Block check valve for cutting off or recovering medium return of oil path of oil supply system

A technology of oil supply system and check valve, which is applied in the field of cut-off check valve to cut off or connect the return flow of the oil circuit medium in the oil supply system, and can solve the problems of inability to meet low-resistance backflow, loss of check function, poor safety and reliability, etc. , to achieve the effect of compact structure, overcoming large resistance, and convenient installation and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

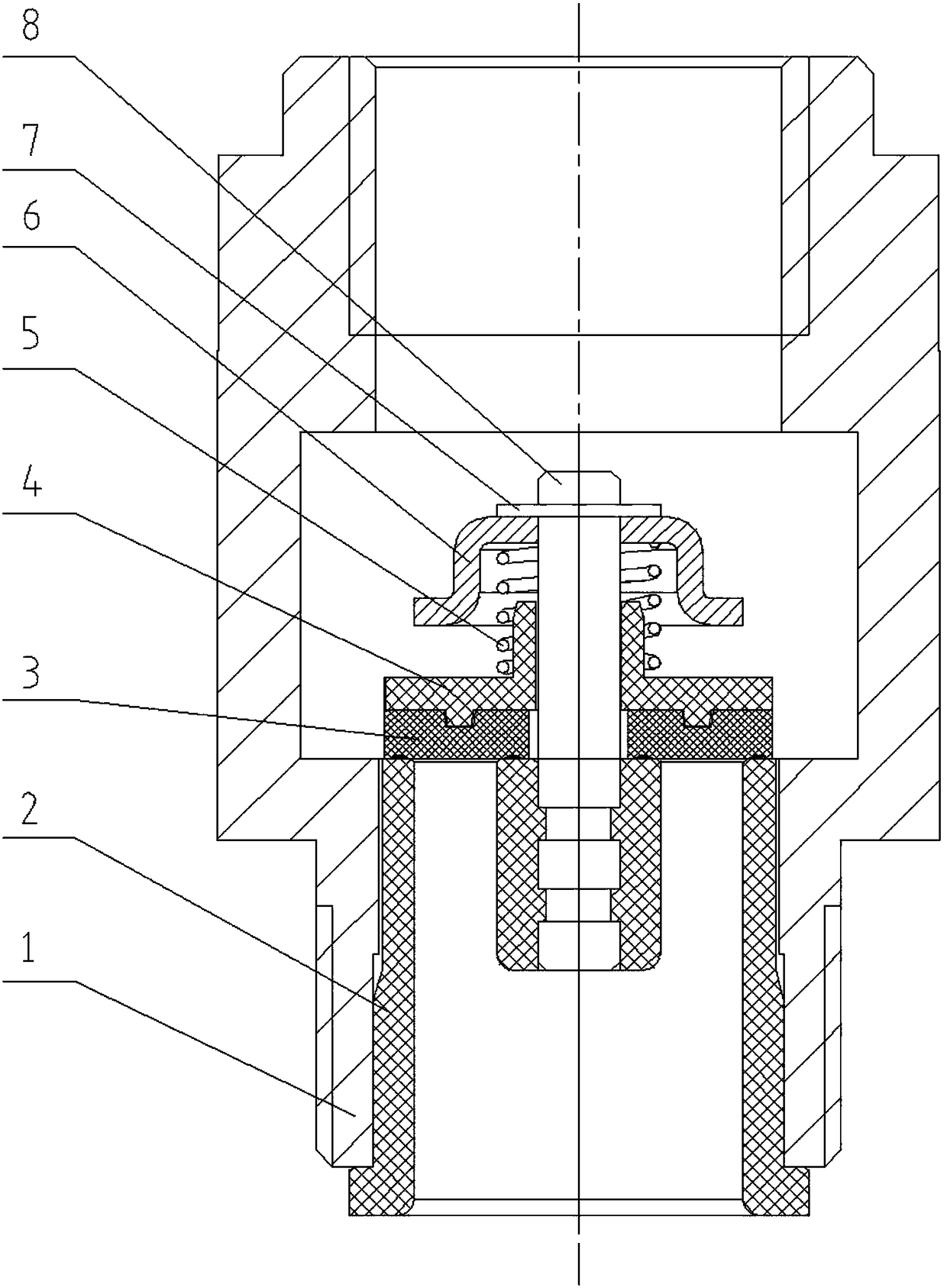

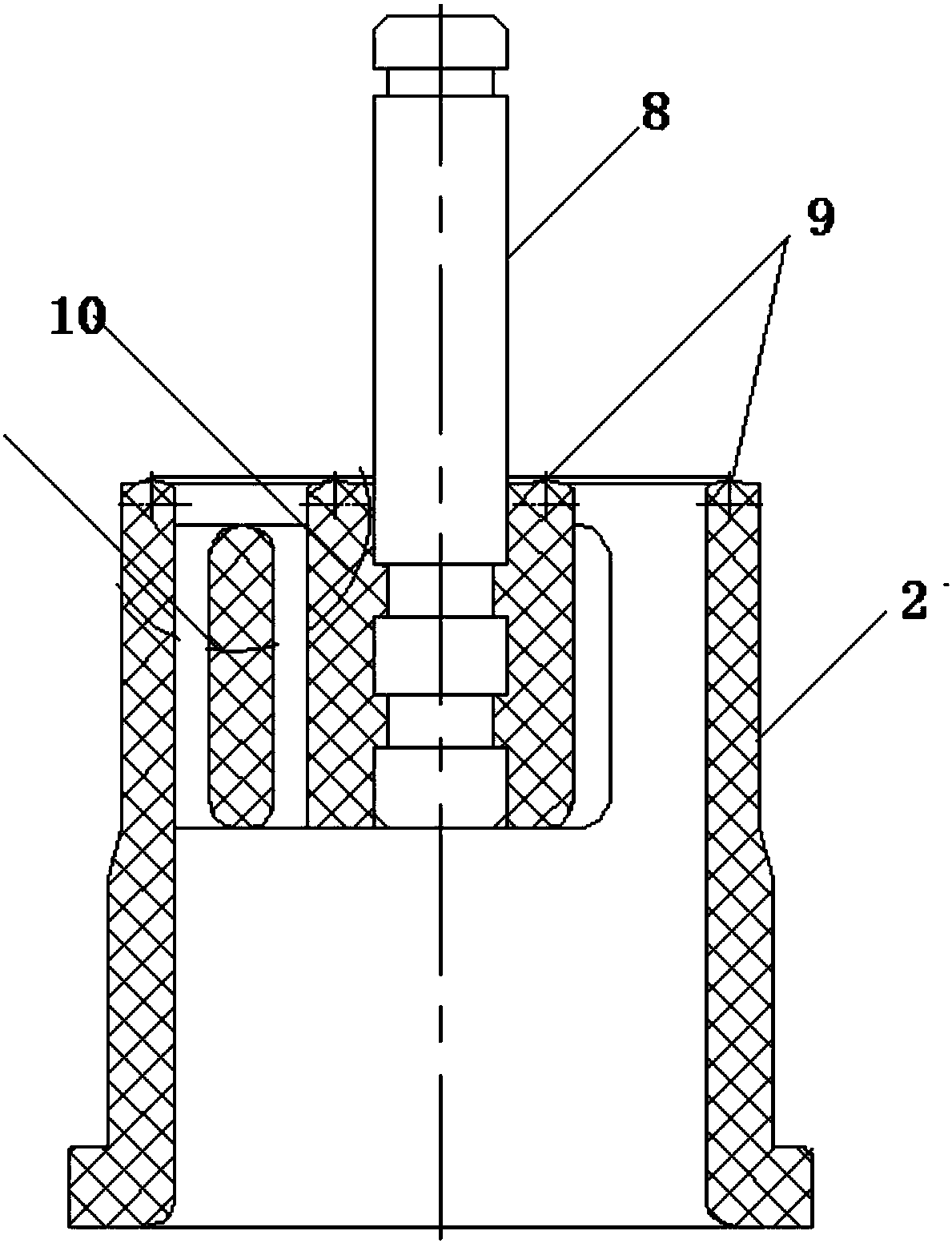

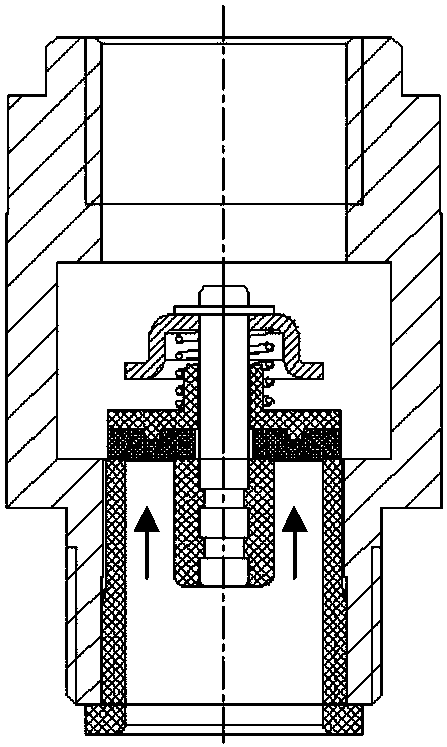

[0015] refer to figure 1 . In the embodiment described below, a blocking check valve that cuts off or connects the return flow of the oil circuit medium in the oil supply system has a threaded direct-current pipeline joint valve body tube 1 and a valve installed on the joint valve body tube 1 The check valve body on the end surface of the step in the cavity, and the check valve seat 2 supporting the check valve body through the valve stem 8, mainly consists of the joint valve body pipe 11, the check valve seat 2, the non-metallic elastic backing plate 3, An inverted T-shaped backing plate 4, a return spring 5, a valve cover 6, an opening retaining ring 7 and a valve stem 8 are formed. The joint valve body pipe (1) is made with a valve chamber with a diameter greater than that of the upper and lower direct current pipelines, and the valve stem 8 is connected to the check valve seat 2 located below the check valve body through the valve cover 6 of the arcuate section and its b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com