Rectangle plane magnetron sputtering cathode

A magnetron sputtering and planar technology, applied in the field of vacuum coating equipment, can solve the problems of affecting the stability of the sputtering process, the deterioration of the vacuum sealing performance of the target material, and changing the parameters of the sputtering process, so as to overcome the difficulty of disassembly and assembly and reduce the cooling effect. Uniform and sufficient effect, stable sputtering process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

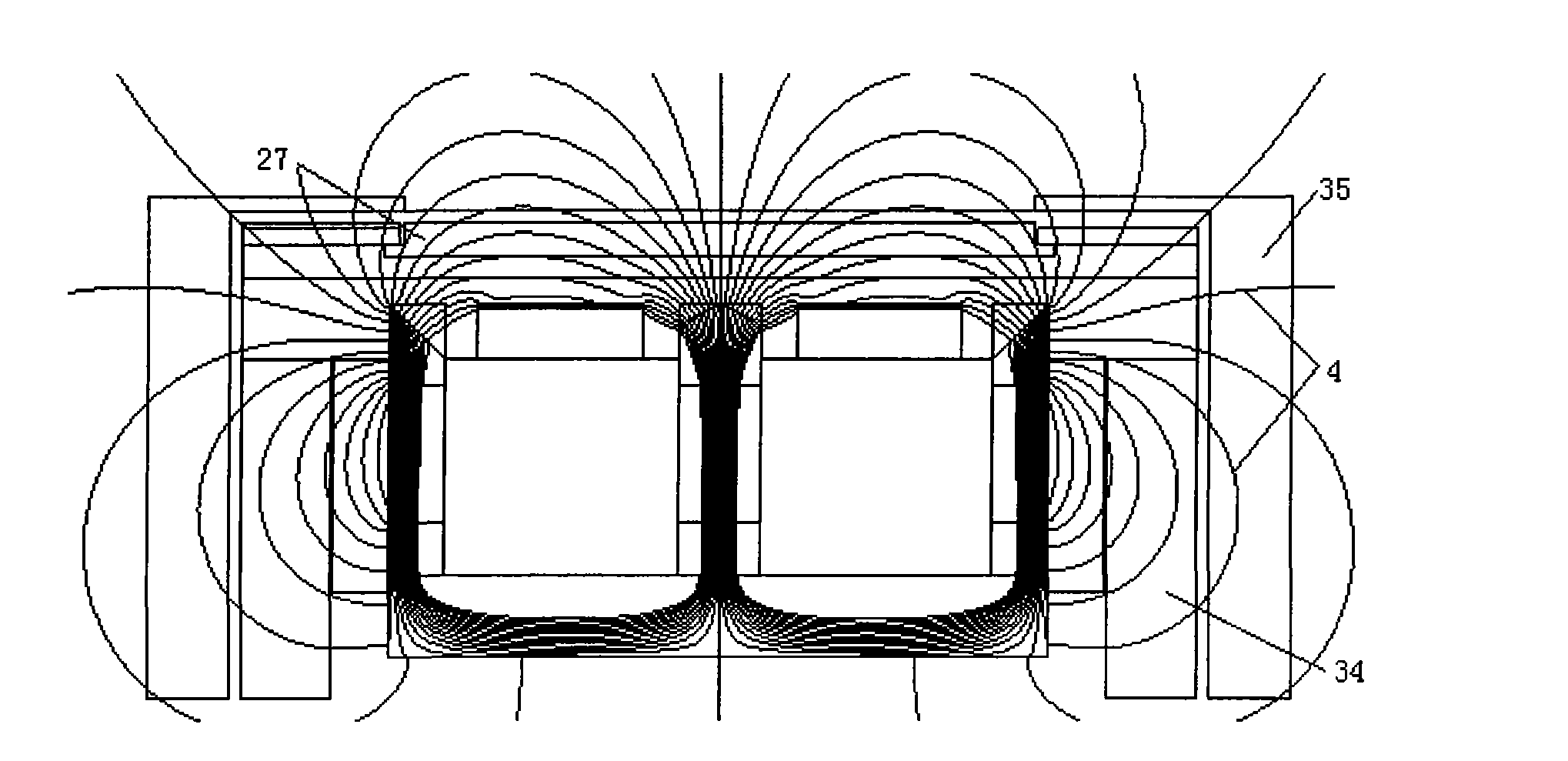

