Waterborne epoxy asphalt anti-corrosive paint and processing technology thereof

A water-based epoxy asphalt and anti-corrosion coating technology, applied in the field of asphalt anti-corrosion coatings, can solve the problems of instability, poor compatibility, easy segregation, etc., and achieve the effect of improving incompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

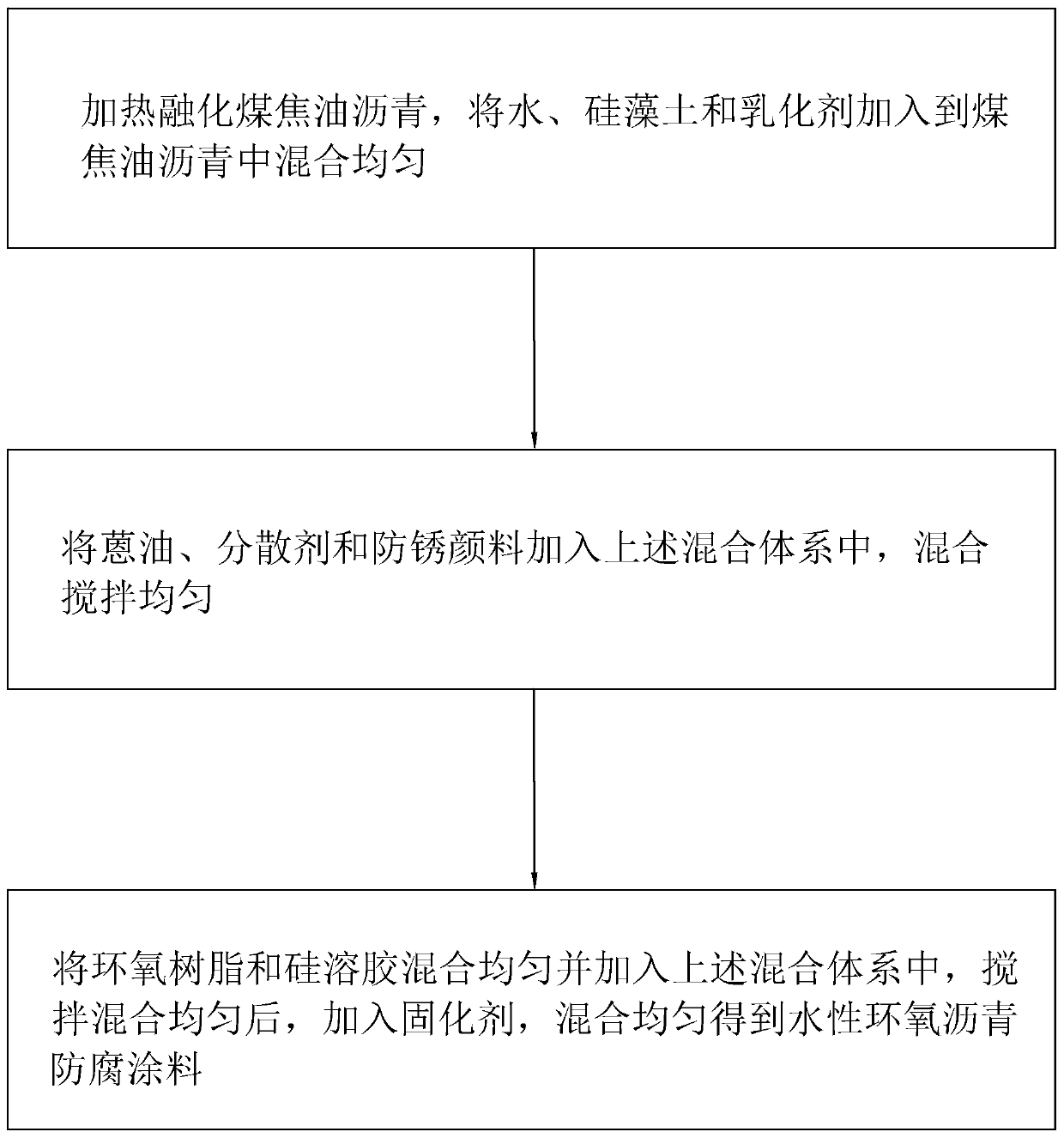

[0040] Embodiment 1: A kind of water-based epoxy asphalt anticorrosion coating, each component and its corresponding parts by weight are as shown in Table 1, and are prepared through the following steps:

[0041] Step 1: Heat the coal tar pitch to a molten state at a temperature of 150°C, add diatomaceous earth, tallow tetramine and polyoxyethylene lauryl ether into water and mix, add the mixed solution to the tar pitch, stir and mix 30min, cool down to 50°C; step 2, add anthracene oil, sodium lauryl sulfate, strontium phosphosilicate and zinc aluminum phosphate to the mixing system of step 1, stir and mix for 30min;

[0042] Step 3: Stir and mix the bisphenol A type epoxy resin with an epoxy equivalent of 200g / mol and silica sol evenly, then add it to the mixing system in Step 2, after stirring and mixing for 2 hours, add polyamide, and stir and mix for 5 minutes to obtain Waterborne epoxy asphalt anticorrosion coating.

Embodiment 2-6

[0043] Example 2-6: A waterborne epoxy asphalt anticorrosion coating, the difference from Example 1 is that each component and its corresponding parts by weight are shown in Table 1.

[0044] Each component and parts by weight thereof in table 1 embodiment 1-6

[0045]

Embodiment 7

[0046] Embodiment 7: A kind of waterborne epoxy asphalt anticorrosion coating, the difference with embodiment 1 is, step 2, with 25 parts of anthracene oil, 0.05 part of sodium lauryl sulfate, 0.05 part of methyl amyl alcohol, 0.9 part of phosphorus Add strontium silicate and 0.6 parts of zinc aluminum phosphate to the mixing system in step 1, and stir and mix for 30 minutes;

[0047] All the other are identical with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Epoxy equivalent | aaaaa | aaaaa |

| Epoxy equivalent | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com