Seal joint for pressurized wind tunnel

A technology of sealing joints and wind tunnels, applied in the field of pressure vessel sealing, which can solve the problems of difficult installation and disassembly, failure, easy loosening and air leakage, etc., and achieve the effect of repeated installation, quick connection and quick installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] This embodiment is a sealing joint for a pressurized wind tunnel.

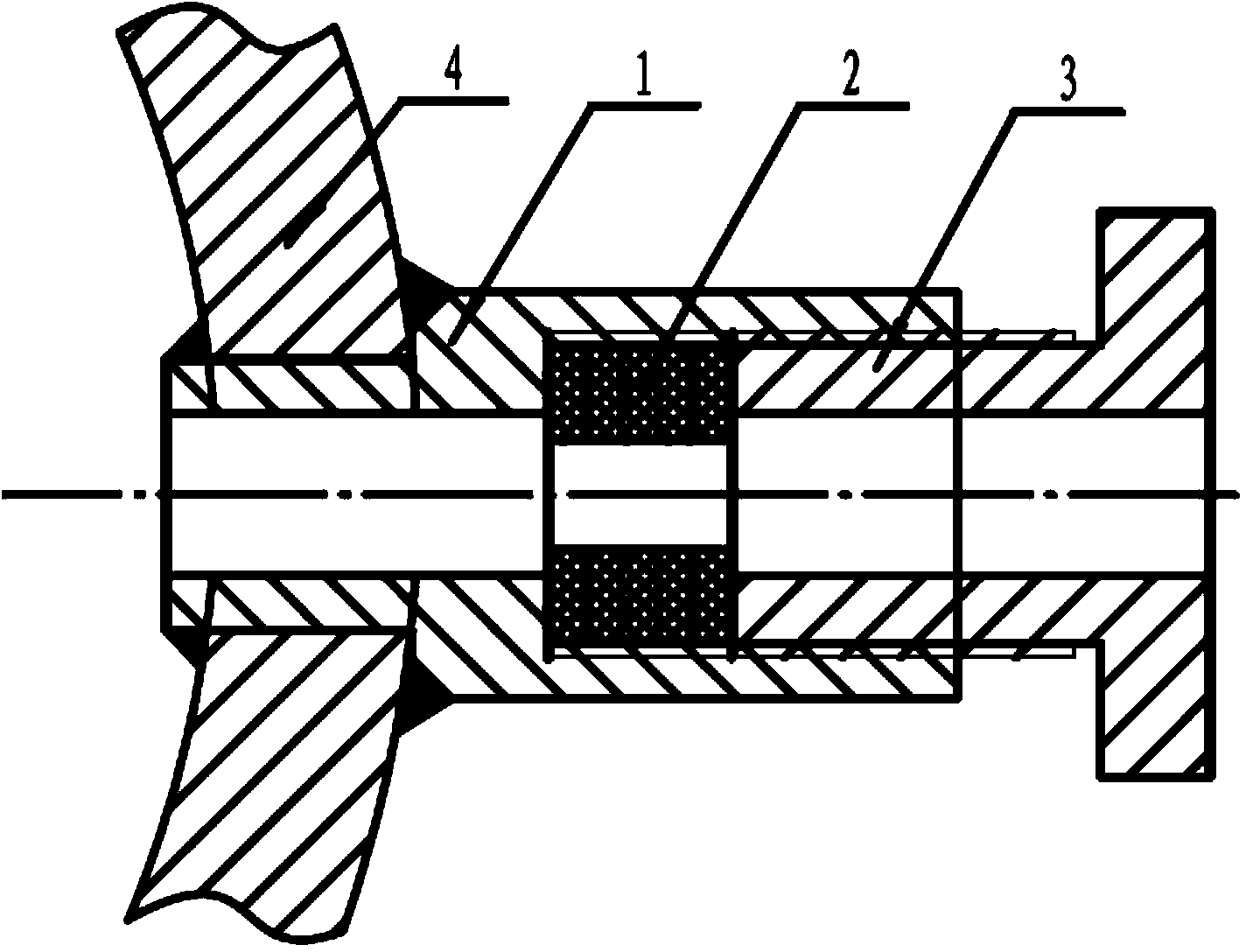

[0017] refer to figure 2 , The sealing joint used in the pressurized wind tunnel in this embodiment consists of a base 1, a pressing wire 3 and a sealing gasket 2. One end of the base 1 is connected to the pressurized wind tunnel wall 4 by welding, and five superimposed sealing gaskets 2 are fixed between the base 1 and the pressure wire 3, and the cables are connected from the base 1 and the pressure wire 3 to the sealing gasket 2. The central circular through hole passes through; through the mechanical extrusion formed by the tension force of the thread connecting the pressing wire 3 and the base 1, the sealing gasket 2 is deformed to hold the cable and squeeze the inner cavity of the base tightly, so as to realize the measurement and control line in the pressurized wind tunnel The technical problem of cable sealing under dynamic pressure conditions.

