Ring cooling machine trolley and ring cooling machine with trolley

A technology of ring coolers and trolleys, which is applied in the field of iron and steel smelting, can solve the problems of pressure loss on the lower plate of the trolley, damage to the static sealing device that has not been completely eliminated, and has a large impact, so as to ensure the effect of unloading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

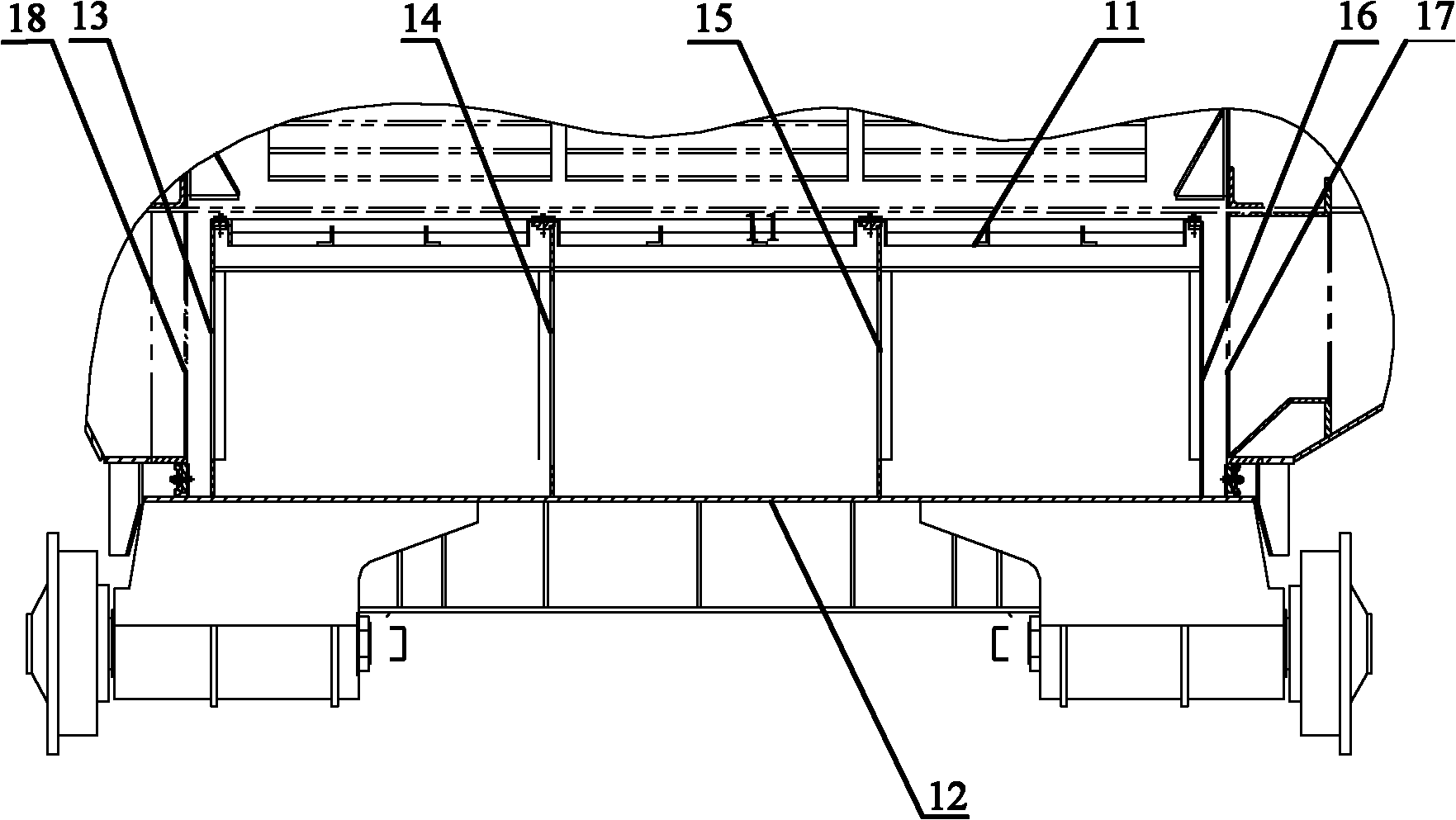

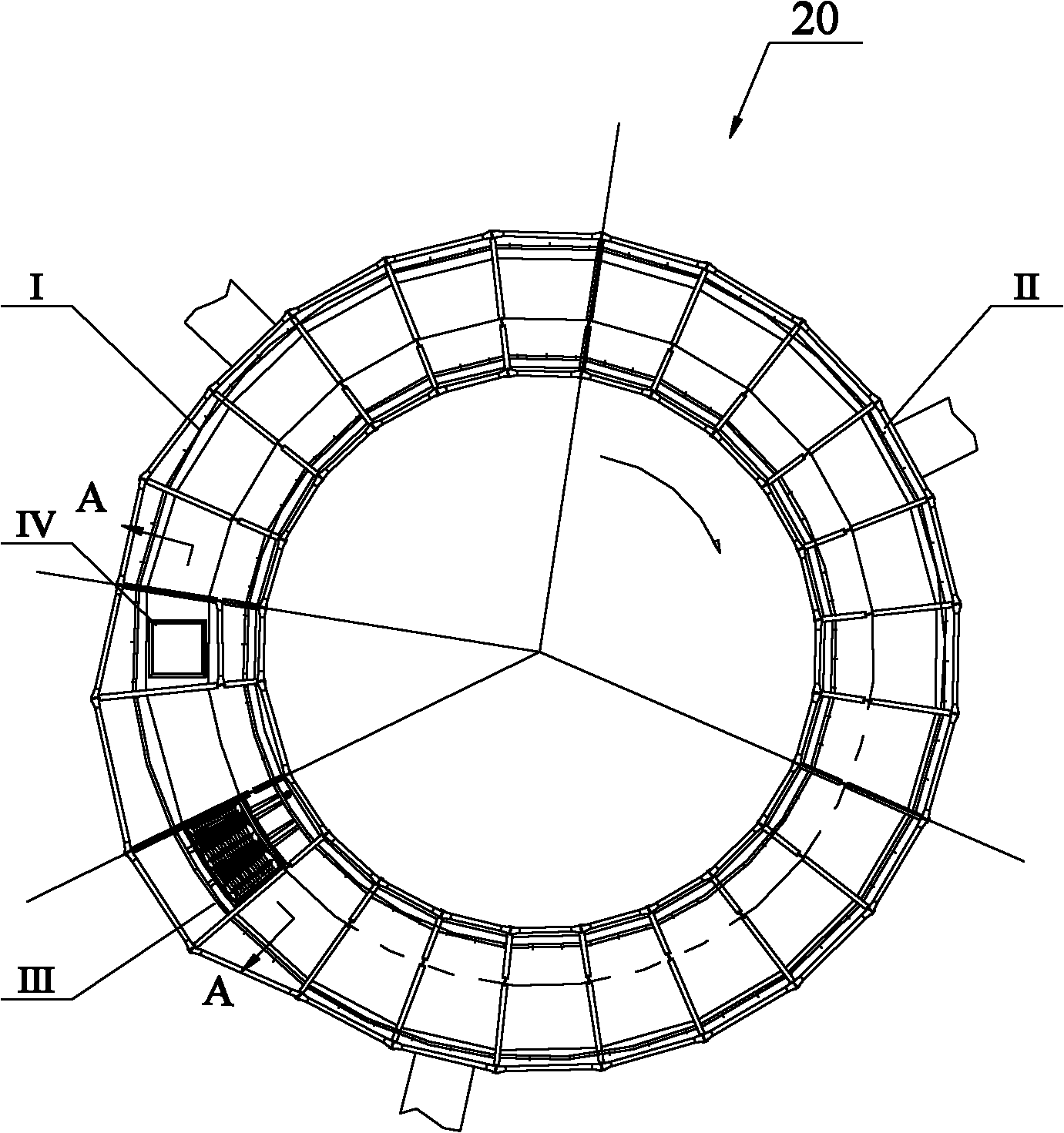

