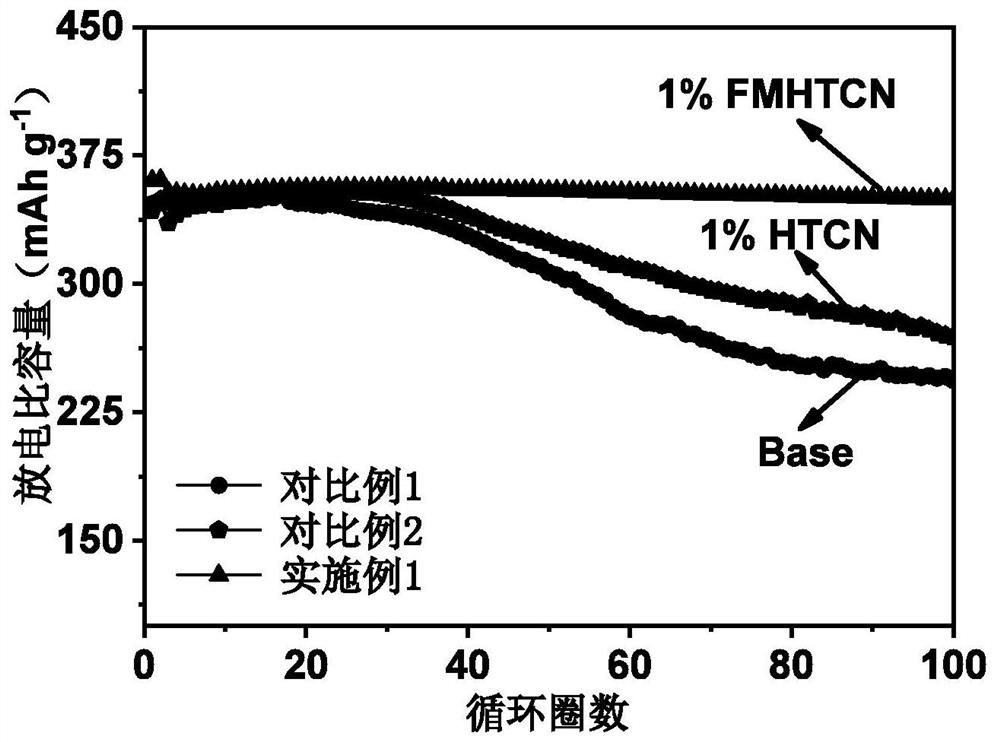

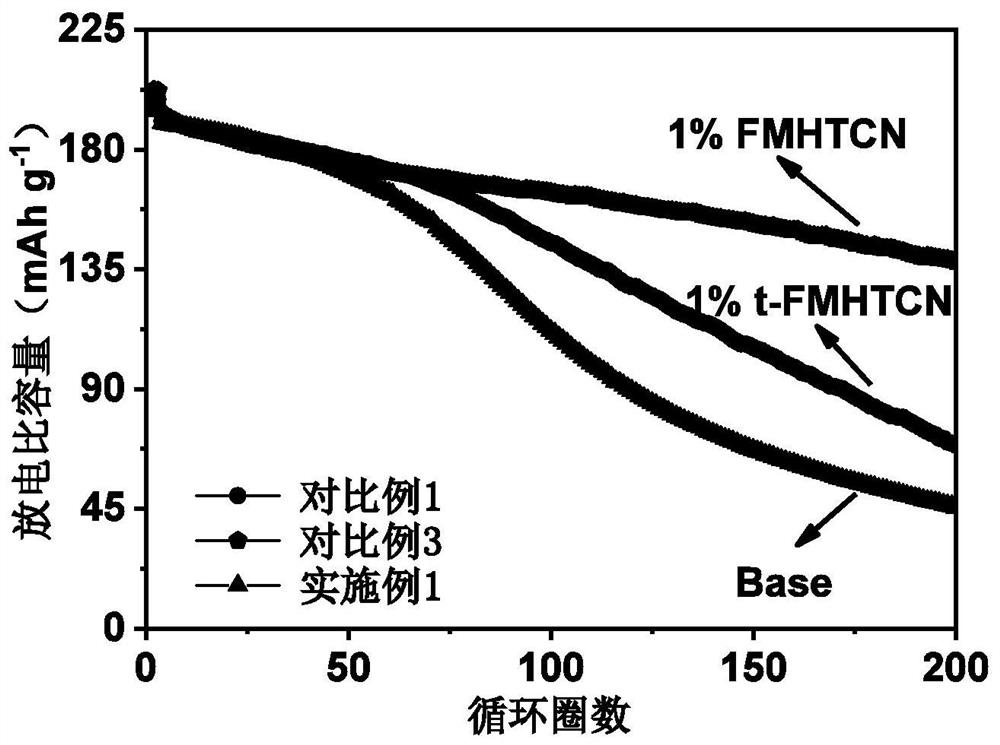

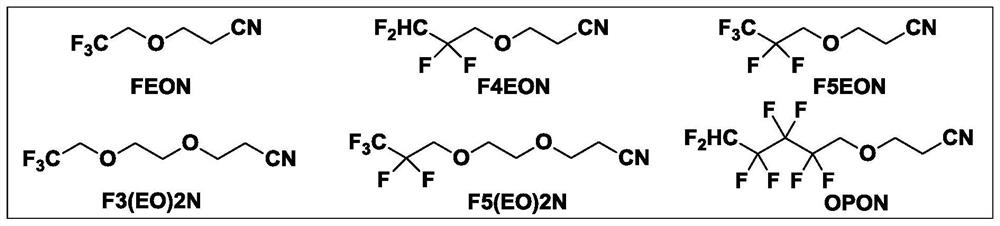

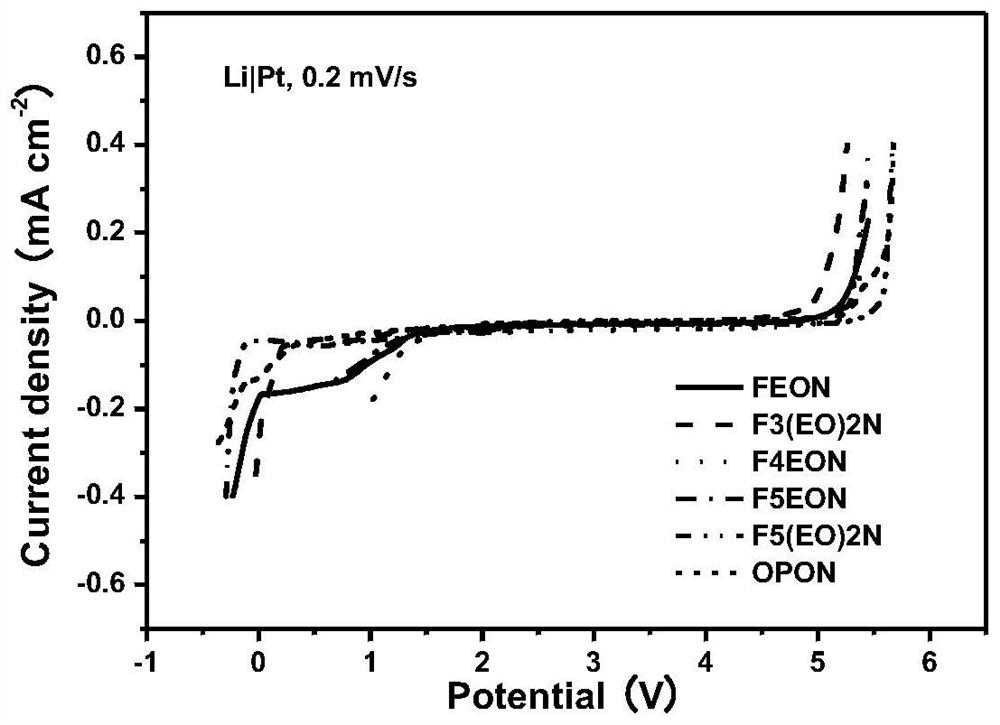

Application of Nitrile Compounds in Preparation of Electrolyte for High Voltage Battery System

ActiveCN111682263BEasy to retouchImprove high pressure stabilityCarboxylic acid nitrile preparationOrganic compound preparationElectrolytic agentElectrical battery

The invention discloses the application of a nitrile compound in the preparation of an electrolyte solution for a high-voltage battery system. The structural formula of the nitrile compound is wherein n 1 , n 2 and n 3 Integers of 0-10 each, but not both 0, R f It is a fluorine-containing functional group. The substitution of the F-containing electron-withdrawing functional group in the present invention can cooperate with the nitrile functional group to modify the positive interface layer well, and further improve the high-voltage stability of the battery; the substitution of the F-containing functional group in the present invention can effectively improve the nitrile molecule. A stable LiF-rich interface layer is formed on the graphite or lithium metal negative electrode, thereby improving the incompatibility of nitrile additives to the negative electrode and improving the overall high-voltage stability of the pouch full battery.

