Method for preparing hydrophobic nano-silica with controllable grain diameter

A nano-silica, hydrophobic technology, applied in the direction of dyeing organosilicon compound treatment, fibrous filler, etc., can solve the problems of high roasting temperature, different product properties, and high energy consumption, and achieves simple method and enhanced function. , the effect of enhancing dispersibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

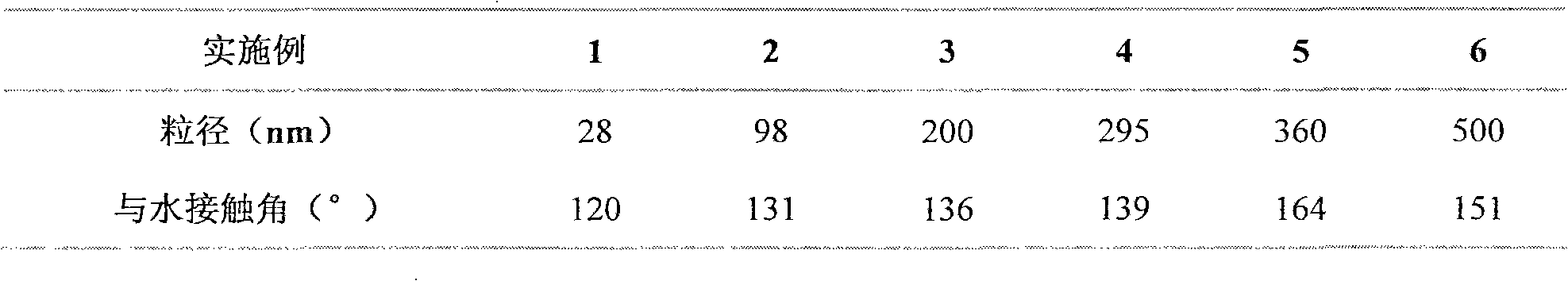

[0020] After mixing 4g of ammonia water (20% by mass) and 2g of water, add it to 150g of absolute ethanol, stir and heat up to 70°C, and stir for 0.5 hours; further add 6g of ethyl orthosilicate dropwise to the above solution , the dropping speed was 0.8g / min, after the dropwise addition, the reaction was kept for 2 hours, and 2.5g of methyltriethoxysilane was further added dropwise, and the reaction was kept for 18 hours. Then filter, wash, and dry to obtain hydrophobic nano-silica, the properties of which are shown in Table 1.

Embodiment 2

[0022] After mixing 4g of ammonia water (28% by mass) and 6g of water, add it to 100g of absolute ethanol, stir and heat up to 50°C, and stir for 1 hour; further add 6g of ethyl orthosilicate dropwise to the above solution , a dropping rate of 0.5g / min, after the dropwise addition, the reaction was kept for 2 hours, and 3.5g of methyltriethoxysilane was further added dropwise, and the reaction was kept for 18 hours. Then filter, wash, and dry to obtain hydrophobic nano-silica, the properties of which are shown in Table 1.

Embodiment 3

[0024] After mixing 5g of ammonia water (25% by mass) and 7g of water, add it to 100g of absolute ethanol, stir and heat up to 60°C, and stir for 1 hour; further add 6g of tetraethyl orthosilicate dropwise to the above solution , the dropping rate was 1.0g / min, after the dropwise addition, the reaction was kept for 3 hours, and 2.5g of ethyltriethoxysilane was further added dropwise, and the reaction was kept for 20 hours. Then filter, wash, and dry to obtain hydrophobic nano-silica, the properties of which are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com