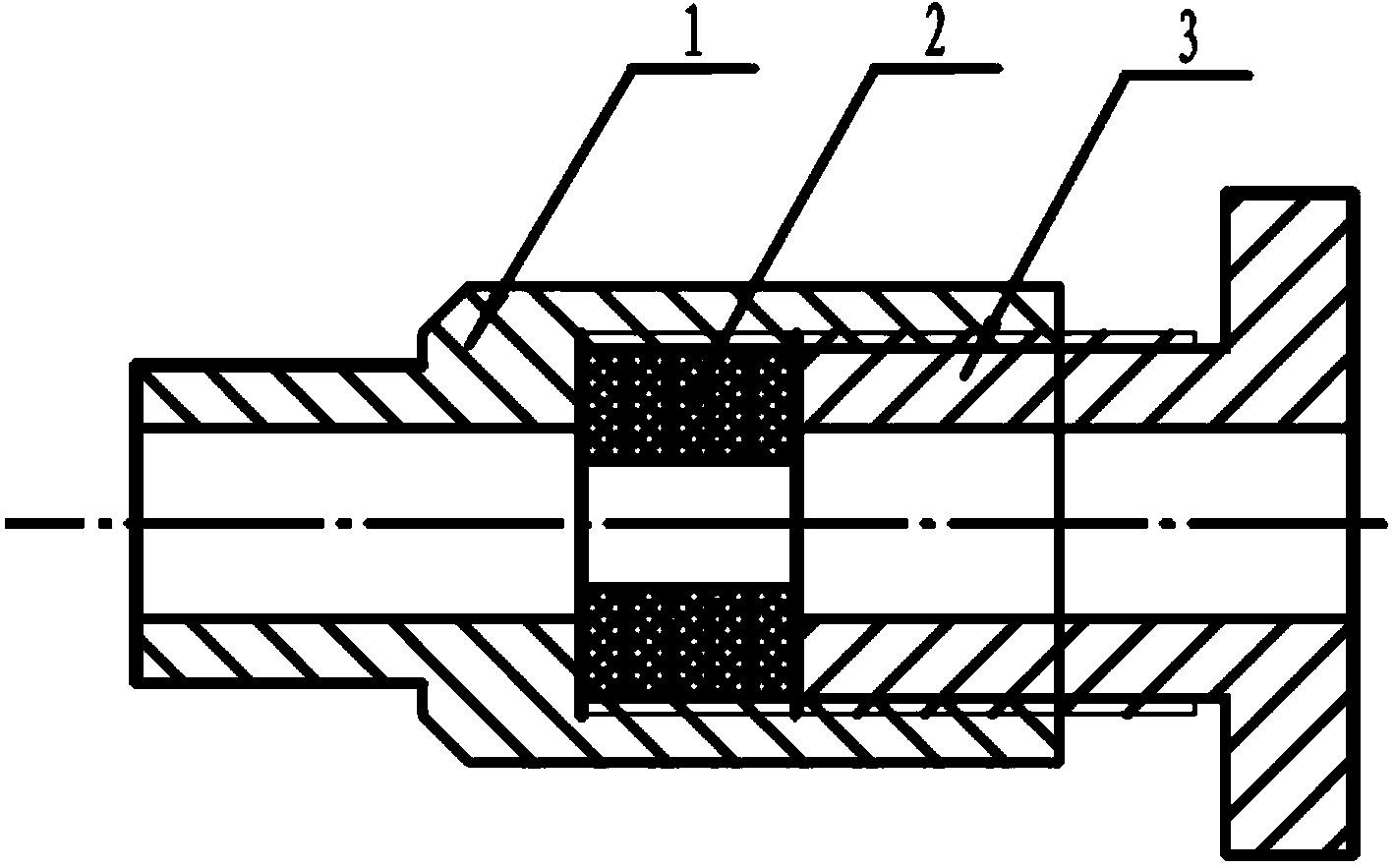

[0018] like figure 1 As shown, the base 1 of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com