Toughened polyphenyl ether and nylon alloy and preparation method for toughened polyphenyl ether and nylon alloy

A polyphenylene ether and toughening technology is applied in the field of polyphenylene ether and nylon alloy materials and their preparation, which can solve the problems of poor processability, intolerance, easy water absorption, etc., and achieve the effect of maintaining external dimensions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

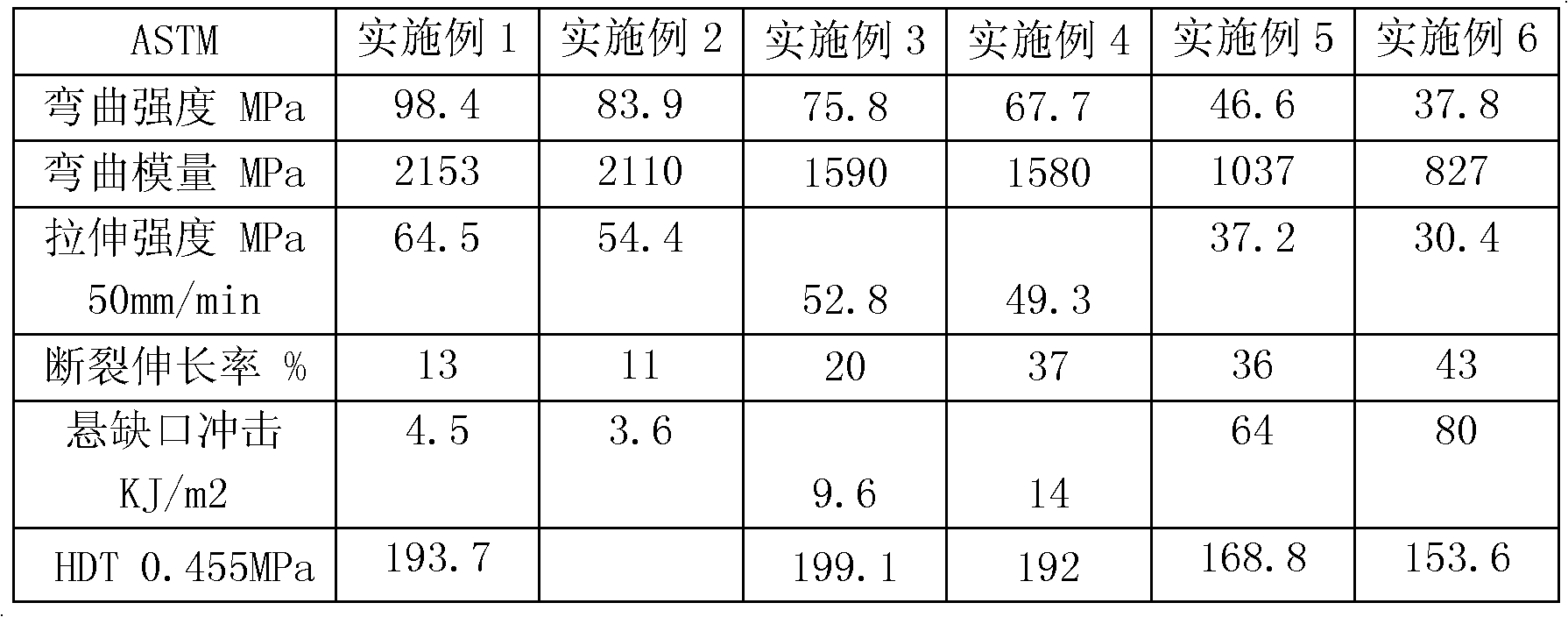

Examples

Embodiment 1

[0037] (1) Weigh PPO 30%, PA6660%, compatibilizer PPO-g-MAH 5%, toughening agent SEBS-g-MAH 5%, antioxidant 1098 / 168 (1:1) 0.4%, lubricant A-C540A 0.6%;

[0038] (2) After mixing the above materials in a high-speed mixer for 3-5 minutes;

[0039] (3) Finally, the mixed material is added into the hopper of the twin-screw extruder, melted and blended, extruded and granulated into an alloy material;

[0040] Among them, the temperature settings of each section of the twin-screw are: the temperature of the first zone is 240-260°C, the temperature of the second zone is 250-270°C, the temperature of the third zone is 265-285°C, the temperature of the fourth zone is 275-295°C, and the temperature of the fifth zone is 275-295°C , the temperature in the six zones is 270-290°C, the temperature of the machine head is 275-295°C, and the speed of the main engine is 15-35HZ.

Embodiment 2

[0042] (1) Weigh PPO 60%, PA6630%, compatibilizer MPPO 5%, toughening agent SEBS-g-MAH 5%, antioxidant 1098 / 168 (1:1) 0.4%, lubricant A-C540A 0.6 %;

[0043] (2) After mixing the above materials in a high-speed mixer for 3-5 minutes;

[0044] (3) Finally, the mixed material is added into the hopper of the twin-screw extruder, melted and blended, extruded and granulated into an alloy material;

[0045] Among them, the temperature settings of each section of the twin-screw are: the temperature of the first zone is 240-260°C, the temperature of the second zone is 250-270°C, the temperature of the third zone is 265-285°C, the temperature of the fourth zone is 275-295°C, and the temperature of the fifth zone is 275-295°C , the temperature in the six zones is 270-290°C, the temperature of the machine head is 275-295°C, and the speed of the main engine is 15-35HZ.

[0046] The preparation method of compatibilizer MPPO is as follows:

[0047] PPO 90%, PS 10%, antioxidant 1098 / 168 (...

Embodiment 3

[0049] (1) Weigh PPO 40%, PA6645%, compatibilizer MPPO 5%, toughening agent SEBS-g-MAH 10%, antioxidant 1098 / 168 (1:1) 0.4%, lubricant A-C540A 0.6 %;

[0050] (2) After mixing the above materials in a high-speed mixer for 3-5 minutes;

[0051] (3) Finally, the mixed material is added into the hopper of the twin-screw extruder, melted and blended, extruded and granulated into an alloy material;

[0052] Among them, the temperature settings of each section of the twin-screw are: the temperature of the first zone is 240-260°C, the temperature of the second zone is 250-270°C, the temperature of the third zone is 265-285°C, the temperature of the fourth zone is 275-295°C, and the temperature of the fifth zone is 275-295°C , the temperature in the six zones is 270-290°C, the temperature of the machine head is 275-295°C, and the speed of the main engine is 15-35HZ.

[0053] The preparation method of compatibilizer MPPO is as follows:

[0054] PPO 70%, PS 30%, antioxidant 1098 / 168 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of grafting | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com