Hydraulic cylinder assembly for a machine for producing a fiber web, especially a paper or cardboard making machine

A fiber web, hydraulic cylinder technology, applied in mechanical equipment, fluid pressure actuation devices, servo motors, etc., can solve problems such as hydraulic oil leakage, achieve reliable piston position detection, and reduce energy costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

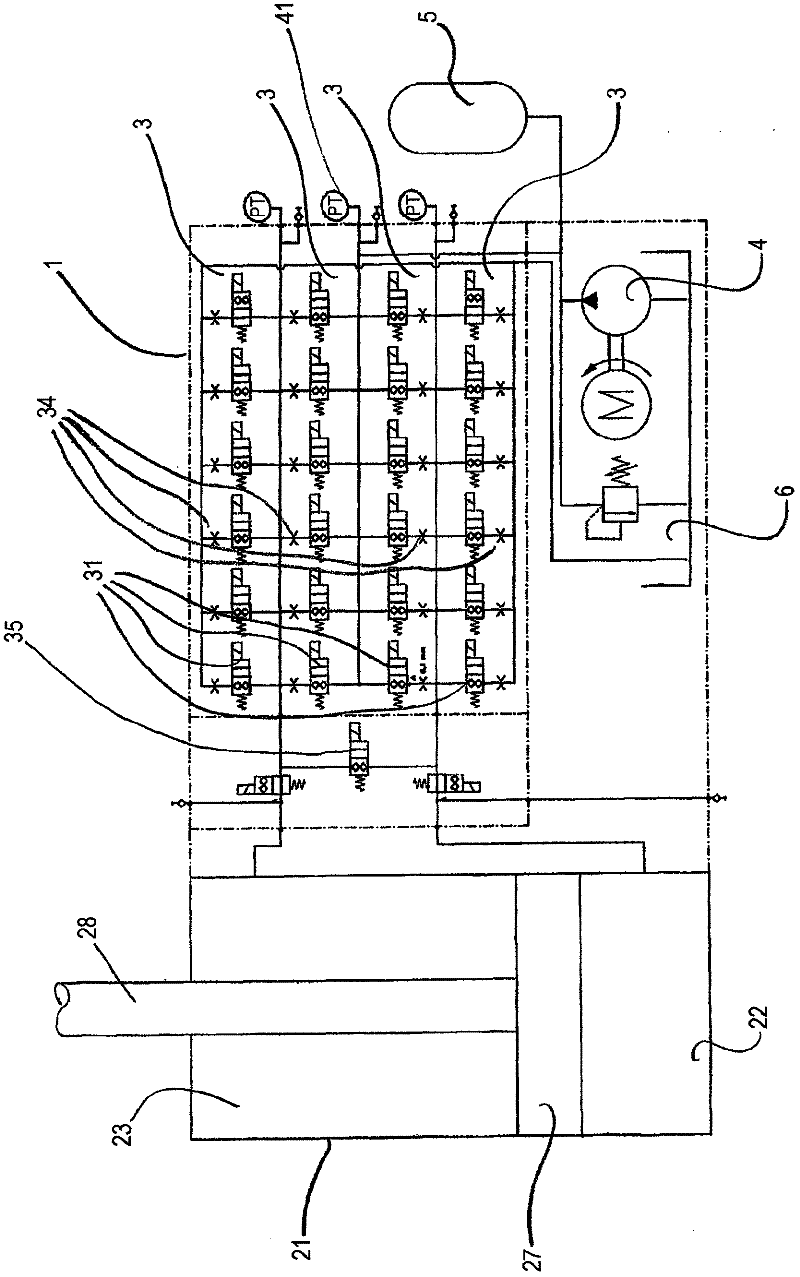

[0048] In the following description of the figures, identical or functionally identical elements are designated with the same reference numerals so that a general functional description and reference can be made based on one figure. Furthermore, if in the following reference is made to a pressure regulator or a flow regulator, if nothing else, it is a digital hydraulic pressure regulator or flow regulator, which works according to the digital hydraulic principles used in the previous description.