Owner:XIAMEN UNIV

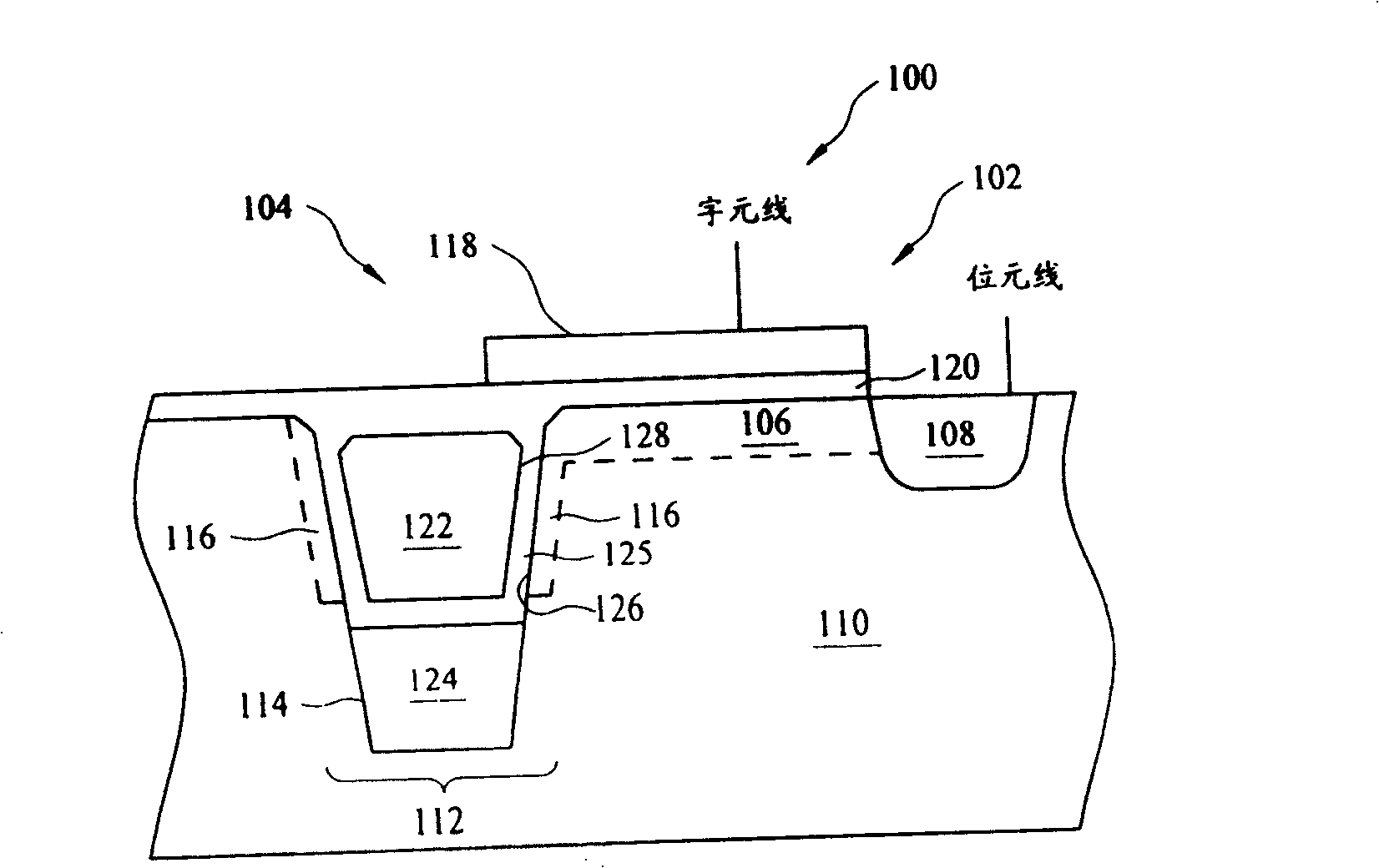

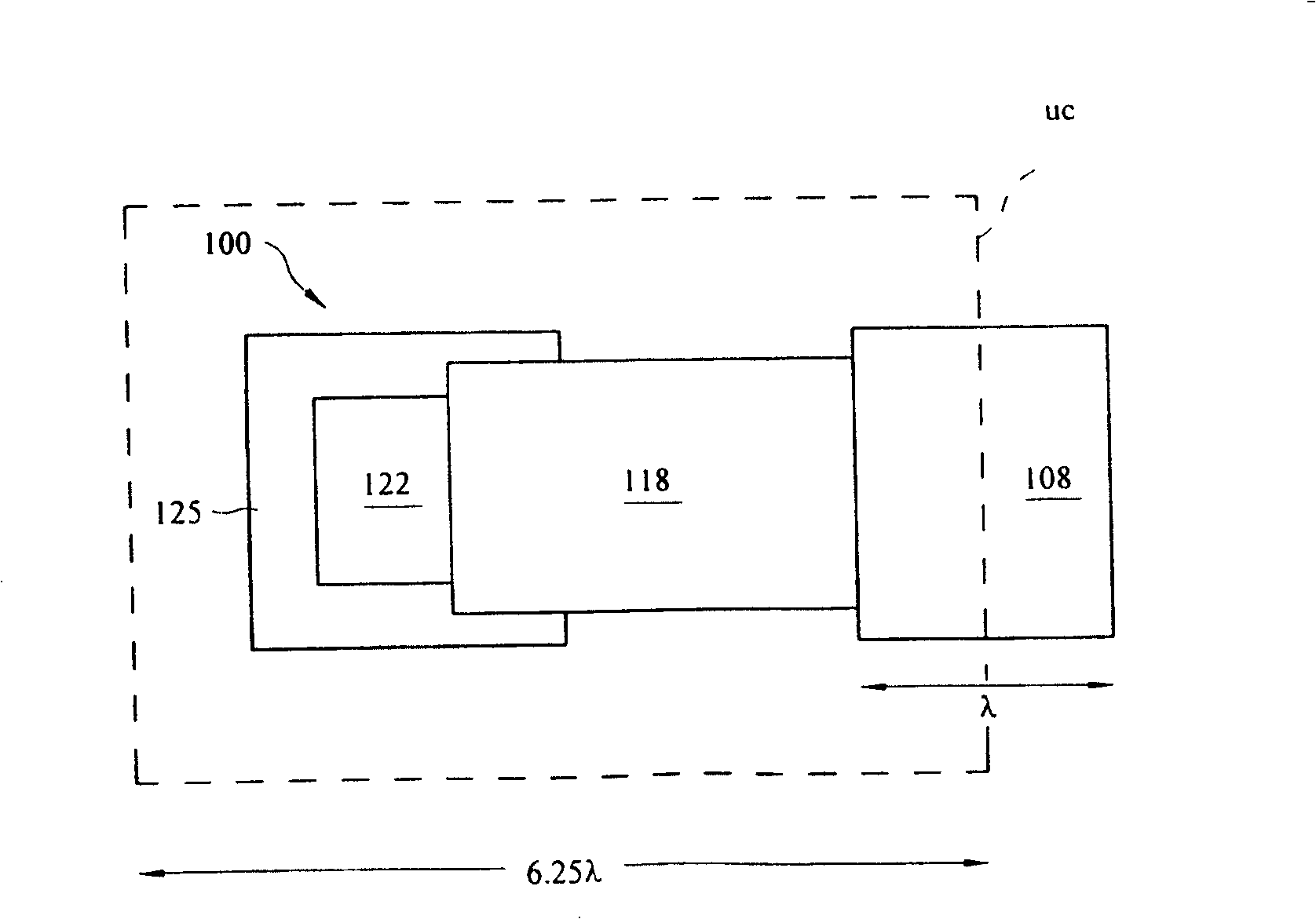

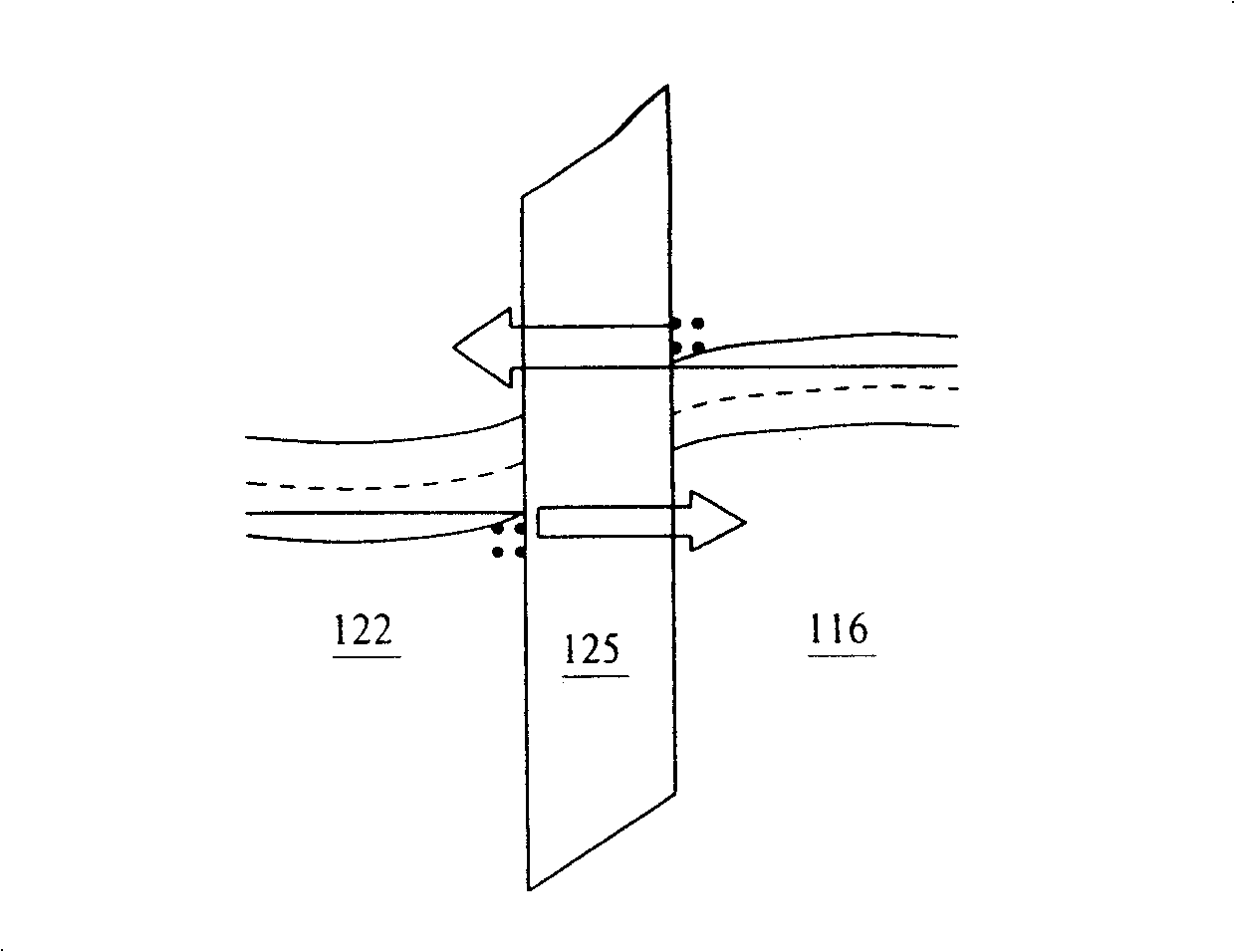

Memory cell and manufacturing method

ActiveCN100416837CSmall sizeExtended shelf lifeTransistorSolid-state devicesPass gateDielectric layer

The present invention provides a memory cell and method for preparation. The memory cell includes a pass-gate transistor and a storage region. The transistor includes a gate and a drain. The storage region includes a trench, which is preferably a Shallow Trench Isolation (STI). A non-insulating structure, e.g., formed of polysilicon or metal, is located in the trench as serves as a capacitor node. The trench is partially defined by a doped sidewall that serves as a source for the transistor. The poly structure and the trench sidewall are separated by a dielectric layer. The write operation involves charge transport to the non-insulating structure by direct tunneling through the dielectric layer. The read operation is assisted by Gate Induced Drain Leakage (GIDL) current generated on the surface of the sidewall. The embodiments of the invention reduce size of the device, increase storage time of the charge and increase compatibility between the standard preparing steps.