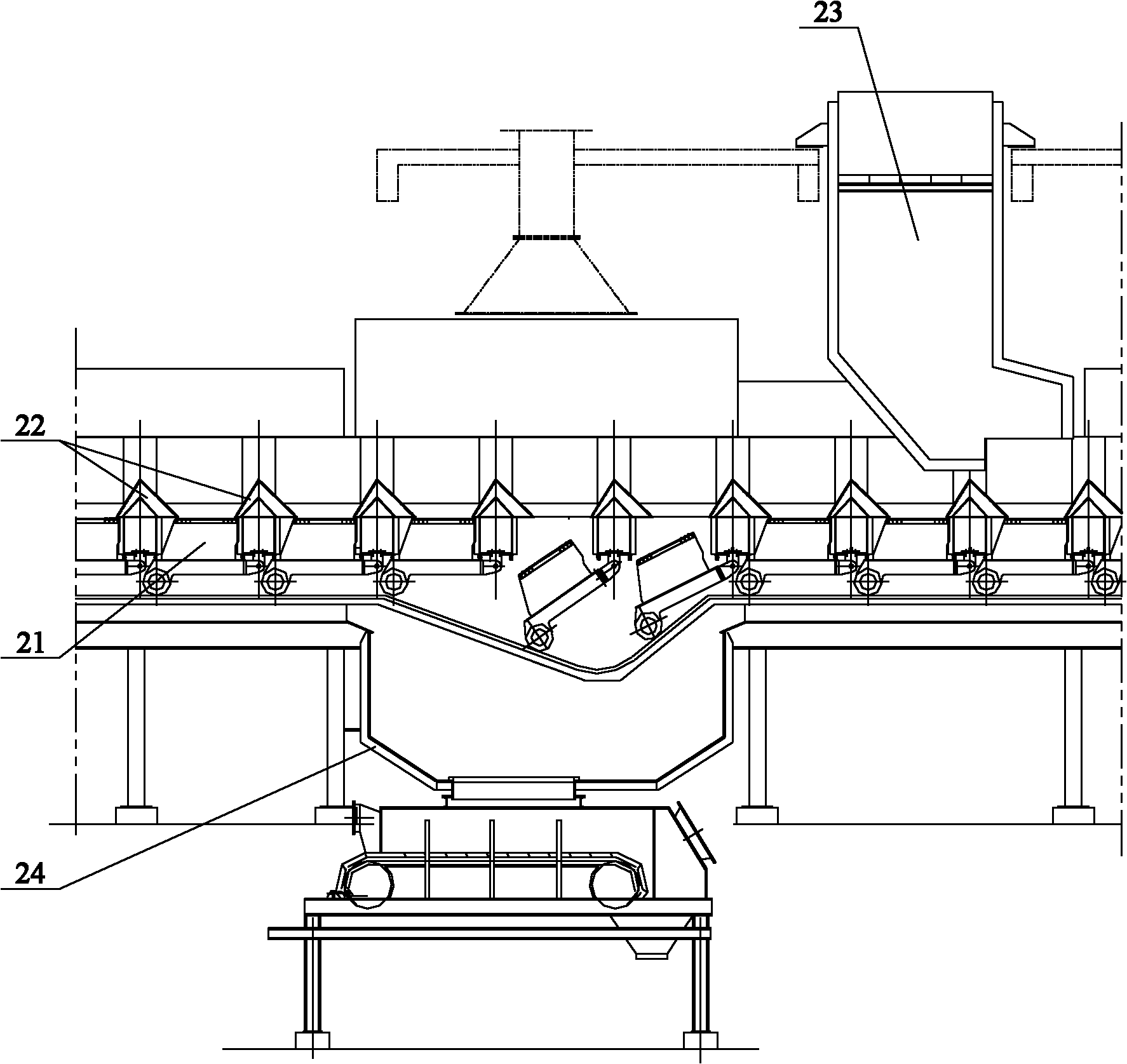

[0041] The core of the present invention is to provide a ring cooler trolley, which mainly realizes the complete unloading of the lower plate of the trolley through the improved design of the supporting vertical plate and its matching relationship, which can effectively avoid damage caused by material accumulation at the front end of the vertical plate Defects in the static seal of the trolley and the lower plate of the trolley.

[0042] Without loss of generality, this embodiment will be described in detail below in conjunction with the accompanying drawings.

[0043] The inside and outside of the orientation words involved in this article are defined based on the center of the annular cooler, and the front and rear of the orientation words involved are defined based on the rotation direction of the annular cooler. It should be understood that the use of orientation words such as inner, outer, front, and back does not limit the scope of protection claimed in this application. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com