Hydrogen compressor host and compression method

A compression method and compressor technology, applied in the direction of machines/engines, mechanical equipment, liquid variable capacity machinery, etc., can solve the problems of complex structure, low working efficiency, and low compressor displacement of metal diaphragm hydrogen compressors, etc. Achieve the effects of simple structure, pollution prevention and small clearance volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

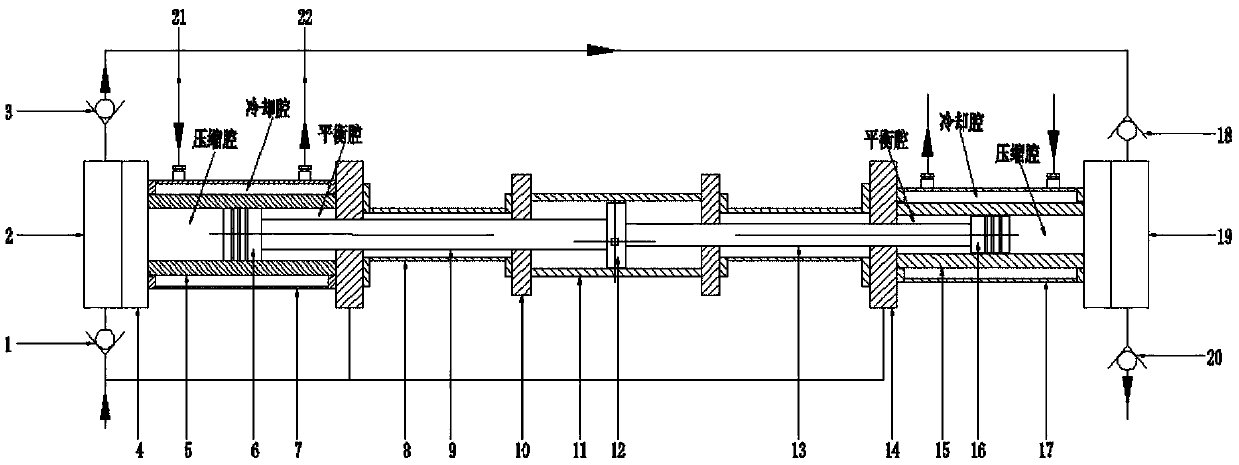

[0036] see figure 1 , the present invention provides a technical solution: a main engine of a hydrogen compressor, including a primary cylinder head 2, the right side of the primary cylinder head 2 is connected with a primary cylinder flange 4, and the right side of the primary cylinder flange 4 A first-stage cylinder 5 is connected, the outer side of the first-stage cylinder 5 is connected with a first-stage water jacket cylinder 7, the right side of the first-stage cylinder 5 is connected with a first-stage cylinder flange 4, and the inner side of the first-stage cylinder 5 is equipped with a first-stage piston 6, The right side of the primary piston 6 is connected with a primary piston rod 9, the right side of the primary cylinder flange 4 is connected with an intermediate connecting body 8, and the right side of the intermediate connecting body 8 is connected with an oil cylinder flange 10. An oil cylinder 11 is connected to the right side of the flange 10, and an oil cyli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com