Owner:TAIWAN SEMICON MFG CO LTD

A kind of water-based epoxy bitumen anti-corrosion coating and its processing technology

ActiveCN110105848BGood compatibilityImprove incompatibilityAnti-corrosive paintsEpoxy resin coatingsAnthracenePolymer science

The invention discloses a water-based epoxy asphalt anticorrosion coating and a processing technology thereof, and relates to the technical field of asphalt anticorrosion coatings. The technical points are: a water-based epoxy asphalt anti-corrosion coating, including the following components in parts by weight: water: 15-30 parts; epoxy resin: 30-45 parts; coker oil pitch: 25-35 parts; silica sol Anthracene oil: 10-20 parts; diatomaceous earth: 5-10 parts; dispersant: 0.1-3 parts; emulsifier: 0.1-3 parts; curing agent: 30-40 parts; anti-rust pigment : 1.5 to 2.5 parts. The waterborne epoxy asphalt anticorrosion coating prepared by adopting the formula of the invention has the advantages of good compatibility, excellent anticorrosion property of the prepared coating film and good mechanical properties.

Owner:安徽欣苗新材料科技有限公司

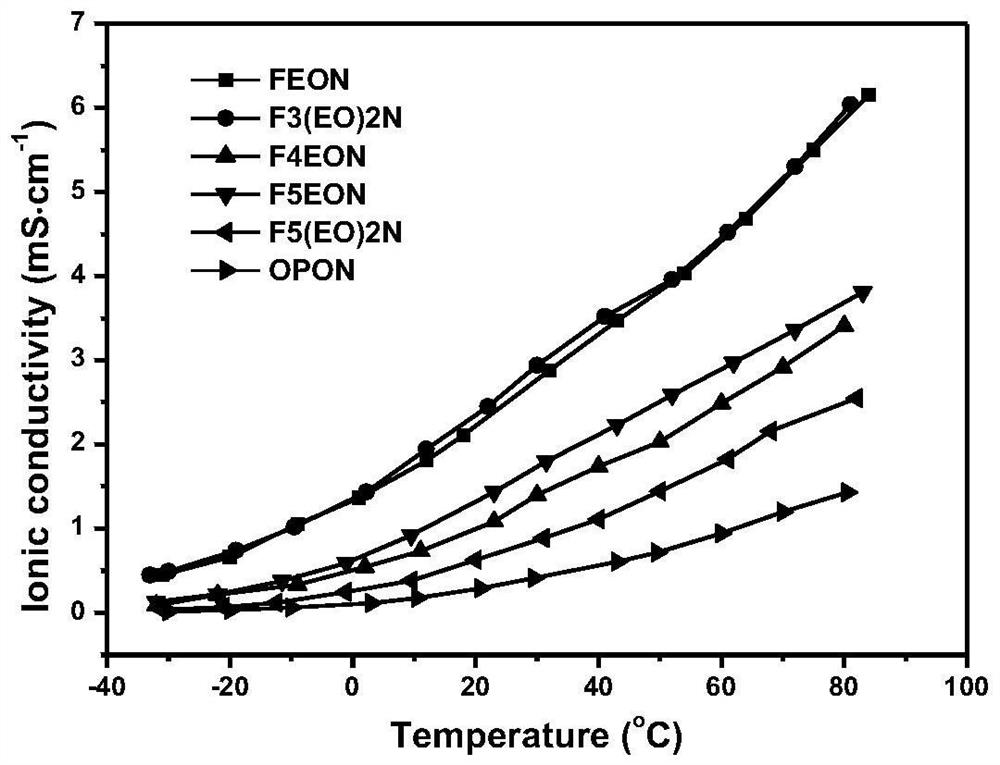

Preparation method of high-safety high-voltage electrolyte containing nitrile compounds

PendingCN114400379AImprove ionic conductivityEnhanced electrochemical windowSecondary cellsOrganic electrolytesOxidation stabilityLithium electrode

The invention discloses a preparation method of a high-safety high-voltage electrolyte containing nitrile compounds, and belongs to the technical field of lithium ion battery materials. According to the electrolyte containing the nitrile compound disclosed by the invention, the structural formula of the nitrile compound is Rf-O-(CH2CH2O) nCH2CH2CN, the Rf group is fluoroalkyl, n is an integer of 0 or 1, and the nitrile compound has the characteristics of high safety, oxidation-resistant stability and high ionic conductivity when being used as the electrolyte. The fluorine-containing nitrile compound electrolyte disclosed by the invention shows good cycle performance and rate capability in a high-voltage lithium ion battery system. The fluoronitrile compound disclosed by the invention is simple to prepare, has relatively good electrochemical stability, and has a certain application prospect when being used as a lithium ion battery electrolyte.

Owner:HUNAN UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com