Combined hydrotreating method

A combined technology of hydroprocessing, which is applied in the fields of hydroprocessing process, hydrocarbon oil treatment, petroleum industry, etc., can solve the problems such as the influence of the operation period of the hydroprocessing unit, and achieve the improvement of energy utilization efficiency, hydrodesulfurization, The effect of increasing the operating cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

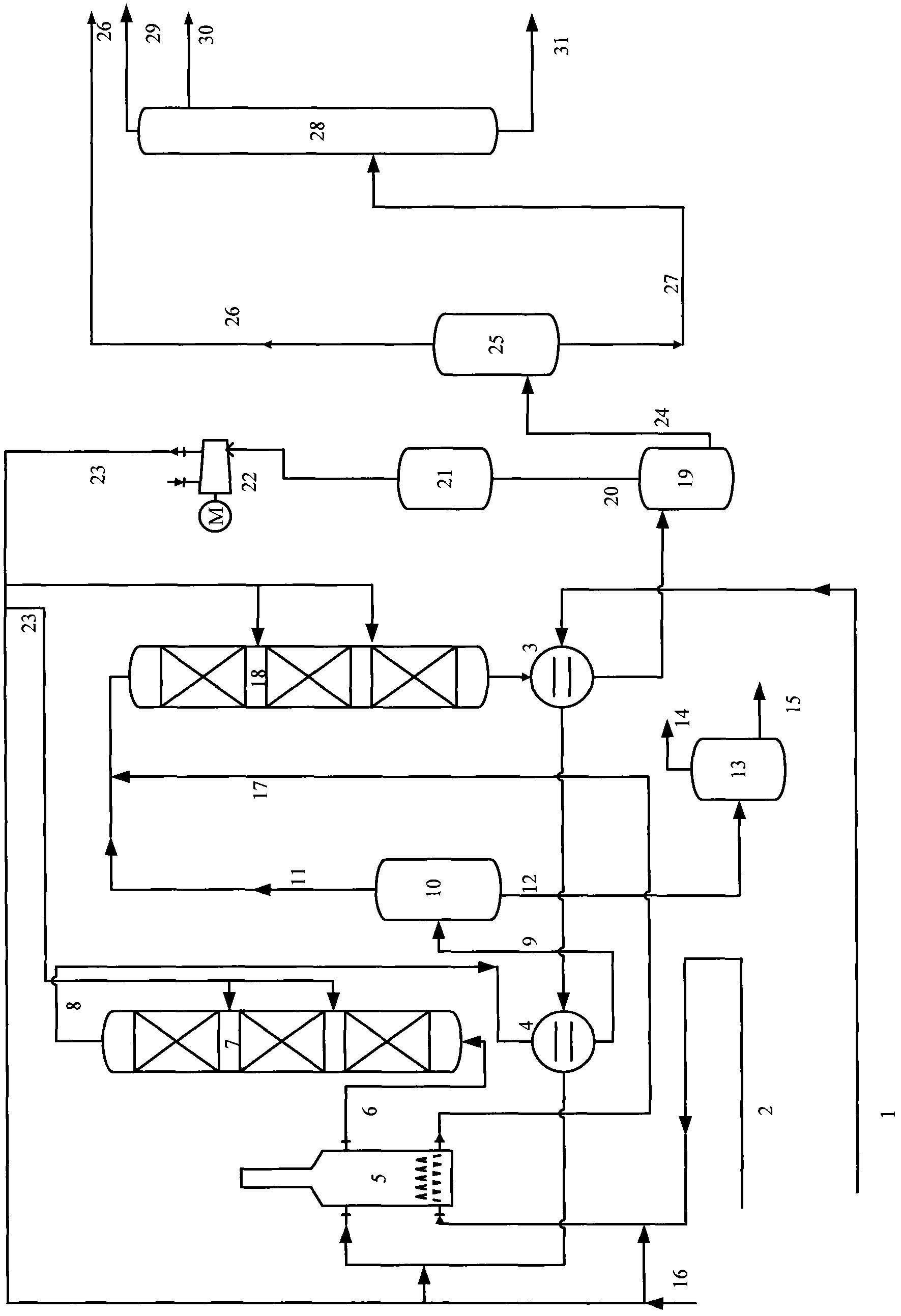

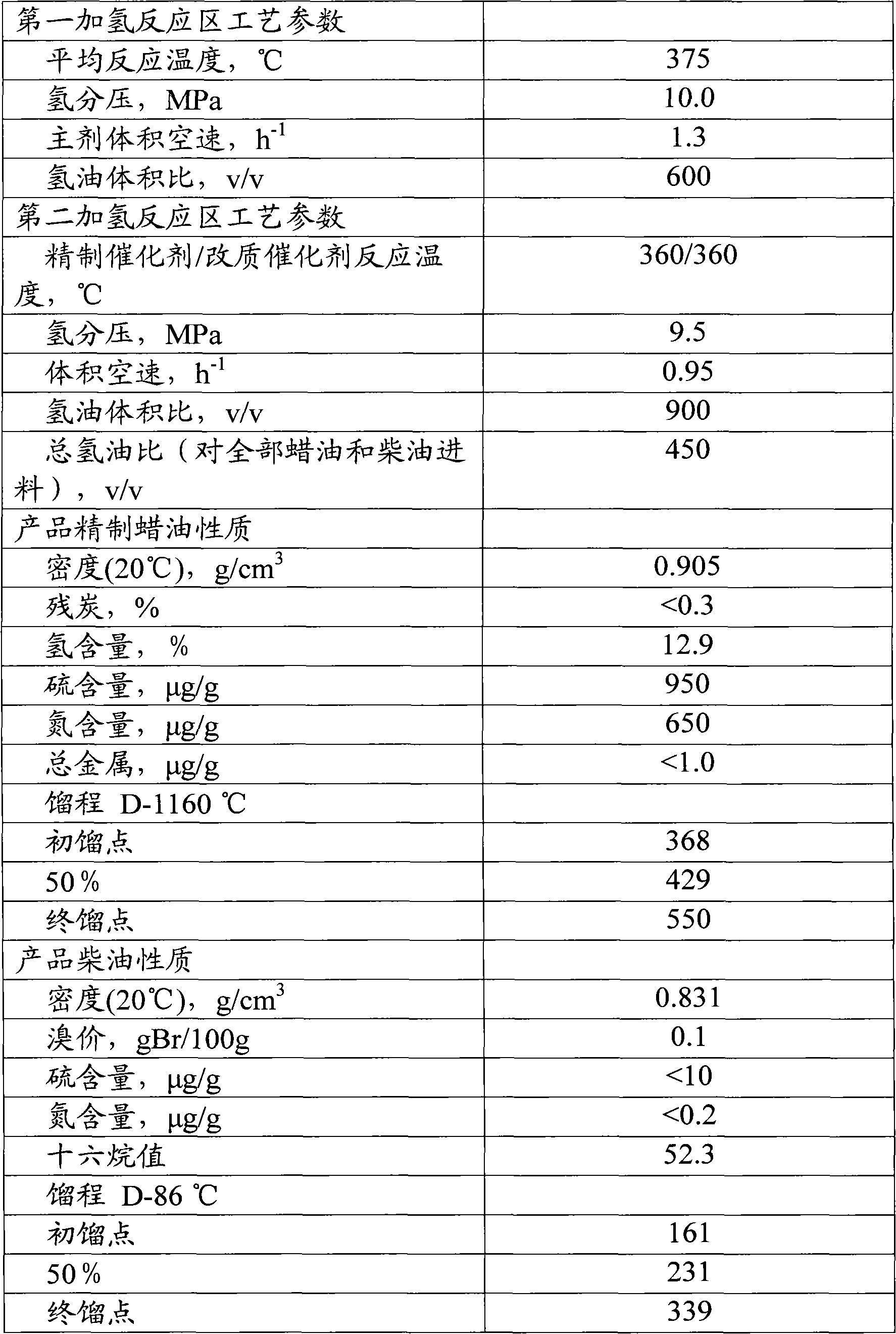

[0053] The method of the present invention will be further described below in conjunction with the accompanying drawings, but the present invention is not limited thereby. as the picture shows:

[0054] The inferior wax oil raw material from the pipeline 1 is exchanged by the heat exchanger 3 and the heat exchanger 4, mixed with hydrogen, heated by the heating furnace 5, and then enters the hydrotreating reactor 7 through the pipeline 6 in an upflow form for hydrogenation. For the hydrogen treatment reaction, the reaction effluent enters the heat exchanger 4 through the pipeline 8 for heat exchange, and then enters the hot high-pressure separator 10 through the pipeline 9 . After the liquid phase stream at the bottom of the hot high-pressure separator 10 enters the hot low-pressure separator 13 through the pipeline 12 to further separate the dissolved gas 14, its liquid phase stream is extracted from the device through the pipeline 15, and directly used as the feed of the cata...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com