Application of Nitrile Compounds in Preparation of Electrolyte for High Voltage Battery System

A high-voltage battery and compound technology, which is applied in the field of lithium-ion batteries, can solve the problems of looseness and low ion conductivity, and the incompatibility of graphite and lithium metal negative electrodes, so as to improve incompatibility, improve high-voltage stability, and increase reduction potential Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

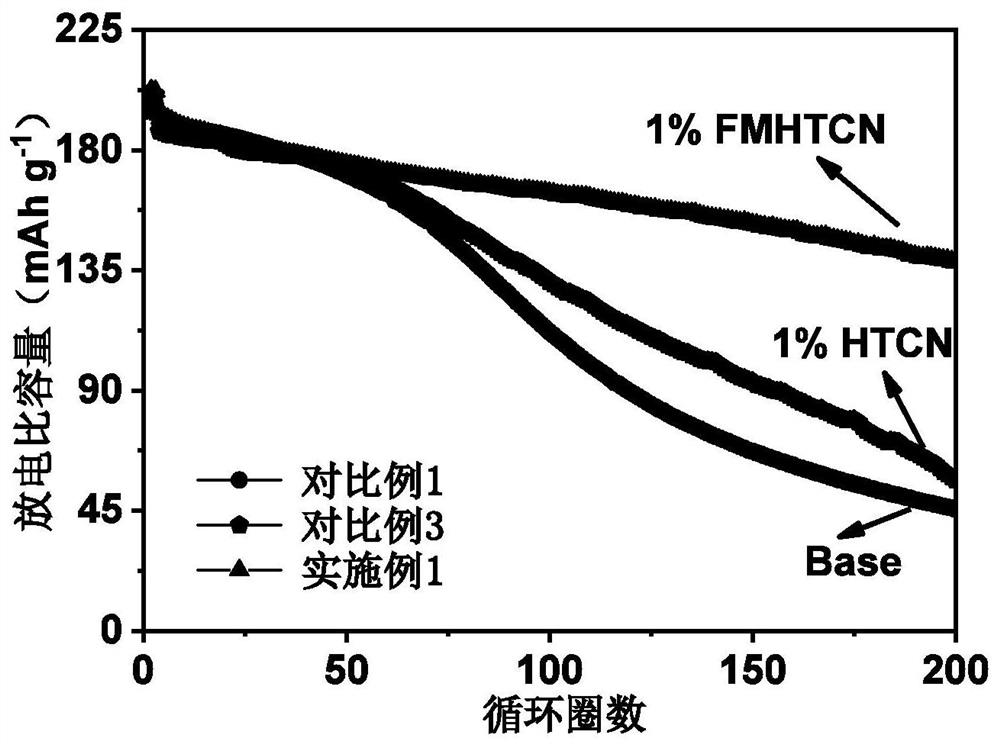

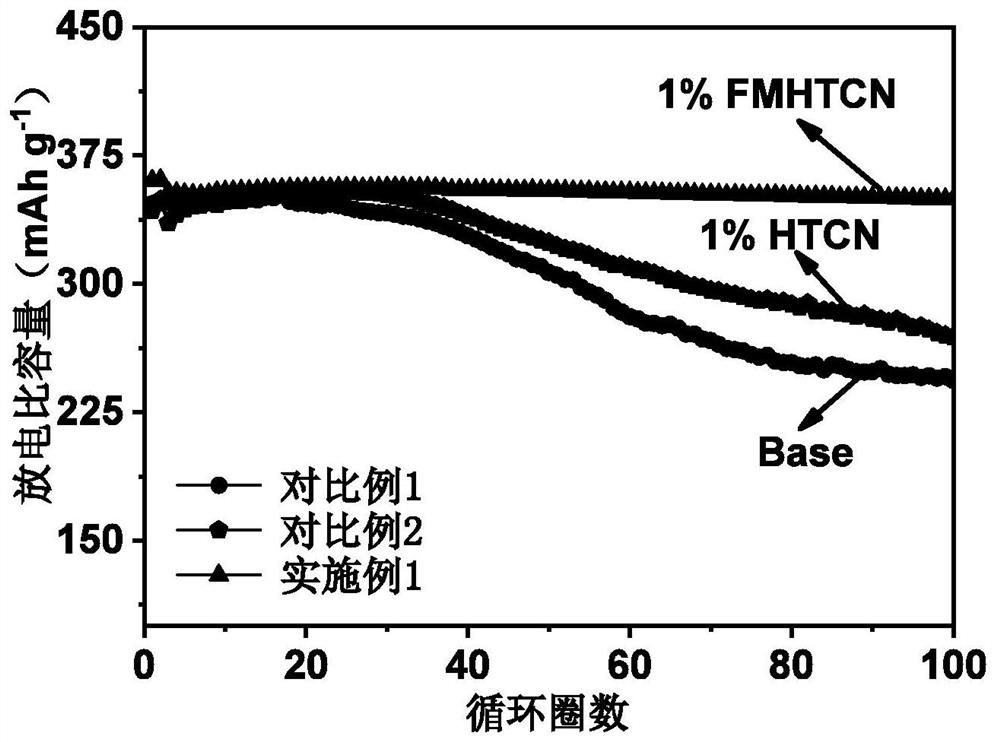

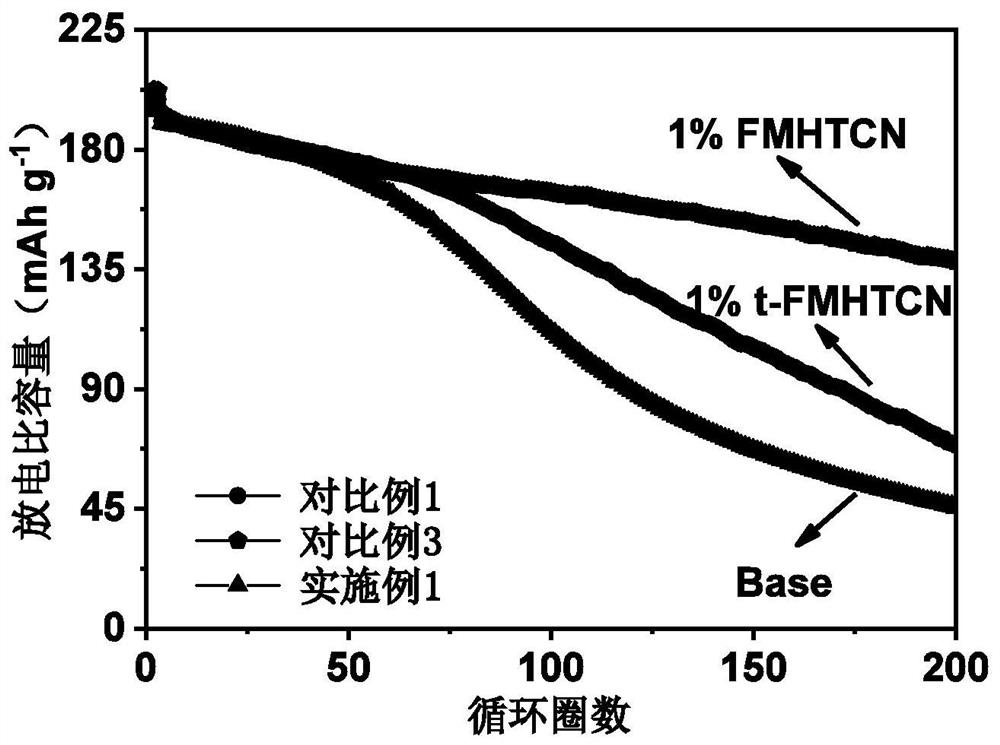

[0028] In a glove box with a water content of less than 1ppm and an oxygen content of less than 1ppm, the lithium-ion battery electrolyte is prepared: LiPF 6 Dissolve in a mixed solvent with a mass ratio of EC:EMC of 3:7, stir and mix evenly, so that the system finally dissolves into a colorless and transparent solution, in which LiPF 6 The concentration is 1.0mol / L. Then add 1wt.% nitrile compound 3-trifluoromethyl-1,3,6-hexanetrinitrile (marked as 1% FMHTCN) after the substitution of F functional group in the above electrolytic solution, prepare the electrolytic solution obtained test.

[0029] Wherein the preparation method of 3-trifluoromethyl-1,3,6-hexanetrinitrile is: get 161g of hexanetrinitrile in the three-necked flask after drying, feed nitrogen into the flask system to ensure that the reaction system Anhydrous and oxygen-free conditions, and place the system in an ice-water bath at 0-5°C. Add 300mL of dried tetrahydrofuran to the system as a solvent, stir and mix...

Embodiment 2

