Preparation method of high-safety high-voltage electrolyte containing nitrile compounds

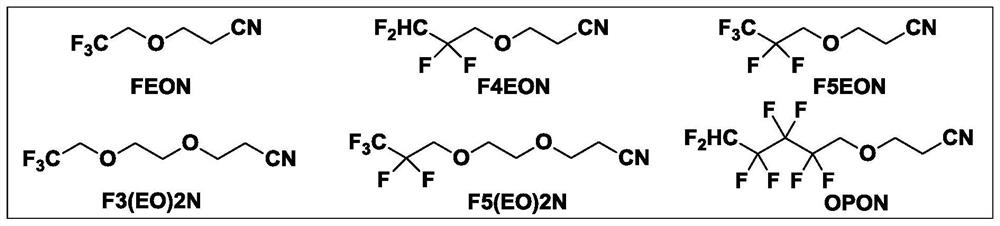

A compound and electrolyte technology, applied in circuits, electrical components, secondary batteries, etc., can solve the problems of limited solubility of lithium hexafluorophosphate, poor reduction stability of nitrile compounds, and insufficient compatibility, so as to improve negative electrode incompatibility, High boiling point, the effect of improving high voltage stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

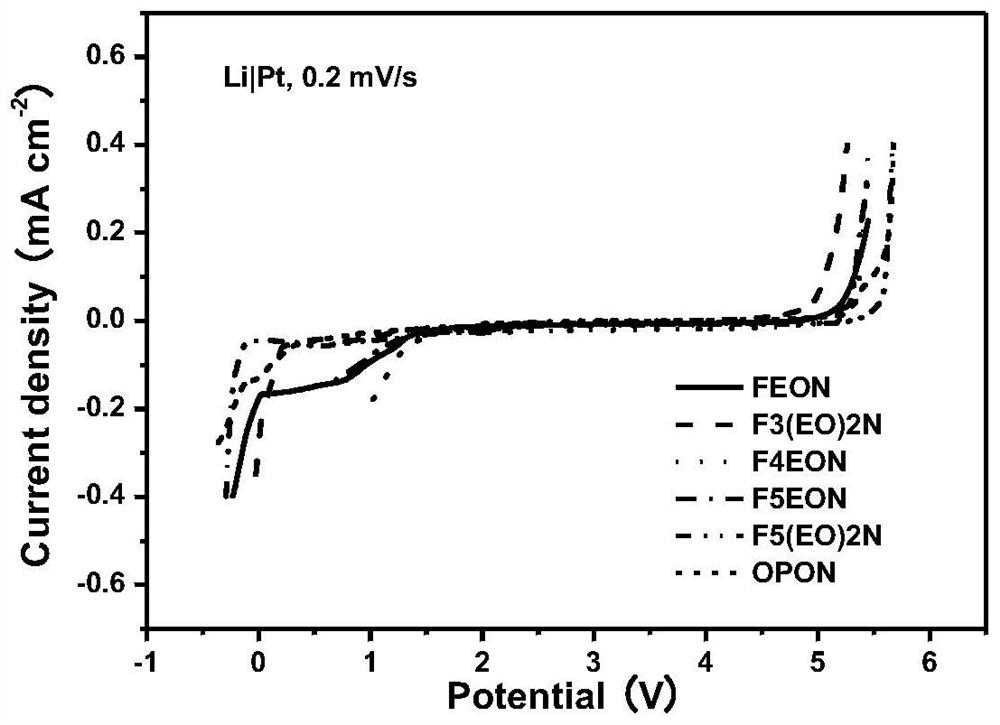

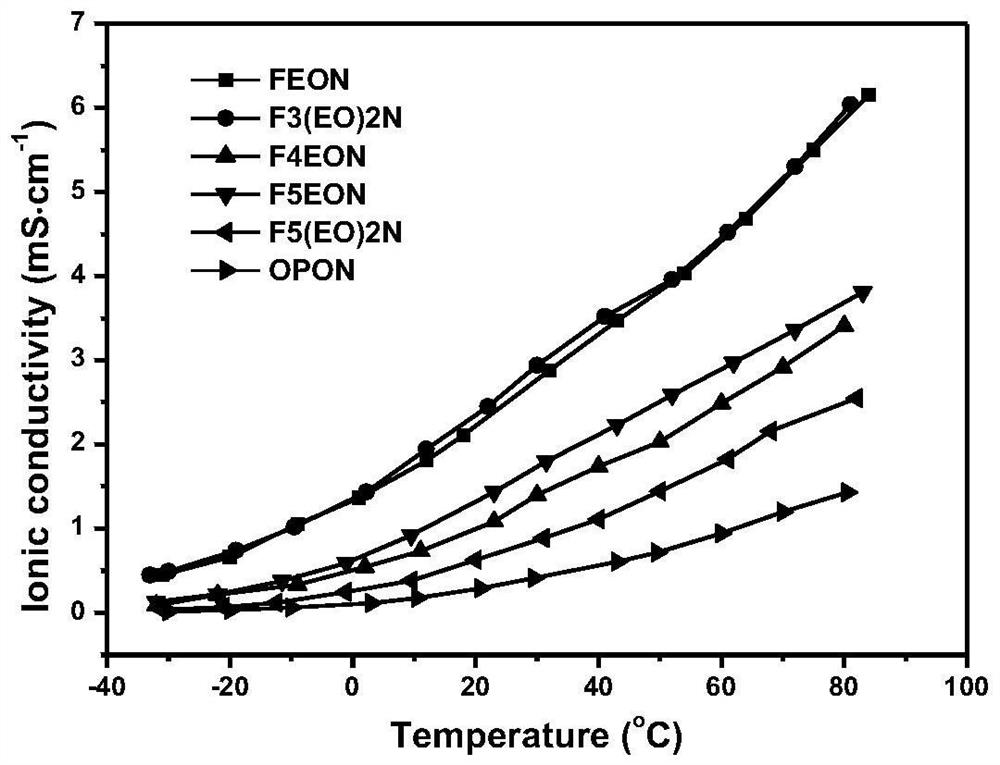

Method used

Image

Examples

Embodiment 1

[0032] Embodiment 1: in the glove box that is full of high-purity argon, the CHF of 0.5vol.% 2 CF 2 CF 2 CF 2 CH 2 OCH 2 CH 2 CN(OPON) added to 1M LiPF 6 / EC:EMC:DMC (1:1:1) in a commercial carbonate electrolyte. The electrolyte using the above-mentioned fluorine-containing nitrile compound additive, the diaphragm is Celgard2400, and Graphite / LiCoO is assembled 2 The battery is subjected to a rate performance test under the condition of 2.8-4.2V; the charge and discharge procedure is to cycle at a rate of 0.05C for 3 weeks, and then cycle at 0.1C, 0.2C, 0.5C, 1C, and 0.2C for 5 weeks.