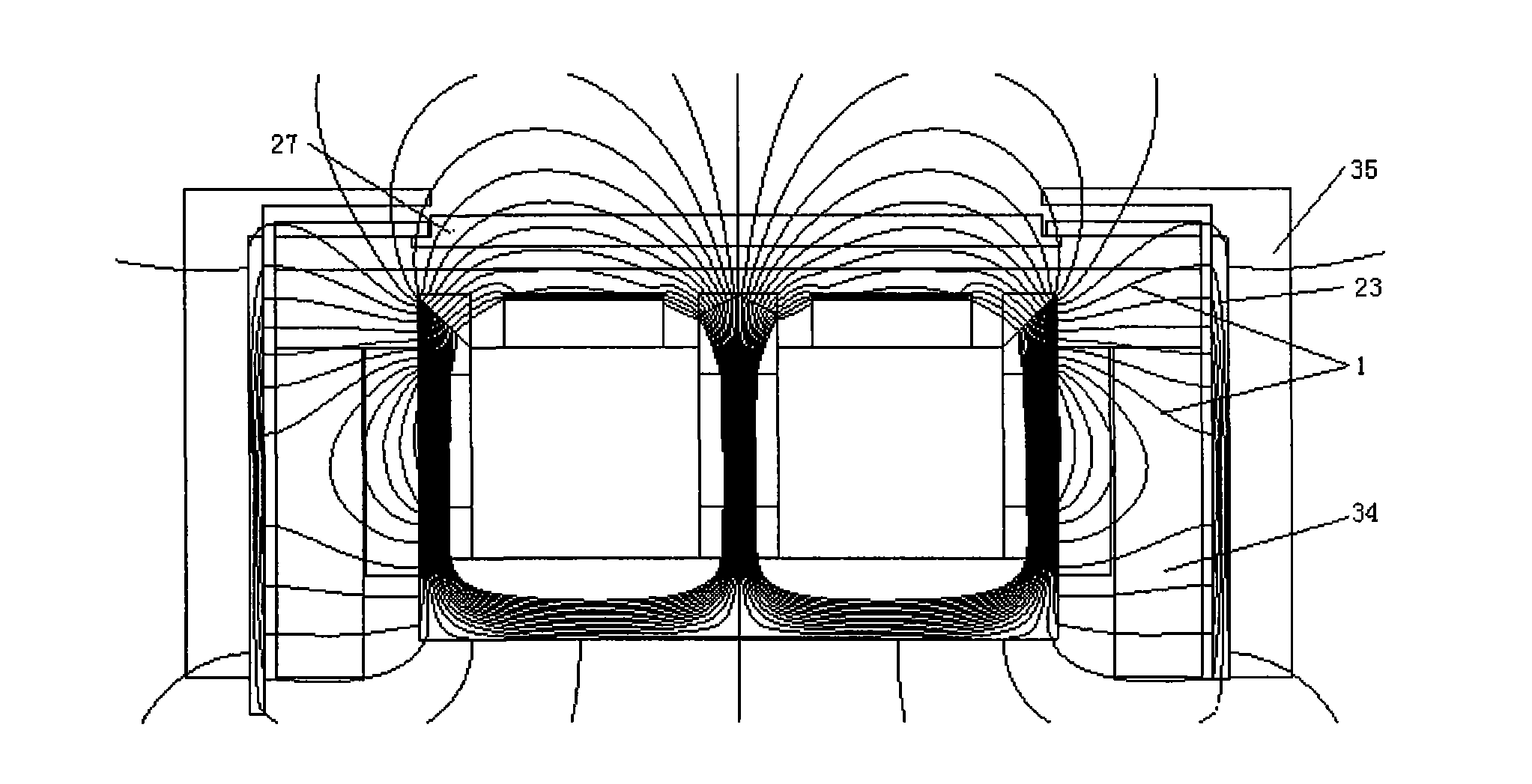

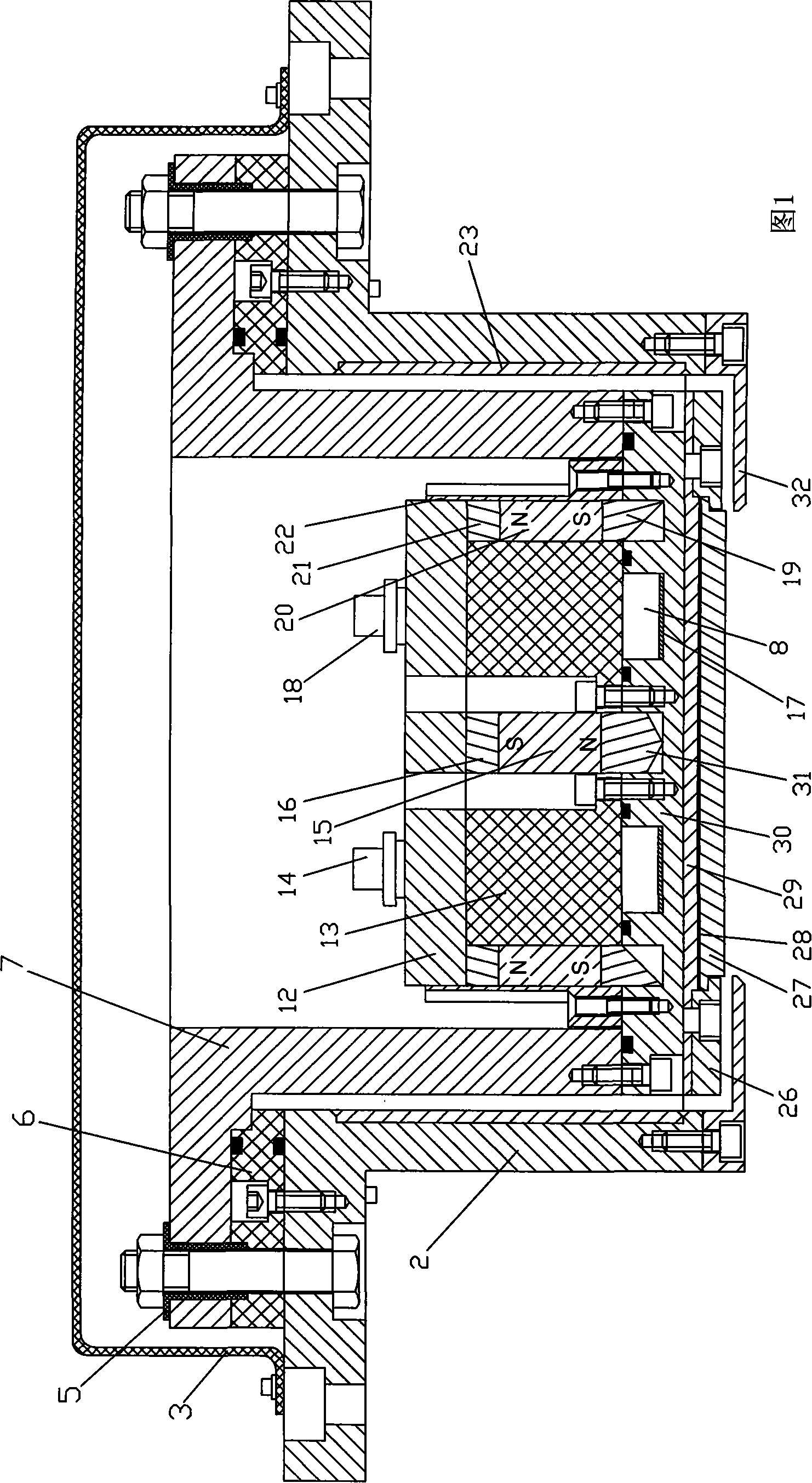

[0030] Referring to Fig. 1, the present embodiment has a target material 27, a cathode assembly and a shield 2 arranged on the periphery of the cathode assembly according to a conventional structure. In the cathode assembly, the magnetic circuit mechanism is fixedly arranged on the target holder 30 and is located inside the cathode body 7 , the target material 27 is fixedly arranged on the lower part of the target holder 30 .

[0031] In this embodiment, a magnetically conductive plate 23 is provided on the outer periphery of the cathode assembly, on the inside or outside of the shielding case 2 . The magnetically conductive plate 23 can be fixedly arranged on the outer sidewall of the cathode body 7, or fixedly arranged on the inner sidewall of the shield cover 2, or can be fixedly arranged on the outer sidewall of the shield cover 2; the magnetically conductive plate 23 adopts a magnetically conductive ferromagnetic material or soft magnetic material.

[0032] In specific i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com