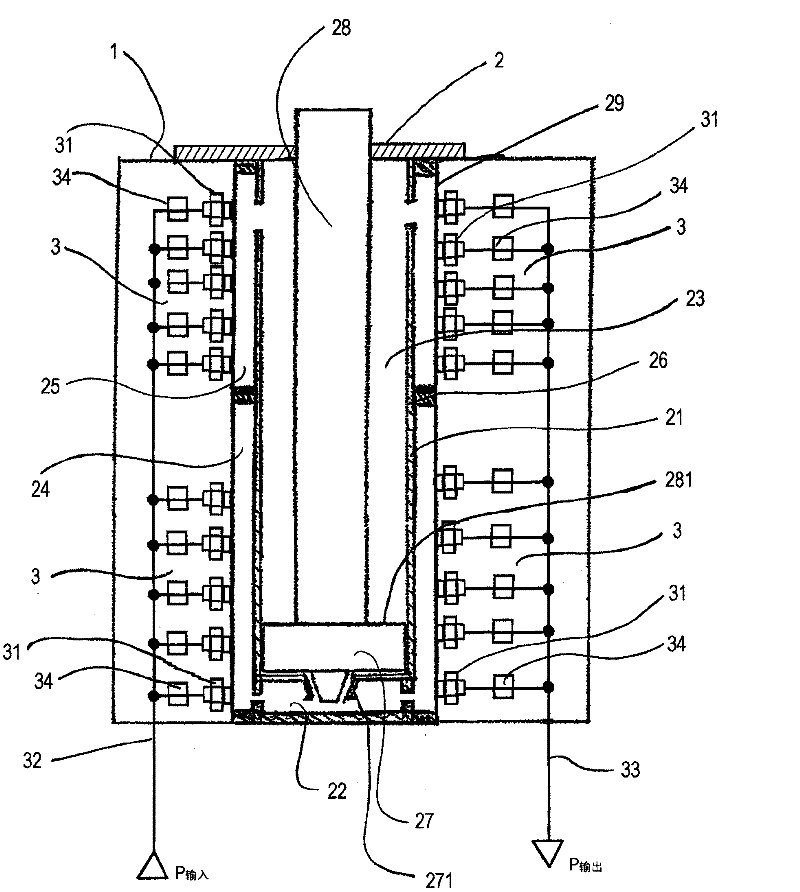

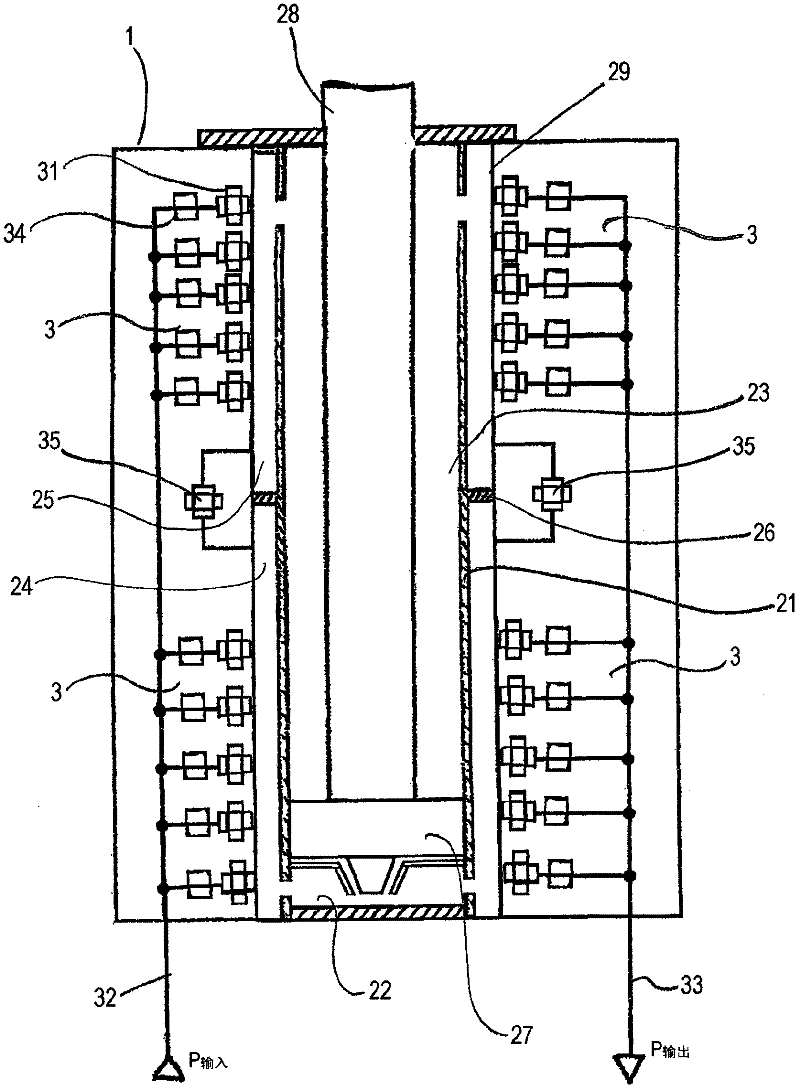

[0049] exist figure 1 Schematically shows a part of the structure of the hydraulic cylinder assembly 1 according to the first embodiment of the present invention.

[0050] The hydraulic cylinder assembly 1 has a hydraulic cylinder 2 and four digital hydraulic pressure regulators 3 . The hydraulic cylinder 2 is a hydraulic differential cylinder which has a cylinder housing 21 and a piston 27 which is movable in the cylinder housing. The cylinder housing 21 is divided into a cylinde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com