Embodiment 2

[0033] Embodiment 2: in the glove box that is full of high-purity argon, the CF of 1vol.%3 CF 2 CH 2 OCH 2 CH 2 CN(F5EON) added to 1M LiPF 6 / EC:EMC:DMC (1:1:1) in a commercial carbonate electrolyte. The electrolyte using the above-mentioned fluorine-containing nitrile compound additive, the diaphragm is Celgard2400, and Graphite / LiCoO is assembled 2 The battery is subjected to a rate performance test under the condition of 2.8-4.5V; the charge and discharge procedure is to cycle at a rate of 0.05C for 3 weeks, and then cycle at 0.1C, 0.2C, 0.5C, 1C, and 0.2C for 5 weeks.

Embodiment 3

[0034] Example 3: In a glove box filled with high-purity argon, 0.8M LiTFSI and 0.2M LiODFB were dissolved in fluoroethylene carbonate (FEC) and CF with a volume ratio of 1:3 3 CF 2 CH 2 OCH 2 CH 2 CN(F5EON) mixed solvent. Use the electrolyte of the above-mentioned fluorine-containing nitrile compound, the diaphragm is Celgard2400, assemble a Li / Graphite battery, and charge and discharge the test under the condition of 0.001-2.0V; Cycle at 0.1C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com