[0032] In a glove box with a water content of less than 1PPM and an oxygen content of less than 1PPM, the lithium-ion battery electrolyte is prepared: LiPF 6 Dissolve in a mixed solvent with a mass ratio of EC:EMC of 3:7, stir and mix evenly, so that the system finally dissolves into a colorless and transparent solution, in which LiPF 6 The concentration is 1.0mol / L. Then, 1 wt.% nitrile compound 3-fluoro-1,3,6-hexanetrinitrile (marked as 1% FHTCN) substituted with F functional group was added to the above electrolyte solution, and the obtained electrolyte solution was prepared for testing.

[0033] The preparation method of 3-fluoro-1,3,6-hexanetrinitrile is as follows: take 161g of hexanetrinitrile into a three-necked flask after drying, and feed nitrogen into the flask system to ensure that the reaction system is anhydrous. Anaerobic conditions, and place the system in an ice-water bath at 0-5°C. Add 300mL of dried tetrahydrofuran to the system as a solvent, stir and mix ...

Embodiment 3

[0036] In a glove box with a water content of less than 1PPM and an oxygen content of less than 1PPM, the lithium-ion battery electrolyte is prepared: LiPF 6 Dissolve in a mixed solvent with a mass ratio of EC:EMC of 3:7, stir and mix evenly, so that the system finally dissolves into a colorless and transparent solution, in which LiPF 6The concentration is 1.0mol / L. Then add 1wt.% nitrile compound 3-trifluoromethanesulfonyl-1,3,6-hexanetrinitrile (marked as 1% FSHTCN) after the substitution of F functional group in the above electrolytic solution, prepare the electrolytic solution obtained test.

[0037] Wherein the preparation method of 3-trifluoromethanesulfonyl-1,3,6-hexanetrinitrile is: get 161g of hexanetrinitrile in the three-necked flask after drying, feed nitrogen into the flask system to ensure the reaction Anhydrous and oxygen-free conditions for the system, and place the system in an ice-water bath at 0-5°C. Add 300mL of dried tetrahydrofuran to the system as a s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com